Used Turning And Milling Centre for sale (24,480)

Alblasserdam

Alblasserdam CNC turning and milling center

Mori SeikiSL-150 SMC

Alblasserdam

Alblasserdam CNC turning and milling center

Mori SeikiZT1000Y

Garvagh

Garvagh CNC turning and milling center

DOOSAN DAEWOOvc3600

+44 20 806 810 84

Germany

Germany CNC Turning- and Milling Center

NAKAMURA TOMESuper NTJ

Tipton

Tipton CNC turning and milling center

HANEX17D

Discover more used machines

Tipton

Tipton CNC turning and milling center

DOOSANS390L

Tipton

Tipton CNC turning and milling center

MORI SEIKISL-35

Tipton

Tipton CNC turning and milling center

MAZAKA12 MEGA TURN

Tipton

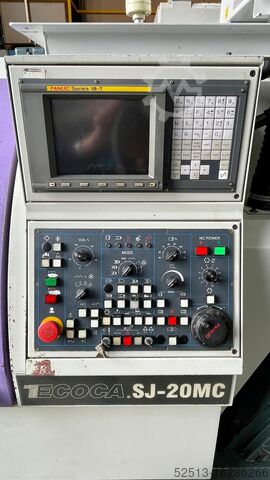

Tipton CNC TURNING CENTRE

ECOCA, MADE IN TAIWANSJ 20MC

Düsseldorf

Düsseldorf CNC turning-drilling-milling center

KlaaßenSDM15-5

Bad Liebenzell

Bad Liebenzell CNC turning and milling center

EMCOTurn 340 TC

Velbert

Velbert CNC turning and milling center

DMG MORICLX 450 TC

Dieburg

Dieburg CNC turning and milling center

MTRENTMTCUT T20MC

Dieburg

Dieburg CNC turning and milling center

MAZAKSQT 200 MS

Dieburg

Dieburg CNC turn-mill center

GILDEMEISTERCTX 200 E

Dieburg

Dieburg CNC turn-mill center

GILDEMEISTERCTX 420

Dieburg

Dieburg CNC turn-mill center

GILDEMEISTERTwin 500 GMX

Root

Root CNC turning and milling center

EMCO TURNE65

Schweiz

Schweiz CNC Turning & milling machine

GILDEMEISTERTwin 42-II

Bayern

Bayern CNC turn-mill center

DMG MORINTX 2500/1500

Hattingen

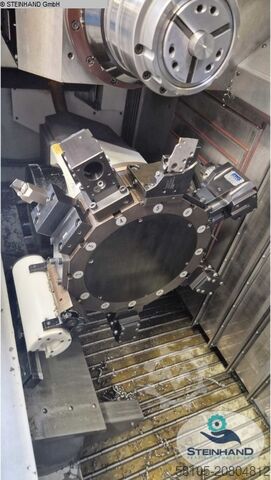

Hattingen CNC Turning- and Milling Center

SPINNERTTS 65 Triplex

Dreieich

Dreieich CNC Turning- and Milling Center

HWACHEONHi-Tech 200 B I

Germany

Germany CNC Turning- and Milling Center

PFIFFNER-MANURHINKMX-XL32

Germany

Germany CNC Turning- and Milling Center

INDEXG300

Hilden

Hilden CNC Turning- and Milling Center

NILES-SIMMONSN20-2 MC

Used Turning And Milling Centre (24,480)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84