Used Nitrogen for sale (331)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Hauzenberg

Hauzenberg

1,616 km

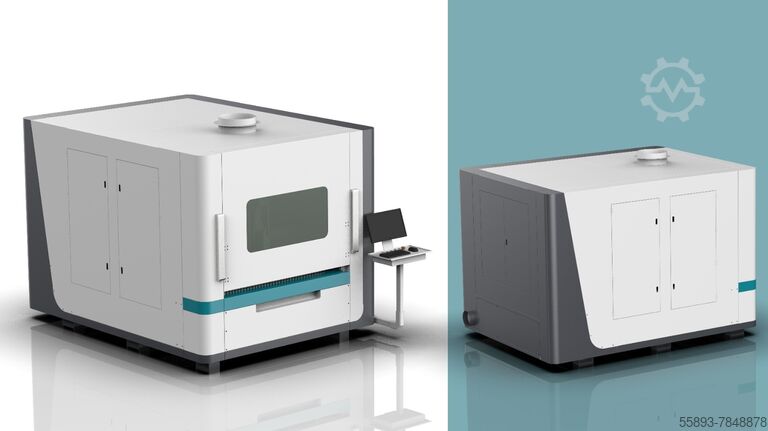

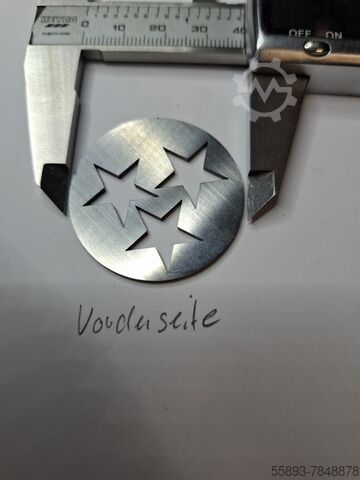

Laser cutting machine

LD-LaserLG-1313 eco-line 1,5 kW Laser

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: MAX Photonics, laser power: 1,500 W, sheet thickness steel (max.): 15 mm, sheet thickness stainless steel (max.): 6 mm, sheet thickness aluminum (max.): 6 mm, sheet thickness brass (max.): 4 mm, input frequency: 50 Hz, type of input current: three-phase, type of cooling: water, compressed air connection: 8 bar, overall weight: 2,800 kg, Equipment: CE marking, centralized greasing system, cooling unit, dust extraction, emergency stop, fume extraction, safety light barrier, Laser Cutting Machine with 1500 W Fiber Laser ecoline

Our goal is to offer highly precise, long-term stable, yet affordable laser machines.

Our machines are ideal for workshops and repair businesses.

A perfectly developed library of cutting parameters is included in delivery, as is first-class service.

The cost-effective entry into laser cutting technology

- High-quality MaxPhotonics laser source

- Extremely energy-efficient cutting system

- Requires only approx. 3.0 x 3.0 meters of installation space

- Top quality, schedule a viewing now!

Cutting capacity:

- Steel sheet up to 15mm

- Stainless steel sheet up to 5mm

- Aluminum sheet up to 5mm

- Travel distance approx. 1300 x 1300mm

- Table size: approx. 1300 x 2500mm

Kwjdpsitu Srefx Adtjt

(suitable for a full mid-format sheet)

- Machine control system in German

- Manual front door

- Extensive collision protection measures

- Large front window for monitoring the cutting process

- Automatic, programmable dual-gas switching (compressed air/nitrogen, oxygen)

- Comprehensive cutting parameter files

- Including nesting module

- CypCut1000 cutting software

- Raytools 240 cutting head

- Very easy operation

- High-performance laser chiller

Sales exclusively to commercial customers.

Delivery / consultation / sales only in Germany / Austria / Switzerland

Machine dimensions approx.:

Width: 3.2m

Height: 2.3m

Length: 3.3m

Total weight: approx. 2800kg

Leasing or hire-purchase available through our financing partner.

Need different laser power, table type or table size?

No problem.

I will be happy to prepare a customized offer.

Not sure which laser power is suitable for your application?

Of course, I can carry out cutting trials tailored to your requirements.

A wide range is possible. From 0.5 kW up to 20 kW laser power.

Listing

Borken

Borken

1,034 km

Selective Laser Melting Machine

SLM SolutionsSLM 280 HL 3D Drucker

Call

Condition: excellent (used), SLM Solutions

Model: SLM 280 HL

For sale is a professional metal 3D printer SLM 280 HL by SLM Solutions (Lübeck).

The machine comes from industrial use, is fully documented, and is delivered including nameplate data and technical documentation.

The SLM 280 HL is designed for 24/7 operation and is suitable for aluminum, stainless steel, tool steel, cobalt-chromium, and many other metal powder materials.

Included modules and accessories:

- AMC 330 WB Air Management/Filter Module

- HRS050-AF-20-M Chiller Unit

- DC 1.5 KAESER Compressor / Compressed Air Module

Technical Data (Excerpt)

Machine

Weight: 1,245 kg

Dimensions (without accessories):

Kodpex Agt Hefx Adtjwt

Width: 1.7 m

Height: 2.0 m

Depth: 1.1 m

Build volume: 280 × 280 × 250 mm (optional depth 350 mm)

Electrical connection:

Power consumption: 15 A

Building-side protection: 32 A

Control voltage: 24 V DC

Heating power: 1,200 W

Protection class: IP50

Power input: 4.7 kW (single optics) / 8.0 kW (twin optics)

Media supply

Argon

Operating pressure: 6 bar

Flow rate (purge): approx. 130 l/min

Flow rate (build process): approx. 3 l/min

Quality: DIN EN ISO 14175 – Class 4.6 (≥99.996 %)

Compressed air

Operating pressure: 6 bar

Flow rate:

without nitrogen generator: approx. 100 l/min

with nitrogen generator: approx. 500 l/min

Quality: ISO 8573-1:2010 Class 1:4:1

Cooling water

Medium: distilled water

Primary circuit:

Pressure: 4 bar

Flow rate: 0.3 l/min

Supply temperature: 18–20 °C

Secondary circuit:

Min. pressure: 2 bar

Max. temperature: 40 °C

Volume: 1.7 m³/h

pH value: 5.8–7.0

Operating conditions

Ambient temperature: 20–25 °C

Max. relative humidity: 60 %

Designed for continuous (24 h) operation

(Weight approx. 1,245 kg).

Important note:

“The table shown in the photos is not included in the sale.”

Condition: used

Scope of supply: (see picture)

- SLM 280 HL machine

- Control cabinet

- Process chamber

- Internal control panel with screen

- Available documentation, parts lists, manuals

(Subject to changes and errors in the technical data!)

We will be happy to answer any further questions by phone.

Listing

Czech Republic

Czech Republic

1,683 km

2.8 Litre Zanchetta Model Rotolab Stainless Steel Mixer/Granulator

ZANCHETTARotolab

Call

Condition: used, Used Zanchetta model Rotolab stainless steel mixer granulator. Total bowl capacity 2.8 litre, working capacity approx. 1.6 litre. Has jacketed bowl with inside dimensions 160 mm diameter x 140 mm height. Main impeller rotation speed 120 - 1200 rpm driven by electric motor. Chopper blade rotation speed 6000 rpm driven by electric motor. Includes local control panel and integrated switchboard, connection for vacuum and nitrogen (.).

Kedpex Ryupofx Adtewt

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Burgoberbach

Burgoberbach

1,385 km

Injection molding machine

KraussMaffeiKM 110-380CX

Call

Year of construction: 2008, condition: good (used), For sale is a Krauss Maffei brand injection molding machine type KM 110-380

The machine is in a good to very good condition, all maintenance and inspections have been performed

Technical data:

Year of manufacture 2008

Extended tie bars

Pneumatic valve gate

2X Hydraulic core puller

31000 operating hours

Cylinder D35mm

Mould closing force: kN 1100

Mold opening force: kN 70

Euromap63 interface for version > 1-04-09

Nitrogen battery present

Included component

Wedge shoes with bolts and nuts

Double bit wrench

Declaration of conformity cpl switchboard

Certificate

USB memory stick

Ejector coupling-mechanical Enclosed in the control cabinet

Ksdpfxjibyate Adtswt

All prices plus VAT

Machines purchase / sale

PURCHASE / SALE OF PRODUCTION & METALWORKING MACHINES ETC.

Do you need a high-quality but inexpensive metalworking machine for your production? Or do you want to sell yours?

For more information or to contact us, please visit our website

Listing

Misterton

Misterton

492 km

Freezing tunnel

LindeCryoline MT1250

Call

Condition: excellent (used), Year of construction: 2016, Linde Cryoline MT1250 Freezing tunnel

Kedpjt N Upcefx Adtewt

Serial: 5-199

2016, Linde CRYOLINE MT 1250 Cryogen/Nitrogen Tunnel Freezer, a top-of-the-line freezing solution for your industrial needs. This machine boasts a cooling capacity of 100 kW/29.41 tons, ensuring efficient and rapid freezing of your products. The fully stainless steel construction, including a fine stainless steel mesh belt, guarantees durability and hygiene compliance. With a net belt width of 1250 mm and a freezing belt length of 4000 mm, this freezer can accommodate a wide range of products with a maximum height of 100 mm.

Equipped with 6 internal high-speed fans that are adjustable, you have full control over the freezing process. The holding time can be set between 0.5 and 20 minutes, providing flexibility based on your specific requirements. The stainless steel switch-board cabinet features a Siemens PLC and HMI Simatic touchscreen for easy operation and monitoring. This Cryoline MT 1250 Cooling Tunnel, manufactured in 2016, operates on N2/Stikstof refrigerant and requires a voltage of 380-500V (50-60Hz). With an absorbed power of 5 kW, this machine is both powerful and energy-efficient. Don't miss out on this opportunity to enhance your production line with this reliable and high-performance freezer.

Discover more used machines

Listing

Prüm

Prüm

1,069 km

Slurry technology

KawecoTurbo-Tanker SI 25000

Call

Condition: used, Year of construction: 2013, Kaweco Turbotanker SI 25000 Year 2013 – 25 m³ capacity – Tires 750/60 R30.5, all 6 with 40-60% tread remaining – 15,000 L centrifugal pump – PTO drive shaft with wide-angle – 27 m Vogelsang SwingMax, year of manufacture 2014 – Heavy-duty BPW axles – Hydraulic forced steering on 1st and 3rd axles – 2,000 L Börger pump for suction via front arm – LED work lights on the tank, sides and rear – LED tail lights – New flow meter installed – Tire pressure control system (defective due to faulty compressor hydraulic motor) – Control board for tire pressure control system recently overhauled by PTG – Track guidance switching via ball valves – Boom section control "half/half" possible from terminal Front arm Marxen front docking station FA 8, year 2021 – 8" centrifugal pump with 10" docking ball – Filling pump with axial piston motor, intermediate bearing and shredder – Spade slide on the filling pump – LED work lights – 8" piping routed centrally over the tractor cab – Nitrogen accumulator for arm damping – Docking height 4 m (+0.2 m–0.4 m) – Bottom: dual-sided 6" hose connector with slide valve – Storage box, storage location: not specified

Ksdjx Ipwbspfx Adtswt

Listing

Borken

Borken

1,027 km

Temperature shock test chamber -70-220°C

VötschVT 7012 S2

Call

Year of construction: 2000, operating hours: 104,382 h, condition: excellent (used), Vötsch Shock Test Chamber VT 7012 S2

System for extreme temperature cycling

Temperature shock testing is used to test the resistance of components, devices, and other products to rapid changes in ambient temperature.

The test specimens are subjected to rapid temperature changes in air with alternating upper and lower temperature loads.

These cyclical stresses and the accelerated aging caused by temperature changes reveal weaknesses in the test specimen.

Vertical arrangement of the test chambers

Ball screw drive for safe guidance of the car

Cart load capacity 50 kg for VT3 7012 S2

All-around grilles in the car secure the test specimens

High air circulation rate, short temperature change times, and uniform temperature distribution in the test chamber

Hot chamber can be used as a temperature storage unit, cold chamber as a temperature exchange unit

Minimal energy consumption

No compressed air required

Manufacturer: Vötsch

Type: VT 7012 S2

Kwsdpfxex Exmtj Adtst

Type: Temperature shock test chamber

Test chamber volume: 120 l

Nominal voltage: 400 V

Nominal power: 10 kW

Nominal current: 25 A

Refrigerant: R452A

Cooling unit: Water-cooled

Shock cooling (nitrogen cooling) via customer-supplied nitrogen

External dimensions

Width: 930 mm

Depth: 2115 mm

Height: 1970 mm

Test chamber dimensions

Width: 470 mm

Depth: 650 mm

Height: 410 mm

Protection class

Device: IP 42

Operating panel: IP 20

Control cabinet: IP 54

Temperature test parameters for single-chamber operation |

Test chamber dimensions

Width: 470 mm

Depth: 650 mm

Height: 410 mm

Protection class ...Temperatur Temperature range

Hot chamber: +50°C to +220°C

Cold chamber: -70°C to +70°C

Temperature deviation over time: ±2 K

in steady state

Temperature deviation over space: ±2 K

in steady state in the car

Heating rate, hot chamber: 11 K/min

Cooling rate, cold chamber: K/min

Heating rate, cold chamber: 2 K/min

Cooling rate, hot chamber: K/min

Observation window: 355 x 355 mm

Pipe opening: 67 mm

Year of manufacture: 2000

Operating hours: 104,382

Weight: 1000 kg

Further items – new and used – can be found in our shop! International shipping costs on request!

Listing

Hauzenberg

Hauzenberg

1,616 km

Laser cutting machine

LD-LaserLG-3015 6kW

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: MAX Photonics, laser power: 6,000 W, laser wavelength: 1,080 nm, sheet thickness (max.): 30 mm, sheet thickness steel (max.): 30 mm, sheet thickness stainless steel (max.): 15 mm, sheet thickness aluminum (max.): 15 mm, table width: 1,500 mm, travel distance X-axis: 3,000 mm, travel distance Y-axis: 1,500 mm, travel distance Z-axis: 120 mm, input voltage: 400 V, type of cooling: water, overall weight: 2,500 kg, door opening width: 1,000 mm, door opening height: 1,000 mm, Equipment: CE marking, cabin, centralized greasing system, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, safety light barrier, New laser cutting machine with 6kW fiber laser

Our commitment is to offer highly precise, long-term stable, and cost-effective laser machines. Our machines are ideal for workshops and repair shops. A perfectly configured cutting parameter library is included with every delivery, along with first-class service.

- Machine with automatic shuttle table

- Very space-saving design

- Exceptionally energy-efficient cutting system

- Only approx. 9 x 3.5 meters installation area required

- 6kW laser source from MaxPhotonics (G5/German version)

- Top quality – schedule a viewing now!

Cutting capacities:

Kwodpfshncfcex Adtjt

- Steel sheet up to 25mm (maximum 30mm)

- Stainless steel sheet up to 15mm

- Aluminum sheet up to 15mm

- Brass sheet up to 12mm

- Travel range: 1500 x 3000mm

- Machine control system in German

- Safety light curtain for maximum operator protection

- Extensive collision protection for the cutting head

- Large laser safety windows on three sides for process monitoring

- Automatic, programmable 3-gas switching (compressed air, nitrogen, oxygen)

- Comprehensive cutting parameter library

- Includes nesting module

- Very easy to operate

- High-performance laser chiller

- German-language machine interface

- German service and spare parts supply

- Powerful laser chiller

- Optional filter extraction

Leasing or hire purchase available through our financing partner

Sales strictly to commercial customers only.

Delivery / consultation / sales exclusively within Germany, Austria, and Switzerland

Machine dimensions approx.:

Length: 9.0m

Height: 2.3m

Width: 3.5m

Total weight: approx. 6500kg

Need a different laser power, table format, or table size?

No problem. I am happy to provide a customized offer.

For example: 1kW machine from €29,990 or 3kW machine from €32,900

Not sure which laser power is right for your application?

Of course, I can conduct cutting tests based on your requirements. Many solutions are possible.

Listing

Gelsenkirchen

Gelsenkirchen

1,058 km

Hydraulic 400 to column press

Hidrobrasil400 Tonnen Viersäulenpresse

Call

Condition: as good as new (ex-display), Year of construction: 2020, Hydraulic 400 to column press

suitable for continuous shift operation, with these basic data:

a) Closing speed 100 - 450 mm/sec.

b) Opening speed 50 - 250 mm/sec ( adjustable via touch screen )

c) Pressing speed 5 - 60 mm/sec ( adjustable via touch screen )

d) Piston accumulator with approx. 4 nitrogen bottles

e) Table size (clamping surface) 2700 x 1700mm ( seen from the front, between the columns )

f) Total table size 3400 x 1700mm

g) 28 T-slots according to customer requirements

h) Table, ram and press head are annealed stress-free.

i) column diameter 250 mm

j) slide size 3400 x 1700mm (clamping surface 2700 x 1700mm )

k) Total size of the machine approx. 3900 x 2200 ( at the bottom ) x 5700 mm height

l) Oil temperature monitoring ( adjustable via touch screen )

m) Automatic lubrication ( adjustable via touch screen )

n) Free positioning of the ram ( adjustable via touch screen )

o) KEYENCE light barriers 14 mm on front and rear side

p) Circuit oil cooling ( adjustable via touch screen )

q) Pressure holding valve 0 to 600 sec. ( adjustable via touch screen )

r) Table top size 3400 x 1700mm, plane milled

s) Laterally monitored doors, 1200mm high, 1000mm wide

t) RITTAL control cabinet, 2200 mm wide, up to 20 m from the press

u) Pressure setting from 50 to 400 tons ( adjustable via touch screen )

v) Travel limitation optionally via pressure or position

w) Programming mode, set-up mode, single stroke + continuous stroke (adjustable via rotary switch )

x) Swivelling control panel with 15 inch touch screen monitor

y) Two-hand operation on both sides

z) Prepared for automatic material feed ( SIEMENS S 7 1500 )

aa) Machine body primed and painted

bb) assembly, commissioning, instruction against separate charge

The hydraulics of the presses we offer are completely based on BOSCH-REXROTH/Parker/HAWE components. In the switch cabinet only components are used (SIEMENS) which are easily available in Germany. The safety technology comes completely from SICK except for the light barriers.

The control system is supplied by SIEMENS. ( S 7 1500 ) as well as the touch screen monitor with 15 inch. The SIEMENS remote maintenance unit SECOME -Ethernet is included in the scope of delivery.

SPECIAL FEATURE: the design chosen by us with two press cylinders and the piston accumulator make it possible to supply the full power with a main motor of 90 kW.

Below under 1.3 the technical details

Technical data

Press design

Press design Column press

Thermally neutral 80 - 120 °C

Number of operating sides 2 sides

Forces

Pressing force max. 4,000 kN

Free ripping force

max. 600 kN

Pressure build-up time Closed tool steel to steel Max. 2 sec.

Dimensions - intended minimum tool height 600 mm

Max. Opening width 1600 mm

Stroke and min. opening 1000/600 mm

Table height above floor 820 mm

Height above floor (headroom) approx. 5700 mm

Hall height min. 7000 mm

Parallel deviation

at 20°C +/- 0,1 mm

Deflection

Determined at max. clamping force with 70% occupancy

< = 0.17 mm/m

Weight

Total weight of the press without operating materials

approx. 52 To

Kwjdpfeg Iihwsx Adtet

Speeds ( see attached cycle diagram )

Fast closing 100 - 450

mm/s

Pressing speed At F max.

Listing

Germany

Germany

1,293 km

Full protected laser cutting machine

BodorC Series 30KW

Call

Condition: new, Year of construction: 2025, Base sheet fiber laser metal cutting machine with full protection

Maximum cutting area reaches up to 12000mm*2500mm, suitable for a variety of cutting options.

The special fiber laser nozzle and cutting process ensure faster carbon steel oxygen cutting, more gas-saving low-pressure stainless steel nitrogen cutting, and better-quality carbon steel air cutting.

Cutting performance and efficiency are improved by maintaining gas flow steady with little turbulence.

Fiber laser heads are able to detect jutting obstacles to effectively reduce the damage rate and save the maintenance cost of a laser cutter.

The cutting process works even at the edge of thin sheets, and ensures no chatter marks.

With One-click Processing, one laser cutter is able to process multiple sheets in batches with a one-off setup, achieving batch processing.

Kedsh S H Rrjpfx Adtowt

Condition: New

Laser Type: Fiber Laser

Laser Power: 1000W - 40000W

Cutting Area: 3048*1524mm - 12500*2600mm

Cutting Speed: 0-110m/min

Positioning accuracy: ±0.05mm

Repositioning accuracy: ±0.03mm

Graphic Format Supported: AI, BMP, Dst, Dwg, DXF, DXP, LAS, PLT

CNC or Not: Yes

Cooling Mode: WATER COOLING

Listing

Hauzenberg

Hauzenberg

1,616 km

Laser cutting machine

LD-LaserLG-3015 12kW

Call

Condition: new, functionality: fully functional, Year of construction: 2025, laser type: fiber laser, laser power: 12,000 W, laser wavelength: 1,080 nm, sheet thickness steel (max.): 35 mm, sheet thickness stainless steel (max.): 35 mm, sheet thickness aluminum (max.): 25 mm, table width: 1,500 mm, travel distance X-axis: 3,000 mm, travel distance Y-axis: 1,500 mm, travel distance Z-axis: 120 mm, input voltage: 400 V, type of cooling: water, overall weight: 5,500 kg, door opening width: 3,000 mm, door opening height: 1,000 mm, Equipment: cabin, documentation/manual, New 12 kW Fiber Laser Cutting Machine

Our goal is to offer highly precise, long-term stable, yet affordable laser machines. Our machines are ideal for workshops and repair businesses. A perfectly developed cutting parameter library is included, as well as first-class service.

- Includes on-site commissioning and training at your facility (approx. 1 week)

- Price includes freight to your facility

- Machine with automatic shuttle table

- Machine bed lined with graphite plates

- Machine measured and calibrated with Renishaw system (including measurement protocol)

- Very space-saving design

- Extremely energy-efficient cutting system

- Only approx. 8.5 x 3.5 meters required installation footprint

- 12 kW laser source from MaxPhotonics (G5/German specification)

- Top quality – schedule a viewing now!

Cutting capabilities:

- Steel sheets up to 35 mm

- Stainless steel sheets up to 20 mm

- Aluminum sheets up to 20 mm

- Travel range: 1500 x 3000 mm

- Machine controller in German

- Safety light curtain for maximum operator protection

- Extensive collision protection measures for the cutting head

- Large laser safety windows on three sides for monitoring the cutting process

- Automatic, programmable 3-gas switching (compressed air, nitrogen, oxygen)

- Comprehensive cutting parameter library

- Includes nesting module

- Very easy to operate

- Powerful laser chiller

- Machine controller in German

Kwsdpfx Adexg Dn Astst

- Extensive service and warranty

- Powerful laser chiller

- Optional filter extraction system

Sale exclusively to commercial customers.

Delivery, consultation, and sales only within Germany / Austria / Switzerland.

Approximate machine dimensions:

Length: 8.5 m

Height: 2.3 m

Width: 3.5 m

Total weight: approx. 5500 kg

Need a different laser power, table style, or table size? No problem. I will gladly provide a suitable quotation.

For example:

2 kW machine from €29,990

6 kW machine from €79,900

Not sure which laser power is suitable for your application? Just call! Of course, I can perform cutting tests according to your requirements. There is a wide range of possibilities.

Listing

United Kingdom

United Kingdom

381 km

Full protected laser cutting machine

BodorP Series

Call

Condition: new, Year of construction: 2025, All-round sheet fiber laser metal cutting machine

Kodpfx Adjhwaapstswt

Equipped with automatic functions of nozzle changing and one-click processing, P-Series is competent for all cutting demands.

Flake graphite in the cutting machine bed improves greatly the shock absorption and wear resistance, and residual stress almost disappears after age hardening, therefore, precision and lifetime of the equipment are improved, and costs saved.

The special fiber laser nozzle and cutting process ensure faster carbon steel oxygen cutting, more gas-saving low-pressure stainless steel nitrogen cutting, and better-quality carbon steel air cutting.

Fiber laser heads are able to detect jutting obstacles to effectively reduce the damage rate and save the maintenance cost of a laser cutter.

The fully closed-loop control adjusts according to feedback to ensure that the actual motion position is consistent with the theoretical input value.

With One-click Processing, one laser cutter is able to process multiple sheets in batches with a one-off setup, achieving batch processing.

Condition: New

Laser Type: Fiber Laser

Laser Power: 1500W - 30000W

Cutting Area: 3048*1524mm - 6100*2500mm

Cutting Speed: 0-169m/min

Positioning accuracy: ±0.03mm - ±0.05mm

Repositioning accuracy: ±0.02mm - ±0.03mm

Graphic Format Supported: AI, BMP, Dst, Dwg, DXF, DXP, LAS, PLT

CNC or Not: Yes

Cooling Mode: WATER COOLING

Listing

United Kingdom

United Kingdom

381 km

Full protected laser cutting machine

BodorC Series

Call

Condition: new, Year of construction: 2025, Base sheet fiber laser metal cutting machine with full protection

Maximum cutting area reaches up to 12000mm*2500mm, suitable for a variety of cutting options.

The special fiber laser nozzle and cutting process ensure faster carbon steel oxygen cutting, more gas-saving low-pressure stainless steel nitrogen cutting, and better-quality carbon steel air cutting.

Cutting performance and efficiency are improved by maintaining gas flow steady with little turbulence.

Fiber laser heads are able to detect jutting obstacles to effectively reduce the damage rate and save the maintenance cost of a laser cutter.

The cutting process works even at the edge of thin sheets, and ensures no chatter marks.

With One-click Processing, one laser cutter is able to process multiple sheets in batches with a one-off setup, achieving batch processing.

Condition: New

Laser Type: Fiber Laser

Laser Power: 1000W - 40000W

Cutting Area: 3048*1524mm - 12500*2600mm

Cutting Speed: 0-110m/min

Positioning accuracy: ±0.05mm

Repositioning accuracy: ±0.03mm

Graphic Format Supported: AI, BMP, Dst, Dwg, DXF, DXP, LAS, PLT

Kedpfx Adehwaa Estewt

CNC or Not: Yes

Cooling Mode: WATER COOLING

Listing

Hauzenberg

Hauzenberg

1,616 km

Laser cutting machine

LD-LaserLG-1325 3kW Premium Line

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: Max Photonics, laser power: 3,000 W, laser wavelength: 1,080 nm, sheet thickness steel (max.): 22 mm, sheet thickness stainless steel (max.): 12 mm, sheet thickness aluminum (max.): 12 mm, table width: 1,300 mm, travel distance X-axis: 2,550 mm, travel distance Y-axis: 1,260 mm, travel distance Z-axis: 120 mm, input voltage: 400 V, type of cooling: water, overall weight: 3,500 kg, door opening width: 2,600 mm, door opening height: 1,000 mm, Equipment: CE marking, cabin, centralized greasing system, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, safety light barrier, New laser cutting machine with 3kW fiber laser

Our goal is to offer highly precise, long-term stable, and yet affordable laser machines. Our machines are ideal for workshops and repair businesses. A perfectly developed cutting parameter library is included, along with first-class service.

- Machine without automatic shuttle table

- Very space-saving

- Extremely energy-efficient cutting system

- Requires only approx. 4 x 4.0 meters installation area

- 3kW laser source from MaxPhotonics (G5 / German version), suitable for aluminum

- Top quality – arrange a viewing now!

Cutting capacities:

- Steel sheet up to 22mm

- Stainless steel sheet up to 12mm

- Aluminum sheet up to 12mm

- Brass sheet up to 5mm

- Travel range 1260 x 2550mm (for medium format sheets)

- Machine control in German

- Safety light curtain for maximum operator protection

- Comprehensive collision protection for the cutting head

- Large laser protection window for viewing the cutting process

- 3-gas selection (compressed air, nitrogen, oxygen)

- Extensive cutting parameter file

- Including nesting module

- Very easy to operate

- High-performance laser chiller

- Machine control in German

- German service and spare parts supply

- High-performance laser chiller

- Optional filter extraction (5.5kW with frequency inverter for whisper-quiet operation)

Leasing or hire purchase available via our finance partner

Sale exclusively to commercial customers.

Delivery / consulting / sales only within Germany / Austria / Switzerland

Kjdpfx Adsxa Ahnotswt

Machine dimensions approx.:

Length: 4.0 m

Height: 2.3 m

Width: 4.0 m

Total weight: approx. 3500kg

Need a different laser power, table type or table size?

No problem.

I will gladly prepare a suitable offer.

For example: 2kW machine from €29,990

Not sure which laser power fits your application?

I will of course carry out cutting trials according to your requirements.

There are many possibilities.

Listing

Norway

Norway

1,121 km

Hydrogen Storage tank containers

UmoeTank container

Call

Condition: like new (used), Year of construction: 2023, functionality: fully functional, We have 5 umoe storage containers for sale. 3 pcs of 20 feet containers and 2 pcs 40 feet containers. 3 of them are not used and stored with 35 bar nitrogen. 2 of them are used, but only a few weeks. One is stored with hydrogen. 25 bar pressure.

Full documentation package available

Kedpfx Asxgn S Sedtowt

Listing

Budapest

Budapest

2,028 km

Laser cutting machine

TRUMPFTruLaser 5030 fiber L76 + Automation

Call

Condition: like new (used), functionality: fully functional, Year of construction: 2023, degree of automation: automatic, laser hours: 2,800 h, laser power: 6,000 W, positioning speed: 280 m/min, Equipment: CE marking, centralized greasing system, cooling unit, dust extraction, emergency stop, fume extraction, nozzle changer, safety light barrier, TruLaser 5030 fiber L76 6kW + LiftMaster Linear + Material Buffer small storage system

BASIC MACHINE:

TruLaser 5030 fiber (L76)

Machine

• Working area: 3000 × 1500 mm

• Box-type frame

• Longitudinal conveyor belt

• Precision motion unit for high-accuracy processing

• Gantry drive with linear direct drives

• Process chiller for machine and laser (water/air)

• Work area lighting

• Pilot laser

• Spraying system

• Automatic nozzle cleaning

• Integrated electrical enclosures

• Integrated cabinet

• Enclosed beam guidance via fiber optic cable (LLK)

• Machine status indicator light

• Transport and installation device

TRUMPF laser

• Pump diode excitation

• Laser power regulation

Cutting unit

• Universal cutting head with fully adaptive lens system

• Protective glass

• Online condition monitoring for protective glass

• Dynamic Focus Control

• Automatic nozzle centering

Control

• Rapid post-production

• SINUMERIK CNC

• Ergonomic control panel with 21.5" wide-format multi-touch color display

• Integrated technological parameters

• Automatic shutdown

• Programmable pressure/cutting gas selection

• Microweld

• Remote maintenance interface

• Production planning

• Multi-sheet processing

• Condition Guide

• Cutting Guide

Functions

• AdjustLine

• BrightLine fiber

• Smart Nozzle Automation

• DetectLine

• Drop&Cut

• Integrated camera 1 for process monitoring

• ControlLine

• FastLine

• FlyLine

• FocusLine

• NitroLine

• PierceLine

• PlasmaLine

• Fusion Cut Performance Package

• Highspeed Cutting Package

• Copper Cutting Package

• Brass Cutting Package

Data transmission

• USB port

• RJ45 network interface

Ksdpfx Adoyah Rcjtewt

• Online Update Manager

Safety

• CE marking and EC Machinery Directive compliant

• Light barriers

• Multi-chamber compact dust extraction unit

• Electric rolling roof

• Enclosed protective housing with certified viewing panels on both right and left sides

Advanced standard configuration

• Compact dust extraction

• Mild steel slats

• Laser powered via the machine

• Automatic longitudinal pallet changer

• Machine ambient temperature range 5-35°C / up to 45°C

• Smart View MT ready

• Data usage agreement

• Nanojoints

• Smart Rerun / Purchase

• External solid-state laser TruDisk 6001 with BrightLine fiber

OPTIONS:

Highspeed Eco cutting package

• High-speed cutting with reduced gas consumption

Thick plate cutting package

Prefilter for nitrogen and oxygen

• Particle filtration for nitrogen/oxygen process gas lines, prefilter with external filter element

Easy Filter

• For annual maintenance of spent cooling water

• Eliminates regular water changes

Wireless Operating Point

Listing

Fumane (Verona)

Fumane (Verona)

1,630 km

Filling Monoblock

BertolasoSyncronia 16-16-1-840

Call

Condition: used, Year of construction: 2000, Technical Specifications & Performance Data

Kwodpfx Adjx E Snkotot

The Bertolaso Filling Monoblock Syncronia 16-16-1-840 is a second hand bottling monoblock designed for high-quality beverage production on glass bottles. This used bottling line component integrates rinsing, filling, and corking in a compact rotary platform engineered for reliable industrial packaging performance. Manufactured by Bertolaso, the machine features an inert gas management concept for both bottle conditioning and closure, making it an excellent choice for premium products requiring oxygen reduction.

Manufacturer: Bertolaso

Model: Syncronia 16-16-1-840

Year: 2000

Container type: Glass bottles

Rinser: 16 grippers with penetrating nozzle and double inert gas treatment

Filler type: Gravity/light depression with nitrogen support

Corker: Single-head straight corking with inert gas and vacuum corking

Formats: Compatible with 0.375L and 0.75L bottle formats

Electrical: 400 V, 50 Hz

CIP readiness: Integrated CIP with stainless steel dummy bottles

Model code & configuration: Syncronia 16-16-1-840

Advanced Automation & Control Systems

The monoblock includes process features aimed at consistent quality and reduced oxygen pickup. The rinser employs double inert gas treatment to pre-condition the bottles. The filler operates in light vacuum/gravity mode with nitrogen, complemented by level control at the valve. A sensor detects hanging bottles at the outfeed to protect product flow and minimize stoppages. Integrated CIP and stainless steel dummy bottles enable efficient cleaning-in-place procedures across rinsing and filling turrets, supporting hygienic operation in beverage production.

Production Line Integration Capabilities

Designed for industrial packaging environments, this monoblock can operate as a standalone unit or be integrated into a complete used bottling line. It is optimized for glass bottle handling and can interface with upstream conveyors and downstream inspection or labeling systems. Format flexibility includes 0.375L and 0.75L sizes, and quick changeover is supported by the turret design and format parts.

Machine Condition & Maintenance History

The machine is in excellent overall condition and has processed approximately 1,000,000 bottles over its lifetime. Its condition and integrated CIP system suggest careful operation and maintenance, making it suitable for facilities seeking ready-for-operation bottling equipment with proven reliability.

Operational Performance & Versatility

This monoblock is particularly suited to oxygen-sensitive products handled in glass bottles. The double inert gas rinsing, nitrogen-assisted filling under light depression, and vacuum corking with inert gas injection collectively provide robust oxygen management. The machine’s engineering by Bertolaso is recognized for precision filling, gentle handling, and closure integrity with straight corks.

Listing

Fumane (Verona)

Fumane (Verona)

1,630 km

Filling Monoblock

BertolasoSyncronia 16-16-1-840

Call

Condition: used, Year of construction: 2000, Technical Specifications & Performance Data

Ksdpfox E Snqox Adtowt

The Bertolaso Filling Monoblock Syncronia 16-16-1-840 is a second hand bottling monoblock designed for high-quality beverage production on glass bottles. This used bottling line component integrates rinsing, filling, and corking in a compact rotary platform engineered for reliable industrial packaging performance. Manufactured by Bertolaso, the machine features an inert gas management concept for both bottle conditioning and closure, making it an excellent choice for premium products requiring oxygen reduction.

Manufacturer: Bertolaso

Model: Syncronia 16-16-1-840

Year: 2000

Container type: Glass bottles

Rinser: 16 grippers with penetrating nozzle and double inert gas treatment

Filler type: Gravity/light depression with nitrogen support

Corker: Single-head straight corking with inert gas and vacuum corking

Formats: Compatible with 0.375L and 0.75L bottle formats

Electrical: 400 V, 50 Hz

CIP readiness: Integrated CIP with stainless steel dummy bottles

Model code & configuration: Syncronia 16-16-1-840

Advanced Automation & Control Systems

The monoblock includes process features aimed at consistent quality and reduced oxygen pickup. The rinser employs double inert gas treatment to pre-condition the bottles. The filler operates in light vacuum/gravity mode with nitrogen, complemented by level control at the valve. A sensor detects hanging bottles at the outfeed to protect product flow and minimize stoppages. Integrated CIP and stainless steel dummy bottles enable efficient cleaning-in-place procedures across rinsing and filling turrets, supporting hygienic operation in beverage production.

Production Line Integration Capabilities

Designed for industrial packaging environments, this monoblock can operate as a standalone unit or be integrated into a complete used bottling line. It is optimized for glass bottle handling and can interface with upstream conveyors and downstream inspection or labeling systems. Format flexibility includes 0.375L and 0.75L sizes, and quick changeover is supported by the turret design and format parts.

Machine Condition & Maintenance History

The machine is in excellent overall condition and has processed approximately 1,000,000 bottles over its lifetime. Its condition and integrated CIP system suggest careful operation and maintenance, making it suitable for facilities seeking ready-for-operation bottling equipment with proven reliability.

Operational Performance & Versatility

This monoblock is particularly suited to oxygen-sensitive products handled in glass bottles. The double inert gas rinsing, nitrogen-assisted filling under light depression, and vacuum corking with inert gas injection collectively provide robust oxygen management. The machine’s engineering by Bertolaso is recognized for precision filling, gentle handling, and closure integrity with straight corks.

Listing

Fumane (Verona)

Fumane (Verona)

1,630 km

Filling Monoblock

BertolasoSyncronia 16-16-1-840

Call

Condition: used, Year of construction: 2000, Technical Specifications & Performance Data

The Bertolaso Filling Monoblock Syncronia 16-16-1-840 is a second hand bottling monoblock designed for high-quality beverage production on glass bottles. This used bottling line component integrates rinsing, filling, and corking in a compact rotary platform engineered for reliable industrial packaging performance. Manufactured by Bertolaso, the machine features an inert gas management concept for both bottle conditioning and closure, making it an excellent choice for premium products requiring oxygen reduction.

Manufacturer: Bertolaso

Model: Syncronia 16-16-1-840

Year: 2000

Container type: Glass bottles

Rinser: 16 grippers with penetrating nozzle and double inert gas treatment

Filler type: Gravity/light depression with nitrogen support

Corker: Single-head straight corking with inert gas and vacuum corking

Formats: Compatible with 0.375L and 0.75L bottle formats

Electrical: 400 V, 50 Hz

CIP readiness: Integrated CIP with stainless steel dummy bottles

Model code & configuration: Syncronia 16-16-1-840

Advanced Automation & Control Systems

Kwedpfox E Sm Tox Adtjt

The monoblock includes process features aimed at consistent quality and reduced oxygen pickup. The rinser employs double inert gas treatment to pre-condition the bottles. The filler operates in light vacuum/gravity mode with nitrogen, complemented by level control at the valve. A sensor detects hanging bottles at the outfeed to protect product flow and minimize stoppages. Integrated CIP and stainless steel dummy bottles enable efficient cleaning-in-place procedures across rinsing and filling turrets, supporting hygienic operation in beverage production.

Production Line Integration Capabilities

Designed for industrial packaging environments, this monoblock can operate as a standalone unit or be integrated into a complete used bottling line. It is optimized for glass bottle handling and can interface with upstream conveyors and downstream inspection or labeling systems. Format flexibility includes 0.375L and 0.75L sizes, and quick changeover is supported by the turret design and format parts.

Machine Condition & Maintenance History

The machine is in excellent overall condition and has processed approximately 1,000,000 bottles over its lifetime. Its condition and integrated CIP system suggest careful operation and maintenance, making it suitable for facilities seeking ready-for-operation bottling equipment with proven reliability.

Operational Performance & Versatility

This monoblock is particularly suited to oxygen-sensitive products handled in glass bottles. The double inert gas rinsing, nitrogen-assisted filling under light depression, and vacuum corking with inert gas injection collectively provide robust oxygen management. The machine’s engineering by Bertolaso is recognized for precision filling, gentle handling, and closure integrity with straight corks.

Listing

Fumane (Verona)

Fumane (Verona)

1,630 km

Filling Monoblock

BertolasoSyncronia 16-16-1-840

Call

Condition: used, Year of construction: 2000, Technical Specifications & Performance Data

The Bertolaso Filling Monoblock Syncronia 16-16-1-840 is a second hand bottling monoblock designed for high-quality beverage production on glass bottles. This used bottling line component integrates rinsing, filling, and corking in a compact rotary platform engineered for reliable industrial packaging performance. Manufactured by Bertolaso, the machine features an inert gas management concept for both bottle conditioning and closure, making it an excellent choice for premium products requiring oxygen reduction.

Manufacturer: Bertolaso

Model: Syncronia 16-16-1-840

Kwedpfxsx E Sndj Adtjt

Year: 2000

Container type: Glass bottles

Rinser: 16 grippers with penetrating nozzle and double inert gas treatment

Filler type: Gravity/light depression with nitrogen support

Corker: Single-head straight corking with inert gas and vacuum corking

Formats: Compatible with 0.375L and 0.75L bottle formats

Electrical: 400 V, 50 Hz

CIP readiness: Integrated CIP with stainless steel dummy bottles

Model code & configuration: Syncronia 16-16-1-840

Advanced Automation & Control Systems

The monoblock includes process features aimed at consistent quality and reduced oxygen pickup. The rinser employs double inert gas treatment to pre-condition the bottles. The filler operates in light vacuum/gravity mode with nitrogen, complemented by level control at the valve. A sensor detects hanging bottles at the outfeed to protect product flow and minimize stoppages. Integrated CIP and stainless steel dummy bottles enable efficient cleaning-in-place procedures across rinsing and filling turrets, supporting hygienic operation in beverage production.

Production Line Integration Capabilities

Designed for industrial packaging environments, this monoblock can operate as a standalone unit or be integrated into a complete used bottling line. It is optimized for glass bottle handling and can interface with upstream conveyors and downstream inspection or labeling systems. Format flexibility includes 0.375L and 0.75L sizes, and quick changeover is supported by the turret design and format parts.

Machine Condition & Maintenance History

The machine is in excellent overall condition and has processed approximately 1,000,000 bottles over its lifetime. Its condition and integrated CIP system suggest careful operation and maintenance, making it suitable for facilities seeking ready-for-operation bottling equipment with proven reliability.

Operational Performance & Versatility

This monoblock is particularly suited to oxygen-sensitive products handled in glass bottles. The double inert gas rinsing, nitrogen-assisted filling under light depression, and vacuum corking with inert gas injection collectively provide robust oxygen management. The machine’s engineering by Bertolaso is recognized for precision filling, gentle handling, and closure integrity with straight corks.

Listing

Stolberg

Stolberg

1,030 km

Selective soldering system SPA 400 F

EBSOSPA 400 F

Call

Year of construction: 2006, condition: good (used), functionality: fully functional, Without solder

Nitrogen hood

IR preheating

Single soldering nozzle

3 solder frames

Kodpjxzrflsfx Adtewt

Software, etc., manual

Tool, spare parts box

New timing belt, new impeller for drive installed

Trust Seal

Dealers certified through Machineseeker

Listing

Eschenz

Eschenz

1,367 km

Air-electric CO2 evaporator 2,000 kg/h

ProcontrolLuft-Elektro-CO2 Verdampfer

Call

Year of construction: 2024, condition: new, functionality: fully functional, Electric vaporizer

Capable of vaporizing liquefied gas at any temperature. We utilize these units to vaporize liquid CO2 and store it in concrete. It can also be used for other applications, such as vaporizing nitrogen, oxygen, or other gases for use in end processes. New price 140,000 CHF.

Kodpfxex H R Rye Adtewt

Listing

Austria

Austria

1,668 km

Bag in Box filler

KreuzmayrKBF 2000

Call

Year of construction: 2020, operating hours: 30 h, condition: new, Semiautomatic filler for hot or cold filling of fruit or vegetable juice or other liquids into bag in box bags with Vitop or Postmix seal.

Components:

Stainless steel buffer tank

Pneumatic acted filling valve

Stainless steel design with 4 rolllers

Filling quantity: 3 to 20 l bag content

Filling capacity 10 l bags approx. 2.000 l/h

Ksdpfxo Uwrqs Adtswt

5 l bags approx. 1.200 l/h

The filling process is checked by the flowmeter system and controlled by a pneumatic valve.

bags evacuation before

optional nitrogen superimposed after filling possible

Listing

Germany

Germany

1,293 km

Semitrailer LNG

LNG tank filling station Methan Gas

Call

Condition: excellent (used), Year of construction: 2011, Schwingenschlögel LNG tank filling station Methan Gas Cryogenic tank gas tank trailer German

Kwsdotzcdrspfx Adtst

Cryogenic gas semi-trailer for LNG (liquid methane).

Tank filling station

Manufacturer: Schwingenschlögel

EU approval.

Year: 2011

Full working condition with valid certificates.

We also have other tankers for LIN, LOX, LAR, LNG and CO2, argon, oxygen, nitrogen and carbon dioxide, Hydrogen, Methane

We would also be happy to provide you with a quotation or give you more information about other pressure vessels.

To discuss the possibilities, please contact us by phone or e-mail.

Listing

Germany

Germany

1,293 km

CO2 tank carbon dioxide gas

CO2 carbon dioxide gasused storage tank

Call

Condition: excellent (used), Year of construction: 1991, We can offer you CO2 carbon dioxide gas used storage tank vessel

Volume 21050L;

Working pressure 22 bar;

Kwedpsk Eac Defx Adtst

Export from EU

We also have other tanks for LIN, LOX, LAR, LNG and CO2, argon, oxygen, nitrogen and carbon dioxide, Hydrogen, Methane

We would also be pleased to prepare an offer for you or provide you with further information. To discuss the possibilities, please contact us by phone or e-mail.

We make it easier for you to find: "nitrogen"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Nitrogen (331)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month