Used Nitrogen for sale (347)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Borken

Borken

1,034 km

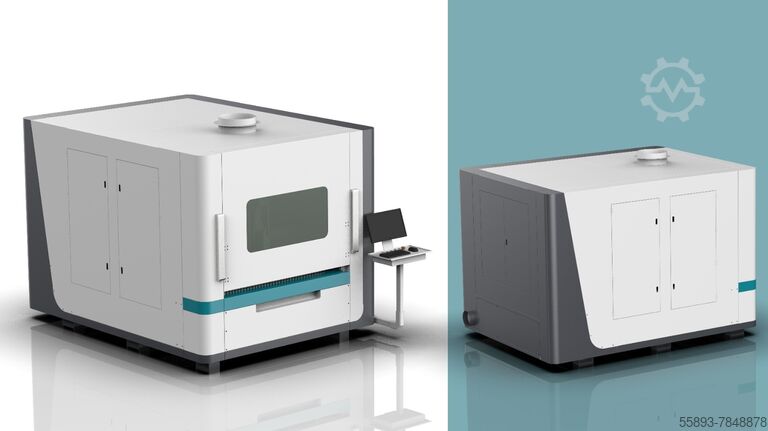

Industrial laser sintering machine

EOSP 390

Call

Condition: good (used), EOS

Type: P390

Eosint P 390 – Laser Sintering System (SLS)

Operating hours: 6,735 h

For sale is an industrial laser sintering system from EOS, model P 390.

It is suitable for additive manufacturing (SLS – Selective Laser Sintering) of plastic components on an industrial scale.

Base machine with control cabinet & operating terminal

Exchange frame with build platform

Multibox is a typical accessory for powder handling in EOS systems, enabling transport and interim storage of materials.

Technical data:

Build volume: approx. 340 × 340 × 620 mm (X × Y × Z)

Minimum layer thickness: 0.1 mm (variance < 0.05 mm)

Powder container capacity: 2 × 45 liters with fluidization and dispenser

Heating: Infrared, 3.2 kW

Nitrogen generator: integrated, purity > 99%

Electrical supply: 400 V ±6/–10 %, 50 Hz, 3 × 32 A, power consumption approx. 2 kW

Extraction: 20 m³/h at 6 bar, DN 100

Cooling: 5.7 l/min at 18–20 °C (± 0.1 °C)

Dimensions & weight:

Machine (W × D × H): approx. 1,230 × 1,175 × 2,100 mm

Control cabinet: 610 × 790 × 2,100 mm

Operating terminal: 950 × 700 × 1,550 mm

SMC HRS024-AN-20-T Thermo-Chiller – Air-cooled – High-pressure pump

Itedpfxsxbgnbs Ag Uob

Technical data:

Model: HRS024-AN-20-T

Cooling capacity: approx. 2.1–2.4 kW

Temperature range: 5 °C to 40 °C

Temperature stability: ± 0.1 °C

Cooling type: air-cooled

Pump: high-pressure pump ("T" version)

Flow rate: up to approx. 14 l/min

Tank volume: approx. 5 liters

Medium: water or water-glycol

Connection: NPT version ("AN")

Power supply: 200–230 V AC, single-phase

Refrigerant: R407C

Weight: approx. 1,110 kg

Condition: used

Scope of delivery: (See image)

(Specifications and technical data subject to change and error!)

If you have further questions, we would be pleased to answer them by phone.

Clickout

Gommern

Gommern

1,356 km

Continuous push-through furnace system

Ipsen International GmbHPP-2-65x65x65-18-G

Condition: good (used), Year of construction: 2005, Pusher Furnace System (PUS1), Manufacturer: Ipsen International GmbH,

Type: PP-2-65x65x65-18-G,

Serial No.: AN 10.1595-01,

Year of manufacture: 2005,

Fuel: Gas/Natural Gas/Nitrogen/Methanol,

Itedpfxeyabxyj Ag Usb

414 kW, 296 kVA

comprising:

Two-Chamber Pre-Washing Machine,

Type: WPSSB-65x65x65-E,

302 A, 199 kVA, electric,

Washing tank 2 m³, rinsing tank 2 m³, 60-80°C

Pusher Preheating Furnace,

Type: DL 65x65x65 4-G,

25 A, 9.5 kVA, natural gas heated, 80-100 mbar, 350-500°C

Pusher Gas Carburizing Furnace (Double Line),

Type: PP-2 65x65x65-18-G,

natural gas heated, 86 A, 29.6 kVA, 10 kWh/m³, 80-100 mbar, 860-950°C, 140 pieces per batch, 695 kg/h

Oil Quenching Bath (Hardening Oil),

Type: QO-65x65x65-E,

161.5 A, 93.1 kVA, electric,

air cooling, 6 m³ tank volume, 120°C max., 60-80°C working temperature

Two-Chamber Post-Washing Machine,

Type: WPSSB-65x65x65-E,

302 A, 199 kVA, electric,

washing tank 2 m³, rinsing tank 2 m³, 60-80°C

Pusher Tempering Furnace,

Type: DL-65x65x65-6-E,

126.8 A, 84 kVA, electric,

300°C max. furnace temperature, 150-240°C working temperature

Batch Transport System,

Measuring, Control, and Switch Cabinet with Conti-Control System,

Type: CO/CO2-2

Batch Data:

Case hardening for transmission parts 650 mm x 650 mm x 650 mm, max. 280 kg,

batch transport height 800/2,200 mm

Listing

Estavayer

Estavayer

1,298 km

Tank with conical bottom ATM

POLSINELLI

Call

Condition: excellent (used), - Atmospheric pressure

- Tanks for the fermentation and storage of wine or beer

- Dome 400 mm made of AISI 304 stainless steel

- Nitrogen connection with stainless steel 3/8" ball valve

- Cleaning line with DIN 32 connection

- AISI 316 stainless steel cleaning ball Ø 65 mm

- Level indicator with return flow into the container

- Sampling

- Bottom conical 30°

- Residual drain Disc valve DIN 25

- Clear drain Disc valve DIN 25

- Bimetal thermometer made of stainless steel -20 °C/+80 °C with 200 mm long shaft

- 3 adjustable feet in stainless steel

- Dimensions: Ø 800 x 1950 mm (h)

- High-gloss polished inside, marbled outside

Iedpfsrigczjx Ag Uotb

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Bitterfeld-Wolfen

Bitterfeld-Wolfen

1,402 km

Soldering device for circuit boards

REHMRefloe SMS-N2-V4 - 3000

Call

Year of construction: 1998, condition: used, temperature: 200-210 °C

throughput speed: 1000 mm/min

max. workpiece length: 200 mm

total power requirement: 50 kw

weight of the machine ca.: ca. 2,0 t

- Soldering device for circuit boards (e.g. Type: SMD &/or Composite design) and drying SMD adhesive.

- Soldering unit works with functions -->intake - flow - soldering - cooling

- With software functions.

- Can be integrated in a production line.

Further technical details:

- Inert gas with Nitrogen 30 m³/h; 6 - 10 bar over pressure

- Water requirement: 20 Liter/min; 2 - 5 bar over pressure

- Exhaust quantity: 1000m³/h

- electr. Operation capacity: 12 kW

- room required: L: 6500 + loading station 2000 x W: 1400 x H: 2100mm

Supplementary equipment incl.:

- Automatic stacker LSB 03 with reloading device and discharge conveyor for intake of e.g. circuit boards

- Plant is applicable as spare part deliverer or for refurbishment or rebuild.

- Documentation available

- Machine is CE98 certified

Itodpfx Aeu Rwaujg Ueb

On sale as is.

Listing

Germany

Germany

1,192 km

CONCEPT LASER LASER M3 Linear

CONCEPT LASERLASER M3 Linear

Call

Condition: ready for operation (used), Year of construction: 2011, operating hours: 35,000 h, number of axes: 3, This 3-axis CONCEPT LASER M3 Linear was manufactured in 2011. It features a robust power supply with a total consumption of 7.4kW, supporting a laser system, IT, and control voltage components. Essential for operations requiring compressed air and nitrogen, it ensures a steady flow and pressure. Ideal for precision metal 3D printing. Contact us for more information about this machine.

Machine Benefits

Technical Machine Benefits

• Machine connection: cee plug, 400v 32a 6h, 3-meter cable

• Compressed air: pressure: 7-8 bar, unlubricated

• Flow rate: 130 l/min

• Machine connection: coupling plug nw 7. 2, 3-meter fabric hose

• Nitrogen n2: pressure: 5 bar, purity: >2. 5

• Flow rate: 100 l/min

• Machine connection: hose nipple with sealing cone - 60° cone, 3-meter fabric hose

Extra Information

Itjdpfjx Nh Rcsx Ag Uob

Power supply:

Supply voltage: 3P/N/PE AC 400V, 10%, 50Hz-60Hz

Fuse: 32A

Power consumption:

Laser system: Max. 34kW

IT: 05kW

Control voltage: 05kW

NC (incl. axes): 10kW

Extraction: 12kW

Air conditioning unit: 08kW

Total: 74kW

Listing

Wiefelstede

Wiefelstede

1,085 km

Powder fire extinguisher

TOTALG 50

Call

Condition: good (used), Fire extinguisher, powder extinguisher

Iodpfx Agob A I Urs Uetb

-Fire classes: A, B and C

-Chassis: with solid rubber tires and swivel caster

-Nitrogen bottle

-10 m high-pressure hose: with lockable extinguishing gun

-Dimensions: 600/450/H1050 mm

-Weight: 120 kg

Auction

Auction ended

Hessen

Hessen

1,199 km

Wave soldering system

SehoMWS 2340-F

Year of construction: 2018, condition: ready for operation (used), functionality: fully functional, Wave soldering system with comprehensive equipment!

A spare parts package worth approximately €20,000 is included in the sale and delivery!

The system comprises the following components:

- Seho wave soldering system MWS 2340-F

- Fluxer SelectFlux

- Streamline transport system including lifts

TECHNICAL DETAILS

- PULSAR preheating: 2 convection and 5 pulsar preheating zones (3,300 mm length)

- Wetting length (soldering system): 40 mm + 30 mm

- Return transport level: raised 405 mm

- Finger conveyor: L-shape, short (3 mm)

MACHINE DETAILS

- Number of processed solder frames: 1,060,540 pcs

EQUIPMENT

- Fluxer SelectFlux

- Streamline transport system incl. lifts

- Automatic solder bar feeder

- Process gas cleaning system

- Finger cleaning unit

- Foldable convection top heater

- Fan speed monitoring for convection preheating

- Standard soldering unit

- Wide solder nozzle unit, 7-row

- Solder frame transport system incl. 2 lifts

- Cooling tunnel in the return transport of the soldering system incl. timer control

- Solder frame lowering station

- Replacement filter for condensate trap at machine infeed and outfeed

- Residual oxygen measurement with lambda probe

- Nitrogen economizing circuit

- Transponder system for automatic switching of soldering programs

- Selective flux module (external unit)

- Flow sensor for flux per spray head

- Flux reservoir tank with connections

- Replacement filters for external spray fluxer module – upper and lower machine sections

- Spare PC

Iedpfox Nhhhsx Ag Ujtb

Listing

Germany

Germany

1,414 km

Hydraulic Pumps Unit

REXROTH

Call

Condition: used, Technical details:

tank capacity: 250 l

overpressure : - bar

motor: -

dimensions L x W x H: auf Anfrage m

There are 5 hydraulic pump units available for sale. (price per piece)

Device no. 1 + no. 2 + no. 6:

Features:

Operating pressure max. 150 bar, connection Ø outside 30; 45; 52mm, capacity 250 litres, nitrogen capacity 20 litres Pressure 90 bar

Device No. 4

Features. Operating pressure 160 bar, connection Ø outside P2=30; P1=45:

Operating pressure 160 bar, connection Ø outside P2=30; P1=45; T=52; L=26mm, capacity 250 litres, nitrogen capacity 2x 10 litres Pressure 54 bar

Itodpfx Aou N E N Iog Ujb

Device No.7

Features. year of construction 2001, operating pressure 100 bar:

year of construction 2001, operating pressure 100 bar, connection Ø outside P2/P3=26, P1=22; L=36mm, capacity 160 litres, nitrogen capacity 10 litres pressure 90 bar

*

Listing

Germany

Germany

1,414 km

Soldering device for circuit boards

REHMRefloe SMS-N2-V4 - 3000

Call

Year of construction: 1998, condition: used, Technical details:

temperature: 200-210 °C

throughput speed: 1000 mm/min

max. workpiece length: 200 mm

total power requirement: 50 kw

weight of the machine ca.: ca. 2,0 t

- Soldering device for circuit boards (e.g. Type: SMD &/or Composite design) and drying SMD adhesive.

- Soldering unit works with functions -->intake - flow - soldering - cooling

- With software functions.

- Can be integrated in a production line.

Further technical details:

- Inert gas with Nitrogen 30 m³/h; 6 - 10 bar over pressure

- Water requirement: 20 Liter/min; 2 - 5 bar over pressure

- Exhaust quantity: 1000m³/h

- electr. Operation capacity: 12 kW

- room required: L: 6500 + loading station 2000 x W: 1400 x H: 2100mm

Supplementary equipment incl.:

- Automatic stacker LSB 03 with reloading device and discharge conveyor for intake of e.g. circuit boards

- Plant is applicable as spare part deliverer or for refurbishment or rebuild.

- Documentation available

- Machine is CE98 certified

On sale as is.

Itsdju Rnd Depfx Ag Uob

*

Listing

Germany

Germany

1,414 km

3D-printer

SinteritLisa Pro

Call

Year of construction: 2019, condition: used, Technical details:

control: Sinterit Studio 2019 Open

voltage: 220/50 V / Hz

total power requirement: 1,0 (max. 1,8) kW

Itodpfx Aou N Auueg Ueb

weight of the machine approx.: 90 kg

dimensions: 690 x 510 x 900 mm

SLS Laser System IR Laser Diode 5 (W)

Max. Print distance diagonal: 316mm

Flexa/TPE - high accuracy max. print volume 110 x150 x 250mm

PA - high accuracy max. print volume 90 x130 x 230mm

X/Y accuracy: 0.05mm

table size/working space: 150 x 200 x 260mm

built-in nitrogen chamber

nitrogen consumption: 0,48 m³/h

heating system with max. chamber temperature: 200°C

Accessories:

Glass plate (Laser Protective Glass)

1x USB (software accessible), Software Sinterit Studio 2019 open, supported formats STL,OBJ,3DS,FBX,DAE,3MF, operating system MS Windows

Light source (Set of Infrared heaters 24V)

various bottles with polyamide powder

div. small parts

*

Listing

Germany

Germany

1,414 km

Hydraulic Pumps Unit

REXROTH

Call

Condition: used, Technical details:

tank capacity: - l

overpressure : - bar

motor: 1400 U/min

total power requirement: 3,0 kW

weight: 312 kg

dimensions L x W x H: 1,05 x 0,67 x 1,94 m

application use of hydraulic components

operation pressure min/max.: 60/70 bar

- nitrogen 54 bar

- hydr. tank size L: 630 x W: 440 x H: 380mm with 100 Liter content

Isdou N E Nhjpfx Ag Ustb

*

Listing

Germany

Germany

1,414 km

Hydraulic Pumps Unit

REXROTHABHAG-0800SS0

Call

Condition: used, Technical details:

tank capacity: 800 l

overpressure : zul./max.=ca.100 bar

motor: 5

weight: ca. 2,4 t

Hydraulic Pressure Storage Plant

Ijdpfx Agju N Erve Uotb

- aggregate= LxWxH=2,48x1,73x2,13m

- oil tank :LxWxH=2,0x1,1x0,5m

- 5 motors ( from 3,8 up to 66 kW)

- coolant: nitrogen

- 5 pumps

iD.

*

Listing

Hardthausen am Kocher

Hardthausen am Kocher

1,305 km

Laser cutting machine

TRUMPFTrumatic L 3050 - 5 kw

Condition: excellent (used), functionality: fully functional, operating hours: 58,000 h, laser power: 5,000 W, TRUMPF Trumatic L 3050 - 5 kw

TECHNICAL DATA:

Make TRUMPF

Type Trumatic L 3050 - 5 kw

Year of manufacture 2005

Working area 3,000 x 1500 x 115 mm

Control Siemens Sinumerik 840 D

Laser power 5,000 watts

Max. Sheet thickness Mild steel 25 mm

Max. Sheet thickness stainless steel 20 mm

Max. Sheet thickness aluminum 12 mm

Operating hours approx. 58,000 h

STANDARD EQUIPMENT:

- Closed machine frame with integrated laser unit

- Laser unit: TLF 5000 CO2 laser, high-frequency excited, cooling unit, logbook function

- Automatic pallet changer

- Longitudinal conveyor belt for small parts/waste

- Drives: Gantry drive in combination with linear direct drives

- Laser power control

- HI-LAS high-pressure cutting

- Plasma sensor system PMS

- Fast processing with SprintLas

- ContourLas for the production of small holes

- Programmable power cycles

- Microweld

- Programmable cutting gas pressure setting

- Laser cutting head with 5" lens and laser cutting head with 7.5" lens

- Quick-change cutting head device

- Automatic sheet outer edge detection

- Capacitive height control (DIAS)

- Process Control System (PCS)

- Position laser diode

- Automatic focus position adjustment AutoLas Plus

- Automatic switch-off

- Work area lighting

- SIN 840D control system: Open control system on PC basis, simple operation, online help,

diagnostic functions, maintenance logbook, technology data, teleservice

- Workshop programming ToPs 100 lite

- Safety: Multi-beam light barriers, beam guidance fully encapsulated and ventilated with nitrogen

ventilated, monitoring system, multi-chamber extraction system and compact dust extractor, safety cabin

- Network connection: BNC/RJ-45 network connection

- Electrical equipment for three-phase current 400 V / 50 Hz

- Paintwork: textured paint white RAL 9002 / gentian blue RAL 5010

Itjdpfx Aorgaw Heg Ueb

EXTENDED EQUIPMENT:

- Additional laser cutting head with 9-inch lens

- NEW transmitter tubes on delivery

Listing

Bünde

Bünde

1,138 km

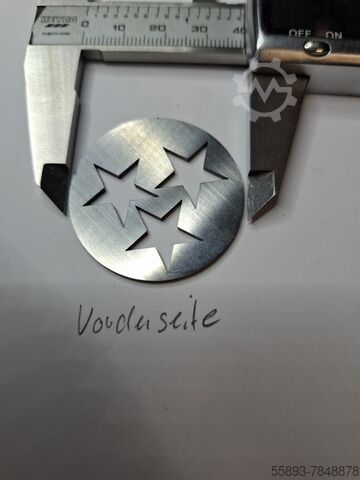

3D printer metal SLM

CONCEPT LaserM2 cusing

Call

Condition: used, Year of construction: 2014, working width 250 mm

working length 250 mm

work height max. 280 mm

laser capacity in Watt 400 Rofin

travel -z axis 10 - 1000 mm/s

positioning accuracy +/- 0,1 mm

repeating accuracy +/- 3,5 my

capacity 6,8 kVA

Required air-pressure 6-10 bar

Type of gas Schutzgas Stickstoff 5 bar

dimensions of the machine ca. 5,9 x 4,2 x 3 m

range L-W-H 2,44 x 1,63 x 2,36 m

weight 2 300 kg

Little used Concept Laser M2 Cusing system for processing reactive and non-

reactive powder materials. Design of process chamber, handling station, powder

suction according to ATEX Directive II for flammable substances.

Materials: steel, stainless steel + aluminum. Supplementing titanium against

additional payment possible.

Dynamic coating system with 3 different wiper blades.

Peripherals and accessories:

Rofin laser source - photo 4

Nitrogen generator (in the other room, photo 7)

External filter including fan and operating hours counter: 10464 - Photo 8.

Storage container for the filter inserts.

Transport device with lift for powder loading - photo 9.

6 stainless steel powder charging containers.

Pneum. Vibrating sieve for attachment to the powder container.

Powder container rack for swap containers, dimensions 1.15 x 0.17 x 1.22 m -

photo 10.

Orange wet vacuum cleaner - photo 8.

Selling due to production change. Price at the time € 1/2 mio!

Vid 1: Machine outside, Vid 2: Machining - created on this machine, Vid 3:

Slide show Workpiece creation on this machine + accessories.

Machine dealer with own stock of 1600 m².

Itodpfxewdiwyo Ag Usb

Listing

Hardthausen am Kocher

Hardthausen am Kocher

1,308 km

Laser cutting machine

TRUMPFTruLaser 5030 - 5 kw

Condition: excellent (used), functionality: fully functional, Year of construction: 2009, operating hours: 39,500 h, laser power: 5,000 W, TRUMPF TruLaser 5030 – 5 kW Classic

TECHNICAL DATA:

Manufacturer: TRUMPF

Model: TruLaser 5030 – 5 kW Classic

Year of manufacture: 2009

Working area: 3,000 x 1,500 x 115 mm

Control: Siemens Sinumerik 840 D

Laser power: 5,000 Watt

Max. sheet thickness (mild steel): 25 mm

Max. sheet thickness (stainless steel): 20 mm

Max. sheet thickness (aluminum): 12 mm

Operating hours: 39,500 h

STANDARD EQUIPMENT:

- Enclosed machine frame with integrated laser unit

- Laser unit: CO2 laser TruFlow 5000, high-frequency excited, maintenance-free turboradial blower, chiller, logbook function

- Automatic pallet changer

- Longitudinal conveyor belt for small parts/scrap

- Drives: Gantry drive combined with linear direct drives

- Quick-change cutting head system

- PlasmaLine

- Fast processing with SprintLas for all sheet thicknesses

- ContourLine for production of small holes

- Programmable power cycles

- Microweld

- Programmable cutting gas pressure setting

- Laser cutting head with 5" lens and laser cutting head with 7.5" lens

- Automatic sheet edge detection

- ControlLine capacitive height control and process regulation

- Positioning laser diode

- Automatic focus position adjustment (FocusLine)

- Automatic nozzle cleaning

- PierceLine

- NitroLine high-pressure cutting

- Laser power control

- Automatic shutdown

- Work area lighting

- SIN 840D control: PC-based open control, user-friendly operation, online help, diagnostic functions, maintenance logbook, technology data, teleservice

- Shop floor programming

- Safety: Multi-beam light barriers, fully enclosed beam guidance with nitrogen purging, monitoring system, multi-chamber extraction and compact dust collector, protective cabin

- Network connection: RJ-45 network port via teleservice installation

- 3.5" floppy disk drive

- TFT color monitor

- Electrical equipment for 400 V / 50 Hz three-phase current

- Finish: Textured white RAL 9002 / gentian blue RAL 5010

Iedpfxew Rytqe Ag Ustb

ADDITIONAL EQUIPMENT:

- Additional laser cutting head with 9-inch lens

OTHER:

- The machine underwent a technical overhaul in 2021

Listing

Borken

Borken

1,034 km

Test cabinet EUCAR 5, CO₂ extinguishing system

Binder Batterie-TestschrankKB 720 Kühlinkubator mit Paket P Plus

Call

Condition: excellent (used), Year of construction: 2022, Binder

BINDER KB 720 Refrigerated Incubator with P Plus Package

– Battery Test Chamber EUCAR 5, CO₂ Extinguishing System

Device Description:

For sale is a BINDER KB 720 (E6) refrigerated incubator, year of manufacture 2022, equipped with the advanced safety and performance test package “P Plus”.

This device is not a standard laboratory incubator but a high-quality safety test chamber, specifically designed for aging, performance, and safety testing of lithium-ion energy storage systems.

Key Added Value:

The unit is designed to reliably detect, monitor, and contain critical battery events safely—including up to EUCAR Hazard Level 5 (fire/flames, no explosion).

What can the device do specifically? (Section 2 – Performance & Application)

– Conduct aging tests on lithium-ion cells

– Performance tests (charge/discharge cycles under temperature)

– Continuous temperature runs and thermal cycling tests

– Testing of non-energized and cyclically energized cells

– Reproducible, precise temperature control throughout the entire usable space

– Safe execution of tests under realistic thermal conditions

– Test environment for R&D, automotive, e-mobility, and energy storage technology

Suitable for:

– Battery & cell manufacturers

– Research and development laboratories

– Test laboratories & safety testing

– Automotive / e-mobility / energy storage sectors

The P Plus package transforms the KB 720 into a genuine battery safety test cabinet:

Integrated Safety Features:

– Automatic & manual CO₂ fire suppression system

– Smoke detector with optical & acoustic alarm

– Mechanical double door locking (secure containment)

– Spark protection in the interior compartment

– Exhaust connection with reversible overpressure flap

– Connections for external inerting (e.g., nitrogen)

– Emergency stop / manual release of extinguishing system

– Ports for charging and measurement cables

Result:

The device is designed for testing lithium-ion cells up to EUCAR Hazard Level 5, where fire or flames can occur, but not explosion or uncontrolled propagation. This is not an abuse or destruction test device, but a secure, standard-compliant test chamber for real-world operating and fault scenarios.

Technical Core Data:

– Temperature range: –5 °C to +100 °C

– Interior volume: approx. 698 liters

– Shelves: 4 × stainless steel

– Max. load per shelf: 45 kg

– Max. total load: 100 kg

Electrical Data:

– Mains connection: 200–240 V AC

– Frequency: 50/60 Hz

– Phases: single-phase

– Power consumption: approx. 2.1 kW

– Circuit protection: 16 A

– Refrigerant: R134a

– Protection class: IP 20

Iodpjx Hf A Rjfx Ag Uetb

Dimensions & Weight:

– External (W × H × D): approx. 1250 × 1950 × 900 mm

– Internal (W × H × D): approx. 970 × 1250 × 576 mm

In short – why is this device special?

– Genuine battery safety test chamber

– Suitable for EUCAR Hazard Level 5

– Integrated CO₂ extinguishing system

– Large chamber (≈700 l)

– High market value & resale attractiveness

– Weight: approx. 285–300 kg

– Condition: used

– Scope of delivery: (see image)

(Technical data subject to change and errors excepted!)

For further questions, we are happy to answer your call.

Listing

Braak

Braak

1,220 km

Reflow system with innovative cooling section

SMT Quattro Peak L Plus

Call

Year of construction: 2017, condition: used, functionality: fully functional, Full convection reflow oven with chain transport

Other features:

8 zones: 5 preheating zones, 3 peak zones (top and bottom)

Bottom-side heating in 5 preheating zones, including fan dimming (individually adjustable)

Cooling zone: Innovative Cooling

Active cooling via water heat exchanger (3 zones)

Easy and fast access from above (full hood)

Entry height: 950 mm +/- 20 mm

Transport width: 60 - 510 mm

Clearance height: (top/bottom) 30/30 mm

Direction of travel: left to right

Nitrogen version

Ijdpfx Asx Sq R Dog Uotb

Intelligent nitrogen control including sleeping mode

Rated current: 155 A

Power: 105 kW

Supply voltage: 3~N, PE, 230 / 400 V, 50 Hz

Listing

Poland

Poland

1,192 km

Other UNI-KAT SPARK 2

OtherUNI-KAT SPARK 2

Call

Condition: ready for operation (used), Year of construction: 2020, This 3-axis plasma cutting machine manufactured in 2020 features a Hypertherm Powermax 65 plasma power source with a rated current of 65 A. It can handle steel cutting up to 32 mm and operates with a duty cycle of 50% at 65 A. The working table measures 3000 × 2000 mm. Ideal for high-quality cutting capabilities, consider the opportunity to buy this plasma cutting machine. Contact us for more information.

• Plasma Power Source: Hypertherm Powermax 65

• Cutting Capacity (Steel):

Isdpfsx Imukjx Ag Ustb

• Recommended cut: up to 16 mm

• Maximum severance cut: 25–32 mm

• Duty Cycle:

• 50% at 65 A

• 100% at 46 A

• Power Requirement: approximately 15 kW

• Cutting Gases: Air, Nitrogen

• Working table: 3000 × 2000 mm

• Plasma cutting machine

• Industrial computer with installed control software

• Full software package included

• The machine is fully connected and under power

• Machine is ready for inspection and demonstration

Listing

Haaksbergen

Haaksbergen

1,015 km

Laser Cutting Machine

TRUMPFTruLaser 3030 Lean Edition

Call

Condition: excellent (used), functionality: fully functional, Year of construction: 2012, Equipment: documentation/manual, Laser Cutting Machine Trumpf TruLaser 3030 Lean Edition

Lasercapacity 3200W

Type L20

Year 2012

Net 400V/50Hz

Power 73 kVA

Control voltage 24V

Fuse 3 x 125 A

Air 7 -10bar

Nitrogen connection 30 bar

Oxygen connection 20 bar

Ijdpfex Drlqox Ag Uetb

Hours Beam on 7755

Hours Laser on 25263

Machine is in excellent condition and completely modified by Trumpf in 2023. Complete documentation is available

Listing

Hauzenberg

Hauzenberg

1,616 km

Laser cutting machine

LD-LaserLG-1313 eco-line 1,5 kW Laser

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: MAX Photonics, laser power: 1,500 W, sheet thickness steel (max.): 15 mm, sheet thickness stainless steel (max.): 6 mm, sheet thickness aluminum (max.): 6 mm, sheet thickness brass (max.): 4 mm, input frequency: 50 Hz, type of input current: three-phase, type of cooling: water, compressed air connection: 8 bar, overall weight: 2,800 kg, Equipment: CE marking, centralized greasing system, cooling unit, dust extraction, emergency stop, fume extraction, safety light barrier, Laser Cutting Machine with 1500 W Fiber Laser ecoline

Our goal is to offer highly precise, long-term stable, yet affordable laser machines.

Our machines are ideal for workshops and repair businesses.

A perfectly developed library of cutting parameters is included in delivery, as is first-class service.

The cost-effective entry into laser cutting technology

- High-quality MaxPhotonics laser source

- Extremely energy-efficient cutting system

- Requires only approx. 3.0 x 3.0 meters of installation space

- Top quality, schedule a viewing now!

Cutting capacity:

Itodpfx Agoitu Sre Ujb

- Steel sheet up to 15mm

- Stainless steel sheet up to 5mm

- Aluminum sheet up to 5mm

- Travel distance approx. 1300 x 1300mm

- Table size: approx. 1300 x 2500mm

(suitable for a full mid-format sheet)

- Machine control system in German

- Manual front door

- Extensive collision protection measures

- Large front window for monitoring the cutting process

- Automatic, programmable dual-gas switching (compressed air/nitrogen, oxygen)

- Comprehensive cutting parameter files

- Including nesting module

- CypCut1000 cutting software

- Raytools 240 cutting head

- Very easy operation

- High-performance laser chiller

Sales exclusively to commercial customers.

Delivery / consultation / sales only in Germany / Austria / Switzerland

Machine dimensions approx.:

Width: 3.2m

Height: 2.3m

Length: 3.3m

Total weight: approx. 2800kg

Leasing or hire-purchase available through our financing partner.

Need different laser power, table type or table size?

No problem.

I will be happy to prepare a customized offer.

Not sure which laser power is suitable for your application?

Of course, I can carry out cutting trials tailored to your requirements.

A wide range is possible. From 0.5 kW up to 20 kW laser power.

Listing

Czech Republic

Czech Republic

1,683 km

2.8 Litre Zanchetta Model Rotolab Stainless Steel Mixer/Granulator

ZANCHETTARotolab

Call

Condition: used, Used Zanchetta model Rotolab stainless steel mixer granulator. Total bowl capacity 2.8 litre, working capacity approx. 1.6 litre. Has jacketed bowl with inside dimensions 160 mm diameter x 140 mm height. Main impeller rotation speed 120 - 1200 rpm driven by electric motor. Chopper blade rotation speed 6000 rpm driven by electric motor. Includes local control panel and integrated switchboard, connection for vacuum and nitrogen (.).

Isdpfx Aox Ryupeg Ujtb

Trust Seal

Dealers certified through Machineseeker

Listing

Borken

Borken

1,034 km

Selective Laser Melting Machine

SLM SolutionsSLM 280 HL 3D Drucker

Call

Condition: excellent (used), SLM Solutions

Model: SLM 280 HL

For sale is a professional metal 3D printer SLM 280 HL by SLM Solutions (Lübeck).

The machine comes from industrial use, is fully documented, and is delivered including nameplate data and technical documentation.

The SLM 280 HL is designed for 24/7 operation and is suitable for aluminum, stainless steel, tool steel, cobalt-chromium, and many other metal powder materials.

Included modules and accessories:

- AMC 330 WB Air Management/Filter Module

- HRS050-AF-20-M Chiller Unit

- DC 1.5 KAESER Compressor / Compressed Air Module

Technical Data (Excerpt)

Machine

Itedpox Agt Hefx Ag Ujb

Weight: 1,245 kg

Dimensions (without accessories):

Width: 1.7 m

Height: 2.0 m

Depth: 1.1 m

Build volume: 280 × 280 × 250 mm (optional depth 350 mm)

Electrical connection:

Power consumption: 15 A

Building-side protection: 32 A

Control voltage: 24 V DC

Heating power: 1,200 W

Protection class: IP50

Power input: 4.7 kW (single optics) / 8.0 kW (twin optics)

Media supply

Argon

Operating pressure: 6 bar

Flow rate (purge): approx. 130 l/min

Flow rate (build process): approx. 3 l/min

Quality: DIN EN ISO 14175 – Class 4.6 (≥99.996 %)

Compressed air

Operating pressure: 6 bar

Flow rate:

without nitrogen generator: approx. 100 l/min

with nitrogen generator: approx. 500 l/min

Quality: ISO 8573-1:2010 Class 1:4:1

Cooling water

Medium: distilled water

Primary circuit:

Pressure: 4 bar

Flow rate: 0.3 l/min

Supply temperature: 18–20 °C

Secondary circuit:

Min. pressure: 2 bar

Max. temperature: 40 °C

Volume: 1.7 m³/h

pH value: 5.8–7.0

Operating conditions

Ambient temperature: 20–25 °C

Max. relative humidity: 60 %

Designed for continuous (24 h) operation

(Weight approx. 1,245 kg).

Important note:

“The table shown in the photos is not included in the sale.”

Condition: used

Scope of supply: (see picture)

- SLM 280 HL machine

- Control cabinet

- Process chamber

- Internal control panel with screen

- Available documentation, parts lists, manuals

(Subject to changes and errors in the technical data!)

We will be happy to answer any further questions by phone.

Listing

Burgoberbach

Burgoberbach

1,385 km

Injection molding machine

KraussMaffeiKM 110-380CX

Call

Year of construction: 2008, condition: good (used), For sale is a Krauss Maffei brand injection molding machine type KM 110-380

The machine is in a good to very good condition, all maintenance and inspections have been performed

Technical data:

Year of manufacture 2008

Extended tie bars

Pneumatic valve gate

2X Hydraulic core puller

31000 operating hours

Cylinder D35mm

Mould closing force: kN 1100

Mold opening force: kN 70

Euromap63 interface for version > 1-04-09

Nitrogen battery present

Included component

Isdpfx Agsibyate Ustb

Wedge shoes with bolts and nuts

Double bit wrench

Declaration of conformity cpl switchboard

Certificate

USB memory stick

Ejector coupling-mechanical Enclosed in the control cabinet

All prices plus VAT

Machines purchase / sale

PURCHASE / SALE OF PRODUCTION & METALWORKING MACHINES ETC.

Do you need a high-quality but inexpensive metalworking machine for your production? Or do you want to sell yours?

For more information or to contact us, please visit our website

Listing

Prüm

Prüm

1,069 km

Slurry technology

KawecoTurbo-Tanker SI 25000

Call

Condition: used, Year of construction: 2013, Kaweco Turbotanker SI 25000 Year 2013 – 25 m³ capacity – Tires 750/60 R30.5, all 6 with 40-60% tread remaining – 15,000 L centrifugal pump – PTO drive shaft with wide-angle – 27 m Vogelsang SwingMax, year of manufacture 2014 – Heavy-duty BPW axles – Hydraulic forced steering on 1st and 3rd axles – 2,000 L Börger pump for suction via front arm – LED work lights on the tank, sides and rear – LED tail lights – New flow meter installed – Tire pressure control system (defective due to faulty compressor hydraulic motor) – Control board for tire pressure control system recently overhauled by PTG – Track guidance switching via ball valves – Boom section control "half/half" possible from terminal Front arm Marxen front docking station FA 8, year 2021 – 8" centrifugal pump with 10" docking ball – Filling pump with axial piston motor, intermediate bearing and shredder – Spade slide on the filling pump – LED work lights – 8" piping routed centrally over the tractor cab – Nitrogen accumulator for arm damping – Docking height 4 m (+0.2 m–0.4 m) – Bottom: dual-sided 6" hose connector with slide valve – Storage box, storage location: not specified

Itedjx Ipwbspfx Ag Uob

Listing

Misterton

Misterton

492 km

Freezing tunnel

LindeCryoline MT1250

Call

Condition: excellent (used), Year of construction: 2016, Linde Cryoline MT1250 Freezing tunnel

Serial: 5-199

Itjdpfet N Upcsx Ag Uob

2016, Linde CRYOLINE MT 1250 Cryogen/Nitrogen Tunnel Freezer, a top-of-the-line freezing solution for your industrial needs. This machine boasts a cooling capacity of 100 kW/29.41 tons, ensuring efficient and rapid freezing of your products. The fully stainless steel construction, including a fine stainless steel mesh belt, guarantees durability and hygiene compliance. With a net belt width of 1250 mm and a freezing belt length of 4000 mm, this freezer can accommodate a wide range of products with a maximum height of 100 mm.

Equipped with 6 internal high-speed fans that are adjustable, you have full control over the freezing process. The holding time can be set between 0.5 and 20 minutes, providing flexibility based on your specific requirements. The stainless steel switch-board cabinet features a Siemens PLC and HMI Simatic touchscreen for easy operation and monitoring. This Cryoline MT 1250 Cooling Tunnel, manufactured in 2016, operates on N2/Stikstof refrigerant and requires a voltage of 380-500V (50-60Hz). With an absorbed power of 5 kW, this machine is both powerful and energy-efficient. Don't miss out on this opportunity to enhance your production line with this reliable and high-performance freezer.

We make it easier for you to find: "nitrogen"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Nitrogen (347)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month