Used Straight Edge for sale (5,074)

Wiefelstede

Wiefelstede Milling motor for edge processing machines

PerskeDVMS2004/2

Wiefelstede

Wiefelstede Milling motor for edge processing machines

Schwabedissen2KF16/19

Wiefelstede

Wiefelstede Milling motor for edge processing machines

PerskeKCUS72.24-2D

+44 20 806 810 84

Wiefelstede

Wiefelstede Edge magazine for edge banders

Homag5 Fach

Wiefelstede

Wiefelstede Milling motor for edge processing machines

HomagLF-55-L-KA

Discover more used machines

Wiefelstede

Wiefelstede Milling motor for edge processing machines

PerskeKNS 21.05-2

Wiefelstede

Wiefelstede Milling motor for edge processing machines

PerskeDKNS 502/2

Wiefelstede

Wiefelstede Edge banding unit

BrandtBRANDT KS 25

Wiefelstede

Wiefelstede Milling unit for edge processing machines

PerskeKNS 21.05-2

Wiefelstede

Wiefelstede Heating basin for edge banding

ENA4-060-15-0600

Wiefelstede

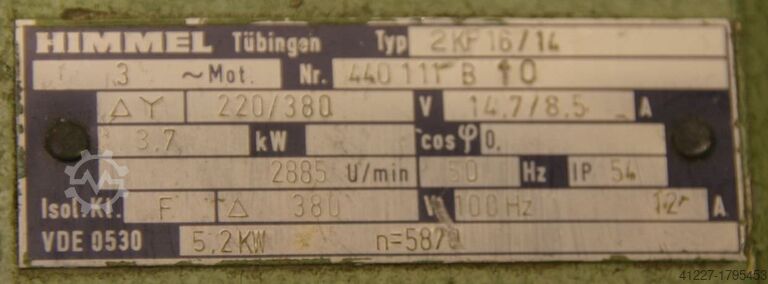

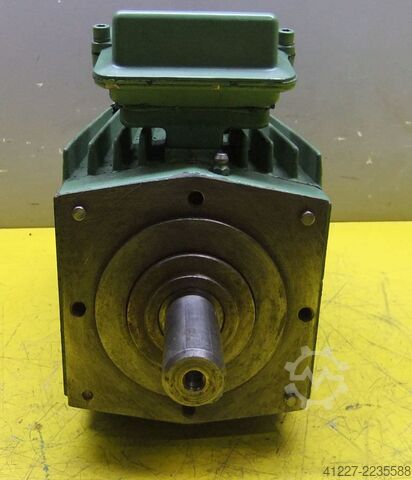

Wiefelstede Milling motor for edge processing machines

Himmel2KF16/14

Wiefelstede

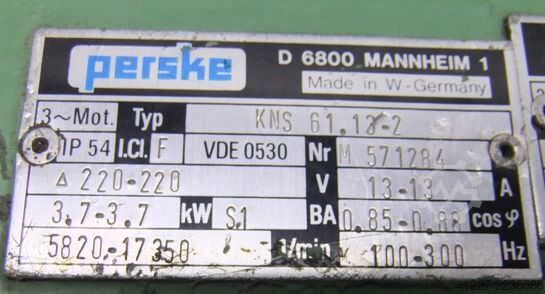

Wiefelstede Milling motor for edge processing machines

PerskeKNS 61.13-2

Rödermark

Rödermark Welding edge former

TRUMPFTKF 1525-2

Rödermark

Rödermark Deburring machine / edge sanding machine

MÜLLERSEL 2000

Nattheim

Nattheim Edge banding machine with joining

SCMME 40 TR

Hradec Králové 4

Hradec Králové 4 5,720 Litre 316L Stainless Steel Vacuum Storage Tank, 1500mm Dia x 2500mm Straight Side

SCHWARTE-MILFOR5,720 Litre

Sierakowska Huta

Sierakowska Huta Edge banding machine with pre-milling unit

HOLZINGG-MAX 360

Oberkochen

Oberkochen Sanding machines for edge

LANGZAUNERLZK 3/2, BB 200

Bielefeld

Bielefeld Edge sanding machine - parquet machine

FRANKGECKO S

Lambsborn

Lambsborn Edge banding machine

HOLZ-HER1436 SE

Mutterstadt

Mutterstadt Edge sanding machine

MBMORION 96 STANDARD

Miechucino

Miechucino Edging line edger with optimization

PAULAB920

Miechucino

Miechucino Vecoplan VTH/55/15/2 edging chipper

VecoplanVTH/55/15/2

Wiefelstede

Wiefelstede Milling motor for edge processing machines

Schwabedissen2KF16/14

Tauberbischofsheim

Tauberbischofsheim Edge banding machine

HebrockEURO 3001

Used Straight Edge (5,074)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84