Used Nc Milling Machine for sale (65,663)

Monheim am Rhein

Monheim am Rhein Tool Room Milling Machine - Universal

AVIAFNE 40 NC

Rossum

Rossum 4 Axis CNC Milling machine

DMG MORIDMF 360-11 - 4 axis

Malakoff

Malakoff Planer-type milling machine - double column

TechmillLaborshape

+44 20 806 810 84

Wijchen

Wijchen Milling machines Deckel MAHO MH 800 C

Deckel MAHOMH 800 C

Wijchen

Wijchen Milling machines Maho MH 600

MahoMH 600

Discover more used machines

Wijchen

Wijchen Milling machines Geldmacher UWF 400

GeldmacherUWF 400

Gijón

Gijón Travelling column milling machine

ZAYER30KCU8000

Gijón

Gijón Bed type milling machine

LAGUNGBM42

Dreieich

Dreieich Tool Room Milling Machine - Universal

DECKELFP 2 NC / DIALOG 11

Iserlohn

Iserlohn CNC bed type milling machine

IBERIMEX-MVRUH-1250

Iserlohn

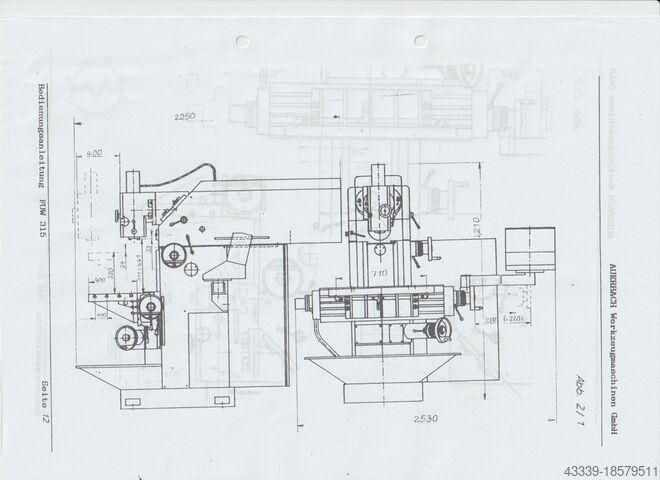

Iserlohn Milling machine

AUERBACHFUW 315

Iserlohn

Iserlohn CNC milling machine

MAHOMH 500 W

Iserlohn

Iserlohn Milling machine

MAHOMH600-C

Iserlohn

Iserlohn CNC universal milling machine

DMG MORIMH 600 C

Iserlohn

Iserlohn Milling machine

MAHOMH 500 W4

Iserlohn

Iserlohn CNC milling machine

DECKELFP5 CC/T

Iserlohn

Iserlohn Spare parts CNC universal milling machine

DECKELFP5NC

Iserlohn

Iserlohn CNC milling machine

TOSFGS40CNC

Iserlohn

Iserlohn CNC universal milling machine console

KLOPPFWS15

Iserlohn

Iserlohn Milling machine

UNITECHFSS 315 - S7

Iserlohn

Iserlohn Universal milling machine

KUNZMANNUF 6 / 3

Iserlohn

Iserlohn Universal tool milling machine

KNUHTWF 5

Iserlohn

Iserlohn Multi-edge milling machine

WITTEMKF 1001

Malsch

Malsch Thread Milling- and Hobbing Machine

WANDERERGF 327 x 7000

Bühl

Bühl Milling machining centers - universal

DECKEL-MAHOMC 600 U

Used Nc Milling Machine (65,663)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84