Used Genome Sequencer for sale (348)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Wald

Wald

1,366 km

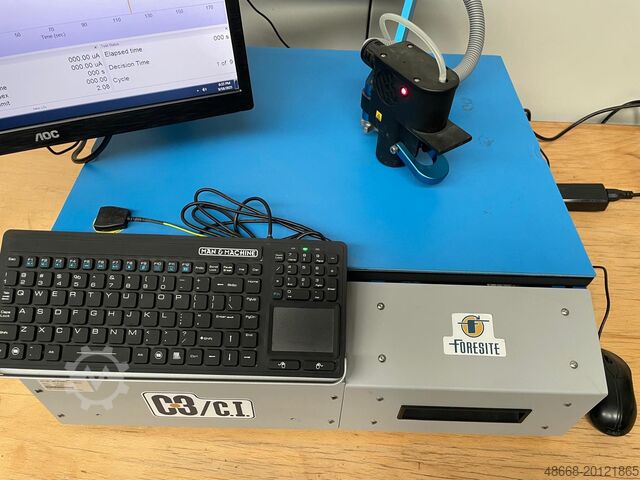

Critical Cleanliness Control Tester

ForesiteC3 / C.I.

Call

Condition: ready for operation (used), Foresite C3 / C.I. Critical Cleanliness Control Tester Analytics Technology

Year of manufacture: 2011

The C3 is unique among electronics cleanliness quality testers. It remains the only tester on the market that indicates whether a specific, critical area of a PCBA (Printed Circuit Board Assembly) is clean.

Simply select the components and/or circuit areas most sensitive and vulnerable to contamination and/or reliability issues, and test a small area (0.1 in²). The C3 quickly provides feedback as to whether potentially detrimental residues, often caused by manufacturing processes, are present.

Bwodpfxexhckle Agzoi

Once the critical areas to be tested have been identified, the operator simply inserts a new disposable test cell into the vapor head and manually positions the head via the articulated arm over the test area. The weight of the arm and vapor head seals the test cell on the test surface. The operator then starts the automated testing sequence. Within 7-10 minutes, the operator knows whether the tested product area meets cleanliness standards. The C3 can be used directly in the production area.

At the end of the test, the cell can be easily removed using the cell ejector on the head. The test sample in the cell, efficiently extracted from the small test area using steam, can undergo further analysis to identify specific contaminants and their concentrations. The entire test is simple and straightforward for the operator, with results not dependent on operator skill. The use of Pro-Site single-use test cells and extraction solution prevents cross-contamination of samples.

You are welcome to arrange an inspection.

We can also organize cost-effective shipping for you!

You will receive a proper invoice.

For foreign customers, a net invoice can also be provided, provided a valid VAT ID number is available.

Subject to prior sale.

Visit our shop and take a look at our other offerings as well.

Brand names and trademarks mentioned are the property of their respective owners and are used solely for identification and product description purposes.

Technical data deviations and errors in the description of the item may occur and are subject to change.

Listing

Hövelhof

Hövelhof

1,156 km

Horizontal broaching machine Broaching machine

Arthur KlinkRIW 10 x 1600

Call

Year of construction: 1999, condition: like new (used), functionality: fully functional, Manufacturer: Arthur Klink

Year of construction: 1999

Type: horizontal broaching machine

Model: RIW 10x1600x400

Weight: 2.700 KG

General / technical data:

horizontal hydraulic internal broaching machine in mint condition with tool holding system ideal for the use of flat broaching tools.

Broaching stroke: 1.600mm

Tractive force: 10,000 kg (100kN)

Mounting in the drawbridge: Ø 85mm Cylindrical

Through-hole in the clamping table: Ø 100mm

Workpiece diameter: max. 400mm (due to the machine body of the tool trough)

Cutting speed: hydraulically infinitely variable from 1.0 m/min to 9 m/min

Return speed: hydraulically infinitely variable from 1 m/min to 24 m/min

Space requirement of the machine: (w x d x h) approx. 6,400 mm x 1,450 mm x 1,600 mm (without working area)

Bsdpfxor A Hcbs Agzowi

Power supply: 400Volt 50 HZ

Connected load: 9kw

Equipment:

- the machine has an electric control for the clearing stroke movement with manual operation and automatic sequence

- the machine has an integrated coolant system

- the machine has a tool holding system for flat broaching tools (no feed)

- The broaching carriage with the pulling head holder is equipped with a flat guide on both sides

Accessories

- 1 universal pulling head for flat shanks from 3mm to max. 25mm wide and a maximum pulling force of 10kN (10,000kg)

- Complete machine documentation and CE declaration of conformity

Remarks:

The machine is ideal for the production of keyways.

Due to the connection with the stable machine bed of the machine and the broaching tool holding system, the machine is particularly suitable for quick and easy use of flat broaching tools.

The machine has been used very little and is in mint condition. The machine is available for inspection in our warehouse and is ready for demonstration under power.

Our direct contact details and further information about the machine can be found in the attached PDF document

Listing

Hüllhorst

Hüllhorst

1,143 km

Edge banding machine

LangeB 90 KFE mit Fügen + Eckenkopieren

Call

Condition: as good as new (ex-display), Year of construction: 2025, One-sided automatic edge banding machine with pre-milling unit, direct glue application to straight workpieces (EVA-PUR Glue pot with run-out function/optional), HF-cut-off saw station, HF-top and bottom milling unit, corner rounding unit, chain feed, double roller top pressure, extendable work piece support, signal lamp for work piece sequence and synchronisation of working units by encoder. For ABS, PVC, melamine and

strong wood veneer roll material as well as fixed lengths from 0.4 – 3.0/6.0 mm and of 8 – 60 mm work piece thickness.

Speed: 10,0 m/min.; 8,0 m/min. with corner rounding • 3 spaces for finishing units • 10“ Colour Touch screen

→Automatic edge feeding for roller material over turntable D = 800 mm

→Longer infeed lineal (650 mm)

→Two reverse, operating-controlled pre-milling units with diamond charged helical joining millers provide a neat and tear-free premilling of the work pieces before the gluing of the edge material

Bedjd R U Agepfx Agzjwi

→Glue application directly to workpieces: Teflon-coated glue pot with a capacity of 1,5 kg, leak proof with glue supply from below (excess glue automatically flows back into the glue pot). Glue roller allows exact dosage of glue. Separate glue roller temperature adjustment. Electronic temperature control with automatic stand-by function (reduces probability that the glue burns if the machine is not used for a longer periods and is still turned on).

Optional: EVA/PUR gluepot with run out / cleaning function for quick change of glue

→Pneumatically operated cut-off knife from roll material up to 3mm edge thickness

→Automatic feeding magazin (70mm magazin capacity) with spiked roller for solid wood

→Pressure unit consisting of one driven pressure roller synchronized with glue spreading roller and two of smaller diameter, conical, one positive and one negative pressure roller with spring tension for a nearly invisible joint of the edge material with the work piece , adjustment of the pressure unit with digital readout.

→High-frequency cut-off saw equipped with HF motor 0.35 kW, 12,000 rpm, 2 saw blades and high-precision linear guides ensure a clean and precise saw cut, with extraction hood.

→High-frequency top and buttom milling station, 2 powerful 0.55 kW high-frequency motors with HM-WPL special millers; suitable for radius, bevel and flush milling, horizontal and vertical scanning of the work piece; aggregate adjustment equipped with digital readouts for setting to various edge types; 2 extraction hoods for shavings with central extraction nozzle 2 x Ø 100 mm; height adjustment of the upper aggregate with the top roll pressure

→Corner rounding unit : Automatic processing of corner edges up to 2 mm edge thickness. Equipped with one high frequency motor 0, 27 kW, selectable on operating panel.

One side (front or back edge) or both side corner rounding unit.

→Rotatable control panel with 10“ color touch screen controls glue temperature settings, automatic temperature reduction for stand-by function of the machine, switching on and off of aggregates and error diagnosis, incl. digital Meter counter

Additional finish aggregates :

→Radius scraper unit : With a slight draw cut eventual radius milling traces are removed to provide a perfect finish. The fine adjustment is made by digital readouts.

→Glue scraper unit : Removes eventual glue rests with a slight draw cut from the glue joint of the work piece surf

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Warszawa

Warszawa

1,959 km

Paper cutting machine

Wohlenberg155

Call

Condition: excellent (used), Year of construction: 2000, Wohlenberg 155 – Industrial Paper Guillotine (155 cm)

For sale: Professional Wohlenberg 155 paper guillotine, designed for high-performance bookbinding and print production applications. This machine offers a cutting width of 1550 mm and is equipped with an air table, which significantly facilitates sheet handling and increases operator comfort.

The guillotine is fitted with a rear gauge (backgauge) with a maximum retraction of 1600 mm, allowing for processing of large paper formats. Additionally, the unit is equipped with a safety barrier system, ensuring a high level of safety in compliance with industrial standards.

The control system allows for the input and storage of cutting programs, which speeds up the execution of repetitive jobs and enhances production precision.

Included in the set is a Baumann jogger, providing an ideal addition to any paper finishing line.

Key parameters:

- Cutting width: 155 cm

- Air table

- Backgauge retraction: 1600 mm

- Safety barriers

- Programmable cutting sequences

Bwjdpoyk Dufjfx Agzji

- Baumann jogger included

Listing

Nijverdal

Nijverdal

996 km

Wendel Mixers

DiosnaWV600 ATP/T/FU

Call

Year of construction: 2010, condition: ready for operation (used), Diosna WV600 ATP/T/FU Premium wendel mixer with 4 bowls 600kg dough

year of build 2010

2 speed frequency controlled

Bwedpjwa Sz Tofx Agzei

geardrive

scraper with temperature measurement

stainless steel

digital Siemens Simatic Multi touch panel

shorter kneading time

fast dough sequence

lower dough heating

suitable for all types of dough, thanks to the gentle kneading

capacity in flour 375kg

bowl contents 1020 liter

Discover more used machines

Listing

Küssaberg

Küssaberg

1,331 km

Sheet metal deburring machine

Timesavers22-Serie-1100-WBB

Call

Condition: excellent (used), functionality: fully functional, Timesavers 22 Series 1100-WBB

1st Station: Abrasive belt for pre-grinding, ideal for removing burrs, laser scale, etc. Optionally, the abrasive belt can be switched to a Scotch-Brite/non-woven belt to achieve a surface finish on the parts. Easy belt change in under a minute thanks to quick-change system. The belt speed is continuously adjustable.

2nd & 3rd Station: Disc brushes for edge rounding, two stations in sequence with both left and right rotation for optimal results. Eccentric mechanism enables lateral oscillation of the disc brush stations (can be switched on or off). Easy brush change using the quick-change system. Disc brush speed is continuously adjustable.

Conveyor belt speed is steplessly adjustable.

Working width: 1100 mm

Maximum part thickness: 100 mm

Bjdpox Uwlajfx Agzswi

The machine is fully operational and can be inspected and tested under power on site.

Listing

Erith

Erith

609 km

Surface grinding machine

NEW DCMIG 482 SD Rotary Table Surface Grinder

Call

Condition: new, functionality: fully functional, IG 482 SD Specifications

Motors

Grinding Spindle Motor 50HP, 200 - 1180RPM

Rotary Table Motor 3HP, 5 - 70RPM

Servo Column Motor 5KW

Coolant Pump 3/4HP, 45GPM

Table

Diameter 48"

Table Features Thru-spindle vacuum/pressure feed

Variable strength 3/4" fine pole electromagnetic chuck

Bwsdpfxsubbqij Agzei

Contact a DCM Technical Specialist for custom table & fixturing options

Capacity

Max Swing Diameter 52"

Max Part Height 12" with grinding segments retracted

10-1/2" with a 2A2T wheel

Grinding Wheel Options

2A2T Suberabrasive or Conventional Segments

26" diameter

Cortland Style Hub & Segment

26" diameter

Ask a DCM Technical Specialist about our wide variety of available abrasives

Feed System

Servo driven Z-axis with precision ballscrew and encoder

Feedrate variable from 0.0006 IPM to 0.1000 IPM

Servo drive X-axis for precision positioning

Electrical Requirements

460V, 50/60Hz, 3 phase

Consult DCM Technical Specialist regarding operation on other voltages

Dimensions

137" wide, 82" deep, 88" high

Weight

Machine & Swarf System: 14,500lbs. (estimated)

Electrical Box: 1,500lbs. (estimated)

IG 482 SD FEATURES

• 48” variable speed electromagnetic chuck with auto demag cycle

• 50HP grinding spindle motor

• Integral coolant filtration & mist collection systems

• Easy to operate touchscreen controls

• Mitsubishi FX5U PLC

• 3 Grinding Modes - Conventional, Incremental and Grind to Height

• Regrind feature allows re-running previous grind sequence without reprogramming

• Continuous grind – the machine can automatically cycle through grind 1, 2 & 3

• Servo-driven precision control of both Z and X-axis with absolute home positioning

• The cross slide X-axis moves with manual pulse generator

• Backlash compensation on both axes

• Password protection & operator lockout features

• SECS/GEM Interfaced to work with 3rd party Scada type software

• Password protection and operator lock-out features

• Automatic routine maintenance reminders

• 120" x 82" Footprint

Listing

Heemskerk

Heemskerk

872 km

Postbox trayingsystem Palamides Sima 220

PalamidesSima 220

Call

Year of construction: 2014, condition: excellent (used), Automatic Postbox traying system for envelope inserting systems. This SIMA 220 was connected to a Buhrs BB700 inserting systems, therefore it is blue. Installed in 2015 and just in use for 16 months! More pictures available on request!

Description:

Adjustable in height 600 mm up to 900 mm.

Gathering section – with buffer for post boxen

Automatic fillingstation for postboxes

Automatic change of postboxes.

Max 10 Postboxen can be in feeder

Touchscreen – simple, and user-friendly user interface

Complete with connection from envelope inserter - connection with all inserters possible!

Format max.: 180mm x 285mm

Format min.: 90mm x 145mm

Speed: up to 20.000 envelopes per hour

Envelope thickness max.: 8 mm

Postbox change-over time: ca. 1,8 sec (max 2000 boxes per hour)

Post boxes: Deutsche Post, Postcon, Schweizer Post, Oesterreichische Post, Belgische Post, Hollaendische Post, USPS Trays, Pin Boxen.

Electrical connection: 16A, 400/230V, 4kW

Pressure air: 6bar, 200l/min

Connection: To all inserting systems possible

The sima Automatic Mail Delivery lines up with any inserter and automates the presorting and letter tray preparation processes.

The delivery checks for open flaps, non-readable addresses, and IMB Barcodes then automatically rejects any letter that should not be delivered. Various reading systems are available for the sima, from simple print mark readers up to a server based OCR/IMB reading system connected to the Digital Front End. Our patented collection unit safely stacks the envelopes individually- without contacting each othermaking

twisting or interleaving almost impossible.

Bwedpfed Etadsx Agzsi

The envelope stack is quickly pressed before filling the letter trays in accordance with USPS regulations (DMM). The exchange of letter trays occurs automatically with an

exchange speed of up to 1,800 boxes/h (2.0 sec). The tray exchange unit can handle MM and EMM letter trays.

A unique feature is its ability to intermix one and two foot

letter trays depending to the presorting need. As an option, a postcode label printer can be integrated into the sima, which applies a tray label to the letter tray.

The filled letter trays are temporarily stored on a large buffer section. The Sequence Repair System (SRS), which marks or separates mails that do not belong to the actual mail sequence, comes standard on this machine. The sima can instruct the operator

what to do with the marked or separated mail. This SRS enables a constant production speed even when sequence problems ap

Listing

Heemskerk

Heemskerk

872 km

Postbox trayingsystem Palamides Sima 220

PalamidesSima 220

Call

Year of construction: 2014, condition: excellent (used), Automatic Postbox traying system for envelope inserting systems. This SIMA 220 was connected to a Buhrs BB700 inserting systems, therefore it is blue. Installed in 2015 and just in use for 16 months! More pictures available on request!

Description:

Adjustable in height 600 mm up to 900 mm.

Gathering section – with buffer for post boxen

Automatic fillingstation for postboxes

Automatic change of postboxes.

Max 10 Postboxen can be in feeder

Touchscreen – simple, and user-friendly user interface

Complete with connection from envelope inserter - connection with all inserters possible!

Format max.: 180mm x 285mm

Format min.: 90mm x 145mm

Speed: up to 20.000 envelopes per hour

Envelope thickness max.: 8 mm

Postbox change-over time: ca. 1,8 sec (max 2000 boxes per hour)

Post boxes: Deutsche Post, Postcon, Schweizer Post, Oesterreichische Post, Belgische Post, Hollaendische Post, USPS Trays, Pin Boxen.

Electrical connection: 16A, 400/230V, 4kW

Pressure air: 6bar, 200l/min

Connection: To all inserting systems possible

The sima Automatic Mail Delivery lines up with any inserter and automates the presorting and letter tray preparation processes.

The delivery checks for open flaps, non-readable addresses, and IMB Barcodes then automatically rejects any letter that should not be delivered. Various reading systems are available for the sima, from simple print mark readers up to a server based OCR/IMB reading system connected to the Digital Front End. Our patented collection unit safely stacks the envelopes individually- without contacting each othermaking

twisting or interleaving almost impossible.

The envelope stack is quickly pressed before filling the letter trays in accordance with USPS regulations (DMM). The exchange of letter trays occurs automatically with an

exchange speed of up to 1,800 boxes/h (2.0 sec). The tray exchange unit can handle MM and EMM letter trays.

Bedpfjd Etagex Agzowi

A unique feature is its ability to intermix one and two foot

letter trays depending to the presorting need. As an option, a postcode label printer can be integrated into the sima, which applies a tray label to the letter tray.

The filled letter trays are temporarily stored on a large buffer section. The Sequence Repair System (SRS), which marks or separates mails that do not belong to the actual mail sequence, comes standard on this machine. The sima can instruct the operator

what to do with the marked or separated mail. This SRS enables a constant production speed even when sequence problems ap

Listing

Crailsheim

Crailsheim

1,355 km

Panel van

Mercedes-BenzSprinter 316 CDI Kasten Klima,Standheizung

Call

Condition: used, mileage: 125,500 km, power: 120 kW (163.15 HP), first registration: 10/2021, fuel type: diesel, overall weight: 3,500 kg, fuel: diesel, color: white, gearing type: mechanical, emission class: euro6, suspension: steel, number of seats: 2, Equipment: air conditioning, airbag, central locking, cruise control, navigation system, parking heater, power assisted steering, seat heater, sliding door, soot filter, E07 Hill Start Assist, JA7 Blind Spot Assist, EY5 Mercedes-Benz Emergency Call System, EY6 Breakdown Management, AI1 Rear Axle Control Code – Ring Gear 215, RS3 Steel Wheels 6.5 J x 16, Z1N N1 Approval, VK8 Plastic Flooring, XO9 Mercedes-Benz MobiloVan with DSB and GgD, XG7 Without Increase/Decrease of Permissible Weight 3,500 kg, IR4 Wheelbase 3665 mm, T77 Entry Grab Handle at Partition in Side Sliding Door to Load Space, W54 Rear Doors: Double-leaf, Opening up to Side Wall, E1E Digital Extra: Hard Drive Navigation, HH9 Semi-automatic TEMPMATIC Air Conditioning, E1D Digital Radio (DAB), Y10 First Aid Kit, E1G Live Traffic Capability, MJ8 ECO Start/Stop Function, ES0 Jump Start Terminal, D03 High Roof, MS1 Cruise Control, HI1 Climate Zone 1 (cold/comfort), T86 Entry Handle on Rear Right Corner Pillar, RM0 All-Season Tires, C6L Multifunction Steering Wheel, LA2 Headlight Assistant, ZM0 Panel Van, H12 Auxiliary Hot-Water Heater, IT4 3.5 tonner, E36 Separation relay for additional battery, H11 Auxiliary Warm-Air Heater, JV7 Pre-installation for Sound Sequence System, H16 Heated Seat for Driver, J58 Seat-belt Warning Device for Driver’s Seat, L13 Fog Lights with Cornering Light, XZ0 Model Generation 0, W73 Rear Door Step, X93 Omission of Model Badge, ED4 Fleece Battery 12 V 92 Ah, FF5 Over-windscreen Storage, JF1 Rain Sensor, FF4 Roof Trim Storage Compartment, ED5 Parameterizable Special Module, T16 Right Sliding Door, LB1 Side Marker Lights, RF1 Tyre Make: Continental (10), MD3 Speed Limiter 120 km/h, E3M MBUX Multimedia System with 7-inch Touchscreen, LB5 3rd Brake Light, D22 Fixed Rear Roof Window, F64 Electrically Folding Exterior Mirrors, H21 Heat-insulating Glass with Band Filter on Windscreen, VF7 Fabric Maturin Black, J65 Out., We are available by phone Monday to Friday until 8:00 PM and Saturday until 4:00 PM! Further details:!! Leasing/financing and trade-in possible!! !! !! - Subject to errors and prior sale!! - All information without guarantee ... more on our homepage

Bwjdpfxjx Tpk Eo Agzoi

Listing

Douarnenez

Douarnenez

656 km

Hydraulic press-brake PETERZEN 3m 125T

Peterzen

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, controller manufacturer: Cybelec, controller model: CybTouch 15, bending force (max.): 125 t, IT2 2026 Design

CNC Controller CYBELEC CybTouch 15

Force 125 T

Bending lenght 3000 mm

Distance between columns 2600 mm

Depth throat 320 mm

Upper Ram stroke 150 mm

Torsion Shaft with double Articulation

Mechanical depth adjustment in each hydraulic Cylinder, Setting by brushless Servototor and transmission between left and right side

Closing Ram speed 9 mm/s

Upgoing Return-speed 40 mm/s

Total Power requirement 10 kW

Machine weight 6900 kg

3 +1 Axes (Y,X,R + compensation crowning) CNC controller CybTouch 15 with 15" Touchscreen with vivid colors and high contrast

200 Programs, 50 Dies, 24 Sequences per program, 10 Materials

Automatic calculation of hydraulic cylinder's stopper position

Easy single bends with the EasyBend page

Correction menu

Many languages available

Upper Ram guidance by grey cast iron slydways

Hydraulic equipment with counter balance compensation- pressure in lower chamber

Centered lower die system 60 mm AMADA-tool Standard and 13 mm WILA Groove

Upper Ram featured with 15 tool holders for punches with AMADA Standard dimensions and Fall down security

Back gauge with linear guide and Ballscrews

Back gauge travel 600 mm (Option 800 mm)

2 back gauge fingers on linear guides

Automatic height adjustment (R axes)

Automatic crowning table

Safety Equipment :

Foot switch with Emergency Stop Position

Closing speed < 10 mm/s

Side covers with safety switch

Rear-protection with sliding door and safety switch

Low control Voltage (24V)

Bwjdpfx Asxhc Spsgzoi

Safety control unit cat IV

Standard configuration and equipment :

Electric control cabinet on right side

CNC control interface with Aluminium - arm

1 Line of punches (Upper tools) 85° R1, Height 150 mm

1 Line of 4 sides Dies, widths: 16 mm / 85°, 22 mm / 85°, 35 mm / 85°, 50 mm / 85°

CE Certificate

Operation manual in English, German or French language

Warranty 2 Years

EXW Douarnenez/ FRANCE special price 55,120 € + VAT loaded on Truck

Delivery and Services need to be quoted seperatly

Listing

Douarnenez

Douarnenez

656 km

CNC press brake PETERZEN MORICO 70065

Call

Condition: new, Year of construction: 2025, High performance CNC press brake PETERZEN model MORICO 70065 6 axis + 2 + 1

Rigid S355 steel frame

Workbench structure and Ram manufactured from laminated S355 steel

Symetric renforced Throats

Heavy grey cast iron slydways with automatic lubrication system

CNC Controller CYBELEC VisiPac 8 axis + 1

Bosch Rexroth servo valves

Inovance servo drive systems

DIEMA high resolution glass scales for high bending precision

Bending force 700T

Bending lenght 6500 mm

Distance between columns 5100 mm

Depth throat 420 mm

Ram stroke 400 mm

Closing Ram approach speed limited to 30 mm/s for human operation

Closing Ram working speed 7 mm/s

Return-speed 40 mm/s

Main hydraulic motor 45 kW

Machine weight 62,000 kg

8 Axes + 1 CNC controller Cybelec VisiPac Touchscreen monitor with vivid colors and high contrast

3D graphical profile drawing (Touch Profile) and precise 2D program creation

The opening value can be setted individually in each sequence

Machine can be inferfaced with different CAM software

Easy single bends with the EasyBend page

Correction menu

Many languages available

Bodswd I Svjpfx Agzswi

Centered lower die system 60 mm AMADA / WILA- tool or COLLY Standard

Ram featured with intermittant tool holder for punches with AMADA or COLLY Standard dimensions and Fall down security

All toolings adopt 42CrMo4 steel, induction hardened and cnc grinded

4 Axis Back gauge adopts linear guides and Ballscrews

Back gauge travel X axis 1000 mm

2 automatic widened back gauge fingers on linear guide rails with helical rack and pinions (Axis Z1 and Z2)

Automatic height adjustment (Axis R)

2 CNC Bending Followers 400 kg up to 60° angle

Motorised displacement of bending followers and parking area on the right of the bending table

Strong automatic mechanical crowning table. The compensation value is calculated and set by the CNC system.

Safety Equipment :

3-position Foot switch with Emergency Stop Position

Closing approaching speed limited to 30 mm/s for human operation

Laser safety protection and permanent speed monitoring

Closing bending (working) speed 7 mm/s

Side covers with safety switch

Rear-protection with sliding door and safety switch

Low control Voltage (24V)

Safety control unit category IV

Standard configuration and equipment :

Electric control cabinet on left side

CNC user interface with Aluminium - arm

1 Line of punches (Upper tools) 85° R1, Height 200 mm

1 Line of centred lower Dies (to be defined)

Place of manufacture : Douarnenez (Britanny) in Northwest FRANCE

Customisation available

CE Certification in respect of CE2006/42 directive and EN12622+A1 European Standard

Operation manual in English, German and French language

Delivery and Services available worldwide

Customized Quotation

GROW YOUR BUSINESS WITH PETERZEN MACHINE TOOLS

Listing

Bruckmühl

Bruckmühl

1,545 km

Minikran

BG LiftM400

Call

Condition: used, functionality: fully functional, Year of construction: 2025, load capacity: 4,000 kg, operating hours: 44 h, empty load weight: 4,300 kg, fuel type: diesel, drive type: Diesel, arm reach: 17,000 mm, Mini crane

Technical condition: New

Bwedpfx Aoya Rkregzoi

Automatic speed increase, 3-phase 5.5 kW - 400V - 50Hz electric motor with frequency inverter and phase sequence monitoring. Hydraulic jib with two extensions and a working range of 195°. Hydraulic winch under the telescopic boom, load capacity 1000 kg, rope length 58 m, guide rollers, rope pulleys for fly-jib, rope pulley at the tip of the main boom. Four-way adjustable boom head at the tip of the telescopic arm. Outrigger pads with holder on the crane, 400x400x50 mm. 1 pair of non-marking rubber tracks. LED light on main boom and jib. BG-Connect2.0 - for 1 year. Prepared for work platform.

Listing

Kežmarok

Kežmarok

2,038 km

Automatic optimising end cutting saw

SalvadorSuperpush 200

Call

Condition: good (used), Year of construction: 2012, I sell the automatic optimising end cutting saw Salvador Superpush 200, year 2012.

Input table automatic feeding 5,10m (pusher system)

Bodpoyi Suwjfx Agzjwi

Outut table 3,00m

Total length: 9,00m

Optimising with automatic cutting sequence modes.

Available immediately.

CE version. Documentation included.

Listing

Gelsenkirchen

Gelsenkirchen

1,058 km

Oil hydraulic double column press 400 T

HidrobrasilDoppelständerpresse 400 Tonnen

Call

Condition: as good as new (ex-display), Year of construction: 2022, Press design double column press

Thermally neutral 80 - 120 °C

Number of operating sides 1 side

Forces

Pressing force max. 4000 kN

Free ripping force max. 400 kN

Pressure build-up time Closed die steel to steel Max. 4 sec.

Dimensions 3,800 mm long and 4,475 mm wide

Max. Opening width 800 mm

Bodpfeph Uk Nox Agzewi

Stroke 800 mm

Table height above floor 1100 mm

Height above floor (headroom) approx. 4300 mm

Hall height min. 5500 mm

parallel deviation at 20°C +/- 0,1 mm

Deflection

Determined at max. clamping force with 70% occupancy < = 0.2 mm/m

Weight

Total weight of press without operating materials and table plate approx. 28 t

Press table

Table size 1500x1500 mm

Speeds

Fast closing with 100 mm sec.

Pressing speed 8 - 3 mm sec.

Sound pressure

Sound pressure level, measured at 1.5m height at the control panel according to DIN 45635-T16-KL3 max. 78 db(A)

Hydraulics

Number of pressing cylinders/driving cylinders 1 pc.

Operating pressure max. 300 bar

Pressing pressure build-up time 4 sec.

Pressure accuracy during pressing stroke +/- 3 bar

Main pump BOSCHREXROTH axial piston pump approx. 145 L/min

Oil volume approx. HLP 46 MW 1000 liters

Ambient temperature max. 40 °C

Oil temperature max. 55 °C

Flow temperature °C

Auxiliary pump BOSCHREXROTH, gear pump 10 L/min Pressure stabilization for up to 300 sec.

Electrical system

Main supply 400 V AC

Control voltage 24 V DC

Frequency 50 Hz

Connection hydraulics main motor 40 kW

Sliding table press with 400 T capacity,

Closing speed up to 100 mm/ ( adjustable via touch screen )

Opening speed up to 100 mm/sec ( adjustable via touch screen )

Starting press speed 10 mm/sec ( adjustable via touch screen )

table top size 1500x1500mm

ram size approx. 1600x1500mm

Oil temperature monitoring 55 degree warning, 60 degree shutdown

Automatic lubrication ( adjustable via touch screen )

Free positioning of the ram ( adjustable via touch screen )

SICK/PILZ light barriers 14 mm, front, up to 1800 mm height

Hydraulic and mechanical ram protection

Circuit oil cooling ( adjustable via touch screen )

Ejector in table, 20 T press force, 350mm travel

Ejector moves outwards with the table

Table plate milled flat, with DIN 22 T grooves

Pressure adjustment from 60 T to 400 T ( adjustable via touch screen )

Travel limitation either by pressure or position

Set-up mode, single stroke and cycle sequence ( adjustable via touch screen )

Swiveling control panel on the cabinet

Two-hand operation, with opening button, manual/single stroke/cycle switchover button

Installation, commissioning, instruction against separate charge

The control is supplied by SIEMENS. ( S 7 1200 ) Also the touch screen monitor with 9 inch. The remote maintenance unit SECOMEA -Ethernet is included in the delivery.

The side of the press has two 1000 mm high and 800 mm wide windows with double doors.

(sliding table press, hydraulic press, hydraulic press, double column press)

Listing

Pirot

Pirot

2,524 km

Press brake

BaykalAPHS 41200 10/27

Call

Condition: used, functionality: fully functional, Year of construction: 2017, operating hours: 1,818 h, machine/vehicle number: 24698, control type: CNC control, actuation type: hydraulic, controller manufacturer: Delem DA-66T CNC CONTROL UNIT, bending force (max.): 200 t, working width: 4,000 mm, throat depth: 410 mm, oil tank capacity: 55 l, overall weight: 12,500 kg, power: 18.5 kW (25.15 HP), input voltage: 415 V, Equipment: documentation/manual, emergency stop, lower tooling, upper tooling, CNC Press brake Baykal APHS 41200 10/27 in excellent condition listed for sale! Year of production is 2017.

Press brake comes with variety of prisms and tools, which can be seen in pictures.

Specifications:

Control Unit DELEM DA66T CNC

Nominal Pressure 200t

Length of Work Table 4100mm

Distance Between Columns 3550mm

Throat Depth 410mm

Maximum Open Height 530mm

Ram Stroke 260mm

No. of machine Axis:5

Safety Guarding System Laser System Type

Backgauge Travel 750mm

Bwsdpoxl Ddhofx Agzji

Motor Power 18.5 / 24.6 kW / hp

Motor Voltage 415V

Nett Weight 12,500kg

-The new generation DA-Touch controls offers an even higher grade of efficiency in programming, operation and

control of today’s press brakes. Ease of use combined with state-of-the-art technology go hand in hand, improving

productivity.

The touch screen gives access to the proven Delem user-interface and enables direct navigation between

programming and production. Functions are directly located where you need them, offering optimised ergonomics

throughout the application.

The DA-66T offers 2D programming that includes automatic bend sequence calculation and collision detection. Full

3D machine set-up with multiple tool stations giving true feedback on the product feasibility and handling.

Highly effective control algorithms optimise the machine cycle and minimise set-up time. This makes using press

brakes easier, more efficient and more versatile then ever.

-Baykal machine frames are manufactured from hot rolled steel sheets of Fe 520. The two side frames are obtained

from the same sheet to ensure the same elasticity under stress. The ram and table are also manufactured from Fe

520 steel and are designed to avoid deflection.

-The hydraulic cylinders are manufactured from high resistance steel chromium plated & ground to size. Cylinder

pistons are lapped to ensure longevity of the hydraulic seals

-The hydraulic unit consists of electronically controlled proportional valves with independent closed loop control of

the two cylinders providing full synchronous control.

-German manufactured Laser Safety Guard System mounted at each end of machine ensuring correct interfacing

and operator safety whilst in operation. The Laser system is designed so each guard will slide up or down to allow

for many different types and sizes of tooling enabling safety at the appropriate points as required by the Australian

standards. Manual height adjustment with scales and lock for easy positioning.

-Sliding front sheet supports enable a wide range of material sizes to be aligned and supported at the correct

required width and height. The sheet supports are mounted on precision linear guides for ease of movement. This

design can also be adjusted vertically to support material with return bends.

-Ram positions (Left & Right) are obtained from independent linear encoders whilst monitoring and adjusting

proportional valves. This produces a closed loop system, with guaranteed beam positioning of +/- 0.01mm (Y1 and

Y2 Axis)

-Accuracy is further ensured by mounting the linear encoders on a C-frame connected directly to the Bed, rather

than the side frames. This ensures that deflection of the side frames and uneven loads have no effect on Beam

position.

Listing

Urk

Urk

931 km

Meat processing machine

SystemateD90 automatic Drum / Thigh Deboner

Call

Condition: good (used), Systemate D90 Drum / Thigh Deboner

Bsdeukd H Hepfx Agzewi

Systemate thigh deboner D90 debones thighs and drumsticks with optimum performance, delivering maximum profitability.

D90 thigh deboner is regarded as the industry benchmark for delivering highly efficient production of deboned thigh and drumstick meat. The system is characterized by its simplicity of operation and unsurpassed yield prior to and post trim.

Operation

One or two operator loads the thigh or drumstick into a the product holder which carries it through a sequence of deboning steps integrated into the carousel mechanism:

The product is positioned by the probe.

The thigh joint is pushed gently through the diaphragm, while the thigh meat, including kneecap remains on the product holder. The bone is released from the diaphragm.

The deboned thigh meat, with or without skin, is discharged on a separate location.

After deboning, the only remaining operations necessary are trimming and grading.

The D90 thigh deboner can mechanically debone anatomical thighs at a maximum capacity of 5.400 products per hour. The thighs are supplied to the stand alone machine by using e.g. a belt conveyor.

Year: 1996

Capacity: Up to 5.400 bph

Machinedimensions (LxWxH): 290x130x200 cm

Listing

Poznań

Poznań

1,685 km

Fully peeling & vacum potatoes line

DORNOW20M-AT-MS

Call

Year of construction: 2020, condition: excellent (used), functionality: fully functional, Our Dornow potato peeling line is for sale, consisting of:

Storage bunker with conveyor belt (capacity approx. 1t raw material)

Potato peeler with knives 20M-AT-MS

Roller inspection table

Pre washer with transporter conveyers

Preserving and bagging device

Vacuum sealer

Extra sets of brand new blade for peeler included

This line can also peeling beetroots, celery and if you keep peeling cycle longer also carrots

For additional monies we can add it: (slicer, metal detector.. Subject to request)

The peeling line runs automatically in sequence:

The pot peeler is filled by the conveyor belt from the storage bunker after a continuously adjustable time. The peeler peels the potatoes for the infinitely variable preset time and then ejects the peeled product onto the inspection table and the sequence starts again.

Depending on the quality and size of the potatoes, the system peels approx. 300 - 1000 kg of raw product per hour

The pot peeler peels with minimal water consumption using a flat jet from a nozzle.

Kobhyc I Hovdvmpecedl

Pot peeler capacity approx. 40 kg raw material, optimum filling quantity for good peeling results approx. 25 kg

Inspection table with removable tuber rinsing device

Bsdpfx Ajw Sfg Ejgzjwi

Storage capacity in the water bath canning and bagging unit approx. 120 kg of peeled goods.

Preserving and bagging unit with discharge belt and dosing belt for the scale as well as draining section and air and water rinsing nozzles.

Single chamber vacuum sealer dimensions chamber: 600x400mm, vacuum pump capacity: 60m³/h

Year of construction 2020, in use until August 2023.

In very good condition and fully functional.

Can be inspected on site by arrangement.

Listing

Naprawa

Naprawa

1,978 km

Weinig PFA17N 4-sided planer

WEINIGPFA17N

Call

Condition: used, Technical data:

Max planing width: 170 mm

Max planing height: 130 mm

Spindle diameter: 40 mm

Number of spindles: 6

Spindle sequence:

bottom 4 kW

right 3 kW

left 5.5 kW

right 5.5 kW

top 5.5 kW

bottom 4 kW

Each spindle driven by a separate motor

Number of upper steel feed rollers: 7

Number of upper rubber feed rollers: 2

Stepless feed speed adjustment – 4 kW

Feed by chains

Bjdpfjyhndrsx Agzswi

Lubrication pump for worktable

Pressure: 6 atm.

Electric raising of the machine body

Power supply: 400 V

Total power: 33 kW

Overall dimensions:

Length: 5000 mm

Width: 1300 mm

Height: 1560 mm

Listing

Naprawa

Naprawa

1,978 km

Four Side Planer

WEINIGUnimat 23

Call

Condition: excellent (used), Four-sided planer WEINIG UNIMAT 23 7/25

Technical specifications:

Max planing width: 240 mm

Max planing height: 130 mm

Spindle diameter: 40 mm

Number of spindles: 8

Spindle sequence:

Bodpoxc D Diefx Agzjwi

- bottom

- right

- left

- right

- top

- top

- bottom

- universal

Each spindle driven by a separate motor

Number of top rubber feed rollers: 6

Number of bottom steel feed rollers: 5

Number of top steel feed rollers: 6

Extraction port diameter: 8 x 140 mm

Stepless feed adjustment

Feed via cardan shafts

Pressure: 6 atm

Electric lifting of machine body

Manual table lubrication pump

Power supply: 400 V

Total power: 50 kW

Overall dimensions:

Length: 6430 mm

Width: 1800 mm

Height: 1700 mm

Listing

Naprawa

Naprawa

1,978 km

Four-sided planer

SCMCompact 23ks

Call

Condition: used, Technical data:

Max planing width: 230 mm

Max planing height: 120 mm

Spindle diameter: 40 mm

Number of spindles: 5

Spindle sequence:

down 5.5 kW

right + left 11 kW

up 7.5 kW

universal 5.5 kW

Each spindle on a separate motor

Bwedpsmiik Tefx Agzsi

Number of upper steel pulling rollers: 5

Number of upper rubber pulling rollers: 3

1 rubber roller in the table top

Extraction port diameter: 150 mm

Smooth feed adjustment: 4-24 m/min

Cardan feed

Table lubrication pump

Pressure: 6 atm.

Electric lifting of the body

Power: 400V

Overall dimensions:

Length: 4240mm

Width: 1550mm

Height: 1560mm

Trust Seal

Dealers certified through Machineseeker

Listing

Buseck

Buseck

1,206 km

Dry steam fast cooker

Hobart305GTP

Call

Condition: refurbished (used), Year of construction: 2018, functionality: fully functional, This is a 305GTP dry steam pressure cooker from the premium manufacturer Hobart, built in 2018.

The medium-sized 305 GTP dry steam pressure cooker is often used in the communal catering sector. With its 3 x 1/1 GN racks, it cooks up to 650 portions per hour fresh and to the minute.

The evaporation of the water and the associated increase in volume creates an atmosphere of saturated steam in the cooking chamber of the GTP, which ensures excellent heat transfer to the food. Saturated steam has major advantages over hot air or combination steam in terms of the heat flux density that can be transferred. Shorter cooking times mean less loss of nutrients and healthy food.

The appliance has been tested in our in-house specialist workshop and is fully functional.

The price quoted is net plus 19% VAT.

The RRP for this appliance is €28,202 net.

Our used appliance service for you

- 6-month warranty on all electrical parts

- High-quality brand appliances at fair prices

- Professional overhaul / inspection & expert cleaning

- Tested & fully functional - or money back

- Flexible choice of shipping or collection

- Expert advice - before and after purchase

- Provision of operating instructions, connection diagrams & spare parts

- Inspection according to DGUV V3

Condition: Used, tested and fully functional

Technical data:

- External dimensions WxDxH: 600x785x950mm

- Electrical connection: 400V 3NPE, 50 Hz, 26,7kW

- SN: 97-0224-579

- Year of construction: 2018

Bwsdpjun R R Tofx Agzei

- Portions: 650/h

- Capacity: 3x 1/1 GN max. 65mm, 2x 1/1 GN max. 100mm, 1x 1/1 GN max. 200mm

Further information:

- Gentle, healthy cooking: Steaming, stewing or blanching

- 3 different pressure levels 0 / 0.5 / 1 bar for individual adjustment to the food to be cooked

- Extremely short cooking times

- Individual temperature program (TP) 50 °C - 99 °C as standard

- Electronically controlled program sequences

- Built-in exhaust steam destruction with vapor condensation as standard

SUITABLE FOODS

- All types of vegetables

- Pulses and rice

- Pasta and dumplings

- Meat that would otherwise be cooked

- Fish and seafood

- Desserts such as yeast dumplings or crèmes

- and much more.

Shipping:

- Delivery or collection by arrangement

- Worldwide shipping on request / Worldwide shipping on request

- Shipping to islands or mountain stations by arrangement only

Do you have any questions, would you like advice or would you like to see something on site? You can reach us by telephone during our opening hours:

Monday-Friday 09:00 - 13:00 and 14:00 - 17:00.

Sales are subject exclusively to our general terms and conditions (AGB)

Listing

Buseck

Buseck

1,206 km

Dry steam fast cooker 305GH-31

HOBART305 GH-31

Call

Condition: refurbished (used), Year of construction: 2018, functionality: fully functional, machine/vehicle number: 305GH-31, This is a dry steam fast cooker 305GTP from the premium manufacturer Hobart, built in 2018. The medium-sized dry steam fast cooker 305 GTP is often used in the communal catering sector. With its 3 x 1/1 GN inserts, it cooks up to 650 portions per hour fresh and to the minute. The dry steam fast cooker is also equipped with a core temperature sensor. The evaporation of the water and the associated increase in volume creates an atmosphere of saturated steam in the cooking chamber of the GTP, which ensures excellent heat transfer to the food. Saturated steam has major advantages over hot air or combination steam in terms of the heat flux density that can be transferred. Shorter cooking times mean less loss of nutrients and healthy food.

The appliance has been tested in our in-house specialist workshop and is fully functional.

The price quoted is net plus 19% VAT.

The RRP for this appliance is €29,497 net.

Our used appliance service for you

6-month warranty on all electrical parts

-High-quality brand appliances at fair prices

-Professional overhaul / inspection & professional cleaning

-tested & fully functional - or money back

-Shipping or self-collection flexibly selectable

-Competent advice - before and after purchase

-Provision of operating instructions, connection diagrams & spare parts

-Testing in accordance with DGUV V3

Condition: Used, tested and fully functional

Technical data:

-Outer dimensions WxDxH: 600x785x950mm

-Electrical connection: 400V 3NPE, 50 Hz, 26,7kW

-SN: 97-0224-123

-Year of construction: 2018

-Portions: 650/h

-Capacity: 3x 1/1 GN max. 65mm, 2x 1/1 GN max. 100mm, 1x 1/1 GN max. 200mm

Further information:

-Gentle, healthy cooking: Steaming, stewing or blanching

-3 different pressure levels 0 / 0.5 / 1 bar for individual adjustment to the food to be cooked

-Extremely short cooking times

-Individual temperature program (TP) 50 °C - 99 °C as standard

-Electronically controlled program sequences

Built-in exhaust steam destruction with vapor condensation as standard

Bwedpfx Aeupzdmsgzsi

SUITABLE FOODS

-All types of vegetables

-Pulses and rice

-Pasta and dumplings

-Meat that would otherwise be cooked

-Fish and seafood

-desserts such as yeast dumplings or crèmes

-etc.

Shipping:

-Delivery or collection by arrangement

-Worldwide shipping on request / Worldwide shipping on request

-Shipping to islands or mountain stations by arrangement only

Do you have any questions, would you like advice or would you like to view something on site?

You can reach us by phone during our opening hours:

Monday-Friday 09:00 - 13:00 and 14:00 - 17:00.

Listing

Hüllhorst

Hüllhorst

1,143 km

Edge banding machine

LangeB 90 KFE Plus mit Fügen + Eckenkopieren

Call

Condition: as good as new (ex-display), Year of construction: 2025, One-sided automatic edge banding machine with pre-milling unit, direct glue application to straight workpieces (EVA-PUR Glue pot with run-out function/optional), HF-cut-off saw station with 2xMotors , HF-top and bottom milling unit, corner rounding unit, chain feed, double roller top pressure, extendable work piece support, signal lamp for work piece sequence and synchronisation of working units by encoder. For ABS, PVC, melamine and

strong wood veneer roll material as well as fixed lengths from 0.4 – 3.0/6.0 mm and of 8 – 60 mm work piece thickness.

Bodpfx Asl Rix Nsgzowi

Speed: 10,0 m/min.; 8,0 m/min. with corner rounding • 3 spaces for finishing units • 10“ Colour Touch screen

→Automatic edge feeding for roller material over turntable D = 800 mm

→Longer infeed lineal (650 mm)

→Two reverse, operating-controlled pre-milling units with diamond charged helical joining millers provide a neat and tear-free premilling of the work pieces before the gluing of the edge material

→Glue application directly to workpieces: Teflon-coated glue pot with a capacity of 1,5 kg, leak proof with glue supply from below (excess glue automatically flows back into the glue pot). Glue roller allows exact dosage of glue. Separate glue roller temperature adjustment. Electronic temperature control with automatic stand-by function (reduces probability that the glue burns if the machine is not used for a longer periods and is still turned on).

Optional: EVA/PUR gluepot with run out / cleaning function for quick change of glue

→Pneumatically operated cut-off knife from roll material up to 3mm edge thickness

→Automatic feeding magazin (70mm magazin capacity) with spiked roller for solid wood

→Pressure unit consisting of one driven pressure roller synchronized with glue spreading roller and two of smaller diameter, conical, one positive and one negative pressure roller with spring tension for a nearly invisible joint of the edge material with the work piece , adjustment of the pressure unit with digital readout.

→High-frequency cut-off saw equipped with 2xHF motor 0.55 kW, 12,000 rpm, 2 saw blades and high-precision linear guides ensure a clean and precise saw cut, with extraction hood.

→High-frequency top and buttom milling station, 2 powerful 0.55 kW high-frequency motors with HM-WPL special millers; suitable for radius, bevel and flush milling, horizontal and vertical scanning of the work piece; aggregate adjustment equipped with digital readouts for setting to various edge types; 2 extraction hoods for shavings with central extraction nozzle 2 x Ø 100 mm; height adjustment of the upper aggregate with the top roll pressure

→Corner rounding unit : Automatic processing of corner edges up to 2 mm edge thickness. Equipped with one high frequency motor 0, 27 kW, selectable on operating panel.

One side (front or back edge) or both side corner rounding unit.

→Rotatable control panel with 10“ color touch screen controls glue temperature settings, automatic temperature reduction for stand-by function of the machine, switching on and off of aggregates and error diagnosis, incl. digital Meter counter

Additional finish aggregates :

→Radius scraper unit : With a slight draw cut eventual radius milling traces are removed to provide a perfect finish. The fine adjustment is made by digital readouts.

→Glue scraper unit : Removes eventual glue rests with a slight draw cut from the glue joint of th

Listing

Hüllhorst

Hüllhorst

1,143 km

Edge banding machine

LangeB 85 KF mit Fügen

Call

Condition: as good as new (ex-display), Year of construction: 2025, One-sided automatic edge banding machine with pre-milling

Bwjdod R U Acspfx Agzji

unit, direct glue application to straight workpieces (EVA-PUR

Glue pot with run-out function/optional), HF-cut-off saw station,

HF-top and bottom milling unit, chain feed, double roller

top pressure, extendable work piece support and signal lamp

for work piece sequence. For ABS, PVC, melamine and strong

wood veneer roll material as well as fixed lengths from 0.4 –

3.0 mm and of 8 – 50 mm work piece thickness.

Speed: 7,0 m/min.

• 2 spaces for finishing units • 7,0“ Colour Touch screen

→Automatic edge feeding for material over turntable D=600 mm

→Infeed lineal (400mm)

→Two reverse, operating-controlled pre-milling units with diamond charged helical joining millers provide a neat and tear-free premilling of the work pieces before the gluing of the edge material

→Glue application directly to workpieces: Teflon-coated glue pot with a capacity of 1,5 kg, leak proof with glue supply from below (excess glue automatically flows back into the glue pot). Glue roller allows exact dosage of glue. Separate glue roller temperature adjustment.

Electronic temperature control with automatic stand-by function (reduces probability that the glue burns if the machine is not used for a longer periods and is still turned on).

Optional: EVA/PUR glue pot with run out / cleaning function for quick change of glue.

→Pneumatically operated cut-off knife from roll material up to 3 mm edge thickness

→A group of two rollers exerting pressure on the edge band mechanically in order to achieve its adhesion onto the panel edge. The first roller is driven and the smaller second one is idle. Adjustment of the pressure rollers with mechanical SIKO display

→High-frequency cut-off saw equipped with HF motor 0.21 kW, 12,000 rpm , 2 saw blades and high-precision linear guides ensure a clean and precise saw cut, with extraction hood.

→High-frequency top and buttom milling station, 2 powerful 0.27 kW high-frequency motors with HM-WPL special millers; suitable for radius and bevel milling, horizontal and vertical scanning of the work piece; aggregate adjustment equipped with digital readouts for setting to various edge types; 2 extraction hoods for shavings with central extraction nozzle 2 x Ø 100 mm; height adjustment of the upper aggregate with the top roll pressure

→Rotatable control panel with 7,0“ color touch screen controls glue temperature settings, automatic temperature reduction for stand-by function of the machine, switching on and off of aggregates and error diagnosis

→LED lights

→Optional : Riepe non-stick spray station and Riepe cleaning spray station

Additional finish aggregates :

→Radius scraper unit : With a slight draw cut eventual radius milling traces are removed to provide a perfect finish. The fine adjustment is made by digital readouts

→Glue scraper unit : Removes eventual glue rests with a slight draw cut from the glue joint of the work piece surface

→Buffing unit : 2 motors 0.05 kW, 1,500 rpm provide a super-finish for ABS and PVC edge material

67641340eaae3

We make it easier for you to find: "genome sequencer"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Genome Sequencer (348)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month