Used Cnc Turning for sale (13,819)

Germany

Germany CNC Turning- and Milling Center

MONFORTSRNC 500 AC

Germany

Germany CNC Turning- and Milling Center

MONFORTSDNC 5

Komorniki

Komorniki CNC turning and milling center

INDEXG200

+44 20 806 810 84

Neubrandenburg

Neubrandenburg CNC turning and milling center

GildemeisterDMG CTX beta 800

Weiterstadt

Weiterstadt CNC turning and milling center

EmcoPc Turn 120

Discover more used machines

Burgoberbach

Burgoberbach CNC turn-mill center 12 AG 2 spindles

MazakQuickturn Nexus 200-II MS

Burgoberbach

Burgoberbach CNC turn-mill center 12 AG 2 spindles

MazakQuickturn Nexus 200-II MS

Burgoberbach

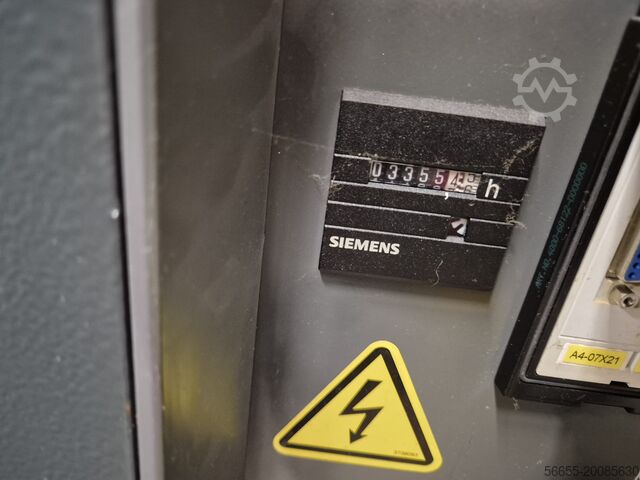

Burgoberbach CNC turning-milling center 6 AGW

DMGCTX 310 Eco (nur 3.350 h)

Germany

Germany CNC Vertical Turning Machine

IndexV200

Thurmaston

Thurmaston CNC turning and milling center

DOOSANPuma 5100 XLY

Hedensted

Hedensted CNC turning and milling center

OkumaLB35II

Freiburg im Breisgau

Freiburg im Breisgau CNC turning automatic lathe

TRAUBTNK 36

Zona Industriale di Robassomero

Zona Industriale di Robassomero CNC turning and milling center

GildemeisterSprint 42

Zona Industriale di Robassomero

Zona Industriale di Robassomero CNC turning and milling center

GildemeisterSPRINT 42

Freiburg im Breisgau

Freiburg im Breisgau CNC turning automatic lathe

TRAUBTNK 36

Freiburg im Breisgau

Freiburg im Breisgau CNC turning automatic lathe

TRAUBTNL 32/7

Halberstadt

Halberstadt CNC - turning machine - Universal

MONFORTSRNC 5 A17

Lauterach

Lauterach CNC turning and milling center

EMCOE 65

Bienne

Bienne CNC turning and milling machining center

BumotecS191 FTL

Iserlohn

Iserlohn CNC turn-mill center

GILDEMEISTERCTX 600 Ersatzteile

Iserlohn

Iserlohn CNC turn-mill center

TRAUBTNC65DG

Ferrara

Ferrara CNC turning and milling center

Nakamura-TomeNTRX-300

Sørumsand

Sørumsand CNC turning and milling center

GildemeisterCTX 310

Bühl

Bühl CNC Turning- and Milling Center

DOOSANPuma TT 1800 SY

Bern

Bern CNC turning and milling center

INDEXG 160

Used Cnc Turning (13,819)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84