Used Bundle Turner for sale (534)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Jüri

Jüri

2,121 km

Log yard machinery

NordautomationLog turner

Call

Condition: ready for operation (used), Year of construction: 2019, functionality: fully functional, Log turner, infeed-outfeed conveyors, log correction hydraulic crane, heavy duty construction

Equipment from 2019

Gsdpfx Aeu N Ac Sjfnebh

Listing

Strenči

Strenči

2,164 km

Mini Bundling mechanization

Jonab

Call

Condition: used, Mini bundeling mechanization IDL000770

- manufacturer Jonab

Gjdpot Ebndjfx Afnsbh

Listing

Kotka

Kotka

2,244 km

Log deck, infeed system, log turner

Tähkä

Call

Condition: ready for operation (used), Log infeed line Tähkä, equipped with a lower device for turning logs

Gbjdpfxexg Rvgo Afnjh

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Germany

Germany

1,293 km

Miscellaneous

PolarPW-1 pileturner

Call

Condition: used, Year of construction: 2004, The Polar PW-1 Pileturner, manufactured in 2004 with serial number 74M1003, is a robust and efficient solution for handling paper stacks in professional print environments. With a maximum sheet size of 52 x 74 cm, it is designed to simplify the turning, aerating, and aligning of piles, ensuring smooth downstream processing. The machine features tub dimensions of 525 x 840 mm, with an adjustable opening range from 470 mm to 1,255 mm, providing flexibility for different pile heights. Capable of handling a maximum pallet weight of 500 kg, the PW-1 combines strength with precision to optimize workflow efficiency.

Currently located in a printshop in Germany, the unit is in excellent working condition and remains a reliable choice for industrial printing companies seeking to improve productivity and ergonomics in material handling.

Format: 520 x 740 mm

Equipment:

Tub dimensions inside 525 x 840 mm

max. opening 1255 mm

min. opening 470 mm

Pallet weight max. 500 kg

Godpfjxdv Txox Afnsbh

Max. sheet size 52 x 74 cm

Listing

Ireland

Ireland

31 km

Bundler / Stretch Bander

CAMA6B38

Call

Year of construction: 2010, condition: good (used), CAM Bundler / Stretch Bander with Heat Shrink

Tubs + Tubs of Trays

Automatic Side loader Infeed

All stainless steel

350mm wide x 1550mm long stainless wire mesh belt

Side infeed belt 230mm W x 1000mm L

110mm Pusher Stroke

Current film 250mm, Max Film 500mm

Complete with spare parts

Pack Details

Size Pot Size Collation Bundle Size

D E F

125g 60 ø x 68mm 4 x 3 x 1 180 68 240

125g 60 ø x 68mm 3 x 2 x 1 120 68 180

250g 75 ø x 68mm 4 x 3 x 1 225 75 300

250g 75 ø x 68mm 3 x 2 x 1 150 75 225

125g Tray (2 x 6) N/A 120 68 368

125g Tray (4 x 3) N/A 183 68 246

250g Tray (4 x 3) N/A 234 75 310

Gsdpfx Afjnu Uh Nonjbh

250g Tray (2 x 3) N/A 144 75 230

Listing

Wormerveer

Wormerveer

878 km

Turnery machine

WEILERCommodor

Call

Condition: ready for operation (used), functionality: fully functional, Weiler Commodor in good working condition.

Specifications:

Swing diameter over bed: 380 mm

Swing diameter over cross slide: 190 mm

Distance between centers: 1000 mm

Spindle bore: 56 mm

Speed: 25–2000 rpm

Motor power: 4 kW

Machine equipped with:

3-axis digital readout

3-jaw chuck with multiple jaws

Coolant system

Multifix quick-change tool post with 4 holders

Collet system with collets

Gsdsx Ngpdjpfx Afnjbh

Bed stop

Listing

Germany

Germany

1,293 km

Stone Production Plant

OmagTronic S22 140-90

Call

Year of construction: 2001, condition: ready for operation (used), A paving stone production line Omag, which has been continuously optimized and upgraded to the latest technical standards, is available. Overhauls: 1) Conversion for an additional hydraulic unit for additional load in 2020. 2) Conversion to servo-vibration with Siemens S7 control in 2016. 3) Conversion to digital path measurement of mould and ram in 2017. 4) New core filling carriages in 2017. Plant components: 1) Board destacker and board stacker including roller conveyor. 2) Board feeder (advance) and board conveyor (scraper) to the lifting frame. 3) Board turner. 4) Horizontal and vertical bundling units Ridder & Signode, years of manufacture: 1994 and 1983. 5) Trafo lifting platform including motors and without control, year of manufacture: 1983. 6) Doppler including hydraulic unit, year of manufacture: 2004. 7) Stone packer Omag K1400 including hydraulic unit, year of manufacture: 1997. The line has no base boards. 8) Stone finisher Omag S22 140-90, year of manufacture: 2001. Documentation available. An on-site inspection is possible.

Gbedpfjw R Uzisx Afnsh

Listing

Stockheim

Stockheim

1,383 km

Vertical high-performance block bandsaw

CANALIPACIFIC

Call

Condition: refurbished (used), Year of construction: 1975, functionality: fully functional, CANALI Vertical Automatic High-Performance Block Bandsaw

Model BBS.V "PACIFIC" K/L-B-P 1800, Type 555, Year 1975

with operator control system in the cabin,

Bandsaw wheels Ø 1800 mm, bandsaw wheel width 280 mm,

Max. saw blade width 310 mm. Bandsaw blade length 11,500 mm

Round timber infeed approx. 20 m long, four strands with inserter

Block carriage with ejector onto block transverse conveyor

CANALI pneumatic log carriage Type 501.09

with 4 clamping claws, 3 log turners, 4 ejectors

Drive power 100 kW, carriage speed 5-120 m/min.

Gsdpfoxvrnisx Afnjbh

driven roller conveyor with side board removal

with brush, lifter with stripper for cut-out removal

Roller conveyor approx. 12 m with lifting stripper for manual stacking

Stacking device with turning unit for bundle packaging

Lowerable bundle with transverse bundle conveyor

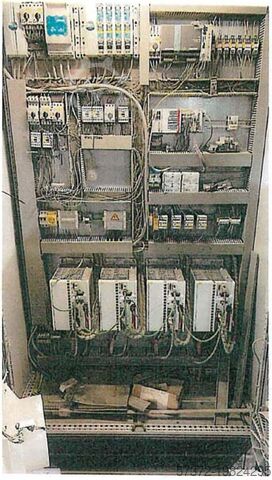

Complete electrical control cabinets

Full band saw blade sharpening equipment

Listing

Kanzach

Kanzach

1,383 km

Automatic feeding

Martek

Call

Year of construction: 2001, condition: used, Fully automatic feeding for finger jointing line

Table width max 620 mm

Spinfeeder

Automatic length sorting 3 lengths

Bundle formation 3 x

Buffer

Packet turner

Packet destacking

Manual loading

Buffer in front of zinc tray with 6 compartments

Specification:

Wood input length: min. 150 mm

max. 600 mm

Godpfx Ajh Icimefnobh

wood cross section: min. 20 x 40 mm

max. 80 x 180

Capacity: 6 milling tables/ min

working height: 960mm

Table width: 620 mm

Plant width:

Plant length:

see pictures

Plant is immediately available, already dismantled

Auction

Ends in

d

h

min

s

Auction ended

Czech Republic

Czech Republic

1,679 km

Laser cutting machine

TRUMPFTruLaser Tube 5000 (T05)

Condition: ready for operation (used), functionality: fully functional, Year of construction: 2014, operating hours: 8,416 h, laser power: 3,200 W, sheet thickness steel (max.): 10 mm, sheet thickness aluminum (max.): 4 mm, pipe diameter (max.): 152 mm, working length: 6,500 mm, TRUMPF Tube Laser Cutting System with LoadMaster Tube 6.5 m and extensive additional equipment!

TECHNICAL DETAILS

Maximum tube diameter: 152 mm

Maximum working length: 6,500 mm

Material thickness (steel): 10 mm

Material thickness (stainless steel): 5 mm

Material thickness (aluminum): 4 mm

Laser power: 3,200 W

MACHINE DETAILS

Control system: SIEMENS Sinumerik 840D SL

Operating hours: 24,428 / 8,416 h

EQUIPMENT

- LoadMaster Tube 6.5 m with bundle magazine

Gjdpfoygu Tkjx Afnobh

- Robust machine frame with integrated laser unit

- Feed station with self-centering clamping jaws

- Raw material tube support with automatically retractable pipe rests

- Through-feed chuck with self-centering parallel clamping rollers

- High-precision drives

- Discharge station for finished workpieces up to 3 m in length

- Tube support for finished parts with extendable guide rollers

- Scrap conveyor with collection bin

- Enclosed beam guide

- NitroLine

- FocusLine

- Laser power control

- Programmable cutting gas pressure

- Automatic power on/off

- Ergonomic control panel with touch color screen

- Work area illumination

- High-frequency excitation

- Maintenance-free turbo radial blower

- TASC 3 laser control

- Laser logbook function

- Cooling unit

- Single cutting head strategy

- Lens cutting head, 155 mm focal length

- ControlLine

- Simple operation

- Online support

- Diagnostic functions

- Integrated technology data

- Remote service via internet

- RJ45 network interface and USB port

- CE marking

- Multi-beam light barriers

- Monitoring system for gas pressure, temperature, and cooling water, among others

- Compact dust extraction system

- Protective enclosure with polycarbonate (Makrolon) panels

- Jaw sets with clamping range 20–85 mm and 85–152 mm

- Quick-change forming shells for round tubes up to 152 mm

- Quick-change forming shells for rectangular tubes (up to a circumscribed circle of 85 mm)

- Quick-change forming shells for rectangular tubes (up to a circumscribed circle of 170 mm)

- Guide rollers for round and rectangular tubes

- SeamLine Tube with inner seam detection

- Adaptive clamping technology – feed station, small circumscribed circle

- Adaptive clamping technology – feed station, large circumscribed circle

- Adaptive clamping technology – through-feed chuck, small circumscribed circle

- Adaptive clamping technology – through-feed chuck, large circumscribed circle

Note: The machine will be dismantled on 02/03/2026 and can be inspected under power until then.

Listing

Ireland

Ireland

166 km

Laser cutting machine

BLM AdigeLT712D

Call

Condition: excellent (used), functionality: fully functional, Year of construction: 2006, operating hours: 22,500 h, control type: CNC control, degree of automation: automatic, controller manufacturer: Siemens, controller model: Sinumerik 840D, laser type: CO₂ laser, laser source manufacturer: Rofin, laser source model: DC 025, laser power: 2,500 W, pipe diameter (max.): 140 mm, pipe length (max.): 8,500 mm, table length: 8,500 mm, working length: 8,500 mm, travel distance X-axis: 8,500 mm, travel distance Y-axis: 400 mm, travel distance Z-axis: 95 mm, workpiece weight (max.): 4,000 kg, type of input current: three-phase, compressed air connection: 6 bar, overall weight: 10,000 kg, total length: 17,536 mm, total width: 4,604 mm, total height: 2,237 mm, Equipment: CE marking, cooling unit, documentation/manual, dust extraction, 2006 BLM Adige LT712D Tube Laser

Machine Manufacturer: BLM Adige

Machine Model: LT712D

Laser: Rofin Sinar series DC K 2.5kW Laser source.

Year: 2006

Infeed: 8,500mm

Outfeed: 6,500mm

Condition: Very Good

Hours: 22,500hrs

Available February or March 2026

This 2006 BLM Adige LT712D is a high-performance CNC tube laser cutting system designed for precision processing of mild steel, stainless steel, and aluminium tube profiles. Known for its reliability and accuracy, the LT712D is one of the most capable mid-range tube laser platforms, delivering clean, repeatable cuts with full automation from loading to unloading.

With only 22,500 operating hours, this machine is in very good condition and has been maintained to OEM standards. It offers exceptional value for fabrication companies, structural steel specialists, subcontractors and manufacturers looking for a high-precision tube laser with proven durability.

⭐ Key Machine Specifications

Working Capacity & Tube Dimensions

Minimum tube length: 3,200 mm

Maximum tube length: 8,500 mm

Round tube diameter: Ø12 – Ø140 mm

Square tube: 12 – 120 mm side dimension

Rectangular / flat-oval: up to 170 mm circumscribed circle, min. side 10 mm, max. side 140–150 mm

Max bar weight:

Linear: 15 kg/m

Total (L=8500 loader): 130 kg

Machine Dimensions & Weight

System footprint (L=8500 version):

17,536 × 4,604 × 2,237 mm (complete system)

13,595 × 4,604 × 2,237 mm (machine body)

Machine weight: approx.10000 daN (= 10 tonnes)

Laser, CNC & Automation

CNC Control: Siemens Sinumerik 840D

Laser Source: Rofin DC-K Series

Cutting Head: Autofocus head with capacitance sensor + collision protection

Working Axes:

X travel: 8,500 mm

Y travel: 400 mm

Z travel: 95 mm

A-axis: spindle rotation

A1-axis: steady rest rotation

V-axis: Bar support on the machining line (90mm)

W-axis: Unload piece support (85mm)

X1-axis: steady rest travel (610 mm)

Loader & Unloader

Automatic bundle loader with alignment, measuring & singularisation system

Scimitar-style tube transfer system for smooth transition to machining line

CNC-controlled tube support system with 5 active support groups

Intelligent cut-piece unloader with conveyor belt for short parts up to 300 mm

Extraction & Cooling Systems

Fume extraction: 2,000 m³/hr with high-efficiency filtration system

Cooling: MTA TAE 121 chiller, 260-litre cooling circuit reserve

Hydraulics: 25-litre tank, 25 L/min pump, 70 bar system pressure

🟢 Condition & Availability

Year: 2006

Hours: 22,500 (very low for a tube laser)

Condition: Very Good – well maintained, clean, fully operational

Availability: February–March 2026

Includes: Full machine, loader, unloader, chiller, documentation supplied.

Why the LT712D Is a Top Choice

The BLM Adige LT series is widely regarded as the benchmark for tube laser systems. This LT712D stands out thanks to:

✔ Exceptional tube cutting accuracy

✔ Reliable automatic loading & unloading

✔ High-quality Rofin laser source

✔ Full CNC control of every movement

✔ Capability to handle a wide range of profiles

✔ Heavy-duty industrial build quality (10 tonnes of rigidity)

Godpfxex Ddagj Afnobh

For fabricators looking to increase productivity, quality, and automation, the LT712D is an ideal investment.

Notes: *Specifications are given in good faith but not guaranteed*

Listing

Deinze

Deinze

846 km

Band sawing machines

Friggiheavy duty 660 x 700 mm CNC

Call

Condition: ready for operation (used), total height: 3,340 mm, total length: 4,500 mm, total width: 1,950 mm, throat depth: 660 mm, Type: ONL 660x700 ACN

Heavy duty double column bandsaw specific for high-alloy steels

CNC touch control with saw parameters for various types of high-alloy steels

cap round: dia 660 mm

cap square: 660 x 700 mm

bundle cap: 555 x 700 mm

autofeed with stroke of 500 mm (with unlimited repositioning)

Gbedpfx Ajygywujfneh

sawing power: 18,5 kW

the in-feed and sawing speeds are frecquency controlled

enlarged height of sawblade: 67 mm

chipconveyor

equipped with fully motorized Weisshaupt rollerconveyors:

- 10,3 meter in-feed rollerconveyor (outside) with 2 hydraulic clamps for aligning workpiece

- 9 meter in-feed rollerconveyor (inside) with 2 hydraulic clamps for aligning workpiece

- max workpiece width: 900 mm

- each roll is motorized

- cap of one roll is 4 ton

- 4 meter out-feed rollerconveyor:

one rollerconveyor is equipped with scales to weigh workpiece after cutting (Sartorius system)

Max height of workpiece: 700 mm

Sawspeed: 10 > 120 m/min

Length of band saw: 8660 x 67 x 1,6 mm

Power needed: 27 kW (58 amp)

Weight: 8,5 ton (only machine)

Listing

Baarle-Nassau

Baarle-Nassau

920 km

Pallet tipper - pallet inverter - pallet

Premier

Call

Condition: ready for operation (used), functionality: fully functional, overall weight: 2,000 kg, load capacity: 2,000 kg, We can offer you a PREMIER pallet inverter / pile turner

Pallet Inverter: PREMIER (made in UK)

Model: Inverter

Machine number: C06 A3096

Platform dimensions: 1365 x 1215 mm

Max. platform opening: 2170 mm

Min. platform opening: 1250 mm

Max. stack weight: 2000 kg

Motor power: 4 kW

Power supply: 380 volt

Machine weight: approx. 2000 kg

Machine dimensions (W x D x H): 3400 x 3100 x 3100 mm

Transport dimensions (W x D x H): 2500 x 2100 x 2400 mm

Price for the PREMIER pallet inverter available upon request by email.

This offer is valid subject to prior sale.

Delivery terms:

Delivery time: ex stock, subject to availability

delivery: ex works Baarle-Nassau

Payment: before collection

Prices: quoted net, excluding VAT.

Machinehandel De Leeuw BV is one of the few companies in Europe specialized in trading and stocking mainly used Kardex Remstar automatic lift and carousel storage systems.

Our VCA-certified technicians have safely installed and dismantled these systems for over 33 years.

Gbsdjyi Ufxjpfx Afnsh

Machinehandel De Leeuw BV

Oordeelsestraat 7-B

5111 PA Baarle-Nassau

The Netherlands

Listing

Oudehorne

Oudehorne

956 km

Baler, clothing baler, plastic baler

DIXI60 S

Call

Condition: ready for operation (used), Year of construction: 2012, Brand: DIXI

Model: 60 Sh

Year of manufacture: 2012

Pressing force: 60 t

Voltage: 400 V

Maximum bale weight: 340–500 kg

Bale dimensions: approx. 120 x 80 x 80–110 cm

Machine weight: 2,400 kg

Machine dimensions: 190 cm wide x 140 cm deep x 230 cm high

Filling opening dimensions: 115 cm wide x 80 cm deep x 55 cm high

Condition: Very good! Functionality checked.

Gbedeyh Dqxspfx Afnsh

FLITS Rental & Sales service: With every machine, we supply a bundle of binding wire (120 wires). Need more bundles? Request a non-binding quote.

FLITS Rental & Sales is your reliable partner for the sale and rental of high-quality machines for both businesses and private customers. We focus on providing efficient solutions in the areas of internal transport, cleaning, waste processing, and working at height.

At FLITS Rental & Sales you will find a comprehensive range of machines suitable for use in various sectors. See our other listings for: waste balers for efficient waste processing, electric pallet trucks/stackers for fast and safe internal transport, scrubber dryers for thorough and professional floor cleaning, forklifts in various models suitable for all types of work environments.

With FLITS Rental & Sales, you choose speed, clarity, and reliability. We think along with you, respond immediately, and ensure that you have the right machine quickly.

Visit our location

You are welcome to view the machines at our premises. We are located at:

Schoterlandseweg 94, 8413NE Oudehorne.

Visits are possible by appointment so we can take the time to provide comprehensive information and show you the right machines.

Contact

Do you have any questions or would you like to receive a non-binding quote? Please do not hesitate to contact us:

We are happy to assist you.

Waste baler | Paper baler | Cardboard baler | Plastic baler | Waste compactor | Recycling | Textile baler | Waste | Waste processing | DIXI

Listing

Poland

Poland

1,192 km

MEBA MEBAeco 510

MEBAMEBAeco 510

Call

Year of construction: 2019, condition: ready for operation (used), overall weight: 1,900 kg, total width: 3,100 mm, total height: 2,200 mm, cutting speed: 150,000 mm/min, product length (max.): 1,200 mm, This Metal Band Saw was manufactured in 2019. The MEBAeco 510 features a cutting capacity of Ø 510 mm and 700 × 510 mm for rectangular materials. It operates with a powerful 7.5 kW motor and a saw blade speed of 15–150 m/min. Consider the opportunity to buy this MEBAeco 510 Metal Band Saw for your cutting needs. Contact us for further details.

Gsdpfx Aoyhqf Sofnebh

• Cutting angle: 90°

• Cutting capacity (round / rectangular): Ø 510 mm / 700 × 510 mm

• Motor power: 7.5 kW

• Saw blade size: 6100 × 41 × 1.3 mm

• Saw blade speed: 15–150 m/min

• Remaining piece length (manual), without bundle clamp: 25 mm

• Remaining piece length (manual), with bundle clamp: 160 mm

• Maximum material size with bundle clamp: Ø 510 mm / 700 × 500 mm

• Minimum cutting length: 5 mm

• Working height: 750 mm

Listing

Romania

Romania

1,192 km

BAZHOU Wanxin

BAZHOUWanxin

Call

Year of construction: 2021, condition: ready for operation (used), total height: 1,300 mm, product length (max.): 4,500 mm, Pipe Production Line manufactured in 2021. This Bazhou Wanxin machine features a dual-station decoiler, hydraulic shear and butt-welding machine, and a cold saw for precise cutting of pipes. It accommodates round pipes with diameters from Ø16-63.5 mm and offers a feeding speed of up to 120 m/min. Consider the opportunity to buy this Bazhou Wanxin Pipe Production Line. Contact us for further details.

• Dual-station decoiler

• Function: Passively unwinds the coil

• Construction: Dual-station with 180° rotation; manual expansion

• Advantage: Fast loading, simple operation

Gbedpfsyhfvlox Afnjh

• Hydraulic shear and butt-welding machine

• Function: Cuts front/rear strip ends, centers, and re-welds

• Construction: Manual hydraulic shear with boom; front/rear pressure rollers; front/rear centering rollers; welding device

• Cutting method: Hydraulic shear

• Pressing method: Double-cylinder press

• Welding method: Manual welding

• Coil accumulator

• Function: Ensures continuous production during strip changeover

• Construction: Frame type with movable and fixed frames (incl. feeding device)

• Feeding speed: max 120 m/min

• Storage speed: max 200 m/min

• Stored strip length: 200–400 m

• Pinching roller motor: AC 11 kW

• Forming and calibration machine

• Working height: +850 mm

• Main drive power: AC/DC motor 160 kW, 1000–2000 rpm; reducer: gear-hardened; gearbox: spiral bevel gear

• Entry/formation: Passive 5-roll straightener; vertical rolls for strip feeding; forming via 7 horizontal + 8 vertical roll stands

• Guiding/pressing/deburring/cooling/calibration: 6 horizontal + 5 vertical roll stands; 1 round calibration stand

• Round calibration stand: 1 smoothing device; 2 sides with 8 rolls (4 per side); Ø30 mm rolls, 40Cr, quenched/tempered/hardened

• Horizontal roller shaft: Ø60 mm, bearing position 55, material 40Cr; surface hardening HRC 50–55

• Vertical roller shaft: Ø40 mm, material 40Cr, quenched/tempered/hardened

• Bearing slider: Forged steel 45#

• Stand style: Gantry type; opening width 120 mm; horizontal stand clamping adjustable via worm gear

• Stands material: Welded, aging annealed

• Pinching roller shaft: Ø50 mm, 2 rollers, manual screw adjustment

• Guide shaft: Ø40 mm

• Deburring knife: 2 pcs (1 in use, 1 spare)

• Cooling tank: Included

• Cold saw (Type KK-5-50)

• Function: Cuts pipes to preset length at line speed

• Pipe diameter: Round Ø16–63.5 mm (and corresponding square/rectangular)

• Cutting length: 1–6 m

• Material thickness: 0.6–2.5 mm

• Saw motor: 11 kW AC with frequency inverter

• Feeding motor: 2.9 kW servo (Yaskawa)

• Drive motor: 11 kW servo (Yaskawa)

• Feeding mode: Servo multi-stage speed

• Speed following: max 110 m/min

• Clamping: Pneumatic

• Saw blade: Ø400 mm

• Saw reducer: Model KK-80

• Sawing stroke (rack length): 3 mNote

• The technical data and descriptions are transcribed from the original order confirmation and are for informational purposes only; they are not binding.

Additional equipment

• Conveyor track, table, and packing machine

• Function: Automatic pipe transfer from mill to table; packages into hexagonal bundles

• Roller track length: 16 m

• Drive: 1 motor YCT200-4A, 5.5 kW

Listing

Bad Berleburg

Bad Berleburg

1,154 km

Injection molding machine

Arburg320C 500-170 mit Integralpicker-262030

Call

Condition: excellent (used), Year of construction: 2022, operating hours: 2,400 h, 1x Arburg 320C 500-170 Golden Edition with integral picker

Year: 05/2022

Operating hours: 2,400

A total of 3 machines available:

1x Year: 2020

2x Year: 2022

Features:

CG series

320 C 500 - 170

Thermoplastic cylinder complete, 35 mm, wear-resistant

Standard screw coupling, double flat coupling geometry

Selogica direct control system

Hydraulic system with 2 variable displacement pumps

Anniversary model GOLDEN EDITION

Thermoplastic processing

Open nozzle 35 mm

Nozzle tip radius 35

Heating band for open nozzle

Clamp plate set 320 central, Ø 125 mm

Pneumatic maintenance unit with 1 pressure regulator (1x1000l/min)

Electric connection for air blow-out device 1 on machine frame

Air blow-out device 2 with 3/2 valve on machine frame

Sorting unit, longitudinal installation including connection

Mold clamping with safety guard open

Programmable conveyor belt integrated in machine frame, longitudinal

Preparation for INTEGRALPICKER V

Robot system interface (according to EUROMAP 67), 50 pin

Socket combination: 1 CEE, 1 Schuko via FI 30mA Type B safety switch

Basic connectivity for further "Connected Services"

Printer interface, serial USB

CompactFlash interface for data storage

Operation authorization via chip card according to EUROMAP 65

Parallel connection for nozzle tip heating band or adapter

User-configurable page for "startup parameters"

Coloring device interface

Shut-off valve for cooling water inlet

Cooling water filter 100 µm included

3 free, manually adjustable cooling circuits

GOLDEN Automation Package with IP-V

Regulated machine cooling circuits

aXw Control Setup Bundle

aXw Control Start-Stop Bundle

ARBURG Remote Service (ARS)

Productivity package

Initial commissioning by ARBURG service

Gjdpoyi Ayqofx Afnsbh

CD operating manual and spare parts list

Sign plates language: German (DE)

Without granulate hopper 50 L

Without heating band for nozzle tip

Elastic machine mounting on rubber-metal elements

Ejector plate connection with safety device

Ejector quick coupling

Water-cooled control cabinet

Hydraulic ejector

Guard open at top

Standard equipment packages

Machine equipped with INTEGRALPICKER

New ARBURG color scheme

5625-S356/XX-B-Z150

Centering on moving mold fixing plate

150 mm instead of 125 mm

Listing

Bad Berleburg

Bad Berleburg

1,154 km

Injection molding machine

Arburg320C 500-170 mit Integralpicker-262029

Call

Condition: excellent (used), Year of construction: 2022, operating hours: 2,100 h, 1x Arburg 320C 500-170 Golden Edition with Integral Picker

Year of manufacture: 05/2022

Operating hours: 2,100

A total of 3 machines are available!

1x Year: 2020

2x Year: 2022

Equipment:

- CG series

- 320 C 500 - 170

- Complete 35 mm wear-resistant thermoplastic cylinder

- Standard screw coupling, square coupling geometry

- Selogica direct control system

- Hydraulic system with 2 variable displacement pumps

- Anniversary model GOLDEN EDITION

- Thermoplastic processing

- Open nozzle 35 mm

- Nozzle tip radius 35

- Heating band for open nozzle

- Central clamping platen set 320, Ø 125 mm

- Pneumatic maintenance unit with 1 pressure regulator (1x1000 l/min)

Gbodpeyi Axmofx Afnsh

- Electric connection for blow-off device 1 on machine base

- Blow-off device 2 with 3/2 valve on machine base

- Selector unit, longitudinal mounting including connection

- Mold clamping while safety guard is open

- Programmable conveyor belt in the machine base, longitudinal

- Preparation for INTEGRALPICKER V

- Robot interface (according to EUROMAP 67), 50-pin

- Socket combination 1CEE, 1 Schuko protected by 30mA residual-current circuit breaker type B

- Basic Connectivity for additional "Connected Services"

- Serial printer interface USB

- CompactFlash interface for data record storage

- Operator authorization with chip card according to EUROMAP 65

- Parallel connection for heating band nozzle tip or adapter

- Freely configurable page for "start-up parameters"

- Coloring device interface

- Shut-off valve for cooling water inlet

- Cooling water filter 100 µm supplied separately

- 3 manually adjustable free cooling circuits

- GOLDEN Automation Package with IP-V

- Regulated machine cooling circuits

- aXw Control Setup Bundle

- aXw Control Start-Stop Bundle

- ARBURG Remote Service (ARS)

- Productivity package

- Initial setup by ARBURG service

- CD with operating instructions and spare parts list

- Signage language German (DE)

- Without granulate container 50 L

- Without heating band for nozzle tip

- Elastic machine mounting on vibration-damping mounts

- Ejector plate connection safety

- Quick-release coupling for ejector

- Water-cooled control cabinet

- Hydraulic ejector

- Open-top safety device

- Standard equipment packages

- Machine equipped with INTEGRALPICKER

- New ARBURG color scheme

5625-S356/XX-B-Z150

Centered in moving mold clamping plate

150 mm instead of 125 mm

Listing

Mühlhausen

Mühlhausen

1,293 km

4 side moulder

WeinigPowermat 700

Call

Condition: used, Working width 230 mm

Gbsdexmh U Hopfx Afneh

Working height 160 mm

control Memory Plus

Listing

Schweiz

Schweiz

1,381 km

CNC-controlled planing mill

Costa

Call

Condition: good (used), Year of construction: 1994, For sale is a fully CNC-controlled planing mill. The planing mill can be inspected while in operation. A demonstration and training is possible before dismantling if purchased.

The plant was exclusively used for the production of paneling and parquet (panels).

Reason for sale:

Construction of a new, complete planing mill.

Equipment:

1. Stacking station

2. Vacuum lifter

- Age: approx. 1.5 years

3. Cross conveyor

4. Canali resaw bandsaw

- 2 bandsaws

5. Longitudinal/cross conveyor including roller conveyors

6. Costa planing machine with 10 spindles

- CNC-controlled

Spindle configuration:

1 spindle horizontal

2 vertical right lift spindles

Gbsdpfx Afjt Ngwrensh

3 vertical left lift spindles

4 spindle horizontal

5 vertical right lift spindle

6 vertical left lift spindle

7 top horizontal spindle

8 bottom horizontal spindle

9 bottom horizontal spindle

10 bottom horizontal jointing spindle

7. Roller conveyor with discharge

8. Roller conveyor

9. Cross and longitudinal conveyor

Inspection and Contact:

The planing mill can be inspected during running operation. Arrange a viewing appointment to see the system before dismantling.

Take the opportunity to acquire a fully functional planing mill!

Listing

Menslage

Menslage

1,080 km

KHS Innopal Palletizer (2005)

KHSBelader / Palettierer

Call

Condition: used, Year of construction: 2005, Overview The palletizer was manufactured by the German company KHS in 2005 and was until recently part of a bottling line in German dairy company. The palletizer is now being released as the owner is sgutting down the production. Technical details/ scope Worked with tray/cartons of 8 units (4x2) Pallet loader With shutter head Incl. protective fences, pallet transport, tray transport, tray turner, formation table, empty pallet magazine

Godpfx Aexb Ar Aofnebh

Trust Seal

Dealers certified through Machineseeker

Listing

Menslage

Menslage

1,080 km

Krones Lavatec KES-2-5-312/25-110 Bottle Washer (1996)

KronesFlaschenreinigungsmaschine

Call

Condition: used, Year of construction: 1996, Overview This Krones Lavatec KES-2-5-312/25-110 bottle washer was manufactured in 1996 and has an output of 29,000 bottles per hour. The machine has been modernized several times, including an S7 control system, caustic filtration with drum screen and pH value measurement for hot water 1. The machine will run until the end of January 2026 and can be inspected in person at any time until then. Technical details Output: 29,000 bottles/hour Bottle diameter: 54 - 90 mm Bottle height: 180 - 340 mm Equipment & modernizations Plastic cell with 110 pitch Suitable for swing-top bottles Bottle diameter: 54 - 90 mm Bottle height: 180 - 340 mm Modernizations: Retrofitted S7 control system Drum screen for caustic filtration Railing on the machine Hanger-specific caustic spraying in the deflector Cleaning & heating system: Rental rotating spraying Heating with tube bundle exchanger and hot water Lye concentration measurement and dosing control, also for post-caustic pH value measurement for hot water 1 Soaking & rinsing system: Double pre-soak with sieve belt Lye volume: 30 m³ Caustic solution, hot water 1, hot water 2, cold water and fresh water Head section can be steamed and rinsed with disinfection H₂ suction

Gbodpfovxtavjx Afnsh

Listing

Bad Berleburg

Bad Berleburg

1,154 km

Injection molding machine

Arburg320C 500-170 mit Integralpicker-255745

Call

Condition: excellent (used), Year of construction: 2020, operating hours: 4,800 h, 1x Arburg 320C 500-170 Golden Edition with Integralpicker

Year of manufacture: 11/2020

Operating hours: 4,800

A total of 3 machines available!

1x Year: 2020

2x Year: 2022

Equipment:

CG series

320 C 500 - 170

Thermoplastic cylinder complete, 35 mm, wear-resistant

Standard screw coupling, two-flat coupling geometry

Selogica direct control system

Hydraulic system with 2 variable displacement pumps

Gbsdpsyibayofx Afnsh

Anniversary model GOLDEN EDITION

Thermoplastic processing

Open nozzle 35 mm

Nozzle tip for open nozzle

Heating band for open nozzle

Clamping platen set 320 central Ø 125 mm

Electrical connection for blow-off device 1 on machine frame

Selector unit, longitudinal installation including connection

Programmable conveyor belt in machine frame, longitudinal

Preparation for INTEGRALPICKER V

Robot system interface (according to EUROMAP 67), 50-pin

Basic Connectivity for additional "Connected Services"

Printer interface, serial USB

CompactFlash interface for data storage

Operation authorization with chip card according to EUROMAP 65

Parallel connection for heating band nozzle tip or adapter

Freely configurable page for "start-up parameters"

Color dosing unit interface

Shut-off valve for cooling water inlet

Cooling water filter 100 µm included

3 manual-adjustable free cooling circuits

GOLDEN Automation Package with IP-V

Regulated machine cooling circuits

aXw Control Setup Bundle

aXw Control Start-Stop Bundle

ARBURG Remote Service (ARS)

Productivity package

Initial commissioning by ARBURG service

Instruction and training on the machine at customer's site

CD operating manual and spare parts list

Label language German (DE)

Without granulate container 50 L

Without heating band for nozzle tip

Flexible machine mounting on anti-vibration elements

Connection for ejector plate safety

Quick-release coupling for ejector

Water-cooled control cabinet

Socket distributor: 1 CEE, 1 Schuko

Hydraulic ejector

Safety guard open at the top

Standard equipment packages

Machine equipped with INTEGRALPICKER

New ARBURG color scheme

Listing

Niederlangen

Niederlangen

1,037 km

Band Saw

MEBA - VOLLAUTOMAT410 DGA 2300

Call

Condition: used, Year of construction: 2012, cutting diameter 410 mm

saw band length 5800 x 41 x 1,3 mm

table height 750 mm

430 mm

410 mm

700 x 410 mm

410 mm

cutting speed 500 x 410 mm

Gjdpfeyb S Emsx Afnobh

down speed 320 mm

dimensions of saw-band 320 x 410 mm

workpiece weight 15 - 150 m/min

5,5 kW

work height max. 3200 kg

connected load 4500 x 2800 x 2000 mm

Equipment:

- Automatic cutting pressure and feed rate monitoring

- Frequency-controlled AC drive 15-150 m/min, 5.5 kW

- Hydraulic full-stroke material clamping

- Automatic movement of the clamping vices

- Automatic saw frame height adjustment

- Minimum speed and saw blade monitoring

- Electric miter tilting via servo motor

- Visualized program input with CNC control

- Integrated MEBA gripper infeed system from 5-2300 mm per stroke with integrated roller conveyor

roller conveyor

*Special equipment:

- Laser light for cutting line display/ scribing saws

- Driven chip brush

- Micro dosing system

- Clamping pressure regulation

- Material bundle clamping

- Job menu

- Material database

- Zero stop

- Scraper belt conveyor for optimum chip removal, 2000 mm length

- Cutting process control

Listing

Hessisch Lichtenau

Hessisch Lichtenau

1,244 km

Column-guided semi-automatic band saw for up to Ø 380 mm with bundle clamping device and material st

METORA - KALTENBACHHMB 380 DS

Call

Condition: used, Column-guided bandsaw semi-automatic METORA - KALTENBACH Type HMB 380 DS

Only for 90° cuts (Made in Austria)

Machine No. 4580028 Year of manufacture: approx. 1993

Cutting capacity round: Ø 380 mm

Square: 380 x 380 mm

Saw blade dimensions: 5650 x 34 x 1.1 mm

Saw band speed: 25–108 m/min, continuously variable

Material infeed height: 870 mm

Hydraulic drive power: 1.5 kW

Saw motor power: 4 kW

Power supply: 400 Volt, 50 Hz

- Fully hydraulic bandsaw in double-column design

- Hydraulic saw bow descent with stepless adjustable cutting pressure

- Stepless adjustable descent speed

- Hydraulic vice clamping with hydraulic bundle clamping from above

- Hydraulic unit integrated in machine base

- Material feed roller on infeed side with geared motor (not mounted on machine frame)

Gbsdpfx Afsdzqtgjnjh

- Coolant system with coolant pump for water emulsion

- Minimum-quantity lubrication system for the saw blade

- Electric heating cartridge for cooling water and hydraulics

- Length stop TRENNJAGER Type EX-Stop1, with handwheel adjustment, digital display, and hydraulic stop carriage clamping

Stop length: 6750 mm, stop travel: 5650 mm, stop arm hydraulically foldable

without roller conveyor

Machine footprint (L x W x H): 2800 x 1400 x 2450 mm

Machine weight: approx. 3 tons

Weight of stop system: approx. 800 kg

In good condition

We make it easier for you to find: "bundle turner"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Bundle Turner (534)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month