Used building material fabrication for sale (61)

Buzău

Buzău Concrete block making machine

S.C. Arghir Prodex S.R.L.Speed 700

Buzău

Buzău Mobile Concrete block making machine

S.C. Arghir Prodex S.R.L.Standard Machine

Buzău

Buzău CONCRETE PIPE MAKING MACHINE

Arghir Prodex S.R.LUTB 1000

Buzău

Buzău Mobile Concrete block making machine

S.C. Arghir Prodex S.R.L.Forte Plus

Buzău

Buzău Mobile Concrete block making machine

S.C. Arghir Prodex S.R.L.FORTE MAXIMUS

Discover more used machines

Susuz

Susuz Bulletproof plate

GALENPROTAC500 BULLETPROOF PLATE

Saray

Saray Concrete Pipe Machine

ZİM MühendislikZIM A SERIES

Saray

Saray Concrete Pipe Machine

ZİM MühendislikBT AUTOMATIC MANHOLE BASE MACHINE

Saray

Saray Concrete Pipe Machine

ZİM MühendislikZIM T SERIES

Turkey

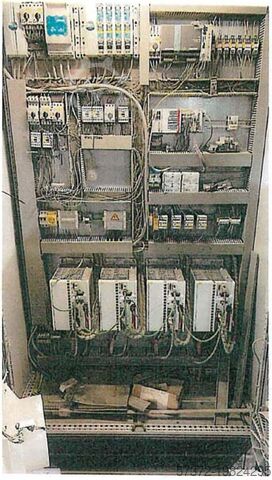

Turkey Control unit

AK EMConcrate Block Making Machine

Zheng Zhou Shi

Zheng Zhou Shi Construction machine/ sand gravel making

Sand gravel fabrication plant50-600 t/h sand gravel crushing plant

Les Sables-d'Olonne

Les Sables-d'Olonne Asphalt mixer

Oberleichtersbach

Oberleichtersbach Drum mixer

HutherTrommelmischer

Oberleichtersbach

Oberleichtersbach Mixer

HändleZwangsmischer

De Lutte

De Lutte Self-propelled concrete distributor

PAI

Germany

Germany Concrete Slab Press Line

Hermetik/Henke

Rohrberg

Rohrberg Feed hopper with pre-screening

Haver & BoeckerUF 1200x3650

Germany

Germany Stone Production Plant

OmagTronic S22 140-90

Trachy

Trachy Mobile jaw crusher on tracks

PowerscreenPremiertrak 400 jaw crusher

Altenburg

Altenburg Dosing system, row dispenser, construction machine

Dosieranlage Reihendoseur Heins4 er Reihendoseur Dosieranlage

Urbach

Urbach Dosing system serial doser for the produ

Dosieranlagen / ReihendoseurRD 700/ 4 Reiheendoseur- Dosieranlage

Orle

Orle Vibration press

OmagTRONIC 120/110

Madrid

Madrid SCHNELL Multifunction Center Bar Wiser 26 Dual

SCHNELLMultifunction Center Bar Wiser 26 Dual

Madrid

Madrid MEP Syntax line 28

MEPSyntax line 28

Madrid

Madrid SCHNELL Automatic Stirrup Bender PRIMA 12

SCHNELLAutomatic Stirrup Bender PRIMA 12

Used building material fabrication (61)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you