Used Turn Mill Center for sale (24,307)

Hagen

Hagen CNC turning and milling center

MazakVariaxis 630-5X II T

Einöden

Einöden CNC turning and milling center

EMCOEmco Turn 365

Pullach im Isartal

Pullach im Isartal CNC turning and milling center

EmcoSL1200 Kurzstangen Lademagazin

+44 20 806 810 84

Wymysłów

Wymysłów Cnc turning and milling center

MazakQuickTurn 20N

Root

Root CNC turning and milling center

NAKAMURA TOMENTJX

Discover more used machines

Schweiz

Schweiz CNC Turning & milling center

MORI SEIKIZT 1500 YB

Malé Výkleky

Malé Výkleky CNC turning and milling center

WeinmannWeinmann B-540

Jakling

Jakling CNC turning and milling center

EMCOMAXXTURN 65-G2 SMY

Aachen

Aachen CNC turning and milling center

DMGCTX Beta 800 V6

Sevilla

Sevilla CNC turning and milling center

Mori SeikiNL 2500 SY

Burgoberbach

Burgoberbach CNC turn-mill center 12 AG 2 spindles

MazakQuickturn Nexus 200-II MS

Burgoberbach

Burgoberbach CNC turn-mill center 12 AG 2 spindles

MazakQuickturn Nexus 200-II MS

Burgoberbach

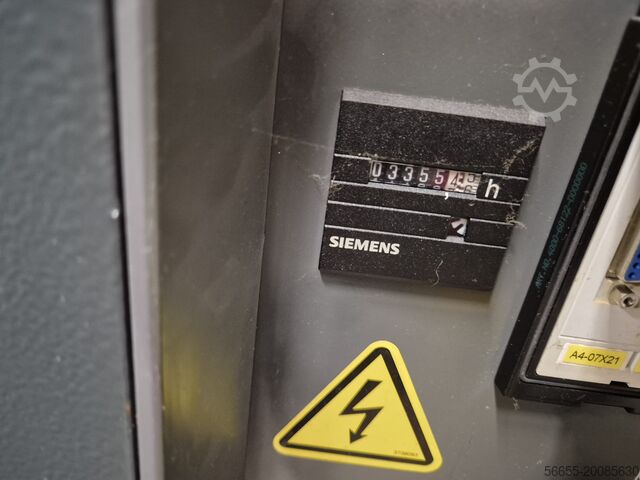

Burgoberbach CNC turning-milling center 6 AGW

GildemeisterCTX 310 Eco (nur 3.350 h)

Donzdorf

Donzdorf CNC turning and milling center

INDEXG200 CNC-Drehmaschine Siemens Sinumerik

Kastl

Kastl CNC turning-milling center

MazakQT 250 MSY

Karlsbad

Karlsbad CNC turning and milling center

INDEXG 200 YB

Bayern

Bayern CNC turning and milling center

GILDEMEISTERGMX 250 linear

Bergisch Gladbach

Bergisch Gladbach CNC turn-mill center

OkumaMacturn 30 W OSP 7000L

Aflenz Land

Aflenz Land CNC turning and milling center

DMG MORINLX 2500 / 700 PLUS WERKZEUGPAKET

Bienne

Bienne CNC turning and milling machining center

DMG MORINTX 1000 -ZSM

Bienne

Bienne CNC turning and milling machining center

DMG MORINLX1500SY/500

Oelde

Oelde CNC Turning- and Milling Center

DMG MORINLX 2500 SY / 700

Denzlingen

Denzlingen CNC turning and milling center

MAZAKINTEGREX i-300 1000U

Kaunas

Kaunas CNC turning and milling center

TsugamiHS20M-5AX

Uttendorf

Uttendorf CNC turning and milling center

MazakINTEGREX i 250H S

Used Turn Mill Center (24,307)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84