Used Shrink Packer for sale (769)

Germany

Germany Shrinking Machine

KallfassKC 8060/650

Germany

Germany Bag Filling Machine

Haver & BoeckerRoto-Packer

Germany

Germany Bottle Packer

KettnerBlitzpac E35 T1

+44 20 806 810 84

Janville

Janville Case packer

CermexSL1100

Janville

Janville Heat shrink machine

Minipack TorreFM 75

Discover more used machines

Janville

Janville Bundling machine / Shrink wrapper

Pester pac automationPEWO-pack 450 (avec tunnel PEWO-therm)

Janville

Janville Semi-automatic case packer

OLI210

Janville

Janville Combi – L-sealer with shrink tunnel

RobopacAthena 5545 / Combi

Janville

Janville Case packer

PRB PackagingPocket 3

Janville

Janville Case packer

CermexSL2100

Janville

Janville Shrink-wrapper

SmipackBP800AR 280ST

Janville

Janville Heat shrink tunnel

M32N

Nauen

Nauen Pester PEWO - pack 450 SN Shrink fit

PesterPEWO - pack 450 SN Schrumpfer

Suffolk

Suffolk Inverted flow packer

IlapakAstra

Misterton

Misterton Hot water shrink tunnel

CryovacSTE96-600

Leipzig

Leipzig Shrink device with cooling unit

KELCHi-tec L

Hobro

Hobro Shrinking equipment

Alpha PackAP-1BT-III

Babenhausen

Babenhausen Shrinking equipment

minipack-torreMinipack FM-75N

Italy

Italy Used shrink wrapper SMI SK 450F

SMISK 450 F

Fumane (Verona)

Fumane (Verona) Used TECMI - Smipack shrink wrapper - 2013

SMIPACKBP802ARV 380R

Germany

Germany Shrinking machine

DiezHTC3822

Derby

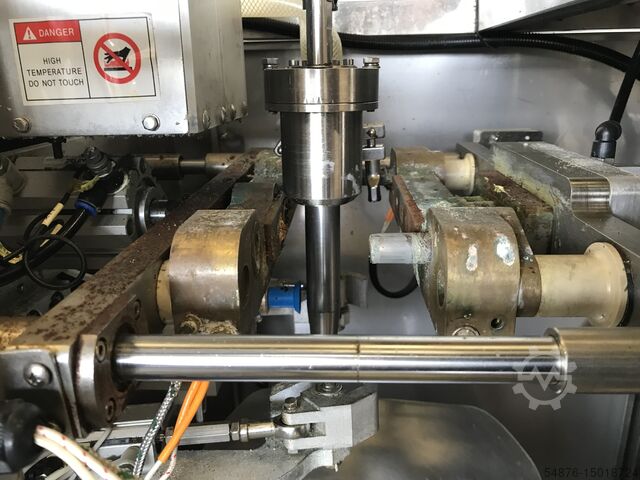

Derby BENHIL 8358 Twin Filling Mini Portions 10g Butter Packer

Benhil8358

Berlin

Berlin Packer

A+F AutomationContiflex Multiformer

Berlin

Berlin Shrinking Tunnel

Quick-packTTN50

Berlin

Berlin Shrink Wrapping Machine

BAUMERWRAP AROUND C86/6

Used Shrink Packer (769)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84