Used Moisture for sale (276)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Zielona Góra

Zielona Góra

1,604 km

Mobile compressor

ERVORRafale 50 SP 4 hours working

Call

Condition: like new (used), Year of construction: 2016, operating hours: 4 h, machine/vehicle number: 84149090, Complete container station with screw compressor, ready for operation in industrial conditions, equipped with a full air treatment system. Ready for immediate start-up. Only 4 hours of test operation.

CONTAINER 10"

Specifications:

Compressor: Ervor Rafale 50 SP (2016) – screw type, oil-lubricated, fixed-speed

Itedpjw D Ut Hefx Ag Usb

Motor power: 37 kW (50 HP)

Capacity (FAD): ~260 Nm³/h at 7–9 bar

Drive: Belt drive with automatic tensioner

Power supply: 400 V / 3 phase / 50 Hz

Dryer: Adsorption (2-column, regenerated, timer or DP-controlled)

Aftercooler: Air-cooled compressed air aftercooler with ventilation

Filtration: Pre-filter, fine filter, and final filter class 1 μm / 0.01 μm

Container: 10 or 20-foot, steel, ventilated, insulated, with service doors

Control: Control panel + pressure switch, hour meter, phase protection

Technical condition: Very good

Cold-regenerated dryer

Adsorption dryer ERVOR – 2-column air drying system

Integrated in the container station. Suitable for continuous operation, with automatic bed regeneration.

The set also includes an aftercooler and a complete set of filters (pre-filter, fine filter, final filter).

System ready for industrial or military operation.

Final humidity: ≤ -40°C PDP (pressure dew point)

Air treatment and cooling system

The station is equipped with a multi-stage compressed air treatment system, including:

- 3-stage filtration (solid particles, oil, moisture),

- Aftercooler with fan,

- Insulated and serviceable pipelines,

- Control manometers, ball valves, service bypasses,

- System designed for heavy-duty use – industrial and mobile applications.

Additional photos or video available upon request.

We invite you to purchase.

Listing

Geestland

Geestland

1,113 km

Incubator

Heraeus KendroHeraCell 150

Call

Year of construction: 2018, condition: excellent (used), Heraeus Kendro HeraCell 150 Co2 Incubator

Technically and optically as good as new HeraCell 150 incubator

HERAcell has instead of the

instead of the usual water tray

new type of water reservoir. This

ensures high relative humidity (rH) and, above all

and above all for short moisture recovery times.

Compared to conventional

CO2 incubators with water trough

HERAcell achieves a moisture recovery time

up to five times faster humidity recovery time.

Consistent humidity

Short humidity recovery times play

an important role, especially when the

the door of the incubator has to be opened frequently

door must be opened frequently or

volumes of media are processed.

For devices with a water tray

the air layer between the

bottom and tray prolongs the moisture recovery time.

The result is high evaporation rates

in the cultures.

HERAcell, on the other hand, ensures

very short - up to five times

times faster - thanks to superior

thanks to superior technology:

- Large water surface area (due to

the use of the entire

inner chamber floor)

- Direct heat transfer from the

heated floor into the

humidifying water

- Patented floor heating after

after door opening and during O2

gassing

Early water level alarm

The water level is continuously monitored

monitored, and an acoustic and

and optical alarm signals

signals in good time that water needs to be

needs to be topped up.

Ijdpfsiv S E Uex Ag Uotb

ContraCon - decontamination with

moist heat at 90 °C

The patented automatic decontamination system specially

developed and patented for Heraeus incubators

ContraCon decontamination routine

has been proven in independent

independent tests at 90 °C and high

and high humidity to eliminate a large number of

microorganisms, including

mycoplasmas completely

eliminated

Listing

Neckartailfingen

Neckartailfingen

1,333 km

Briquetting press, briquette press

mütek SystemtechnikMGP 60

Call

Condition: new, Year of construction: 2025, Another machine immediately available!

Briquetting press with PLC control and automatic briquette length adjustment

Throughput: up to max. 60 kg/h

Briquette: 50 mm cylindrical

Motor: 5.5 kW

Dimensions: 1,900 x 1,350 x 1,410 mm

Weight: approx. 860 kg

Requirements:

Feed material should ideally be shorter than 25 mm chip length

Moisture content 6–12% ATRO

Ijdpfx Aov Rpxlog Ustb

Machine suitable for intermittent operation. E.g. briquetting for up to 2.5 hours; 1 hour break, etc.

If the machine needs to run longer than 2.5 hours continuously, optional cooling must be connected.

Listing

Eich

Eich

1,355 km

Veneer gluing machine

Fisher+Rückle AGOmnimaster-900

Call

Condition: excellent (used), Year of construction: 2011, operating hours: 216 h, functionality: fully functional, machine/vehicle number: 20MS090000/007, total length: 3,000 mm, type of input current: AC, total width: 2,500 mm, total height: 1,900 mm, overall weight: 1,450 kg, empty load weight: 1,450 kg, working width: 900 mm, compressed air connection: 6 bar, throughput speed: 50 mm/s, Gluing and longitudinal splicing machine

For 0.4 to 3 mm thickness with direct gluing. With pre-gluing of edges up to 5 mm.

Machine used very little, available ex location.

Features:

- Separate electric motors for chain and glue application

- Glue is applied to the edge of the newly inserted veneer strip, increasing the strength of the glued joint

- Robust, durable stainless steel conveyor chain with weighing joints

- Separate temperature, speed, and pressure adjustment

- Quick and easily accessible glue reservoir for fast and simple refilling or cleaning

- Multiple heating zones for individual temperature adjustment

- Extended service life of glue reservoir due to integrated cooling unit

- Infinitely variable feed speed

INCLUDES GLUE COOLER

Technical specifications:

Throat depth: 900 mm

Minimum veneer strip width: 45 mm

Minimum veneer strip length: 300 mm

Veneer strip thickness: 0.4 – 3.0 mm (up to 5 mm)

Veneer moisture content: max. 8 – 12 %

Working height: 900 mm

Feed speed: 5 – 50 m/min

Ijdpfx Asw E Rfbjg Uetb

Heating section length: 1000 mm

Maximum heating temperature: 250°C

Electrical connection: 9.0 kW, 400 V, 50 Hz

Compressed air: 6.0 bar

Dimensions (L x W x H): 2400 x 2300 x 1900 mm

Weight: 1500 kg

Listing

Kaunas

Kaunas

2,084 km

Complete planing mill

Call

Condition: excellent (used), functionality: fully functional, Complete, high-performance planing mill with WACO 6-head planer, double resaw bandsaw, full mechanization, moisture measurement, control system, etc., etc. Simply complete! Capacity approx. 2,500 m3/month per shift, depending on dimension.

Ijdpfow N S Nhsx Ag Uetb

The installation consists of:

Tip destacking, single piece feeding, Brookhuis moisture measurement, double resaw bandsaw by Brau Canali, small bundle strapping with Böhl bundle formation and feed to the stacking machine, 2 x stacking machines with batten placing, complete packaging line with film dispenser, package press with lower squared timber insertion. The full Siemens control system, complete steel substructure, all wiring and piping, etc. Very well-maintained installation for the production of battens, tongue and groove, and dimension lumber.

Listing

Buseck

Buseck

1,206 km

Freezer

LiebherrGGPv 6590 Index 42C /001

Call

Condition: used, functionality: fully functional, Year of construction: 2022, machine/vehicle number: 83.178.489.6, This is a deep freezer from premium manufacturer Liebherr, year of manufacture 2022. The unit has been inspected in our in-house workshop and is fully functional.

With a gross volume of 601 liters, it offers space for stackable 2/1 GN containers or E2 crates. The rounded stainless steel runners for GN containers make cleaning very easy. The Liebherr ProfiPremiumLine GGPv 6590-40 freezer offers various safety features, including the option to connect to an alarm system for optimal protection of valuable stored goods. The dynamic cooling system quickly brings products down to the desired temperature between -10°C and -26°C, thanks to the powerful refrigeration unit and professional-grade electronic controls, even at ambient temperatures up to +43°C. Defrosting is automatic but can also be initiated manually. Predefined cooling programs are available for easy operation, specifically designed for the storage of frozen goods and the deep-freezing of ice cream and frozen desserts. The unit has been inspected in our in-house workshop and is fully functional.

You will receive an invoice with VAT shown separately.

Condition: Used, tested and fully functional

Technical data:

• WxDxH: 700 x 830 x 2120mm (external)

• WxDxH: 510 x 650 x 1550mm (internal)

• Type: GGPv 6590 Index 42C /001

• Serial no.: 83.178.489.6

• Power supply: V: 230 / A: 1.0 / W: 500 / Hz: 50

• Volume: 601 liters (gross capacity)

• Refrigerant: R 290

• Weight: 139 kg

• Year of manufacture: 2022

Further details can be found on the photographed nameplate.

Additional information:

• Height-adjustable feet: Where daily hygiene is essential, height-adjustable feet provide sufficient ground clearance and ensure easy, convenient cleaning underneath the unit.

• NoFrost technology: Never defrost again – Liebherr’s NoFrost professional-grade equipment provides reliable long-term freshness. Frozen goods are cooled with circulating air and moisture is dissipated, keeping the freezer compartment completely frost-free and preventing food from becoming iced over.

• Temperature alarm: The integrated temperature alarm signals if preset temperature thresholds are exceeded or undercut. This alarm is equipped with both acoustic and visual alerts, ensuring maximum safety for stored goods.

• Reversible door hinges: Units are supplied with a right-hand door hinge as standard. Thanks to the option to reverse the door hinge, the unit can always be optimally positioned in the installation area and individually adapted to your needs.

Itjdpfx Agoxz Tf Hs Uob

• SwingLine: The elegant SwingLine design with illuminated side edges makes these appliances the first choice for the highest design requirements. The elegantly curved construction makes Liebherr appliances a visual highlight in professional settings. The SwingLine doors feature an integrated recessed handle along the full height of the door, making them ergonomic, easy to open, and particularly easy to clean.

Shipping:

• Delivery or self-collection by arrangement

• Worldwide shipping on request

• Shipping to islands or mountain stations only by arrangement

Listing

Neckartailfingen

Neckartailfingen

1,333 km

Chipper, wood shredder

mütekMGZ 1030 - 22 kW

Call

Condition: like new (used), functionality: fully functional, Year of construction: 2025, operating hours: 55 h, Machine with special rotor

Available immediately

Advantages:

+ Special rotor, with reduced knife protrusion, suitable for both hard and soft materials

+ 22 kW motor

+ Efficient square blades

*For pallets: up to 10 pallets per hour max. *Depending on screen and material. Significantly higher throughput with smaller wood waste.

Motor: 22 kW; 400 V - 50 Hz - 3 ph,

Screen: 15/20 mm or as agreed (10 to 40 mm possible)

Hydraulically operated pusher

Current screen perforation (15/20 mm) *can be changed

Extraction nozzle Ø 200 mm

Feed opening 1000x1000 mm

Dimensions: 2000x1800x1645mm

Sample image above: color of the unit may vary

Weight: 1,920 kg

Standard equipment included:

- Control cabinet with PLC control

- Automatic star/delta starter

- Fast hydraulic system

- Automatic shutdown in rotor idle mode

- Speed: 70–90 rpm for high throughput

Itedox Af Rdopfx Ag Ueb

- Cycle control to minimize idle times

- Performance-enhancing step control of hydraulic pusher

- Pertinax guides for hydraulic pusher

- Vibration-damping machine feet

- CE compliant

The following options are available at extra cost:

*Visible in the last 2 images.

- Additional blade row + €2,790

- Segmented bottom + €6,890

(recommended for materials with wall thickness less than 3 mm)

- Special K-rotor bearing + €3,480

(Recommended for shredding plastics with screens under 15 mm or with a high fine fraction. Not necessary if bearings are lubricated about every 4 weeks of operation)

- Raise shredder by 30 cm (preparation for conveyor belt) + €2,480 net

- Angled conveyor belt (discharge height approx. 220 cm) + €12,980 net

- Overband magnet + €5,980 net

- Control for conveyor belt and overband magnet + €2,750 net

(Synchronous start-stop with shredder)

- Enlarged feed hopper 1500x1500 mm + €3,480 net

Raw material requirements:

- Moisture content (atro) must be below 25%

- The infeed material must be free of metals and mineral impurities. Damage to the tools and/or increased wear may result otherwise.

Listing

Barntrup

Barntrup

1,181 km

Multi-blade saw for parquet

A. CostaZefiro 1450

Call

Condition: ready for operation (used), Year of construction: 1998, functionality: fully functional, power: 30 kW (40.79 HP), Multi-blade crosscut saw / Splitting machine for parquet strips

Manufacturer: A. Costa

Model: Zefiro 1450

Machine from parquet production, previously used as a grooving machine.

Professional splitting machine for parquet strips.

In engineered parquet production lines, this machine is typically positioned directly after the press, so that the parquet slats coming out of the press are fed directly to the Zefiro grooving and milling machine to mill/saw channels in the plywood backing.

These grooves on the underside ensure that the manufactured parquet strips are more flexible and resilient. As a result, the parquet is less prone to deformation, which usually occurs due to moisture. This significantly increases the quality of the parquet flooring.

Technical data:

Working width: 1400 mm

Max. feed width: approx. 1650 mm

Cutting height: approx. 30 mm

Min. distance between saw blades: approx. 20 mm

Feed speed adjustable, approx. 3 - 13 m/min

Main motor: 30 kW

Itsdpfxoxrlb Is Ag Ujb

CE marking

Saw dimensions approx. 2800 x 2400 x 1800 mm

Saw weight approx. 2,650 kg

Including 2 conveyor belts for the removal of the grooved parquet slats

Listing

Groningen

Groningen

983 km

Packaging machine for broiler chickens

Moba NetherlandsM16

Call

Year of construction: 2005, condition: excellent (used), machine/vehicle number: 72164xxx, The Moba maxipacks

Worldwide, the Moba maxipack M16 and M22 are the only machines that are able to package entire chickens in a bag, both frozen and fresh. The maxipack is an extremely reliable machine. Therefore, these machines are well-known in the chicken slaughtering industry for decades. The maxipack is made of stainless steel and high-quality, wear-resistant plastics. These ensure that the maxipack is able to continue to run for years in the production process after extensive mechanical, electrical and electronic revision.

Moba M16

The Moba M16 taper machine is, suitable packing smaller chickens with a range of 900 to 1200 grams per chicken.

- The machine consists of four protective covers with an interlock system that immediately deposits the machine when opened. In combination with the emergency stop, this ensures that the machine is safe to use.

- Plastic bags can be easily changed by using the change function. This function ensures that the turntable rotates a quarter turn to ensure enough space to change the bags.

- The compressed air system on this Maxipack is adjustable by means of a pressure reducing valve. The pressure reducing valve ensures that the moisture is filtered out of the compressed air.

- The maxipack is also equipped with a pressure regulator, that ensures the maxipack to switch off if the pressure drops below 5 bar.

Revision Moba M16

Maxipacks that arrive at Bos Technical Support are thoroughly cleaned before starting the revision. For the revision, original Moba high qualitiy components are used. Each maxipack is equipped with a new PLC (Program Logic Controller) that includes the latest software. The 8 pneumatic cylinders that this machine includes are all checked and replaced when necessary. The electrical cabinet is being rebuilt and provided with new wiring.

All machines come with an instruction manual and will be extensively tested to determine whether the machine is ready for a prolonged period of time in the production proces.

Itedpfxeh Ri A Aj Ag Uob

More information?

We have multiple Moba M16 and M22 machines in stock for sale and rental. For more information see also our website

Specifications Moba Maxipack M22 taper:

- Capacity: 800 chickens/hour (per machine)

- Tape: 9-12 mm wide (optional 19 mm tape)

- Machine weight: 540 kg

- Machine size (L-W-H): 2395-850-1700 cm

- Weight range: 900-1200 grams

- Electrical 3 phase, neutral and ground

- Voltage: 400 V

- Power consumption: 1.4 KVA/hour

- Frequency: 50/60 Hz

- Airpressure: 6 bar

- Maximum dewpoint: 3 Celsius

- Air consumption: 7500 L/hour

Bos Technical Support import-export packaging machines.

Sorteermachine eier verpakkingsmachine eiersorteermachine egg gradingmachine sortiermachine sortieranlage eierverpackungsmachine Maxipack, Moba, Sanovo, Staalkat, Prinzen, Rational, Kletec

Listing

Wettenberg

Wettenberg

1,194 km

Piston compressor

KaeserKCT 401-TAH 6-100

Call

Condition: excellent (used), Year of construction: 2011, functionality: fully functional, machine/vehicle number: KCT401THA6100, total length: 1,000 mm, total width: 1,000 mm, total height: 1,150 mm, space requirement length: 1,000 mm, space requirement width: 1,000 mm, space requirement height: 1,150 mm, motor manufacturer: KAESER, fuel type: electric, operating pressure: 10 bar, type of cooling: air, Equipment: documentation/manual, refrigerant dryer, type plate available, Hello everyone, for sale here is a piston compressor together with a refrigeration dryer (KAESER FILTER ECO DRAIN31), TAH 6. Both the piston compressor and the filter are mounted compactly on a frame. There is a sound insulation box fitted around the compressor motor. The machine is in like-new condition and has always been maintained. It was used in our prepress area in the office building – no moisture or cold. Our maintenance company confirms that the machine is in absolutely top condition. The compressor is currently not connected to the power supply. If you have any questions, feel free to contact me.

Ijdpfx Aex Hfcdog Ustb

Listing

Lorquí

Lorquí

1,788 km

ZACMI stainless steel multi-stage linear blancher

ZACMI

Call

Condition: like new (used), SUITABLE FOR ALL TYPES OF PRODUCTS: green peas, green beans, spinach, carrots, okra, beans, strawberries, artichokes, sweet corn, broccoli, cauliflower, mushrooms, etc.

WATER CONSUMPTION: 1.5 L water per 1 KG of product.

STEAM CONSUMPTION: 1.5 L steam per 4-7 KG of product.

The machine can operate in three modes: with water, with steam, or as a moisturizer (hydration).

Isdpfox S H U Sjx Ag Uotb

Hydration Blancher Version:

In this configuration, the machine is suitable for completing the rapid rehydration process of cereals or legumes pre-started with the pre-heater.

- Module 1 functions to treat the product with a water spray.

- Modules 2, 4, and 6 work with steam. The temperature is controlled by a probe located in module 6, which regulates the modulating valve on the steam supply line to module 6, provided the pneumatic steam shut-off valve on module 2 is open.

- Modules 3 and 5 use cold atomized water.

- Module 7 is designed as a water-to-air cooler.

- Module 8 works with water, and its temperature does not exceed 14ºC to lower the temperature of the product.

Water Blancher Version:

In this configuration, the machine operates in counter-current, meaning the product moves in the opposite direction to the cooling water flow. The first seven modules are equipped with trays with rotary water recovery filters, as well as associated level controls and water recirculation pumps.

- Modules 1, 2, and 3 function as pre-blanchers for the product.

- Modules 4 and 5 are specifically designed for blanching with hot water. Water is recirculated by pumps, and temperature is regulated in module 4.

- Module 6 acts as the first cooling module and is fitted with a by-pass pump for recirculating warm water, which is redirected to the 2nd or 3rd module; supply to the 3rd module is regulated by a solenoid valve.

- Module 7 cools the product using a water mist and removes humid air with a fan.

- Finally, module 8 further cools the product by spraying water above and below the conveyor net, with all water collected in module 8’s recovery tank.

Steam Blancher Version:

In this variant, the machine can steam-blanch vegetables across eight modules:

- Module 1 serves as a barrier to prevent steam loss.

- Modules 2, 3, 4, 5, and 6 operate on steam. The temperature is maintained by a probe in module 6, controlling the modulating valve on the steam supply line, provided the pneumatic steam shut-off valves are open.

- Module 7 is designed for WATER-AIR cooling.

- Module 8 is water-cooled, with the temperature not exceeding 14ºC to rapidly reduce the product temperature.

Listing

Lorquí

Lorquí

1,788 km

FMC finisher

FMC

Call

Condition: like new (used), These machines are used in the food industry to process fruit and vegetables, separating the pulp from skins, seeds, and other waste. The machine is primarily used as a juice and purée extractor. It is also used to remove seeds and pulp from juice extracted by other machines. The extractor offers a high production capacity, which varies depending on the following factors: type of product (citrus fruits, pomegranates, tomatoes, etc.), condition of the product, and type of processing the product has already undergone. In general, the 'Finisher' extractor offers the following advantages: - Production of clearer juices (from mixtures of pulp, seeds, and skins) due to the lower solids content compared to crushing processes. - Prevention of aeration in the extracted juice. - Achieving the lowest possible moisture content in the waste.

WORKING MEASUREMENTS:

Mesh length: 60.5 cm

* Output may vary depending on the product.

Itedpfxsx S Hy Ue Ag Usb

Listing

Lorquí

Lorquí

1,788 km

Pulper Finisher

JBT

Call

Condition: like new (used), functionality: fully functional, These machines are used in the food industry to process fruit and vegetables, separating the pulp from skins, seeds, and other waste. The machine is primarily used as a juice and purée extractor. It is also used to remove seeds and pulp from juice extracted by other machines. The extractor offers a high production capacity, which varies depending on the following factors: type of product (citrus fruits, pomegranates, tomatoes, etc.), condition of the product, and type of processing the product has already undergone. In general, the 'Finisher' extractor offers the following advantages: - Production of clearer juices (from mixtures of pulp, seeds, and skins) due to the lower solids content compared to crushing processes. - Prevention of aeration in the extracted juice. - Achieving the lowest possible moisture content in the waste.

WORKING MEASUREMENTS:

Itedpsx S Hxdofx Ag Ujb

Mesh length: 60.5 cm

* Output may vary depending on the product.

Listing

Wysoka

Wysoka

1,676 km

Impregnation system

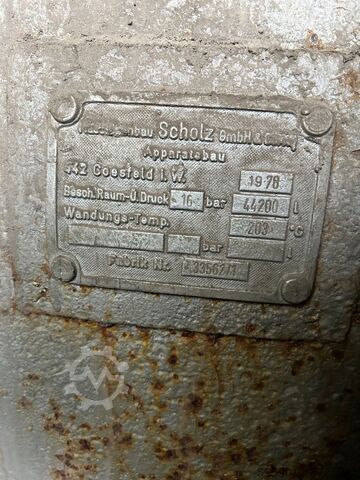

ScholzAutoklaw

Call

Condition: excellent (used), Year of construction: 1978, AUTOCLAVE Scholz

A wood autoclave is a specialized device used for the pressure impregnation of timber. It is a hermetically sealed chamber in the form of a large, thick-walled cylinder, where the wood saturation process with protective agents is carried out.

The impregnation process in autoclaves takes place in several stages:

Iodot Tq Szopfx Ag Uotb

1. Wood is placed in the tightly sealed chamber.

2. A vacuum is created, removing air from the wood cells.

3. The chamber is filled with preservative.

4. High pressure is then applied, forcing the protective agent deep into the wood structure.

5. Finally, a vacuum is applied again to fix the preservative.

Pressure impregnation in autoclaves ensures deep and uniform saturation of the wood with protective agents, significantly increasing its durability and resistance to degrading factors such as moisture, insects, or fungi. Wood treated in this way can last up to 20 years even in harsh outdoor conditions.

TECHNICAL SPECIFICATIONS:

Manufacturer: Scholz

Year of manufacture: 1978

Capacity: 44,200 l

Weight: approx. 20 tons

Length: 14.5 m

Width: 2 m

Internal rails for trolleys

Pressure: 16 bar

Operating temperature: 203°C

Autoclave with complete equipment, in very good condition.

Listing

Germany

Germany

1,293 km

Elevator

WieseP20 Z-Form

Call

Year of construction: 2016, condition: ready for operation (used), A Wiese pendulum bucket elevator in Z-shape for gentle vertical and horizontal conveying of sensitive, light bulk materials (potato chips) is available. Particle size range: 50mm-60mm, max. conveying material temperature: 30°C, moisture: dry, bulk density: 0.07t/m³, conveying capacity: approx. 14.3m³/h, belt speed: 0.22m/s, max. bucket filling: 60%, belt material: EPDM, bucket width: 476mm, support roller diameter: 95mm. Lower edge discharge: 4960mm, feed vertical shaft center: 3490mm, vertical shaft center last discharge: 1675mm. Documentation available. An on-site inspection is possible.

Itodpfex H S N Dex Ag Ueb

Listing

Aalen

Aalen

1,374 km

Vacuum dryer / drying chamber

ISVEES 3

Call

Condition: new, No. 3183

Vacuum dryer / drying chamber ISVE ES 3 / NEW

New machine, delivery time 120 days

Construction features: AISI-304 stainless steel, partially insulated

External diameter: 1300 mm

Length of cylindrical part: 5000 mm

Dryer length: 5900 mm

Dryer total length plus sliding guides: 11000 mm

Max. operating vacuum: -730 mm Hg

Timber pile length: 5000 mm

Timber pile width: 800 mm

Timber pile height: 790 mm

Net wood volume: approx. 2,5 m3

Installed electrical power: 8,80 kW

Average hourly power input: 4,4 kW/h

Includes:

- 9 electric heating plates (each 800 x 5000 x 10 mm LWH / 40 kg / 0,695 kW)

- 1 oil vacuum pump (65 m3/h / 1,8 kW / 380 Vca)

- 1 vacuum pump condenser (stainless steel tube with internal condensation system)

- 2 internal condensers (turbofan of 0,37 kW each 380 VCa)

- 2 one-way valves (clapet: one ¾” for vacuum circuit; one ½” for condenser discharge)

- 1 solenoid air return valve (24 Vca: one 1” for the autoclave and one ½” for the condenser)

- 1 manual air return (1” ball valve)

- 1 electrical control panel (PLC type Siemens S7-1200, with touch panel)

- 1 ISVE server connect with remote service and control

- 2 wireless moisture probes (double probes for core and surface moisture reading)

- 1 wireless temperature probe (for wood core reading)

- 2 plates-holder stands

- 1 instruction booklet (in English with CE certificate and wiring diagrams)

Transport dimensions approx. 5900 x 1300 x 2000 mm LWH

Weight approx. 2000 kg

Itjdpfx Asu Tipksg Ueb

Technical details, year of construction and scope of delivery according to the manufacturer, without guarantee

Subject to prior sale

New machines are covered by the manufacturer's warranty

Images and videos serve as examples and do not represent the actual scope of delivery

Terms of payment: Prices plus VAT, payment before collection or dispatch

Terms of delivery: ex location

Listing

Aalen

Aalen

1,374 km

Vacuum drying kiln

ISVEES 2

Call

Condition: new, No. 3171

Vacuum drying kiln ISVE ES 2 / NEW

New machine, delivery time 120 days

Construction features: AISI-304 stainless steel, partially insulated

External diameter: 1000 mm

Length of cylindrical part: 5000 mm

Dryer length: 5900 mm

Dryer total length plus sliding guides: 11000 mm

Max. operating vacuum: -730 mm Hg

Timber pile length: 5000 mm

Timber pile width: 800 mm

Timber pile height: 400 mm

Net wood volume: approx. 2 m3

Installed electrical power: 5,27 kW

Average hourly power input: 2,7 kW/h

Includes:

- 6 electric heating plates (each 800 x 5000 x 10 mm LWH / 40 kg / 0,695 kW)

- 1 oil vacuum pump (40 m3/h / 1,1 kW / 380 Vca)

- 1 vacuum pump condenser (stainless steel tube with internal condensation system)

- 2 one-way valves (clapet: one ¾” for vacuum circuit; one ½” for condenser discharge)

- 1 solenoid air return valve (24 Vca: one 1” for the autoclave and one ½” for the condenser)

- 1 manual air return (1” ball valve)

- 1 electrical control panel (PLC type Siemens S7-1200, with touch panel)

- 1 ISVE server connect with remote service and control

Iedpfouvi Saox Ag Uotb

- 2 wireless moisture probes (double probes for core and surface moisture reading)

- 1 wireless temperature probe (for wood core reading)

- 2 plates-holder stands

- 1 instruction booklet (in English with CE certificate and wiring diagrams)

Transport dimensions approx. 6100 x 1150 x 1300 mm LWH

Weight approx. 1300 kg

Technical details, year of construction and scope of delivery according to the manufacturer, without guarantee

Subject to prior sale

New machines are covered by the manufacturer's warranty

Images and videos serve as examples and do not represent the actual scope of delivery

Terms of payment: Prices plus VAT, payment before collection or dispatch

Terms of delivery: ex location

Listing

Aalen

Aalen

1,374 km

Vacuum dryer / drying chamber

ISVEES 5

Call

Condition: new, No. 3187

Vacuum dryer / drying chamber ISVE ES 5 / NEW

New machine, delivery time 120 days

Construction features: AISI-304 stainless steel, partially insulated

External diameter: 1600 mm

Length of cylindrical part: 5000 mm

Dryer length: 5900 mm

Dryer total length plus sliding guides: 11000 mm

Max. operating vacuum: -730 mm Hg

Timber pile length: 5000 mm

Timber pile width: 1100 mm

Timber pile height: 990 mm

Itsdpfx Aevc Axpjg Usb

Net wood volume: approx. 5 m3

Installed electrical power: 16,01 kW

Average hourly power input: 8 kW/h

Includes:

- 12 electric heating plates (each 1100 x 5000 x 10 mm LWH / 57 kg / 1,25 kW)

- 2 internal condensers (turbofan of 0,55 kW each 380 VCa with stainless steel pipes)

- 1 one-way valve (clapet: one ¾” for vacuum circuit)

- 1 solenoid air return valve (24 Vca: one 1” for the autoclave)

- 1 manual air return (1” ball valve)

- 1 electrical control panel (PLC type Siemens S7-1200, with touch panel)

- 1 ISVE server connect with remote service and control

- 2 wireless moisture probes (double probes for core and surface moisture reading)

- 1 wireless temperature probe (for wood core reading)

- 2 plates-holder stands

- 1 instruction booklet (in English with CE certificate and wiring diagrams)

Transport dimensions approx. 5900 x 1620 x 2300 mm LWH

Weight approx. 2900 kg

Technical details, year of construction and scope of delivery according to the manufacturer, without guarantee

Subject to prior sale

New machines are covered by the manufacturer's warranty

Images and videos serve as examples and do not represent the actual scope of delivery

Terms of payment: Prices plus VAT, payment before collection or dispatch

Terms of delivery: ex location

Listing

Lemgo-Lieme

Lemgo-Lieme

1,158 km

Flatbed truck

MANTGX 33.520 6x6 BL Pritsche Kran Fassi F235A.2.24

Call

Condition: new, power: 382 kW (519.37 HP), fuel type: diesel, overall weight: 33,000 kg, axle configuration: 3 axles, brakes: retarder, color: white, gearing type: automatic, Equipment: ABS, air conditioning, all wheel drive, crane, electronic stability program (ESP), navigation system, parking heater, Internal reference for customer inquiries: 4-093

---- Wheelbase 4,200 mm 6x6 !!! ALL-WHEEL DRIVE !!! !! IMMEDIATELY AVAILABLE FROM STOCK !! ----

EURO 6E !! Cab type TM: the comfortable option (narrow, long, medium-high)

* 6x6 all-wheel drive

* Suspension type: leaf/air (BL)

* Main wheelbase 4,200 mm, 1,400 mm distance between rear axles

* MAN D2676 LF78 diesel engine, 520 hp output, 2,600 Nm torque, Euro 6e

* MAN TipMatic 12.28 OD automatic transmission with Retarder 35

* Retarder Eco, speed-dependent, multi-level, energy-efficient

* MAN EVBec high-performance engine brake, multi-level

* Differential locks: front, rear, and centre of the driven rear axles

* Trailer coupling: ROCKINGER Type 500 G 6A (or 40 mm on request)

* MAN EasyControl control panel with 4 functions, operable from the outside with the door open

* Driver comfort seat, air-suspended, with lumbar support, shoulder adaptation, and seat heating

* Multifunction leather steering wheel, height and tilt adjustable

* Lower bunk with slatted frame and adjustable head section

* Electric sunblind for windscreen (interior)

* Pull-out refrigerator and drawer

* MAN SmartSelect infotainment controller with touchpad and direct access

* MAN Mediasystem Navigation Professional 12.3-inch

* MAN Soundsystem Advanced with subwoofer

* Smartphone integration

Body: Flatbed dimensions 5800 x 2480 x 800 mm, sideboards split (2 drop-sides) per side, with sideboard relief. The floor panel is standard, made of bonded, Finnish multilayer wood, 30 mm thick, screwed to the galvanized outer frame (perforated at 45°) and cross-members. Edges are sealed against moisture ingress.

* Central tie rail inset in the direction of travel

* 4 work lights

* 2 stainless steel toolboxes, mounted after the 3rd axle, one on each side (right and left)

Fassi F235 Loader Crane:

* F235A.2.4 e-dynamic, 4 hydraulic extensions

* Lifting capacity at 12.7 m: 1,345 kg

* Slew angle: 400°

* Double linkage system with PROL1NK (over-bending knuckle by up to 15°)

* Electronic overload protection with FX500

* Fassi RCS Maxi radio remote – 6 functions with 3 joysticks (2-2-2) (Alternative linear control available in stock)

* Emergency stop, optical alert (90% and 100%), including adjustable digital swing limitation

* FASSI stability control FSC incl. LMB II

* Control system for 2 auxiliary functions with 2 hose guides for e.g. grapple or grab (5th & 6th hydraulic circuit)

* Manual extensions for 5th and 6th extension possible at extra cost

Financing / hire purchase as well as leasing / partial amortization leasing available through our leasing partner.

Itodpfx Aexvb Rteg Ueb

For further questions, our sales team will be happy to assist you.

This is a non-binding offer. Subject to prior sale, errors and changes.

Listing

Vincennes

Vincennes

901 km

Manual Dough Resting Device RP-31

SALVARP-31

Call

Condition: new, -Dimensions (A x B x C): 1610 x 1272 x 1392 mm

-Max. dough piece weight: 700 g

-Number of compartments: 31

Itodpfxjxv R Rcj Ag Ujb

-Part No.: 7309535

-Ball capacity per compartment: 8

-Total ball capacity: 248

-Power: 0.37 kW

-Voltage: 400 V

-Frequency: 50 Hz - 1.06 A

-Weight: 380 kg

The RP manual intermediate prover is a resting chamber for dough, loaded and unloaded manually, which allows the dough to relax for the necessary time after dividing and before final shaping.

During resting time in the RP manual chamber, the dough balls ferment gently and gain some volume, which enables them to become more supple and easier to shape.

This chamber is specially designed for artisan bakers who want to optimally preserve their dough’s quality.

Standard baskets can hold pieces up to 650 g.

Optional germicidal treatment available for enhanced hygiene.

DURABILITY:

-Painted steel frame provides great rigidity to the chamber. An oversized chain is used for the 'large wheel' of the proving nests to extend the service life of the chamber.

-Smooth gear operation ensures extremely quiet machine performance.

VERSATILITY:

-Equipped with electrical sockets for a moulder and divider, allowing for integrated workflows.

-Manual left/right control button available, with a highly ergonomic hands-free control option.

HYGIENE:

-Proving nests made from polyester to prevent moisture buildup.

Iedcvyqoxv R Rcsi Aobd

-Optional integration of a germicidal lamp.

The listing was translated automatically. Translation errors are possible.

Listing

Rösrath

Rösrath

1,086 km

Vibrating conveyor trough

CyrusSRU 1200x5000 - EG

Call

Year of construction: 2015, condition: used, functionality: fully functional, machine/vehicle number: 1412016.02, SRU 1200x5000-EG-A-UK

Vibratory Conveyor Trough 1200 x 5000 mm

Original purchase price: €81,600

Negotiable

Original invoice available

Conveyed material: Metal mix, steel scrap

Itodexy Rqdopfx Ag Ujb

Capacity: approx. 15 t/h

Bulk density: 0.5 – 0.6 t/m³

Grain size: typically approx. 0 – 300 mm (~90%), max. 850 mm diagonal dimension

Moisture: dry, free-flowing and easy to convey, not cohesive

Temperature: cold

Application: Feeding material onto the vibratory trough

Trough width: 1200 mm

Trough length: 5000 mm

Trough height: 250 mm

Inclination: horizontal

Mounting: on hollow rubber springs

Vibration-resistant steel construction, consisting of:

the trough body, 6 mm thick, grade R St 37-2 with reinforcements

bolted exciter console, stress-relieved annealed and machined

bolted special discharge with flanged collar incl. 2 outlets approx. 600 mm wide

the bolted wear liners for base and sides, 8 or 6 mm thick, made from wear-resistant special steel (e.g., Hardox 450 or similar)

two steps: 1st step approx. 400 mm high after approx. 1,500 mm of conveying length; 2nd step approx. 200 mm high after an additional approx. 1,250 mm of conveying length

acceleration sensor

hollow rubber springs

supporting structure for a trough bottom height of approx. 1,800 mm

Drive:

2 vibration motors, 400 V, 50 Hz, IP 65, rated power approx. 2 x 7.5 kW = approx. 15.0 kW at 960 rpm.

The amplitude can be infinitely adjusted when at a standstill.

Equipped with PTC thermistors for temperature monitoring in frequency inverter operation

Drive arrangement: underneath, within horizontal profile

Permissible ambient temperature: -20 to +40°C

This vibratory conveyor trough is used and sold in its current condition, with any and all warranties excluded. The buyer has had the opportunity to inspect the item thoroughly.

Trust Seal

Dealers certified through Machineseeker

Listing

Seevetal

Seevetal

1,208 km

Piston compressor

HoKuTechhoku 119-90

Call

Condition: new, machine/vehicle number: 691340002, hoku 119-90 – 2-stage compression mobile piston compressor

Itjdpfx Ajvl Ev Asg Usb

The universal one with V-belt drive and high-quality equipment,

especially suitable for tradesmen, for use where quality of compressed air

as well as durability and efficiency are essential, long service life thanks to

high-performance units with low speed, safe transport and

excellent stability thanks to large wheels with parking brake, optimal cooling

thanks to large fan wheel, aftercooler with cooling fins ensures a low

boiler inlet temperature and thus less moisture in the compressed air,

better efficiency thanks to optimized units, standard

with Condor pressure switch, pressure gauge, pressure reducer with water separator

and quick coupling, motor with overload protection

Technical data:

Suction capacity 674 l/min., filling capacity 505 l/min., maximum pressure 10 bar,

tank capacity 90 l, cylinders/stages 2/2, speed 920 min-1 ,

Engine power 4 kW / 400 V

from the Seevetal location,

without transport, as seen,

subject to prior sale.

Listing

Seevetal

Seevetal

1,208 km

Piston compressor

HoKuTechhoku113-90

Call

Condition: new, Year of construction: 2024, machine/vehicle number: 6913390001, hoku 113-90 – Solid tradesman compressors with V-belt drive

and 2-cylinder high-performance unit made of gray cast iron

The universal one with V-belt drive and high-quality equipment,

especially suitable for tradesmen, for use where quality of compressed air

Itsdpsvl Euxsfx Ag Usb

as well as durability and efficiency are essential, long service life thanks to

high-performance units with low speed, safe transport and

excellent stability thanks to large wheels with parking brake, optimal cooling

thanks to large fan wheel, aftercooler with cooling fins ensures a low

boiler inlet temperature and thus less moisture in the compressed air,

better efficiency thanks to optimized units, standard

with Condor pressure switch, pressure gauge, pressure reducer with water separator

and quick coupling, motor with overload protection

Technical data:

Suction capacity 500 l/min., filling capacity 375 l/min., maximum pressure 10 bar,

tank capacity 90 l, cylinders/stages 2/1, speed 1,300 min-1,

engine power 3 kW / 400 V

from the Seevetal location,

without transport, as seen,

subject to prior sale.

Listing

Budapest

Budapest

2,039 km

APM500/30 Compact Pellet line

Arth-Pax LtdAPM 500/30 Compact

Call

Condition: new, Year of construction: 2025, functionality: fully functional, machine/vehicle number: 500/30, type of input current: three-phase, overall weight: 2,400 kg, power: 64 kW (87.02 HP), We offer a complete solution for recycling waste materials/by-products with our APM/500/30 Compact pellet line.

With this, you can convert waste materials into various usable products, such as: fire pellets, feed pellets, poultry litter, manure pellets. etc.

We have more than 20 years of experience in this industry. This machine is a mature technology that allows you to work quickly and efficiently, we produce all its parts ourselves and the supply of parts is continuous.

We are a European Union company. We have production lines in Canada, the Netherlands, Belgium, Poland, Hungary, Slovakia, Romania. We can manufacture machines according to all relevant CE, UL, CLA standards, upon request

Iedpfxjht U Hxe Ag Uetb

We have resellers in Canada and Belgium

For production, you can use, for example, sawdust, alfalfa, straw, sunflower seed hay, etc.

The maximum moisture content of the raw material for pellet production is 15%

The advertised APM 500/30 compact pellet line includes the following units and can produce 0.5 T/h pellets:

1. Hammer mill

2. Conditioner,

3. Pellet press,

4. Pellet cooler,

5. Big-bag packaging unit

6. Automatic control cabinet

7. Conveyor belts.

The price is 68,000 euros

We also have 1 ton/h pellet lines for 123,000 euros called APM 500/30 Compact Tandem, and the APM 500/30 Compact can also be expanded later on if needed

The pellet line is ready for use within 2-3 hours after delivery!

If you are interested in the equipment, write an e-mail or call us

Listing

Siedlce

Siedlce

2,045 km

Compressed Air-Dryer 2800l/m

CORMAKIzberg N20S

Call

Year of construction: 2025, condition: new, The purpose of a compressed air refrigerant dryer is to lower the temperature of the compressed air and remove water and oil particles contained in the air flow. Refrigerant dryers are important in applications where moist air could cause corrosion, contamination or damage to tools, machinery or products. By removing moisture, the dryer increases the reliability and durability of compressed air systems.

The refrigerant dryer is designed for maximum efficiency and durability. The main design elements include:

1. Air-to-air heat exchanger

In the first stage of the process, the inlet air passes through a heat exchanger, where it is pre-cooled by the cooler air leaving the evaporator. By using countercurrent flow, heat recovery increases the energy efficiency of the entire system.

2. Refrigeration system evaporator

In the second stage, the compressed air is fed to the evaporator, where it is cooled to a dew point temperature of 3°C. This results in the condensation of water vapor and oil particles contained in it. 3. Condensate separator

After cooling, the gas and condensate mixture goes to an efficient separator, where the condensate is separated and automatically drained outside the device.

4. Fan control system

The variable speed fan technology allows intelligent adjustment of the cooling intensity to the actual demand, which reduces energy consumption and increases the service life of the components.

Technical parameters

Inlet/outlet pipe diameter (BSP) 1"

Maximum operating pressure 10 bar

Maximum inlet air temperature ≤ 38°C

Dew point temperature 3°C

Efficiency 2800 l/min

Power 0.58 kW

Supply voltage 230 V

Dimensions (L x W x H) 420 x 700 x 690 mm

Isdsmt Dcfspfx Ag Ustb

Weight 37 kg

Type and amount of refrigerant R134a, 550 g

We make it easier for you to find: "moisture"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Moisture (276)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you