Used Edge Gluing Machine for sale (84,298)

Nattheim

Nattheim Edge banding machine

Holz HerUno 1302

Tauberbischofsheim

Tauberbischofsheim Edge planing machine Kölle AH50

KölleAH50

Iserlohn

Iserlohn Multi-edge milling machine

WITTEMKF 1001

+44 20 806 810 84

Saint-Nicolas-de-Redon

Saint-Nicolas-de-Redon Edge banding machine (spindle moulders)

SCMOLIMPIC K360

Langenfeld (Rheinland)

Langenfeld (Rheinland) Edge banding machine

HebrockAKV 3005 DKF

Discover more used machines

Germany

Germany Edge banding machine

Holz-HerArcus 1334

Nattheim

Nattheim Edge banding machine with joining

SCMME 40 TR

Aalen

Aalen Edge banding machine

SudhoffV 30

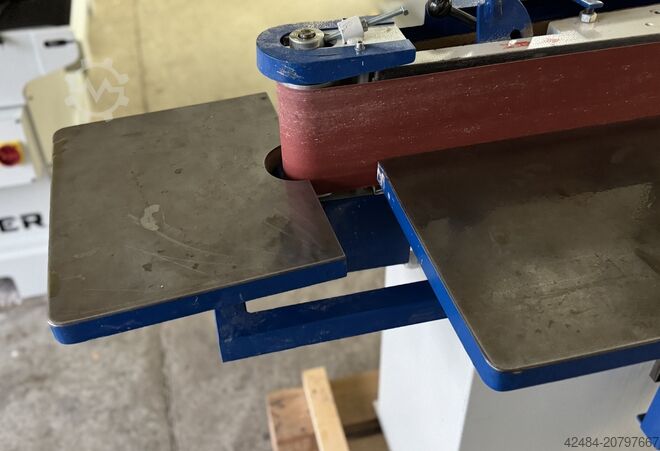

Dornstetten

Dornstetten Edge sanding machine

ComandulliMusa Next

Eich

Eich Veneer gluing machine

Fisher+Rückle AGOmnimaster-900

Mutterstadt

Mutterstadt Profile edge grinding machine

MontresorLuna 740

Germany

Germany Edge banding machine

HebrockAKV 2000 DK

Nattheim

Nattheim Edge banding machine

HebrockAKV 2000 DK

Egenhofen

Egenhofen Edge sanding machine

RehnenJunior R1

Germany

Germany Folding box gluing machine automatic

EternaEfold 1100 Elite

Tauberbischofsheim

Tauberbischofsheim Edge banding machine Hebrock EURO 3001

HebrockEURO 3001

Oberaurach

Oberaurach HOMAG edge banding machine with ZHR05

HOMAGKAL210

Germany

Germany Edge sanding machine

WegomaKS 2640

Enschede

Enschede Folding and gluing machine

ZH-500

Boxmeer

Boxmeer Edge milling machine

FacettestarEF Kantenfrees

Heede

Heede Edge banding machine

HEBROCKF4

Tauberbischofsheim

Tauberbischofsheim Edge planing machine Penika

Penika

Neuhausen

Neuhausen Edge banding machine

Karl TränkleinKAM II - OB - 60

Germany

Germany Veneer gluing machine

HaugFZZ 70

Neuhausen

Neuhausen Edge banding machine

Karl TränkleinKAM II - 60

Used Edge Gluing Machine (84,298)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84