Used Cnc Turning Centre for sale (16,694)

Dieburg

Dieburg CNC turn-mill center

GILDEMEISTERCTX 420

Dieburg

Dieburg CNC turn-mill center

GILDEMEISTERTwin 500 GMX

Velbert

Velbert CNC turning and milling center

DMG MORICLX 450 TC

+44 20 806 810 84

Root

Root CNC turning and milling center

EMCO TURNE65

Schweiz

Schweiz CNC Turning & milling machine

GILDEMEISTERTwin 42-II

Discover more used machines

Hattingen

Hattingen CNC Turning- and Milling Center

SPINNERTTS 65 Triplex

Dreieich

Dreieich CNC Turning- and Milling Center

HWACHEONHi-Tech 200 B I

Germany

Germany CNC Turning- and Milling Center

PFIFFNER-MANURHINKMX-XL32

Germany

Germany CNC Turning- and Milling Center

INDEXG300

Hilden

Hilden CNC Turning- and Milling Center

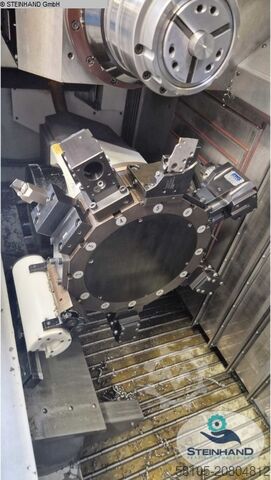

NILES-SIMMONSN20-2 MC

France

France Turn-Mill Centre

NAKAMURATome WT150 II

Lüdenscheid

Lüdenscheid CNC turn-mill center

BIGLIAB 470 YSM

Germany

Germany CNC Turning- and Milling Center

NILES-SIMMONSN30 - 3MC-2500

Payerne

Payerne CNC turning and milling center

DMG MORILASERTEC 20 PrecisionTool

Bremen

Bremen CNC turning and milling center

TRAUBTNX 65/42 DGY

Bremen

Bremen CNC turning and milling center

TRAUBTNA 480

Haut-Mauco

Haut-Mauco CNC turning and milling center

CMZTA-20-YT

Germany

Germany CNC Turning- and Milling Center

EMAGVLC 800 MT

Zevenbergen

Zevenbergen CNC Horizontal Machining Centre

MazakHCNexus 5000-ll

Sheffield

Sheffield CNC turning and milling center

TakisawaTM3000Y2

Sheffield

Sheffield CNC turning and milling center

TakisawaTM4000Y2

Rietheim-Weilheim

Rietheim-Weilheim CNC turn-mill center

Doosan PumaST20G

Belgium

Belgium CNC Machine Centres With Pod And Rail

BIESSEROVER A 4.55 K2

Germany

Germany CNC turn-mill center

GildemeisterCTX beta 1250 4 A

Hessen

Hessen CNC turning and milling center

EMCOHYPERTURN 65-1300 (SM2Y2)

Used Cnc Turning Centre (16,694)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84