Used cNC-processing machines for sale (772)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Düsseldorf

Düsseldorf

1,043 km

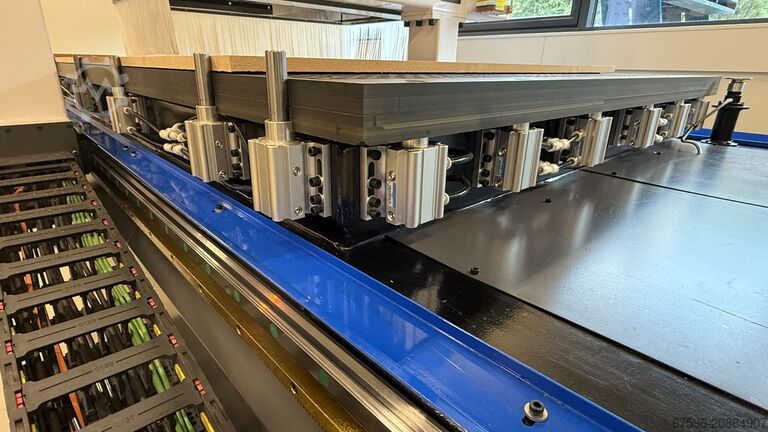

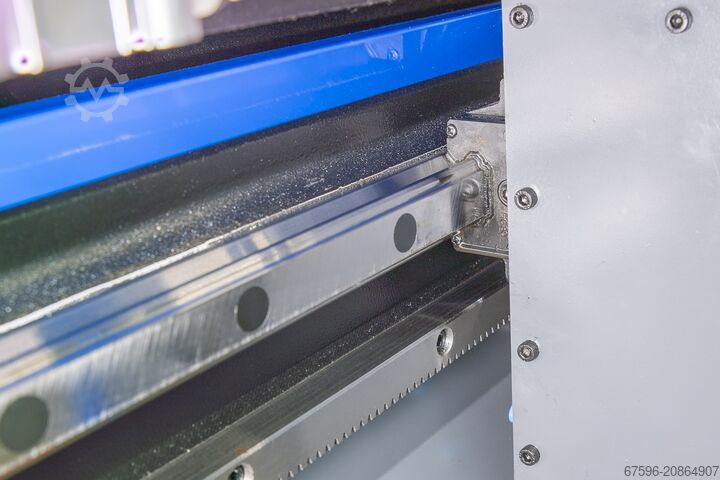

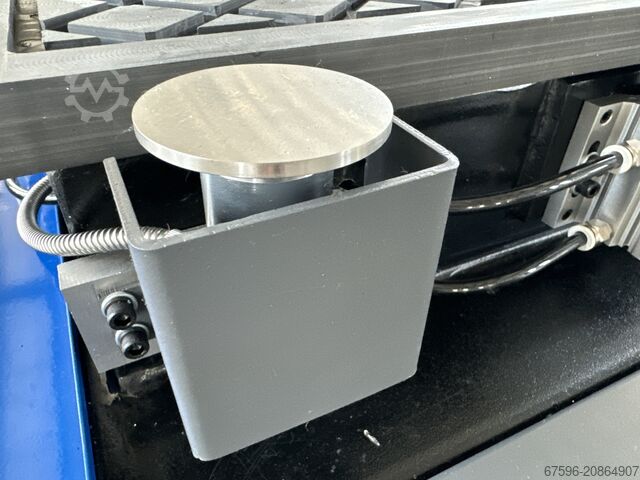

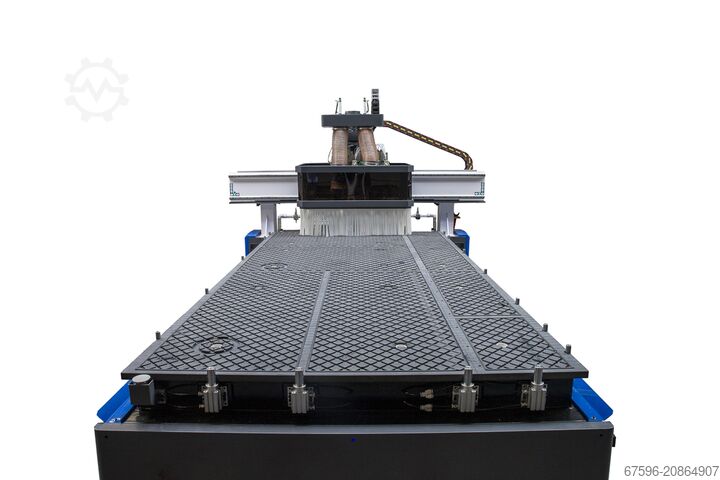

Machining center

Format4PROFIT H20

Call

Condition: used, Year of construction: 2009, operating hours: 5,600 h, functionality: unexamined, travel distance X-axis: 3,550 mm, travel distance Y-axis: 1,680 mm, travel distance Z-axis: 275 mm, total height: 2,340 mm, total length: 5,900 mm, total width: 4,020 mm, rotational speed (max.): 24,000 rpm, overall weight: 3,350 kg, spindle speed (min.): 6,000 rpm, number of spindles: 20, input voltage: 400 V, Equipment:

- Linear tool changer with 8 positions, traveling with the gantry

- Lateral pick-up station for 2 tools

- Traveling pick-up station for HSK F63 aggregate/tool

- 14 vertical drilling spindles (9 in X-direction, 5 in Y-direction)

- 6 horizontal drilling spindles (4 in X-direction, 2 in Y-direction)

- 1 grooving saw (4-10 mm), arranged along the X-axis

- 1 main spindle HSK F-63, 9 kW, 0-24,000 rpm

Fedpfjx Swp Tox Adaspb

- Preparation for 0-360° C-axis

- 6 consoles for vacuum clamp holders

- Traveling laser for vacuum cup positioning

- 2 processing zones for pendulum operation

- Handheld terminal

- Automatic central lubrication

- Working dimensions X/Y/Z: 3,060/1,210*/100 mm

- Travel path X/Y/Z: 3,550/1,680/275 mm

- Rapid traverse rates X/Y/Z: 80/80/25 m/min

*1,260 for the rear reference row

- Installation dimensions LxWxH: 5,900 x 4,020 x 2,340 mm

- Extraction port diameter: 200 mm

- Weight approx. 3,350 kg

All information is subject to confirmation based on the actual equipment.

The machine was in daily operation until August 2025, after which it was replaced with a new one and is now stored dismantled at our warehouse in Düsseldorf. The sale is made as-is, untested, and without any warranty.

Listing

Willroth

Willroth

1,124 km

Machining center

SCMTech Z 5

Call

Condition: excellent (used), Year of construction: 2017, functionality: fully functional, Used CNC from business closure. SCM Tech Z 5 - year: 2017 - 5-axis - drilling head - immediately available

Fpsdpfxex Tcv Is Adasb

Listing

Almelo

Almelo

1,002 km

Machining center

DMA MACHINERY-ROUTERSEXPRESS1326-ATC

Call

Condition: new, Year of construction: 2026, functionality: fully functional, travel distance X-axis: 2,600 mm, travel distance Y-axis: 1,300 mm, travel distance Z-axis: 200 mm, rapid traverse X-axis: 40 m/min, rapid traverse Y-axis: 40 m/min, rapid traverse Z-axis: 15 m/min, workpiece height (max.): 350 mm, total length: 3,500 mm, total width: 2,100 mm, rotational speed (min.): 1,000 rpm, rotational speed (max.): 24,000 rpm, overall weight: 2,460 kg, input voltage: 400 V, Equipment: chip conveyor, documentation/manual, rotational speed infinitely variable, CNC Nesting Machine

The EXPRESS-ROUTER CNC milling machine is the new customized machining center for those who demand precision and reliability. Designed and assembled in the Netherlands according to the strictest European standards. This machine is built for small and medium-sized businesses.

With a robust welded steel chassis, servo drive, automatic tool changer, and smart software integration, this is the ideal solution for everything from cabinet making to complex 3D relief machining.

Why DMA MACHINERY

- Price & Quality

- Minimal floor space required

- Complies with the latest European Machinery Regulation (EU)2023/1230

- CNC Gantry Router

- Suitable for processing: wood, plastic, aluminum, acrylic, foam, plastic, …etc

- Unlimited possibilities

- No licenses required

- CadCam software Pegasuds (see videos)

- 1 year online helpdesk support

Fpsdjx R D Rnopfx Adajb

CNC Machines: Fairly priced, for the skilled professional who can do it themselves.

Pay for steel, not for service. Our CNCs for the smart, self-reliant entrepreneur.

Focus on functionality: Your machine, your control, our lowest price.

Choose to do it yourself and save tens of thousands of euros on your new CNC machine.

The power of CNC without overhead costs. For professionals with technical knowledge.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Switzerland

Switzerland

1,381 km

CNC Machine Centres With Pod And Rail

BIESSEROVER A S 1325 UTS

Call

Condition: used, machine/vehicle number: 008359, X axis working area: 2500 mm

Fodpsx Swcasfx Adaepb

Y axis working area: 1320 mm

Working Table: Pod and Rail

Main Electrospindle power: 13 KW

Number of controlled axes: 4 axes

Total number of drilling spindles: 16

Total number of tool changer positions: 22

Listing

Switzerland

Switzerland

1,192 km

IMA BIMA 310 120/300

IMABIMA 310 120/300

Call

Condition: ready for operation (used), Year of construction: 1999, travel distance X-axis: 3,000 mm, travel distance Y-axis: 1,000 mm, controller manufacturer: SIEMENS, overall weight: 5,000 kg, spindle speed (max.): 9,000 rpm, spindle motor power: 12,000 W, number of axes: 3, This 3-axis IMA BIMA 310 120/300 CNC Wood Machining Centre was manufactured in 1999. If you are looking to get high-quality woodworking capabilities, consider the IMA BIMA 310 120/300 machine we have for sale. Contact us for more information.

Additional equipment

• 1 vertical drilling unit in Y Direction

• 1 vertical drilling unit in X Direction

• 1 main spindle with programmable direction of rotation

• 1 centrally integrated CNC axis rotating 360 degrees

• 1 adapter unit saw, fixed at 90 degrees

• Saw blade diameter: 200 mm

• 1 adapter unit horizontal drilling and milling head (cross head)

• 1 adapter unit horizontal milling cutter (face milling)

• 2x adapter units for hinge drilling

• Includes 1 new Siemens vacuum pump + numerous accessories

Machine Benefits

Technical Machine Benefits

• Max. Clamping height from top edge of the suction plate: z1 100 mm

• Working height: 950 mm

• Path operation speed: 20 m/min

• Acceleration: 5 m/s²

• Changing field area without pendulum machining: x 2 x 1400 mm

• Free space in the middle: x 200 mm

• With pendulum machining: x 2 x 900 mm

• Free space in the middle: x 1200 mm

• Tool feed: automatic

• Feed force: 11000 n

Extra Information

Fpedpfxsx N Ulms Adaob

Media

Extraction standard: Connection for 200 mm, 120 mm, and 100 mm diameter

Extraction speed: Approx. 28 m/sec

Extraction volume: Approx. 3200 m³ per hour

1 vacuum pump 40 m³/h

Compressed air: Central connection for 1/2" with maintenance unit. Air pressure 6 bar constant

Electrical Equipment

Electrical installation according to EN

Control cabinet dimensions (HxWxD): 2000 mm / 1200 mm / 600 mm

Safety and protection measures according to CE regulations

Discover more used machines

Listing

Bitburg

Bitburg

1,087 km

Machining center

SCM MorbidelliM 100

Call

Condition: excellent (used), Year of construction: 2018, MORBIDELLI M100 CNC Machining Center

Working Area X-Y: 3,110 x 1,320 mm

Max. workpiece height above suction cups: Z180 mm

Technical Data

Working range X axis: 3,110 mm *

Working range Y axis: 1,320 mm *

Panel passage Y: 1,600 mm

Panel passage Z: 180 mm

Workpiece length for pendulum operation: 1,400 + 1,400 mm

Travel speed of X-Y axes:

PRO-SPACE: 56 m/min (184 ft/min)

Travel speed of X-Y axes:

PRO-SPEED: 78 m/min (256 ft/min)

PRO-SPACE Safety Devices 1

Enables the machine to be installed without perimeter safety fencing, thereby reducing space requirements.

The safety devices are mounted directly to the machine frame.

Max. X-axis speed = 25 m/min.

63.03.73 "TECPAD wired" remote control with 7" touchscreen display

Tool Changer TRB11 (configuration Y=1,320)

Tool Changer FAST14

1 vacuum pump, capacity 250/300 m³/h at 50/60 Hz

F31LTC drilling unit

The F31LTC drilling head is equipped as follows:

Connection for vertical and horizontal drills Ø 10 mm, WELDON type (max drill length = 70 mm)

Distance between spindles: 32 mm

21 vertical spindles, selectable independently

5 horizontal drill heads with dual output (one on each side), 3 in X direction and 2 in Y direction

Drill spindle speed: 4,500 rpm (with optional inverter 2,500–8,000 rpm)

Fodpfx Adex Nrwgsaopb

1 integrated saw blade in X direction (max diameter 125 mm, thickness 2.2–6 mm)

Saw blade speed: 5,500 rpm

Drilling unit with inverter

Pressure booster on the Z-axis

5-axis unit, version "JQX" 10 kW

The 5-axis unit includes:

HSK 63F tool holder with double reference surface for rigid connection between taper and electrospindle

Standard electronic control of rotation speed from 1,800 to 24,000 rpm, with static inverter and quick stop function

Continuous power (S1/S6): 8.5/10 kW (11.5/13.6 HP) from 12,000 rpm

B-axis rotation: ± 185°

B-axis rotation speed: 7,000°/min

C-axis rotation: ± 320°

C-axis rotation speed: 7,000°/min

Right- and left-hand rotation programmable via NC

Internal air blast to ensure optimal tool holder coupling

Cooling system with circulating fluid and external heat exchanger

Ceramic ball bearings on main spindle

Internal pressurized air circuit to prevent contamination by dust

Surrounding extraction hood for chip removal with pneumatic ON/OFF function

Extraction hood for 5-axis electrospindle

6 "TV FLEX" worktables 1,300

Chip and waste conveyor belt for X=3,110 mm

4 loading aid devices H=75 1,300

Front stops H=75 for 6 supports

Main front reference stop

Vacuum suction cups 145x145 mm, H=75 mm – 12 pcs

Vacuum suction cups 145x55 mm, H=75 mm, rotatable – 6 pcs

Additional hardware dongle for Maestro CNC (for USB port)

High-performance PC

Location: ex works customer site

- Immediately available -

System must be dismantled by the seller

Listing

Germany

Germany

1,447 km

Throughfeed machining center

WeekeOptimat BHX 500

Call

Condition: excellent (used), Year of construction: 2009, Weeke BHX 500 – Operator Side Right

Weeke Machining Center, each with one machining support above and below

Infeed table with automatic workpiece feeding and positioning

WORKPIECE DIMENSIONS

Min. workpiece length: 200 mm

Max. workpiece length: 2,500 mm

Min. workpiece width: 70 mm

Max. workpiece width: 1,000 mm

Min. workpiece thickness: 8 mm (2*4 mm)

Max. workpiece thickness: 80 mm

Max. workpiece stacking: 2 pieces

Machine configuration:

2V21 HIGH SPEED 7500

Vertical drilling unit arranged in both upper and lower machining supports, each with 21 drilling spindles (individually controllable with variable speed range).

2H4X/1Y

Horizontal drilling unit arranged in both upper and lower machining supports, each with 10 spindles individually selectable via program.

Each with 8 drilling spindles: in X-direction

Each with 2 drilling spindles: in Y-direction

N2 X-Y 90°

Grooving saw unit arranged in both upper and lower machining supports for machining operations in the X-Y direction, swiveling 90°.

Cutting depth: 30 mm

ADDITIONAL NOTE ON GROOVING SAW BLADE

The saw blade width can be 8.4 mm. The cutting cross-section must not exceed 70 mm².

F2-ETP-6 KW

Milling unit arranged in both upper and lower machining supports, suitable for receiving shank tools.

Manual tool change.

Tool clamping: manual, Hydro quick-clamping system ETP 25

Rotation direction: right/left

Speed: 6,000 – 18,000 rpm, stepless programmable

Machining up to 3,000 mm

Infeed table with automatic workpiece feeding and positioning

Workpiece discharge area with cross belt conveyor and lifting arms

– Workpiece length measurement in the machine

Fpodpfx Adex S Hzlsaeb

– Movable operator terminal

– Barcode software incl. scanner

Listing

Willroth

Willroth

1,124 km

Machining center

MORBIDELLIM 600 F

Call

Condition: excellent (used), Year of construction: 2013, operating hours: 16,750 h, functionality: fully functional, Used MORBIDELLI M600 F

- Complete nesting cell

- Year of manufacture: 2013

- Good condition, fully functional

- Working area x=5000 / y=2120 mm

- 5-axis spindle

Fedpfxsx S Ha Is Adaspb

- Drilling head

- 2 vacuum pumps

- Automatic loading and discharge conveyor

- Available by arrangement

- (without tools)

If you have any further questions, please do not hesitate to contact us.

Listing

Almelo

Almelo

1,002 km

Machining center

DMA Machinery CNC-ROUTERSExpress-1326 ATC ( COMPACT )

Call

Condition: new, Year of construction: 2026, functionality: fully functional, travel distance X-axis: 2,600 mm, travel distance Y-axis: 1,300 mm, travel distance Z-axis: 200 mm, rapid traverse X-axis: 60 m/min, rapid traverse Y-axis: 60 m/min, rapid traverse Z-axis: 20 m/min, controller manufacturer: syntec, workpiece length (max.): 6,000 mm, workpiece width (max.): 2,100 mm, workpiece height (max.): 350 mm, total height: 2,200 mm, total length: 4,200 mm, total width: 2,100 mm, table load: 1,500 kg, rotational speed (min.): 1,000 rpm, rotational speed (max.): 24,000 rpm, overall weight: 2,800 kg, spindle mount: MK 3, number of slots in tool magazine: 10, input voltage: 400 V, type of input current: three-phase, Equipment: documentation/manual, rotational speed infinitely variable, Cost savings for the end customer: €80,000 instead of €40,000

DMA delivers high-quality CNC machines at unbeatable prices by eliminating expensive service contracts and installation visits. Ideal for professionals who want to maintain full control.

Included in the purchase price:

- CNC controller "SYNTEC"

- CNC nesting/milling CAD/CAM

- PEGASUS Professional CAD/CAM including online training/helpdesk

- Starter kit with cutting and drilling tools for CNC sheet metal processing

• Spare parts supply: In the event of a defect within 12 months, after diagnosis (photo/video), spare parts will be supplied free of charge. • Labor costs not included: You can replace the part yourself or commission an external service provider.

• Low-maintenance designs.

• Digital commissioning: Via app or TeamViewer, direct online service. This means technician visits can be avoided, saving both time and costs.

• 24/7 online support.

Fjdex Rz Auopfx Adaopb

Digital support as an alternative

• Video tutorials: Clips for calibration or parts replacement.

• Exploded diagrams: Components immediately identifiable.

Functionality in focus: Your machine, your management, our best price.

Usable working area: 3,200 x 1,600 mm (standard sizes available).

Z-axis: 200 mm.

Automatic tool changer with 9 kW router spindle.

Up to 26 spindle positions.

Row drilling unit optional. Grooving unit optional.

CadCam nesting software.

Pressure rollers (for uneven materials) optional.

Becker VTLF2.250 vacuum pump.

All axes servo-driven.

Heavy-duty CNC milling machine

Type "NESTING"

Working area: 1,300 x 2,600 mm (standard sizes available)

Z-axis: 200 mm

ATC 9 kW router spindle

Drilling unit optional

Grooving unit optional

CadCam nesting software

Pressure rollers (for uneven materials) optional

Becker VTLF2.250 vacuum pump

All axes servo-driven

Listing

Wijchen

Wijchen

961 km

CNC Horizontal Machine centers SCM Tech Z5 2014 5 Axis

SCMTech Z5

Call

Condition: used, Year of construction: 2014, Price: On request

What are Presale Items at Second Owner?

Presale items are machines that we sell in their current condition ("as-is"). We have purchased these machines based solely on photos and sell them with the information provided in the advertisement. Unfortunately, we do not have additional details, such as exact dimensions or machine specifications. Additionally, these machines are often not yet in stock and have not been inspected by us.

These machines are offered at competitive prices, which means the prices are lower than usual, but the risk lies entirely with the buyer. Please carefully review the information in the advertisement before making a purchase.

If you have any questions, feel free to contact us!

- Machine available from: 2026-03-30

- Year: 2014

- Documentation available: No

- CE certificate present: Yes

- Serial number: AA1/017825

- Number of milling spindles [pcs.]: 1

- Type milling table: Beam table

- Drilling unit present: Yes

- Tool changer positions [pcs.]: 12

- CNC documentation available: USB stick

- Table length [mm]: 5200

- Table width [mm]: 1550

Fodpfx Adox Hwhxoaopb

- Z-axis working range [mm]: 160

Financial information

VAT: The price shown is exclusive of VAT

VAT/margin: VAT deductible for entrepreneurs

Delivery and trade-in always possible for everything in the industrial sectors

Glenn Smeets

Listing

Garbsen

Garbsen

1,197 km

Machining center

HOMAGBOF311/60/F/FT

Call

Condition: good (used), Year of construction: 2004, functionality: fully functional, The complete technical description is included in the attachment as a PDF file.

Fedpjx S E Htjfx Adajpb

Listing

Bitburg

Bitburg

1,087 km

Machining center for traversing and edging

HomagGenius BAZ20/30/14/D

Call

Condition: ready for operation (used), Year of construction: 1998, Homag Processing Center Genius BAZ20/30/14/D

Electronically controlled milling and edge-banding machine, post-processing, and drilling center designed for batch production of furniture parts, solid wood, or similar materials.

Base Machine:

- Heavy-duty, stable machine bed with a compact linear guide system.

- Aggregate carrier with linear guide system, ball screw, and digital AC servo motor for Z-axis positioning, travel distance 340 mm

- Automatic central lubrication for all drives and linear guides

- Designed for the attachment of various table configurations

Control System: Wood Wop 5.0

- Enlarged Z-axis travel, 500 mm

- Extended safety step mat

- Manual through-feed table B20/30+40/…/D

- Motorized width adjustment of the longitudinal console D-table

- Chip conveyor belt for B../30+40/K

- Stop pins for laminate overhang

- Main spindle, 12 kW

- Chain tool changer, 70 positions for B20, for HSK 63 F tools

- Aggregate interface for main spindle

- Electrical/electronic interface 220/24 volt

- Edge gluing aggregate, 4 sides for main spindle

- Melting unit with granulate container

- External automatic triple edge changer

- Rack changer system for aggregates and tools

- Rabbet pressure zone for main spindle

- Flush trimming unit for tool changer

- Saw and crosscut unit for tool changer

Fedpfx Asx Nrk Hedaspb

- Boring/milling unit with 4 spindles for tool changer

- Lock case milling unit for rotary magazine

- Vertical milling unit with tracing ring

- Sanding unit with air blast nozzle

- CNC programming system Wood-Wop

- Post-processor for BAZ

- Free-standing control panel

Location: Ex works, customer site

- Immediately available -

Machine must be dismantled by the buyer.

Listing

Hilzingen-Duchtlingen

Hilzingen-Duchtlingen

1,352 km

Biesse Rover 20

BiesseRover 20

Call

Condition: excellent (used), Opportunity from Swiss liquidation in excellent condition

Fedjxhg Etepfx Adaopb

Listing

Nattheim

Nattheim

1,390 km

CNC machining center

SCMMorbidelli M100

Call

Condition: used, Year of construction: 2023, Exhibition Machine Garbsen CNC-CONTROLLED MACHINING CENTER morbidelli m100 Drilling and Milling Made for You! This numerically controlled machining center is equipped with a comprehensive range of accessories and tools for milling and drilling, enabling it to meet every requirement in the field of wood processing. Highly efficient – with drilling spindles reaching up to 8,000 rpm – and featuring technology that includes the most robust spindle available on the market, offering more than 1,000 hours of maintenance-free operation. Fully equipped – the suction cups can be individually configured with the TV FLEX worktable to adapt the machine precisely to your requirements. Easy and intuitive programming thanks to the integrated Cad-Cam MAESTRO CNC software. User-friendly operation is ensured by the lowered machine frame, which provides unrestricted access to the worktable at all times. The control cabinet and vacuum pump are integrated into the machine base, and the PRO SPACE variant requires no additional structural safety measures.

Robust Construction The supporting structure consists of an especially sturdy monolithic steel base, ribbed for stability and durability. The extra-wide bearing surface is purpose-designed to provide the machine with stability, ensuring constant precision in all working conditions. Anchoring to the floor is not required. The base forms a large, solid foundation for the moving gantry: the working unit is equipped with a balanced, stable, and resilient support, withstanding the highest stress, which ensures superior quality performance and greater accuracy. The moving gantry is a solid single piece anchored to the base, running on high-quality prismatic guides with ball bearing carriages. The working unit is mounted to this and moves along the Y and Z axes on prismatic guides with ball bearing carriages as well. Movement of the lower movable unit (X-axis) and the working unit along the gantry (Y-axis) is driven by a helical toothed rack and pinion system; this produces greater tooth-by-tooth thrust, achieving higher acceleration and increased speed on the X and Y axes. The specially designed helical gearing ensures reduced wear of mechanical components and quieter operation.

The vertical Z-axis is driven by a recirculating ball screw, providing perfect balance under dynamic load and withstanding significant acceleration and deceleration. The main milling unit is directly coupled to the Z-axis carriage, enabling superior surface finish quality as vibrations are completely eliminated. Travel along the X-Y-Z axes is achieved with brushless motors powered by static inverters. These provide:

Fodpfxsx A Dfge Adaopb

- Reduced processing times due to improved acceleration

- Increased positioning accuracy due to high-resolution encoders

- Elimination of setup tasks at machine startup thanks to absolute encoders

- Elimination of general maintenance tasks, as the brushless system has no brushes

Axis movement management and general operation of the working elements...

Listing

Almelo

Almelo

1,002 km

Machining center

CNC nesting Machine CE-DUTCH normeringCNC Best solution 3022

Call

Condition: new, Year of construction: 2026, functionality: fully functional, Cost savings for the end user €80,000 vs. €40,000

DMA supplies high-quality CNC machines at bottom prices by eliminating expensive service contracts and on-site installation visits. Ideal for professionals who prefer to remain in control themselves.

The purchase price includes:

- CNC control “SYNTEC”

Fpsdpfx Adexx Uc Uoasb

- CNC Nesting/Milling CadCam

- PEGASUS Professional CadCam including online training/helpdesk

- Starter kit of cutting and drilling tools for sheet metal machining CNC machining centers.

• Parts supply: In the event of a defect within 12 months, components will be shipped free of charge after diagnosis (photo/video).

• Excluding labor costs: Replacement of the part is done by you or outsourced at your discretion.

• Designed with minimal maintenance requirements

• Digital preparation: via app or TeamViewer for direct online service. This makes technician visits unnecessary, resulting in significant cost and time savings.

• Online service: 24/7

Digital Support as an Alternative

• Video manuals: Clips covering calibration or part replacement

• Exploded view diagrams: Instantly identify the necessary component

Focus on functionality: Your machine, your management, our lowest price.

You can call or WhatsApp us for more information and/or to make an appointment.

WhatsApp:

Auction

Auction ended

Gelderland

Gelderland

961 km

CNC machining center

EssetreTechno Wall 2165A

Condition: ready for operation (used), Year of construction: 2017, operating hours: 1,717 h, functionality: fully functional, machine/vehicle number: 904B0018, table width: 3,500 mm, table length: 14,400 mm, saw blade diameter: 1,000 mm, Equipment: CE marking, documentation/manual, TECHNICAL DETAILS

Maximum saw blade diameter: 1,000 mm

C1: 540°

B1: 250°

C2: 540°

B2: 90°

Table length: 14,400 mm

Table width: 3,500 mm

X-axis maximum travel: 5,000 mm

Y-axis maximum travel: 15,870 mm

Z-axis maximum travel: 1,000 mm

MACHINE DETAILS

Number of milling spindles: 1

Number of controlled axes: 2

5-axis unit power: 12 kW

Operating hours: 1,717 h

Main motor power: 55 kW

Fjdpfsx Hg Stex Adaepb

Voltage: 400 V

Current consumption: 130 A

Power: 65 kW

Transport dimensions (L x W x H): 40,000 mm x 2,400 mm x 2,700 mm

EQUIPMENT

Saw blade unit with flange connection

Milling unit with tool changer

Documentation

CE marking

Listing

Erdmannhausen

Erdmannhausen

1,316 km

Machining center

Hamuel ReichenbacherVision II Sprint

Call

Condition: used, Year of construction: 2006, functionality: fully functional, machine/vehicle number: 1961, controller manufacturer: Siemens, workpiece length (max.): 3,200 mm, workpiece width (max.): 1,400 mm, workpiece height (max.): 72 mm, total length: 18,300 mm, total width: 9,710 mm, number of spindles: 2, number of slots in tool magazine: 60, Retrofitted in 2016

Ready for operation

Includes stacking and unstacking gantry crane

Fodpex Ezh Tofx Adajpb

Listing

Bad Honnef

Bad Honnef

1,107 km

Frame tensioning element (WS15) HOLZ-HER - used -

Rahmenspannelement Typ H (WS15)

Call

Condition: used, Frame clamping element (WS15) HOLZ-HER - used - ATTENTION: SET price for 4 pieces! Clamping cover type O, Clamping to console via toggle switch, Opening/closing via toggle switch

Fsdpfevtrk Asx Adaepb

----- Technical data -----

Clamping range: 40 - 115 mm

Listing

Germany

Germany

1,293 km

Complete manufacturing line for bed slatted frames

Weinig Raimann Linde Koch Panhans GreconHydromat KR KS OPTICUT E14 E16 CNC

Call

Condition: used, Complete production line for the manufacture of slatted frames.

From woodworking through to final assembly and packaging.

Includes all components such as moulders, saws, profile processing, forklifts, compressors, etc.

The larger machines/plants are from around year of construction 2000.

Consisting of:

Production of solid wood rails:

- 2 x Multiblade rip saws RAIMANN KR 450 + KS 310

- Optimising cross-cut saw GRECON ILLERTISSEN OPTICUT 704R

- Four-sided planer WEINIG HYDROMAT 23

- Stacking unit

Foiling / Finishing of longitudinal rails:

- 2 x Profile wrapping machines FRIZ OPTIMA PU25-PAP

- Foil cutting machine FRIZ FSM 1500

CNC drilling and sawing units:

- KOCH CNC drilling and sawing line with turning and stacking unit

- ISE CNC drilling and sawing unit with stacking unit

- 2 x ISE CNC woodworking centres / drilling units

- ISE CNC machining centre for spring slats

- 2 x Manual slat drilling machines

Single machines:

- GANNOmat CNC drilling and dowelling machine

- Pnahans table routing machine

- 2 x EiMa double mitre saws

- SCM panel saw

- Barth frame press

- 2 x FLOTT column drilling machines

- SAMCO combination sawing and milling machine

- 2 x Multi-spindle drilling machines

- 2 x Belt sanders

- Spray booth

- Various small machines

Assembly:

- Automatic assembly machine for standard slatted frames

- Capping press / line

- 14 x Pneumatic assembly tables

Logistics – operating equipment:

- 3 x LINDE forklift trucks E16 / E20

- 7 x LINDE high-lift/ electric pallet stackers

- WEYCOR wheel loader 95E SUPER

- Atlas-Copco compressor system

- WEIMA single-shaft shredder

- Kärcher ride-on sweeper

- HONDA snow blower

- Extraction system outdoor area

- Batch of mesh boxes & Euro pallets

- Various racking systems

Packaging:

- Shrink tunnel system

- Stationary pallet wrapper

- Mobile pallet wrapper

Materials:

- Remaining stock of timber / spring slats

Fedpfx Adex S Scbeaopb

- Remaining stock of end caps / plastic parts

- Miscellaneous remaining assembly materials

Many more PHOTOS and detailed DATA available on request.

Listing

Nattheim

Nattheim

1,390 km

CNC waterjet machine

waterjet3000 x 1800

Call

Condition: used, Year of construction: 2005, Processing size: 3000 x 1600 x 180 mm High-pressure pump 60 HP / 45 kW Model E-60 Operating pressure 4,130 BAR Water consumption 4.69 liters/min. Software: Watercad-CAM Automatic cutting optimization Storage location: customer

Fodpfoxgfbqox Adajpb

Listing

Wijchen

Wijchen

961 km

CNC Horizontal Machine centers SCM Record 110 AL TVN Prisma 2006

SCMRecord 110 AL TVN Prisma

Call

Condition: used, Year of construction: 2006, Empty weight: 4.000 kg

Price: On request

What are Presale Items at Second Owner?

Presale items are machines that we sell in their current condition ("as-is"). We have purchased these machines based solely on photos and sell them with the information provided in the advertisement. Unfortunately, we do not have additional details, such as exact dimensions or machine specifications. Additionally, these machines are often not yet in stock and have not been inspected by us.

These machines are offered at competitive prices, which means the prices are lower than usual, but the risk lies entirely with the buyer. Please carefully review the information in the advertisement before making a purchase.

If you have any questions, feel free to contact us!

- Machine available from: 2026-05-25

- Year: 2006

- Documentation available: No

- CE marking present: Yes

- CE certificate present: No

- Number of milling spindles [pcs.]: 1

- └ Milling spindle 1:

- - Number of controlled axes [pcs.]: 5

- - Min. spindle speed [rpm]: 600

- - Max. spindle speed [rpm]: 20000

- - Main motor power [kW]: 11

- - C-axis present: Yes

- Type milling table: Beam table

- Tool clamping system: HSK-F63

Fpodpsx Hfiksfx Adaeb

- Drilling unit present: Yes

- └ Horizontal drill spindles [pcs.]: 6

- └ Vertical drilling spindles [pcs.]: 12

- Saw unit present: Yes

- Tool changer positions [pcs.]: 16

- System/software: Xilog plus

- Safety feature: Safety mat

- Vacuum pump present: Yes

- └ Main motor power [kW]: 5.5

- └ Capacity [m³/h]: 250

- CNC options: Offcut conveyor, Manual control

- Table length [mm]: 3050

- Table width [mm]: 1240

- Z-axis working range [mm]: 200

- X-axis maximum stroke [mm]: 3500

- Y-axis maximum stroke [mm]: 1815

- Z-axis maximum stroke [mm]: 440

- Transport weight [kg]: 4000kg

- Transport packages [pcs.]: 1

Financial information

VAT: The price shown is exclusive of VAT

VAT/margin: VAT deductible for entrepreneurs

Delivery and trade-in always possible for everything in the industrial sectors

Glenn Smeets

Trust Seal

Dealers certified through Machineseeker

Listing

Bad Honnef

Bad Honnef

1,107 km

MASTERWOOD machining center project TF 100 2.0

MasterwoodProjekt TF 100 2.0

Call

Condition: new, - Edition Partnership -

Fpjdpju Tiwvofx Adajb

With our TF 100 2.0 "Partnership Edition" we offer

CNC technology for the highest demands.

And at a sensational price.

Drilling, grooving, milling

Unique in operation and in the

"Partnership Edition" even more so in terms of features:

The TF 100 2.0, specially developed for furniture and interior

TF 100 2.0, specially developed for furniture and interior

than 5 m² production area, it can perform drilling

5 levels of the workpiece, groove sawing work

and also milling work.

The machine impresses with its extremely high

processing speed with maximum precision

and ease of operation. The

standard pre-equipment for angular gears, the optional

the optional CLAMEX and lock case milling cutters can be

can be retrofitted easily and at any time.

The TF 100 2.0 "Partnership Edition" is completely manufactured in

in our large factory in Rimini, the headquarters of

Masterwood, and is 100% "Made in Italy".

----- Technical data -----

Max. workpiece length X: unlimited,

max. workpiece length Y: 1,000 mm,

max. tool thickness Z: 60 mm,

Vertical spindles X - direction: 5 pieces,

Vertical spindles Y - direction: 5 pieces,

Horizontal double drilling spindles X - direction: 2 + 2 pieces,

Horizontal double drilling spindles Y - direction: 1 + 1 piece,

Units: 16 drill head,

Drilling spindle speed: 4,000 rpm,

Distance between drilling spindles: 32 mm,

Motor power: 1.7 kW,

Grooving saw: X - direction,

Saw blade Ø: 125 mm,

Extraction connection Ø: 150 mm,

Dimensions (LxWxH): 1,920 x 2,818 x 1,620 mm,

Weight: 1,500 kg

Listing

Wijchen

Wijchen

961 km

CNC Horizontal Machine centers Holz-her Promaster XL 7222 4XL 2014

Holz-herPromaster XL 7222 4XL

Call

Condition: used, Year of construction: 2014, operating hours: 11,517 h, Price: On request

What are Presale Items at Second Owner?

Presale items are machines that we sell in their current condition ("as-is"). We have purchased these machines based solely on photos and sell them with the information provided in the advertisement. Unfortunately, we do not have additional details, such as exact dimensions or machine specifications. Additionally, these machines are often not yet in stock and have not been inspected by us.

These machines are offered at competitive prices, which means the prices are lower than usual, but the risk lies entirely with the buyer. Please carefully review the information in the advertisement before making a purchase.

If you have any questions, feel free to contact us!

- Year: 2014

- Documentation available: No

- CE certificate present: No

- Serial number: 070614/B/1-407

- Operating hours: 11517

- Number of milling spindles [pcs.]: 1

- └ Milling spindle 1:

Fodpfx Aex E Uk Uedajpb

- - Number of controlled axes [pcs.]: 4

- - C-axis present: Yes

- Working range X [mm]: 7220

- Working range Y [mm]: 1580

- Z-axis working range [mm]: 180

Financial information

VAT: The price shown is exclusive of VAT

VAT/margin: VAT deductible for entrepreneurs

Delivery and trade-in always possible for everything in the industrial sectors

Glenn Smeets

Listing

Bad Honnef

Bad Honnef

1,107 km

Ceiling laser LAP LASER CAD-PRO -used-

LAP LASERCAD-PRO

Call

Condition: used, Ceiling Laser LAP LASER CAD-PRO - used - Retrofit kit suitable for: e.g. HOLZ-HER ProMaster, Dynestic, Epicon, incl. LAP Ethernet gateway, 4 swivelling targets with bracket ----- Technical Specifications ----- Projection color: green, Supply voltage: 24 V DC, LAP connection cable: 25 m

Fodpoxltvyjfx Adajpb

Listing

Bad Honnef

Bad Honnef

1,107 km

Machining center HOLZ-HER 7405 EVOLUTION CONNECT -exhibition machine-

Holz-Her7405 EVOLUTION CONNECT

Call

Condition: new, HOLZ-HER 7405 EVOLUTION CONNECT machining center

-Exhibition machine-

This offer is an equipment package.

The following items and options are already included in the price:

- Material support

- Height-adjustable infeed roller conveyor

- EVOLUTION diamond formatting cutter set

- CAMPUS V8 EVOLUTION CAD/CAM software

- Flat screen 21.5", 16:9

- Workpiece length measurement LASER

- Milling unit 7830

- 7887 tool changer 6-position magazine pick-up

- ECO vacuum system

- Air conditioning unit for switch cabinet cooling

- Tool changer 7874

- Angular gear 7869

- Adapter for Clamex milling cutters

Fpedpfx Adju Tid Hjasb

- Tool set - 4-axis CLAMEX

- Tool holder HSK-F 63

- Drilling unit XL 7885, 19 spindles

- Manual control unit

- Tool set - EVOLUTION for XL drilling head 7885

- new exhibition machine -

We make the search easier for you

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used cNC-processing machines (772)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

- Cnc 4 Axis Machine

- Cnc 5 Axis Machining Center

- Cnc Automatic Lathe

- Cnc Bed Type Milling Machine

- Cnc Center

- Cnc Center Lathe

- Cnc Control

- Cnc Controller

- Cnc Double Column

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month