Used Envelope To Léger for sale (165)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Bacău

Bacău

2,603 km

CNC VTL ,2 heads ,2 discmagazines

REMSCR 50 CNC 2S

Call

Condition: new, Year of construction: 2026, Vertical Turning center SCR 50 2S

Turning Center’s Specifications

Nominal Turning Envelope

Bcsdohh Dnxspfx Aa Eot

Faceplate Diameter 4.500 mm

Machining Diameter

Optional 4.700 mm – with the CE Enclosure - 5.300 mm ( without )

Machining Heights 2.100 mm /3500 mm

Work Piece Weight 30.000 kg / 50T

Nominal Turning Travels

X & U - Axis Ram Carriage

From -100 mm

To 2.600 mm

Z and W - Axis Ram 1.250 mm / 1700 mm

Faceplate Diameter

4.500 mm/Normal face plate with T-slots

Jaw chucks height 200 mm

Work Table Speed: 0-50rpm

Power Continuous S1 96 kW / 2X75kW

Torque Continuous S1 130,000 Nm / 320,000Nm

Turning main drive mechanism Gear box reducer ZF and belt transmission

Z & W - Axis Ram

Turning Ram - Left and Right side

Ram Size 250 by 250 mm or bigger

Tool holder type KM 63

Tool Storage (ATC)

No. of Tool storage 2 Tool Storage, left and right sides

Stations qty 12 stations per each tool storage

Stations type Turning toolholder

ATC turning capabilities:

Maximum Singular Tool Weight – turning toolholder

Maximum tool weight 50 kg

Maximum tool size 250 x 150 mm X 700 mm

Axes Drives

X and U - Axes Ram Carriage

Power Continuous S1 6.5 kW

Thrust Continuous S1 45,000 N

Z-Axis Ram

Power Continuous S1 6.5 kW

Thrust Continuous S1 45,000 N

Axes Rates

X, U And Z, W-Axes Feed Rates 0.02 to 6,000 mm/min

X, U And Z, W-Axes Rapid Rates 6,000 mm/min

Coolant System

Coolant Tank Capacity 2,000 L

Coolant Pressure / Flow Rate:

-external coolant (turning)

-internal

Filtration unit:

-type

-accuracy

6 bar at 100 LPM

40 bar at 60 LPM

Chips conveyor

Conveyor type Hinged (Hardox material)

Width The conveyors should have a width of 600 mm

CNC Control

-type

-producer Sienumerik One Siemens / Fanuc oiF

Listing

Burgas

Burgas

2,880 km

Industrial robot

KUKAKRC2 KR 150 2006 MODEL ROBOT

Call

Condition: excellent (used), Year of construction: 2006, load capacity: 150 kg, arm reach: 2,700 mm, The KUKA KR 150 is a 6-axis industrial robot designed for high-precision and high-speed applications. With a 150 kg payload capacity and a wide working envelope, it delivers reliable performance in tasks such as welding, assembly, handling, and machining.

Model: KR150 L130

Condition: Used

Year: 2006

Included: Manipulator + KRC2 + KCP2 Teachpendant + All Wire Sets

Bedpew Nat Ijfx Aa Eoct

Please get in touch with us for a quote and also the refurbishment options. As PLC Merkezi EOOD, we have more than 300 robots in our inventory and deal with the brands of KUKA, ABB, FANUC and Motoman.

(Source: Kuka's Website)

Listing

Leinfelden-Echterdingen

Leinfelden-Echterdingen

1,322 km

FGT Graphic Machinery - DigitalPress

XeroxVersant 3100

Call

Condition: good (used), Year of construction: 2018, Xerox Versant 3100 - 06/2018 🌟

We're excited to present a fantastic deal for this high-performance, pre-owned Xerox Versant 3100 digital printing machine! 🎉 Perfect for professional print environments, this machine is packed with essential features for efficiency and top-quality output. 📈✨

Technical Specifications and Included Features:

- 🌡 Cooling/Decurling Module: Keeps prints smooth and flat for a polished finish.

- 🎯 Full-Width Array: Achieves automatic, precise color calibration and image alignment.

- 🚀 EFI Fiery NX Controller (External): Delivers high-speed processing and enhanced color accuracy.

- 🎨 EFI ES 2000 Spectrophotometer: Ensures consistent, professional color matching.

- 📄 Dual High-Capacity Paper Trays: (2 x 2,000 sheets) for extended print runs and efficiency.

- 📏 Extended Output for XLS Format: Handles sheets up to 660 mm in length, ideal for a variety of formats.

Bjdpfeu Ik Ugox Aa Ejct

- ✉️ Envelope Kit for Paper Trays: Versatile paper handling, including envelope printing.

- 📚 Production Ready Finisher with Booklet Maker: Includes booklet-making and 2/4-hole punching.

- 🔥 Fiery FS200 Pro System: High-powered processing for demanding print jobs.

- 🎨 Graphics Art Package: Equipped with Image Viewer, Compose, and Impose tools.

- 🎛 Color Profiler Suite: For advanced color profiling and management.

Listing

Handewitt

Handewitt

1,154 km

Inserting machine

KASMailmaster 465 Hs

Call

Condition: ready for operation (used), Year of construction: 2009, 1 x KAS Papersystems 465HS 465 HS inserting machine inserting system kuver

Bcsdpfx Aajwdihls Eot

Fully functional - fully serviced every year - Printcenter tasks have been outsourced - therefore now for sale

Ready on pallets

Inspection welcome in Flensburg

Video and more photos available

B2B sale only

Listing

Alkmaar

Alkmaar

876 km

Dozen vouw en lijm machine

ROPIFK-3500

Call

Condition: used, Year of construction: 2000, Compact foldergluer machine for folding carton boxes

Able to process straightline boxes, crashlock boxes and envelopes.

Bsdexb Dabepfx Aa Eoct

Maximum feeding width 50cm, maximum feeding length 40cm.

Paperweights 120 to 400 gr/m2

Speed up to 10.000 pcs/hour

Overstock machine

Discover more used machines

Listing

Hämeenlinna

Hämeenlinna

2,116 km

Industrial robot

ABBIRB 540

Call

Condition: ready for operation (used), functionality: fully functional, BB IRB 540 & IRB 580 – Industrial Painting Robots for Sale

Available for sale: ABB IRB 540 and ABB IRB 580 industrial painting robots.

Both models are designed for high-precision, high-throughput painting applications, offering excellent reliability, repeatability, and low maintenance costs. Suitable for automotive, metal fabrication, general manufacturing, and other industries requiring automated coating processes.

ABB IRB 540 – Specifications

General

Type: Industrial painting robot

Configuration: 6-axis articulated robot

Typical Controller: ABB S4P / S4P+

Application: Painting, coating, spraying

Technical Data

Payload Capacity: 10 kg

Reach: approx. 1,600 mm

Repeatability: ±0.2 mm

Number of Axes: 6

Mounting: Floor or wall mounted

Protection Class: Designed for hazardous painting environments (Ex-rated versions available depending on configuration)

Performance

Suitable for high-speed, high-accuracy painting paths

Excellent surface quality and consistency

Wide working envelope for medium-sized components

ABB IRB 580 – Specifications

General

Type: High-speed painting robot

Configuration: 4-axis or 6-axis (depending on version)

Typical Controller: ABB IRC5P

Application: Automotive and industrial painting, powder coating, spraying

Technical Data

Bodpox Ei T Rsfx Aa Esct

Payload Capacity: 7 kg

Horizontal Reach: 2,000 mm (standard version)

Repeatability: ±0.15 mm

Number of Axes: 4 or 6

Mounting: Floor, wall, or rail-mounted options

Protection Class: Fully ATEX-compliant (depending on variant)

Performance

High-speed operation for maximum throughput

Optimized path accuracy for premium coating finish

Suitable for larger workpieces and long-stroke applications

Condition

Both robots are suitable for industrial use and provide stable operation in painting environments.

Additional accessories, controllers, and application equipment may be available on request.

Transport, packaging, and installation support can be arranged.

Note

Verify all specifications with the seller.

Listing

Aalen

Aalen

1,378 km

Sanding machine

LoewerLeistomat SD Video

Call

Condition: new, Number of sanding units 8 st.

sanding width 180 (260) mm

Sanding height max. 160 mm

Dimensions (L/W/H) 3065x1600x1900 mm

weight of the machine ca. 1500 kg

LÖWER Leistomat SD

-----

Automatic fine grinding machine for wood grinding (smoothing, defibering and

Edge breaking) or intermediate sanding of profiled window bars. With soft disc

Technology for the visible surfaces as well as automatically safe profile and

Width adjustment.

- 2 lamella roller units on the side, each 0.75kW, L=120mm, D=200mm

1 softisc unit Ø=200mm above 0.75kW,

1 slat roller unit L=200mm top 0.75kW,

1 soft disc unit Ø=200mm bottom 0.75kW,

1 slat roller unit L=200mm bottom 0.75kW,

2 lamella roller units on the side, each 0.75kW, L=120mm, D=200mm

- Linear guidance of all grinding units

Linear ball bearing sets on hardened shafts

- time-controlled immersion of all lamella roller units

directly above the incoming workpiece edges. By the

It is possible to immerse the aggregates deeper into the profiles

to be able to deliver.

- Motorized workpiece thickness adjustment of the machine

- variable grinding flap speed via frequency converter

for adjusting the grinding intensity using frequency converters

(separate for discs, surface rollers and side rollers)

- Disc aggregates as soft discs with Velcro fastener for

Grinding wheels (wood pulp)

- Feed via three lower and one upper conveyor belts and

Spring-loaded pressure rollers with infinitely variable speed 4-15m/min

Bcedsvnv Uhopfx Aa Eot

- Parameters that can be set using the touch panel are workpiece thickness,

Workpiece width (left side units individually), immersion depth

Side units, spindle speed, feed speed

- Saving the parameters as machine programs in program mode

- Working in automatic mode with non-contact

Workpiece width detection and profile detection as well as automatic

Adjustment of the sanding units to the workpiece width and the

Profile shape (workpiece height is set in advance)

- pneumatically clocked driven feed roller, automatic

Clamping of the workpiece and feeding in after unit adjustment

- Red/green indicator lights to indicate operational readiness

- shortest workpiece length 380mm

- Transport belt width 200mm

- max. workpiece width 180mm (260mm in the envelope process)

- Workpiece height 12-160mm

- Suction connection 4 x 100mm and 2x80mm diameter

- Sensor-controlled tool blow-off directly on the discs

- Length (case) x width x height (mm): 3065x 1600 x 1900

Complete length: 4365mm (including roller conveyor with integrated

workpiece width detection)

- Weight: 1500kg

- Operating voltage 400V, 50Hz, 3P, air connection 6 bar

- CE version

-----

Price of the above machine on request!

-----

Special accessories with additional costs:

Set of replacement slats for Leistomat SD-200

consisting of

Area aggregates:

30 strips EH45 / 200 - 7 (rolls)

30 strips EH45 / 200 - 20 (rolls)

Folding units:

96 strips M55 / 120 - 4

SmartFlex slat disc Ø200 solid

with 30 grooves 50mm long

Set of replacement slats for SmartFlex slat disc

consisting of

60 strip M35 / 50 K 180-7 p

Sandpaper disc VB for soft disc

D=200mm grit 220

with velor backing (Velcro), pack of 100.

Sandpaper disc VB for soft disc

D=200mm grit 280

with velor backing (Velcro), pack of 100.

-----

Price of the above-mentioned special accessories on request!

-----...

Listing

Lauda-Königshofen

Lauda-Königshofen

1,312 km

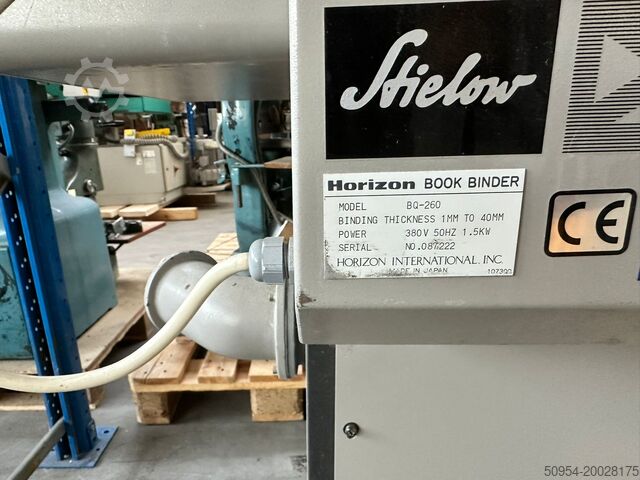

Adhesive Binder

HorizonHorizon BQ-260

Call

Condition: good (used), machine/vehicle number: 087222, Horizon Perfect Binder BQ-260, 1 station, hotmelt glue, envelope feeder, machine number 087222, in good condition, immediately available.

If interested, we are happy to provide information on further machines available at our facility.

Bcjdpfexdh Etsx Aa Eet

You are welcome to view the machine at our premises by appointment.

Listing

Nowy Sącz

Nowy Sącz

2,033 km

Vertical machining center

HARTFORDVMC 1270 S

Call

Condition: excellent (used), Year of construction: 2004, functionality: fully functional, travel distance Y-axis: 600 mm, feed length X-axis: 1,270 mm, feed length Y-axis: 635 mm, feed length Z-axis: 515 mm, controller model: Heidenhein ITNC 530, total height: 2,750 mm, total length: 4,200 mm, total width: 2,700 mm, table width: 600 mm, table length: 1,370 mm, overall weight: 7,000 kg, spindle speed (max.): 8,000 rpm, The Hartford VMC 1270 S Vertical Machining Centre from 2004 is a robust and precise machine made in Taiwan, designed for three-axis machining operations. This model offers a generous working envelope with travels of 1270 mm on the X-axis, 635 mm on the Y-axis, and 515 mm on the Z-axis. Control is handled by the reliable Heidenhain system, ensuring stable operation and convenient programming.

The machine is equipped with a table measuring 1370 × 600 mm, allowing workpieces of up to 950 kg to be mounted. The spindle reaches speeds of approximately 8000 rpm, providing solid performance for most applications. The machining centre features a 20-position tool magazine and automatic tool changer, significantly speeding up operations and enabling more complex machining processes.

Bcsdpfx Ajx Daxxoa Eet

The construction of the machine is exceptionally stable—the total weight of around 7000 kg translates into high rigidity and machining accuracy. A chip conveyor is also included, facilitating cleanliness and uninterrupted operation.

Technical specifications for HARTFORD VMC 1270 S:

Operating time: 7,600 hours

Control: Heidenhain

Table dimensions: 1370 × 600 mm

Maximum table load: 950 kg

Travel X/Y/Z: 1270 / 635 / 515 mm

Rapid traverse X/Y/Z: 20 m/min

Spindle speed: approx. 8000 rpm

Tool magazine: 20 positions

Automatic tool changer

Chip conveyor

Power requirement: 29 kVA

Machine dimensions (L×W×H): approx. 4.2 × 2.6–2.7 × 2.8 m

Transport dimensions: 3.22 × 2.28 × 2.68 m

Total weight: 7000 kg

Listing

Heerhugowaard

Heerhugowaard

877 km

Filling machine and sealing machine

Can filling and seamingmonobloc

Call

Condition: ready for operation (used), Can diameter range: 50 mm - 100 mm

Can height range: 28mm - 120mm

Capacity: up to 200 cans per minute

Tooling for approx.: 73mm

Bodownriaepfx Aa Eoct

No. or seaming heads: 6

No. of filling pistons: 16

Single knive member separator

Driven lifters

Siemens touchscreen

Listing

Bischofszell

Bischofszell

1,398 km

DIGITAL PRINTER

XEROXCOLORPRESS 1000 / Colour 1000

Call

Year of construction: 2011, condition: excellent (used), machine/vehicle number: 3130055185, with Freeflow Printserver and Clear Toner

Counter (m): 7.3

Colors: 4 + varnishes

Format : A7 – A3+ (SRA3)

Equipment / Additional information:

Image Resolution: 2400 x 2400 dpi VCSEL ROS

Productivity/Print Speeds—AWM

• 80/100 ppm (8.5" x 11"/A4 letter), all weights

55–350 gsm (15 lb Bond to 130 lb Cover)

• 4800/6000 full process color A4 (letter) 4/0 impressions

per hour

• 44/50 ppm (11" x 17"/A3–12" x 18"/SRA3), all weights

55–350 gsm (15 lb Bond to 130 lb Cover)

• 2400/3000 (11" x 17"/A3–12" x 18"/SRA3 tabloid) 4/0

impressions per hour and 4800/6800 (8.5" x 11"/A4) IMP

Paper Format/Sizes

• Maximum Sheet Size: 13" x 19.2" (330 x 488 mm)

• Minimum Sheet Size: 7.2" x 7.2" (182 x 182 mm), tray

inserter kit supports for 4" x 6" (102 mm x 152 mm);

see Optional High Capacity Feeder

• Maximum Print Area: 12.83" x 19.05" (326 mm x 484 mm)

• Maximum Print Image Assurance: 12.48" x 19.05"

(317 mm x 484 mm)

Machine can staple, punch, fold & front cut

Complete machine with software & RIP

Brochures, flyers, business cards

Envelopes can also be printed

Various spare materials:

Contains 1 bottle Blaue, 1x yellow, 1x blue, 1x red

1x Kit Beet Assy – FSR Module IEC

1x Chamonix Waste Tonner Bottle

2x Tonner Waste Container

10x Cartridge M 006R01472

3x Cartridge C 006R01471

Bcjdpfsh Nvm Djx Aa Ejt

4x Cartridge K 006R01470

2x Cartridge Y 006R01473

7x Staple Cartridges 008R12925

1x Belt Assy-IBT 064K93191

8x Fuser Belt Assembly

1x Chamonix Deutemle

1x MM Assy-1

5x Copy Cartridge

4x Chamonix Corotion Assy

Listing

Trenčianske Stankovce

Trenčianske Stankovce

1,890 km

(2008) SEPRO SR AXESS 22 S3 Linear robot, X 1500 mm, Y 650 mm, Z 1200 mm

SEPROSR AXESS 22 S3

Call

Condition: good (used), Year of construction: 2008, Robot Specification – for Injection Molding Machines (Sepro Type)

Payload Capacity:

1. Max load: 10 kg

Working Envelope:

1. X-axis stroke: 1500 mm

2. Y-axis stroke: 650 mm

3. Z-axis stroke: 1200 mm

Robot Dimensions (L × W × H):

1. 2490 × 1505 × 2125 mm

Weight:

1. Robot: 305 kg

2. Electrical control box: 110 kg

3. Box dimensions: 600 × 400 × 1200 mm

Suitable for Injection Molding Machines:

1. Clamping force range: 150 – 350 tons

Bedpfou It Dqjx Aa Ejct

Link to Sepro Reference Catalog:

Listing

Borken

Borken

1,027 km

Robot assembly station, dosing station

EpsonG10-854SR

Call

Condition: excellent (used), Epson G10-854SR Robot Assembly Station Dispensing Station

The assembly station is divided into the following sub-stations: 3.1 Dispensing Area, 3.2 Assembly Area KK+SW, and 3.3 Assembly Area Front. (KK = heatsink, SW = front wall bracket)

St.3.1: Dispensing Area

- A workpiece carrier (WT) with mounted chassis and circuit boards is conveyed via the transfer belt into the dispensing area.

- The WT is stopped at the lift-positioning unit (HuPo), raised off the belt, and secured in place

- The X-Y-Z handling system moves the dispensing head to the designated position and initiates the dispensing process.

- Once dosing is completed successfully, the handling system moves to the home position and the WT is placed back onto the conveyor

- Transfer continues into the assembly area KK+SW (prerequisite: no WT in placement position)

St.3.2: Assembly Area KK+SW

- A WT transported from the dispensing area enters the KK+SW assembly area via the transfer belt.

- It is stopped at the lift-positioning unit (HuPo), raised from the conveyor, and fixed in place; during this, the chassis side panels of the partially assembled component are aligned

- Simultaneously, the positioning of the KK and SW tray is carried out

- Both a KK tray stack (12) and a SW tray stack (12) are manually placed onto each respective infeed conveyor outside of the safety enclosure

- The two safety shutters are opened and the loaded tray stacks are conveyed into the gripping position of their respective stackers

- The safety shutters are then closed

- The respective grippers pick up the corresponding tray

- Using the Z-axis, trays are singled and transported upwards (above the actual pick-up height)

- To center and stabilize the trays, a centering support is positioned beneath each tray using the X-handling system.

- Using the stacker Z-axis, each tray is placed onto its centering support

- The trays are now ready for component pick-up

- The SCARA robot with a multi-gripper picks up the KK from the tray and places it in an intermediate alignment position (to compensate for inaccuracies in the pick-up and establish a fixed gripping point for assembly)

- The KK is scanned, picked up again, and if the scanner result is OK, installed onto the WT

- Non-OK KKs are placed in a non-OK container

- The multi-gripper on the SCARA robot then picks up the SW from the tray and places it in the alignment position

- The SW is picked up again and installed onto the WT

- Continue with Assembly Area Front

Technical Data

Design: SCARA (4-axis robot)

Payload: nominal 5 kg, maximum 10 kg

Horizontal reach: 850 mm

Vertical reach: Axis 3: 420 mm

Rotational range: J4: +/- 360°

Horizontal repeatability: +/- 0.025 mm

Vertical repeatability: J3: +/- 0.01 mm

Bsdpfxoibx S Ns Aa Eoct

Rotational repeatability: J4: +/- 0.005°

Maximum work envelope: Axis 1: +/- 152°, Axis 2: +/- 152.5°, Axis 3: 420 mm, Axis 4: +/- 360°

Maximum operating speed: J1,J2: +/- 11,000 mm/s, J3: +/- 2,350 mm/s, J4: +/- 2,400°/s

Permissible inertia: nominal 0.02 kg*m², maximum 0.25 kg*m²

User cabling, electrical: 1x D-Sub 9 pin, 1x D-Sub 15 pin

Z-axis: Outer diameter: 25 mm

Press-in force: 250 N

Weight: 48 kg

Control: EPSON RC180

Mounting type: Ceiling

IP protection class: IP20

Power and signal cables: 3 m

Additional assembly modules in other sizes – new and used – can be found in our shop!

International shipping costs on request.

Auction

Auction ended

Hessen

Hessen

1,199 km

Horizontal machining center

HellerMCT 160

Condition: ready for operation (used), Year of construction: 2003, functionality: fully functional, travel distance X-axis: 450 mm, travel distance Y-axis: 450 mm, travel distance Z-axis: 450 mm, spindle speed (max.): 10,000 rpm, TECHNICAL DETAILS

Working Area

Working envelope (X/Y/Z): 450 × 450 × 450 mm

Maximum workpiece height: 700 mm

Pallet size: 320 × 320 mm

Maximum pallet/table load: 300 kg

Spindle

Number of spindles: 2

Tool spindle: 10,000 rpm, 95 Nm

Speed extension: 18,000 rpm

Tool interface: HSK 63

Feed

Acceleration: 10 m/s²

Rapid traverse: 60 m/min

Chip-to-chip time: 2.6 s

Tool Magazine

Tool positions: 2 × 60

Tool magazine with 60 positions: included

MACHINE DETAILS

Weight

Machine weight: approx. 14 t

Control

Control system: Siemens Sinumerik 840D

Bsdpowx Er Nsfx Aa Eoct

EQUIPMENT

Double-spindle, 4-axis horizontal machining center

4 machine pallets

Renishaw probe

Infrared receiver for probe, Renishaw model Vaf72a0p

Operator panel at workpiece setup station

Operator panel at tool setup station

Workpiece setup stations manually rotatable

Hydraulic workpiece clamping, 60 bar

Pneumatic support control at workpiece setup stations

Automatic swing door

Extended coolant supply 70 bar / 1,500 l

VF 250 coolant chiller

Work area flushing

Emulsion mist extraction

Roto-Clear

Automatic setup sequence

Automatic teardown sequence

Run-time and quantity recording

Status lamp, 3 colors

Modem for remote diagnostics

Control cabinet lighting

Listing

Juszczyn

Juszczyn

1,965 km

Two-spindle mill

Balestrini

Call

Condition: excellent (used), Balestrini NOVA 3 envelope tenoning machine

Main motors 2 x 2.2 kW

Diameter of spindles 25 mm

Spindles length 70 mm

Spigot diameter 2 x 100 mm

Bsdjvkcfrspfx Aa Ejct

Automatic material loading and discharge

Workpiece length min/max 199.5 mm / 2030 mm

Thickness of workpieces 100 mm

Width 90 mm

Listing

Heerhugowaard

Heerhugowaard

877 km

Filling machine

LubecaLW792 clincher and can filler

Call

Condition: ready for operation (used), Can format can be round as well as oval or rectangular.

Suitable for food cans. Several sizes available.

Bcsdpfovy Tt Sox Aa Eot

Listing

Bischofszell

Bischofszell

1,398 km

ADDRESS PRINTER

BRYCEBOS 13K

Call

Condition: excellent (used), machine/vehicle number: 12991843, Power : Up to 13,000 #10 envelopes/hour in draft quality

Up to 13,000 #10 envelopes/hour in letter quality

Bcsdpfxjic N Epj Aa Ejt

Up to 12,000 #10 envelopes/hour in executive quality

Image Area: 9.4" x 15" (23.876 x 38.1 cm)

Equipment / Additional information:

Media Size: Width: 3” minimum to 12.25” maximum

Length: 5” minimum to 15” maximum

Thickness: Up to 1/4" (subject to weight)

Print Resolution: 150, 200, 300, 600 dpi horizontal, 600 vertical

Print Modes: Draft, Letter, Executive

Documentation

Listing

Porażyn

Porażyn

1,649 km

Robot ABB IRB6400RM2000

ABBIRB6400RM2000

Call

Condition: used, Year of construction: 2002, MAIN APPLICATIONS

- Spot welding

- Press tending

- Material handling

- Machine tending

- Palletizing

- Assembly

High performance industrial robot

The 6-axis IRB 6400 manipulator and S4Cplus robot controller provide short and precise cycle times, rapid change-overs and consistently high process precision. IRB 6400 accounts for one third of the 90,000 ABB robot installations.

The family of 6400 robots consists of different arm variants and payload categories which are controlled by the advanced dynamic model based control function, QuickMove™, always ensuring the highest acceleration, path accuracy and speed over the entire working envelope.

Adaptability

IRB 6400 is designed to be compact with a small interference radius to ensure flexible installations in areas with high density of production equipment. The process media, which is integrated through the robot base is easily exchanged and changing from a 2.5 to 3 meter overarm takes less than 30 minutes. The robot can be calibrated one axis at a time to ensure a quick return to full production.

Reliability and safety

IRB 6400 features robust all-steel construction with high material strength. The arms are mechanically balanced and equipped with double bearings. Advanced motion control and collision detection option greatly reduce the risk of tool and workpiece damage, making this a highly reliable and safe robot.

Bedpfx Aasxrcvpe Eoct

Type: IRB6400RM2000

Robotversion: IRB6400R/3.0-100

Serial number: 64-24036

Date of manufacturing: 2002

Net weight: 350 kg

Power: 8,3 KVA

Voltage: 3x400 V

Frequency: 50-60 Hz

Handling capacity: 100 kg

Listing

Borken

Borken

1,027 km

Continuous scale Volume measuring system

BizerbaCWL Eco flex

Call

Year of construction: 2008, condition: excellent (used), Bizerba CWL Eco flex continuous scale with Sick VMS520 volume measuring system

Bizerba CWL Eco flex continuous scale

Dynamic weight detection with volume determination

The CWL Eco flex can be integrated almost effortlessly into existing parcel shipping, sortation systems and feeding lines.

Bizerba WM-CWL flex Conveyor scale

Model: CWL Eco in Motion

DE-09-MI006-PTB018

Max 60 kg

Min 0,4 kg

230 V

Sick VMS520 Volume Measuring System

Special features

- Non-contact, active measuring method

- Measurement of length, width and height of cuboid objects

- Measure length, width and height of objects with almost any shape

- Works with a wide range of surface structures and on various flat conveyor systems

- Flexible system configurations

- Calculation of the small enveloping cuboid (box volume)

- Calculation of real volume

Device components

Sick VMD520-2000 Volume measuring device

Bedpfx Aomgax Usa Eect

Sick CLV 490 Stationary barcode scanner

Year of manufacture: 2008

Further articles - new and used - you will find in our store!

International shipping costs on request!

Listing

Obererbach (Westerwald)

Obererbach (Westerwald)

1,127 km

Brochure production system

DuploDSF-6000 PRO DIGITAL, 2021, tower

Call

Condition: like new (used), Year of construction: 2021, functionality: fully functional, STC-Ref:G-821-0097

Duplo DSF-6000-Pro DIGITAL, Year: 2021, total counter: 1,8 Mio.

format: 356x525 mm

Bcsdpev U Tvpofx Aa Est

equipped:

- 2 x loop stitching heads Duplo i saddle

- trimmer DBMS-T Front trimmer

- DKT-200 head and foot trim

- DBM-LSW belt delivery lang/long

- PC-controler

- Cut-off device parallel 6mm for DKT-200tr

- envelope feeder für/for DSF6000

- touchscreen

- batch counter DKT-200

- DSF-6000 digital sheet feeder

- barcode kit for cover feeder DSF 6000

- Barcode kit for DSF 6000 content compartment

- Duetto LDR connection bridge DSF

- 2 x collating tower DSC-10/60 i

- Bridge

- DBMS-F collating-, scoring- and plough folding unit

- DBMS-S saddel stitcher 2 x Hohner

- 2 x spare knives upper knive / lower knive

--> available: 04/2025

Listing

Hamburg

Hamburg

1,205 km

Tea packaging machine

AMTECTB-PAP M GL

Call

Condition: new, Year of construction: 2025, Automatic packing machine for filling and packing tea into tea into common rectangle tea bags with final packing of the bag into a paper envelope. Including Volume dosing unit and tag system. Tag system: in the standard version the label is folded and glued together with the inserted thread. Optionally, a heat-sealing module is available for this production step. Method for attaching the thread to tea bags: by heat sealing into the tea bag edge. Output device for grouped bags (5 pieces). - Specifications: max. speed of the machine in neutral: 110 cycles per minute; dosing volume: max. 6cm³; tea bag dimensions LxW: 62.5x50 mm; roll width tea bag material: 125 mm; suitable tea bag material: 16.5-20g/m², one side heat sealable; paper envelope dimensions LxW: 70x65 mm; material paper envelope: paper 70g/m²; label (LxW): 28x24 mm; thread length: 210 mm; power supply: 380V; power consumption: 1.5kW; machine dimensions LxWxH: 1700x900x2000 mm; weight: 640kg.

Bjdpfx Aov Nliqoa Eect

Please note that our new prices are often below the usual used prices. Please feel free to inquire and tell us your packaging task. - Usually 30-50 different new machines are available immediately from stock. In addition, we have very short delivery times from approx. 3 weeks for customized machines. Deviations from the sample photo are possible. - All machines are available with full warranty.

Trust Seal

Dealers certified through Machineseeker

Listing

Dätgen

Dätgen

1,195 km

Inserting machine

MailmasterMailmaster 465HS-4

Call

Condition: used, Year of construction: 2025, functionality: unexamined, Envelope inserting machine / inserting system 0 KAS Mailmaster 465HS-4 – Year of manufacture 11/2016 / Location: 24589 Dätgen (Schleswig-Holstein) LSV1208

Bedpfx Asw Urvroa Esct

We are offering for sale an inserting system, as per the following:

0 KAS Mailmaster 465HS-4 from 11/2016.

The inserting system has been dismantled and placed into storage.

It was purchased on 17.12.2020 for a then price of €107,880.00.

The machine is located in 24589 Dätgen (near Hamburg).

Shipping within Germany is possible.

Additional photos are available upon request.

You are welcome to submit a price proposal.

Reasonable counter-offers will be considered.

When inquiring, please provide your complete contact details!

Delivery can potentially be arranged for an additional fee.

You are also welcome to inspect the unit onsite. Simply call to arrange an appointment.

This item comes from insolvency proceedings and shows signs of use accordingly. Maintenance and professional cleaning are the responsibility of the buyer.

The sale takes place without any warranty.

Liability, reduction, rescission are expressly excluded.

We recommend an inspection prior to purchase, as the item is sold as seen.

All information is given without guarantee. Subject to errors and changes.

The item is sold as inspected onsite, in used condition, under retention of title, and with the exclusion of any warranty for visible and hidden defects, in particular defects of a technical, qualitative, or functional nature as well as usability.

Due to time constraints, we will only respond to serious inquiries and price offers!

This is an advertisement for informational purposes only.

Viewing is only possible by appointment!

Best regards

Listing

Bischofszell

Bischofszell

1,398 km

ENVELOPING MACHINE

NEOPOSTAS 970 C

Call

Condition: excellent (used), Year of construction: 2015, machine/vehicle number: 100037280, Printing system: Fixed head, Memjet, full color

Color printing: up to 16.8 million colors

Print output: 7500 envelopes/h

Print area: 215 x 431 mm

Minimum material size: 107 x 76 mm

Maximum material size: 431 x 241 mm

Material thickness: 0.5 mm

Bcedpfewktrzox Aa Est

Built-in fonts: All available TrueType fonts

Additional fonts downloadable: yes

Barcode printing: yes

Graphics printing: yes

Ink tanks (or compatible): Special inks with a capacity of 250 ml each

Interfaces: USB and Ethernet

Monthly output: 500,000 prints

without a stand

Listing

Hamburg

Hamburg

1,205 km

Tea Packaging Machine

AMTECTB-PAP M GL

Call

Year of construction: 2025, condition: new, Automatic packing machine for filling and packing tea into tea into common rectangle tea bags with final packing of the bag into a paper envelope. Including Volume dosing unit and tag system. Tag system: in the standard version the label is folded and glued together with the inserted thread. Optionally, a heat-sealing module is available for this production step. Method for attaching the thread to tea bags: by heat sealing into the tea bag edge. Output device for grouped bags (5 pieces). - Specifications: max. speed of the machine in neutral: 110 cycles per minute; dosing volume: max. 6cm³; tea bag dimensions LxW: 62.5x50 mm; roll width tea bag material: 125 mm; suitable tea bag material: 16.5-20g/m², one side heat sealable; paper envelope dimensions LxW: 70x65 mm; material paper envelope: paper 70g/m²; label (LxW): 28x24 mm; thread length: 210 mm; power supply: 380V; power consumption: 1.5kW; machine dimensions LxWxH: 1700x900x2000 mm; weight: 640kg.

Bcjdpfsv Nm R Nsx Aa Est

Listing

Bischofszell

Bischofszell

1,398 km

COVER OFFSET PRINTING MACHINE

W+D232

Call

Condition: excellent (used), Year of construction: 2011, machine/vehicle number: 16035, Format (mm): 229x162

Max. Speed: 560 pcs / min.

Paper weight (g / m2): 90

Counter : 53000 /h

Performance data // Technical data

The specified values are listed as the machine-technical performances using original W + D format parts and components. The achievable performance in practice depends on various parameters beyond our control, e.g. on the characteristics of the materials to be processed, the product and blank shape, window size and position of the windows, feed direction, position and type of the closure flap, as well as the print motif and printing ink.

STANDARD

The machine is used to print on both sides of pre-made envelopes and mailers with conventional offset printing inks. The printing units are arranged in satellite form around a central counterpressure cylinder.

Power:

Perfecting: perfecting:

Max. 1200 envelopes per minute for papers according to DIN 6733

with a surface mass of 60-165 g / m2

Bjdpfx Ash Icf Uoa Ejct

for format heights up to 162 mm in double use

Max. 700 envelopes per minute for papers according to DIN 6733

with a surface mass of 60-165 g / m2

for format heights up to 162 mm in single use

Max. 500 envelopes per minute for papers according to DIN 6733

with a surface mass of 60-165 g / m2

for format heights up to 229 mm in single use

Max. 700 envelopes per minute for papers according to DIN 6733

with a surface mass of 60-165 g / m2

For format heights up to 180 mm in single use

We make it easier for you to find: "envelope léger"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Envelope To Léger (165)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you