Used Bottel Filling Machinery for sale (78,156)

Gargždai

Gargždai Bath pasteurizer for bottles

ProFruit MachineryBath pasteurizer for bottles

Rumbula

Rumbula Outdoor WPC PE profile production line

Zhangjiagang anda machinery co,.ltdYF-240

Jüri

Jüri Drum chipper

Heinola Sawmill MachineryTT-75RS

+44 20 806 810 84

Győr

Győr Heavy duty laminator

Reliant Machinery Ltd.Powerbond-HPC 1800 Laminator System

Chișinău

Chișinău Long belt grinder

LINYI RUTFENG MACHINERY FACTORYR-RP1700

Discover more used machines

Košťany nad Turcom

Košťany nad Turcom Flexographic printing machine

Focus Label Machinery LtdE-FLEX 330 2S

Gargždai

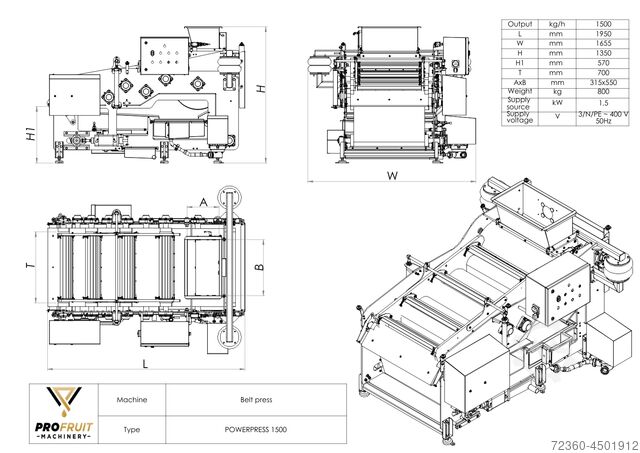

Gargždai Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 1500

Jonava

Jonava Machining centre

WOODLAND MACHINERY1325

Mārupe

Mārupe Electric pallet truck

Global Machinery; HOPEWT-BD-01

Kežmarok

Kežmarok 7 spindle fourside moulder

SK MACHINERY907S

Italia

Italia HIPAK

AutoBox MachineryHIPACK MULTICUT

Dievogala

Dievogala Vertical Flow Pack machine

HUAYUAN MACHINERY

Gargždai

Gargždai Semi-automatic Bag in Box Filler

ProFruit MachinerySEMIFLOW Filler

Jonava

Jonava Optimization cross cut machine

Woodland MachineryS120/S260

Oğlananası Atatürk

Oğlananası Atatürk WOOD SHAVING MACHINE

AVB MACHINERY LLCAVB-HELIX100BB

Rīga

Rīga Squeeze Dryer for washed plastic film

GENIUS Machinery CoDW300

Oradea

Oradea Blow moulding machine

Zhangjiagang Sevenstars Machinery CoLtdSJ-65/33

Gargždai

Gargždai Diesel Pasteurizer

ProFruit MachineryHEAT 500

Jonava

Jonava 21-09- Corner rounding machine WOODLAND

Woodland machinery

Oğlananası

Oğlananası WOOD SHAVING MACHINE

AVB MACHINERY LLCAVB-48

Gargždai

Gargždai Juice filtration

Profruit MachineryDouble juice filters

Jonava

Jonava 20-13-552/3 Brush sanding head

WOODLAND MACHINERY300

Gargždai

Gargždai Belt press for juice

Profruit machineryPOWERPRESS 800

Jonava

Jonava 20-29-551 Brush sanding machine

WOODLAND MACHINERYDTW-120A

Gargždai

Gargždai Manual bottle filler GRAVITY

ProFruit MachineryGRAVITY

Used Bottel Filling Machinery (78,156)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84