Used Sumab for sale (184)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Vilnius

Vilnius

2,174 km

Baler

HSMV-PRESS 610

Call

Condition: used, Year of construction: 2008, power: 3 kW (4.08 HP), The HSM V-Press 610 is a powerful baler designed for medium to large volumes of waste, making it ideal for commercial and industrial use. This model combines high capacity, efficiency, and reliability, allowing for the effective compaction of a wide range of waste materials.

Pressing force: 120 kN

Drive power: 3 kW

Filling height: 655 mm

Filling opening (width x height): 800 x 495 mm

Bale length x bale width x bale height: 800 x 600 x 600 mm

Bale weight: 100 kg

Dimensions (W x D x H): 1198 x 823 x 1986 mm

Redpsx Dk Tgefx Aa Eol

Weight: 540 kg

Related product line: V-Press

Consumables: Strapping

Compression materials: Plastic film, mixed paper, cardboard, punching waste!

PRICE ON REQUEST!

Listing

Saerbeck

Saerbeck

1,076 km

Plasma cutting system 3000 mm x 8000 mm

DURMAPL-C 3080

Call

Condition: new, Year of construction: 2024, Everything is configurable on demand, very short production & delivery time.

We will be happy to provide you with further information on request.

Technical data on request.

Standard equipment:

welded steel construction

DURMA CNC control unit (AURORA)

Remote control diagnostics (Ethernet)

Lantek Software W / Automatic Nesting

Position determination of the sheet metal to be cut by laser

DURMA Burner height control

Double-sided drive system (rack and pinion)

AC servo motors for X and Y axis movement

CNC control outputs/inputs for the filter unit

Consumables Starter-Kit

Plasma torch *

Ignition console *

Burner height regulation with

Ball screws on double

Linear bearings *

Redpefiqgrjfx Aa Esl

Special equipment:

Hypertherm Max Pro 200 + hose package + nozzles + Durma THC + torch

Hypertherm HPR 130 XD + hose package+ nozzles + Durma THC + ignition console + burner Hypertherm

HPR 260 XD + hose package+ nozzles + Durma THC + ignition console + burner Hypertherm +

Hypertherm HPR 400 XD + hose package + nozzles + Durma THC + ignition console + burner

CE Standard Safety wire

Automatic gas console for Hypertherm,

Manual gas console for Hypertherm,

Autogenous cutting torches

Plasma torch protection system

manual plasma angle cutting head,

CNC angle cutting head (+/- 45).

Single drilling head

Multiple drilling head

Filter for 130A, 260A or 400A

Pipe cutting unit Ø50 mm - Ø400 mm

Additional support for the pipe cutting unit

Warning lamp for error and program end

With over 60 years of experience

Listing

Petershagen

Petershagen

1,155 km

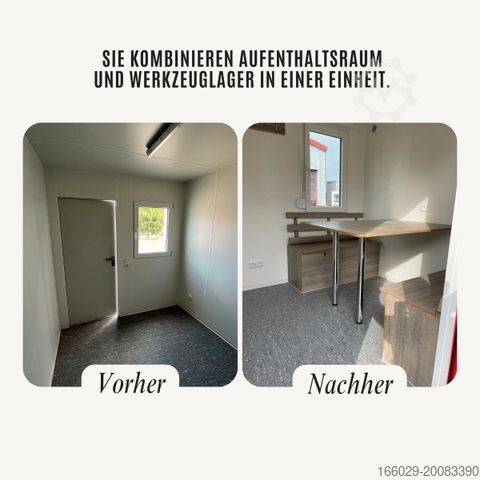

Swap body semitrailer

Kombicontainer Büro / Lager

Call

Condition: used, first registration: 01/2025, total width: 2,550 mm, General Description

This object is a converted shipping container designed for use as a mobile space. The unit has been upgraded to a high standard, featuring insulated and clad interior fittings as well as an independent electrical installation.

Exterior Shell

Base: Standard shipping container (presumably 20 ft), painted inside and out.

* Access: In addition to the container doors, an access door with window is installed.

Walls and Ceiling (Interior)

The walls are clad with light, smooth wall panels.

* The ceiling has been suspended and fitted with a lamp.

Floor

The floor is finished in a dark and durable design.

Windows and Doors

A window provides natural daylight and ventilation.

* The access door is permanently built-in and insulated.

Electrical Installation

A complete sub-distribution board, including fuse box, is installed.

* Several sockets (standard and high-voltage/CEE) are available.

* Ceiling-mounted lighting.

* An electric heater is installed.

Possible Uses

- Mobile office

- Break room

- Construction site container

Rjdpfsxf Rz Tex Aa Ejl

For further information or specific details, please feel free to contact us. Just send us your inquiry!

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Ennepetal

Ennepetal

1,082 km

Vertical Turret Lathe - Double Column

RAFAMETKCF 320 / 350

Call

Condition: used, Year of construction: 2000, faceplate diameter 3200 mm

swing diameter 3500 mm

turning height 2200 mm

range L-W-H 7730 x 6240 x 6700 mm

control Typ 840 D sl

voltage 3 x 400 V

frequency 50 Hz

turning speeds 0,8 - 40 U/min

max. turning diameter 3500 mm

total power requirement 51 kW

weight of the machine ca. 86 t

Technical specifications

Machine type: CNC vertical lathe

Manufacturer: Rafamet

Year of manufacture: 1973 conventional

General overhaul with control retrofit 2010

Control upgrade 2016

Control: Siemens 840 D Sl

Condition: very good

faceplate

Turning diameter of the faceplate 3,200 mm

Number of rotation stages of the face plate 3 (infinitely variable)

Speed ??ranges of the faceplate 0.8 - 40 rpm

Level I 0.8 – 3 rpm

Level II 0.8 - 11 rpm

Level III 0.8 – 40 rpm

processing of workpieces

Max. turning diameter 3,500 mm

Max. turning height of the workpieces above the faceplate 2,200 mm

vertical supports

Smallest axis distance between the vertical supports 470 mm

Largest ram travel of the left vertical support 985 mm

Largest ram travel of the right vertical support 985 mm

Axis Feeds - Infinitely variable feed

Max.: X1.2 3m/min

max.: z1.2 2.5 m/min

Plunger cannot be pivoted

Support — crossbar

Rapid feed of the cross beam 600 mm/min

Larger distance of the cross beam to the faceplate 2,300 mm

load sizes

+Permissible turning force when turning workpieces with a

turning diameter of 2,000 mm and a turning speed

of 20 m/min. 8,000kg

+Largest chip cross-section for workpieces made of steel Fz = 50 kg/mm²

at a turning speed of 20 m/min for all supports 45 mm²

+Largest chip cross-section for workpieces made of steel Fz = 50 kg/mm²

at a rotation speed of 20 m/min for a vertical support

with max. plunger length 985 mm 2.5 mm²

+Largest chip cross-section for cast iron workpieces HB = 160 kg/mm²

at a turning speed of 20 m/min for all supports 120 mm²

+Largest chip cross-section for cast iron workpieces HB = 160 kg/mm²

at a rotation speed of 20 m/min for a vertical support

with max. plunger length 985 mm 22.5 mm²

+Largest permitted workpiece weight at 0.8 - 3.15 rpm 17,500 kg

+Largest permitted workpiece weight at 4 - 40 rpm 7,500 kg

electric motors

Main drive motor power and revolutions 51 kW

Power of the feed motors of:

- Vertical support beam (2 pieces) 16 Nm (gear 1:10)

- Tappet (2 pieces) 16 Nm (gear 1:12)

Power and revolutions of the drive motor

of the hydraulic pumps (2 pieces) 3kW - 1,500 rpm

Power and revolutions of the clamp hydraulic motor

of the vertical support beam 1.5 kW - 1,500 rpm

Power and rotation for crossbar adjustment 15 kW - 1500 rpm

3.5 Information on the compressed air supply and other consumables

Compressed air connection: 6 bar free of oil and water

3.6 Energy Consumption Conditions

Voltage: 3 x 400V

Control Voltage: 24V

Frequency: 50Hz

Fusing: 315 A

Main dimensions and weight of the machine

Length 7,730mm

Width 6,240mm

Height: 6,700mm

Weight: 85,750 kg

Tool:

Capto 60 recording

Not powered

front panel

Turning diameter of the front plate 3,200 mm

Clamping disc diameter 3,400 mm

Number of rotation levels of the front panel 3 (continuously adjustable)

Front panel speed ranges 0.8 - 40 rpm

Level I 0.8 - 3 rpm

Level II 0.8 - 11 rpm

Level III 0.8 - 40 rpm

Rsdpfxouddcge Aa Eol

processing of workpieces

Max. turning diameter 3,500 mm

Max. turning height of the workpieces above ...

Listing

Nevers

Nevers

1,083 km

Power Generator

Leroy Somer TA12800VL12

Call

Condition: ready for operation (used), Technical characteristics

Power supply : 240 KVA

Output voltage : 220 V or 380 V

Rotations : 1500 RPM

Consumption : 8 liters/hour

Consumable : fuel oil

Supplied with tank

Arranged in a container

Plug and play

Rjdpfotv Thxsx Aa Esl

Power and Motors

Power: 192 Kw

Motor: 260 CV

Overall dimensions

Weight: 1070 Kg

Discover more used machines

Auction

Auction ended

Bayern

Bayern

1,408 km

Dip coating plant

FISACCB 40 UV + 2x RB 50

Year of construction: 2017, operating hours: 29,187 h, condition: not inspected (used), functionality: unexamined, total length: 20,000 mm, machine/vehicle number: 46236, Submission of a bid obligates the buyer to collect the equipment by 26.09.2025. Dismantling will require at least one week!

Up for auction is a comprehensively equipped dip coating system with extensive accessories!

No minimum price - guaranteed sale to the highest bidder!

The system is divided into 16 stations. The following components are included in the offer:

- FISA CCB 40 UV

- FISA RB 50 (2 units, serial no. 49052)

- 5 tanks

- Buffer and coating area

- Heraeus UV light system

- DYMAX Blue Wave 200

- EuroChiller air filter package

- Pre-filters (2 units)

- Absolute filter

- Modular product carriers

- Loading tables

Redpoxbyc Ssfx Aa Eol

- Racks for Kanban consumable dispensers

- Liquid filter package

- Stainless steel frame

Additional equipment:

- Various spare parts (filters, replacement pump, hoses, gaskets)

- Numerous connectors, inspection windows, maintenance openings, rinse pumps, circulation units

MACHINE DETAILS

Dimensions:

- Total length: approx. 20 m

Operating hours: 29,187 h

Note: The machine has not been tested by the seller but was in use until recently. Further information about the system can be found in the attached documents.

Listing

Delfina

Delfina

1,852 km

Package crosscut saw, panel saw

TA TechnologyOBS1300-A

Call

Condition: new, Year of construction: 2025, functionality: fully functional, cutting height (max.): 1,300 mm, cutting width (max.): 1,300 mm, overall weight: 9,000 kg, workpiece weight (max.): 8,000 kg, saw drive: 11,000 W, The OBS1300 bundle cutting saw has been developed to optimize production in terms of time and efficiency when formatting material to the desired length.

The presented machine is available immediately—viewings are welcome.

Technical specifications:

• Maximum bundle dimensions (width/height): 1300 x 1300 mm

• Minimum bundle dimensions (width/height): 800 x 800 mm (hydraulic clamp operating limit—smaller bundles can also be cut)

• Additional equipment enables cutting bundles with a minimum length of 600 mm

• Maximum cut-off bundle length: 3000 mm

• Maximum feed bundle length: 6000 mm

• Maximum bundle weight: 8,000 kg

• Cutting accuracy: +/- 2 mm

• Dedicated guide lubrication unit

• GB TITANIUM cutting guide (rigid and robust, milled from a single steel block. Backward compatible with STHIL guides*)

• STHIL RM404 cutting chain

• 11 kW WEG guide drive motor

• Fast measurement system with absolute encoder (retains position memory after power loss) and 0.2 mm positioning accuracy

• Innovative strapping unit with intelligent system determining strapping point based on preset cut lengths

• System of three sets of hydraulic clamps

• Hydraulic system built using PONAR components

• Crosswise infeed conveyor for loading bundles onto the machine

• Intelligent unloading system with crosswise chain conveyor

• Two pairs of tilting rollers (hydraulic) allowing large offcuts to freely fall onto the conveyor

• TA DRIVE geared motors

• HIWIN linear guides with increased load capacity

Rsdjxn Rt Ujpfx Aa Eel

• YHY Japan bearings

• YASKAWA inverters and servomotor

• 21-inch touchscreen operator panel

• SIEMENS PLC controller (with remote access system)

• Safety system and SICK brand sensors

Warranty:

12-month warranty. Service response time: 24 hours. Spare parts and consumables warehouse.

Machine supplied with:

• Operating manual

• Declarations of conformity

• Warranty card

• Electrical diagrams

• Hydraulic diagrams

Listing

Saerbeck

Saerbeck

1,076 km

Plasma cutting system 3.000 mm x 12.000 mm

DURMAPL-C 30120

Call

Condition: new, Year of construction: 2024, Everything is configurable on demand, very short production & delivery time.

We will be happy to provide you with further information on request.

Technical data on request.

Standard equipment:

welded steel construction

DURMA CNC control unit (AURORA)

Remote control diagnostics (Ethernet)

Lantek Software W / Automatic Nesting

Position determination of the sheet metal to be cut by laser

DURMA Burner height control

Double-sided drive system (rack and pinion)

AC servo motors for X and Y axis movement

CNC control outputs/inputs for the filter unit

Consumables Starter-Kit

Plasma torch *

Ignition console *

Burner height regulation with

Ball screws on double

Linear bearings *

Rsdpfx Aajfirx To Ejl

Special equipment:

Hypertherm Max Pro 200 + hose package + nozzles + Durma THC + torch

Hypertherm HPR 130 XD + hose package+ nozzles + Durma THC + ignition console + burner Hypertherm

HPR 260 XD + hose package+ nozzles + Durma THC + ignition console + burner Hypertherm +

Hypertherm HPR 400 XD + hose package + nozzles + Durma THC + ignition console + burner

CE Standard Safety wire

Automatic gas console for Hypertherm,

Manual gas console for Hypertherm,

Autogenous cutting torches

Plasma torch protection system

manual plasma angle cutting head,

CNC angle cutting head (+/- 45).

Single drilling head

Multiple drilling head

Filter for 130A, 260A or 400A

Pipe cutting unit Ø50 mm - Ø400 mm

Additional support for the pipe cutting unit

Warning lamp for error and program end

D9hnyc97o

With over 60 Yes

Listing

Germany

Germany

1,228 km

Dust collectors

NestroNE 300 J Eco

Call

Condition: new, Year of construction: 2023, New machine

Year of manufacture: 2023

NESTRO® extractor, a new generation, powerful, compact, economical, and with some highlights that will inspire you.

Redpow Naazsfx Aa Esl

Vacuum filter for extraction and filtration of wood dust and wood chips. H3 test according to GS-HO-07 (BGHM), GS scheduled. Fire extinguishing device, fire protection flap / oxygen closure. Vacuum filter with JET compressed air pulse cleaning including suction nozzle, 5 m cable for socket connection (protective measure grounding), suction connection left / fan right

Technical data:

• Airflow max./nom.: 6,000 / 5,850 m³/h

• Vacuum max./nom.: 2,950 / 2,400 Pa

• Suction side connection: Ø 300 mm

• Mode of operation: continuous operation

• Current type: three-phase current

• Power consumption: 7.5 kW / 16 A / 50 Hz

• Fan/drive: IE3 asynchronous motor

• Filter area: 36.2 m²

• Filter regeneration: JET / automatic

• Compressed air consumption per cycle: 560 Nliters

• Chip disposal: chip bin with PE bag

• PE bag (consumable): 500020

• Collection volume: 3 x 0.16 m³

• Weight: approx. 1,250 kg

• Noise level according to EN 11201: 72-74 dB(A) in accordance with MRI (+/- 4dB)

• Length x width x height: 3880 x 1020 x 2250 mm

Required connections:

• Compressed air standard coupling NW 7.2; 6 bar, compressed air dry and oil-free

• 1 x 32 A CEE socket / fuse 25 A

For systems with chip sack filling, uniform filling cannot be guaranteed due to different extraction volumes and varying chip/dust contents

Availability: short-term

Storage location: Flörsheim

Listing

Langenfeld (Rheinland)

Langenfeld (Rheinland)

1,066 km

Cutter metallography laboratory

METKONServocut 302

Call

Year of construction: 2025, condition: as good as new (ex-display), SERVOCUT 302-MA Automatic abrasive cutting machine

- programmable with 7" touch screen operating panel with SIEMENS-PLC control

Rodpfxecw Ipas Aa Ejl

- automatic moving table + manual chop cut (other types available)

- cutting machine for a variety of different programmable cutting processes

- programming of cutting parameters via LCD display

- precise and motorized positioning of the sample in X - Y and Z axis

- integrated moving table control with force-dependent adjustable infeed speed

- variable cutting force, mode for pulse cut, overload protection of the drive motor

- compact engine 2,800 rpm cutting disc speed

- electronic braking system

- cutting capacity up to 110 mm solid material (with cut-off wheels Ø 300 mm)

- double, split (left/right) stainless steel T-slot table

- floor assembly made of solid die-cast aluminum

- incl. 80 l circulation cooling system complete with connection hoses

- delivery ready for operation (without clamping devices)

- power supply 400 V / 50 Hz, 3 phases with neutral 16 A back-up fuse

- delivery including test equipment Consumables consisting of:

* Assortment of 20 cutting discs with 300 mm diameter

* 5 litre METCOOL coolant liquid

Listing

Borken

Borken

1,027 km

Analysis system Acridinium ester

SiemensAdvia Centaur XP

Call

Year of construction: 2010, condition: good (used), Siemens Advia Centaur XP Analysis System

With Siemens Healthineers services and maintenance until 02/2022

Advanced AE immunoassay technology

Meet clinical needs with acridinium ester (AE) technology that provides the flexibility and sensitivity needed for new and innovative assays.

Comprehensive diagnostic clarification of various disease patterns thanks to a test menu with over 70 different assays.

Simplified inventory management and reduced costs by using the same ready-to-use reagents on all ADVIA Centaur analysers.

Simplified operation, continuous operation

All samples, reagents and consumables can be loaded and unloaded on the fly.

Easier training and operation thanks to an intuitive, icon-based user interface.

Less operator intervention as daily maintenance is low and the system does not need to be cleaned monthly or booted up daily.

New and updated test definitions can be read in by the customer by simply scanning the 2D barcodes included in the usage information.

Consistent, predictable turnaround time (TAT) and accuracy

Up to 240 tests/hour for short turnaround time even during peak periods.

Rapid prioritisation of emergency samples possible at any time thanks to a dedicated access (STAT port).

Disposable pipetting tips prevent carry-over and contamination of samples.

Automatically perform repeat and confirmatory testing for reactive hepatitis B surface antigen samples using Siemens Healthineers SMART algorithms.

Rsdpfx Aohr Rw Ioa Eel

Direct connectivity

Adapt to different sample volumes with easy connection to Aptio and VersaCell® X3 automation solutions.

Efficient operation thanks to diagnostic IT including CentraLink® data management system

Atellica Process Manager and Smart Remote Services for Diagnostics

Direct pipetting from the automation solution through point-in-space technology.

Shorter turnaround times for emergency samples thanks to a dedicated STAT port that allows front loading of emergency samples even when connected to an automation solution.

Technical specifications

Product specifications

System type: Random access immunoassay system

Throughput: Up to 240 tests per hour

Time to first test result

18 minutes, further results every 15 seconds (method dependent)

Method capacity on board: 30 test methods

Indication groups§§

Allergy, anaemia, diabetes, fertility, hepatitis, HIV, immunosuppressants, infectious serology, cardiology,

Bone metabolism, Liver fibrosis, Adrenal function, Oncology, Thyroid diseases, Sepsis, Therapeutic drug monitoring (TDM)

Continuous operation

Loading and unloading of samples and consumables at any time during continuous operation. This includes sample racks, emergency samples, reagents, ancillary reagents, reaction cuvettes, sample tips, calibrators, controls, wash solutions, water and waste.

Samples and sample management: Sample tubes

3 ml, 5 ml, 7 ml and 10 ml tubes, 1 ml and 2 ml secondary tubes, micro tubes

Sample supply

Universal rack with 5 positions for different types of tubes, total capacity 180 samples; loading and unloading during operation.

Listing

Hessisch Lichtenau

Hessisch Lichtenau

1,244 km

Electric dual screwdriving unit with automatic feed and pneumatic double stroke,; screwdriving techn

BÖLLHOFF / BOSCH REXROTHUVS-100-2-R-E / EC302 SZ3 /

Call

Condition: used, Electro Dual Screwdriving Unit with Automatic Feed and Pneumatic Double Stroke

BÖLLHOFF Type UVS-100-2-R-E

The Böllhoff Uniquick Vario UVS-100-2-R-E dual screwdriving unit is equipped with a pneumatic double stroke, operated via Festo valves and cylinders. Additionally, various monitoring systems are installed for full automation.

Technical data:

Torque of electric screwdriver: 0.6 Nm

Gearbox torque: max. 10 Nm

Speed: max. 20,000 rpm

Rated voltage: 3~ 0-230 VAC

Current consumption: max. 7 A (per screwdriver)

Pneumatic long-stroke cylinder: 80 mm

Pneumatic short-stroke cylinder: 20 mm

Total pneumatic stroke: 100 mm

Spring stroke for screwdriver: 20 mm

Distance between both screwdriving tools: 73 mm

- Equipped with a TORX bit T27 or TP27 (presumably for M6 screws)

- Requires Bosch Rexroth LT303 power module for operation (power module not included)

Screwdrivers 1 and 2 are each composed of the following components:

Rexroth type servo motor

Rexroth type 0 planetary gearbox

Rexroth type 0 encoder

Rsdpfshxvu Eex Aa Eol

Rexroth type 0 straight drive output

Component details:

Electric screwdriver unit Rexroth

Servo motor Rexroth

Type: EC302 SZ3

Material number: 0

Torque: 0.6 Nm

Peak torque: 0.7 Nm

Speed: max. 20,000 rpm

Current consumption: max. 7 A

Rated voltage: 3~ 0-230 VAC

Weight: 0.8 kg

Gearbox unit Rexroth

Type: 3GE27 SZ3

Material no.: 0

Efficiency: 90%

Gear ratio: i=18.9

Torque: max. 10 Nm

Weight: 0.4 kg

Installation length: 65.5 mm

Encoder Rexroth

Type: 2DMC012 SZ2

Material no.: 0

Nominal torque: 12 Nm

Reduction ratio: 1

Efficiency: 1

Weight: 0.55 kg

Installation length: 118.5 mm

Straight drive output Rexroth

Type: 2GA82 SZ2 1/4" SQ

Material no.: 0

Spring travel: 20 mm

Spring force: 16 - 34 N

Tool holder: 1/4" square

Max. torque: 10 Nm

Reduction ratio: 1

Weight: 0.2 kg

Installation length: 90 mm

One 7 m motor connection cable is included in the delivery.

Overall dimensions W x H x D: approx. 180 x 920 x 300 mm

Total weight: approx. 20 kg

Good condition

Listing

Langenfeld (Rheinland)

Langenfeld (Rheinland)

1,064 km

Welding machine

Alpha Laser LaserschweißenALM, ALW, AL Kipp-Schwenk-Optik (KSO)

Call

Condition: new, Year of construction: 2024, functionality: fully functional, laser wavelength: 1,064 nm, AL, ALM, ALW tilt and swivel optics (KSO), new 1 year guarantee,

still packed. Other devices and accessories in stock on request. Sale only within the EU.

Laser welding consumables, Lawitex starter pack. As a laser welding wire manufacturer, we can create a wire selection specifically for your

wire selection specifically for your requirements, welding parameters are personally customized by us.

explained and stored for easy retrieval. We supply original Alpha Laser spare parts, offer application

product training and service at very good conditions.

Rsdpjpcf Ntjfx Aa Eel

We are an official sales partner for Alpha Laser laser welding systems and, thanks to our almost 30

years of experience in the field of welding technology, we offer advanced laser welding technology

from a single source.

Inquiries, explanatory welding training and instructions (also by telephone) in: German, English and Polish

Supplier

Lawitex GmbH 40764 Langenfeld (Rhineland), DE

Listing

Germany

Germany

1,293 km

Bandsaw - Horizontal

BERG & SCHMIDDGS 500/600 HA-I

Call

Condition: new, capacity 90 degrees: round 500 mm

capacity 90 degrees: square 420 mm

600x400

saw band length 5320x34x1,1 mm

band speed 15 - 100 m/min

table height 805 mm

total power requirement 3,0 kW

weight of the machine ca. 1,45 t

dimensions of the machine ca. 1,72 x 2,5 x 2,5 m

Double miter band saw, hydraulic semi-automatic, DGS 500/600 HA-I

• miter left + right 60°

• Frequency-controlled saw drive

• 34 mm saw band height

• Wear-free material support turntable, ball-bearing

• To position the saw blade guides using a very wide linear guide

• Strong, robust gearbox

• Large chipboards

• 2 integrated support rollers left and right

Rsdpfxjupxupo Aa Ejl

• Removable chip tray (disinfection)

• Free-standing control panel, safe and ergonomic

• Storage space for tapes, consumables

• Hydraulic cutting pressure control valve

• Material height sensor (automatic cut start detection)

• Preload super fast (front loading)

• Hydraulic control of saw frame and vice

• LEDs for monitoring all safety functions

• Minimum cutting range from around 10 mm

Semi-automatic function:

1. Clamp material

2. Saw starts

3. Rapid lowering to the start of the material or the same for series cutting

cut

4. Saw band off

5. Raise the frame to just above the material

6. Open the vise

Listing

Rödermark

Rödermark

1,235 km

Vertical band sawing machine

BAUER500 VS

Call

Condition: good (used), Year of construction: 1997, machine/vehicle number: 97-04002, Offer 25114

Technical specifications approx.:

- Roller diameter 500 mm

- Throat depth 500 mm

- Max. clearance height 400 mm

- Table size 630 x 530 mm

Rsdewmnz Njpfx Aa Esl

- Table tilts 10/30°

- Table height from floor 950 mm

- Saw blade length approx. 3900 mm

- Saw blade width approx. 3 - 25 mm

- Cutting speeds (presumably) 81 - 145 - 208 - 267 m/min

- Drive 400 V / 1.1 kW

- Weight approx. 400 kg

- Space required approx. W 750 x H 2000 x D 1000 mm

Listing

Langenfeld (Rheinland)

Langenfeld (Rheinland)

1,066 km

Metallographic abrasive cutting machine

METKONMetacut 302

Call

Year of construction: 2025, operating hours: 1 h, condition: as good as new (ex-display), The METACUT 302 is the best value quality wet cutting machine available on the market for abrasive cuts. The cutting process is purely manual by operating the hand lever on the right side. The type METACUT 302 is able to cut solid materials with a diameter up to 90 / 110 mm (round) or 65 x 130 (square). In order to enable the cutting of extremely long workpieces, a lateral opening was created on the left side of the machine.

The machines are equipped with a powerful motor that drives the abrasive cutting wheel safely through the workpiece. The base assembly of the machine consists of large die-cast aluminum housing. The clamping table made of stainless steel is equipped with T-slots, which allows a multitude of different clamping's. The optional quick-clamping devices can be disassembled to allow the installation of conventional clamping tools and thus the clamping of large or irregular workpieces.

After only a few cutting attempts, the user is able to make perfect cut-offs with this easy-to-operate wet cut-off grinding machine to create the best conditions for the following grinding and polishing work to be carried out efficiently.

Keywords: Manual, abrasive wet cut-off machine, 4.6 kW compact motor, electronic brake system, cutting capacity for solid workpieces with Ø ᐸ 90 mm (110 mm with cut-off wheel Ø 300 mm), for cut-off wheels with a Ø up to 250 / 300 mm, double T-slot table, floor assembly made of solid die-cast aluminum, powder-coated machine body, GRP plastic protective housing, 80 litre circulation cooling system with tank and pump included in the basic price. Delivery ready for operation (options: clamping device, base cabinet)

Delivery including a test equipment consumables consisting of:

* Assortment of 20 cutting discs

Redo Ebqnjpfx Aa Esl

* 5 litres METCOOL coolant

Option: Machine base cabinet

Listing

Staufenberg

Staufenberg

1,199 km

Plasma cutting system 6.000 mm x 3.000 mm

DURMAPL-C 3060

Call

Year of construction: 2024, condition: new, Everything is configurable on demand, very short production & delivery time.

Rjdpfx Aaofirx No Esl

We will be happy to provide you with further information on request.

Technical data on request.

Standard equipment:

welded steel construction

DURMA CNC control unit (AURORA)

Remote control diagnostics (Ethernet)

Lantek Software W / Automatic Nesting

Position determination of the sheet metal to be cut by laser

DURMA Burner height control

Double-sided drive system (rack and pinion)

AC servo motors for X and Y axis movement

CNC control outputs/inputs for the filter unit

Consumables Starter-Kit

Plasma torch *

Ignition console *

Burner height regulation with

Ball screws on double

Linear bearings *

Special equipment:

Hypertherm Max Pro 200 + hose package + nozzles + Durma THC + torch

Hypertherm HPR 130 XD + hose package+ nozzles + Durma THC + ignition console + burner Hypertherm

HPR 260 XD + hose package+ nozzles + Durma THC + ignition console + burner Hypertherm +

Hypertherm HPR 400 XD + hose package + nozzles + Durma THC + ignition console + burner

CE Standard Safety wire

Automatic gas console for Hypertherm,

Manual gas console for Hypertherm,

Autogenous cutting torches

Plasma torch protection system

manual plasma angle cutting head,

CNC angle cutting head (+/- 45).

Single drilling head

Multiple drilling head

Filter for 130A, 260A or 400A

Pipe cutting unit Ø50 mm - Ø400 mm

Additional support for the pipe cutting unit

Warning lamp for error and program end

With over 60 years of experience

Listing

Hessisch Lichtenau

Hessisch Lichtenau

1,244 km

Single column - hydraulic press

MAES63SZ SO

Call

Condition: used, Single-column hydraulic press MAE type S63SZ SO

. 551277 Year of manufacture approx. 1977

Nominal pressing force: 63 tons

Pressing force: 50 tons (practically tested)

Throat depth: 320 mm

Table area: 850 x 630 mm

Ram area: 1050 x 500 mm

Ram stroke: 500 mm

Max. installation height: approx. 730 mm

Table height above floor: 970 mm

Hydraulic tank capacity: 600 liters

Drive power: 15 kW

Power supply: 380 Volt, 50 Hz

- Hydraulic draw cushion below the table with bores through the tabletop

- Two-hand operation

Rsdpfxjdzp Trj Aa Esl

- Electrical control cabinet damaged

Required space (L x W x H): 2000 x 1200 x 3420 mm

Weight approx. 5 tons

The machine is operational, the control cabinet is mechanically damaged.

During test run, the machine achieves a pressing force of 50 tons, presumably a pressure relief valve is venting.

Listing

Nonnweiler

Nonnweiler

1,133 km

Face mask production line

PIA Automation Amberg GmbH

Call

Year of construction: 2020, operating hours: 1,800 h, condition: good (used), functionality: fully functional, machine/vehicle number: 50850283/P.0000893.03.05, The assembly line is a production system consisting of three separate units, interconnected by conveyor belts. In the first section, consumable materials are fed in via rollers, folded, the nose clip is integrated, welded, and then cut to the correct length. The finished mask blanks are transported via an indexing conveyor and additional transport belts to the next units, which are arranged in parallel. Each of these stations feeds and welds the ear loops to the mask body.

The line is suitable for the manufacture of surgical and general medical face masks, made from single- or three-layer PP (polypropylene) nonwoven fabric.

System configuration

Rsdpfx Ajw Dn Uwea Eel

Each production cell is based on an aluminum profile frame with swing doors made from Makrolon. For the required process stability, the stations are mounted on a solid aluminum table plate. The control cabinets are integrated into the frame. The equipment includes, among others, 3 ultrasonic welding units, Siemens PLC control, and various pneumatic systems from Festo.

Performance requirements

Output (gross): ≥ 80 units/minute

Technical availability: ≥ 90% (VDI 3423)

Required floor space for the complete system: approx. 6,000 x 5,000 mm

Connection values

Electrical connection:

Operating voltage: 3P/N/PE 400 V AC 50Hz

Mains fluctuation: ± 5%

Short-circuit design: < 10kA

Network type: TN-S

Pneumatic connection:

Compressed air: 6 bar ± 1 bar

Ambient conditions

Temperature range: 10°–35°C

Max. humidity: 75% (non-condensing)

Emissions

Sound pressure level during operation: ≤ 78 dB(A) according to EN ISO 11204:2010

The machine is currently out of use and was regularly serviced during its operational period. At present, the machine is dismantled, with individual components stored under dust protection.

Upon request, we can also sell our remaining raw material stocks for production.

Listing

Germany

Germany

1,293 km

Bandsaw - Horizontal

BERG & SCHMIDDGS 350/450 HA-I Easy 34

Call

Condition: new, capacity 90 degrees: round 350 mm

capacity 90 degrees: square 330 mm

450x320

saw band length 4250x34x1,1 mm

Rjdsfgyicjpfx Aa Eol

band speed 40 + 80 m/min

table height 845 mm

saw band width 34 mm

total power requirement 2,2 kW

weight of the machine ca. 0,985 t

dimensions of the machine ca. 1,4 x 2,0 x 2,2 m

Double miter band saw, hydraulic semi-automatic, DGS 350/450 HA-I

· miter left + right 60° without machine conversion

· 34 mm saw blade width

· Large material support turntable, ball bearings

· To position the saw blade guides using a very wide linear guide

· Strong, robust transmission

· Large chipboards

· Infeed and outfeed roller

Removable chip tray (disinfection)

· Free-standing control panel, safe and ergonomic

· Storage space for tapes, consumables

· Cutting pressure regulator Feed regulator

· Fully hydraulic vise

Preload super fast (front loading)

· Material height sensor (automatic cut start detection)

Semi-automatic function:

1. Clamp material

2. Saw starts

3. Rapid lowering to the start of the material or the same for series cutting

cut

4. Saw band off

5. Raise the frame to just above the material

6. Open the vise

Optimum, material-independent cutting result through fine adjustment of the

saw frame by means of:

*Pressure Control Valve (Cutting Pressure Force)

*Feed Control Valve (Speed)

*Switch with pictogram, easy and clear to use

Auction

Auction ended

Bourgogne-Franche-Comté

Bourgogne-Franche-Comté

1,106 km

Flame cutting system

FICEPGEMINI 15 1530PG

Condition: ready for operation (used), Year of construction: 2014, operating hours: 26,400 h, functionality: fully functional, machine/vehicle number: 1530PG, Submission of a bid obligates timely collection by 29.07.!

No minimum price – guaranteed sale to the highest bidder!

TECHNICAL DETAILS

Table dimensions

Table width: 1,500 mm

Table length: 3,000 mm

MACHINE DETAILS

Redpewzw Insfx Aa Esl

Control: Control panel

Generator: Hypertherm 130XD

EQUIPMENT

Consumables and nozzle set

Central vacuum system

Trust Seal

Dealers certified through Machineseeker

Listing

Langenfeld (Rheinland)

Langenfeld (Rheinland)

1,066 km

Metallografie mounting press

METKON MetallografieECOPRESS 102

Call

Year of construction: 2025, condition: as good as new (ex-display), ECOPRESS 102 is an automatic hot mounting press with an electro-hydraulic pressure system and therefore does not require a separate compressed air connection. The working pressure reaches up to 300 bars and an embedding temperature up to max. 200°C. The mounting time can be set up to 60 minutes. The automatic process results in short cycle times: thermostatically controlled heating and cooling times, heating output of 1650 W, automatic cooling cycle.

Mounting cylinders and pistons with diameters of 25, 30, 40, 50 mm (and inch) are available. The end of the embedding sequence is signaled acoustically by the device. The delivery is made ready for operation (incl. To be ordered separately

Mounting cylinder with piston and intermediate piston for 2 mountings), required power supply: 230V / 50 Hz, 1 phase (220V), water inlet, water outlet, delivery included

Test equipment consumables consisting of:

• 5 x 1 kg (5 kg) different investment materials

• 1650 watt heating power

• up to 200 ° C embedding temperature

• Embedding time adjustable up to 60 minutes

• automatic cooling cycle

• no compressed air required

• 12 month warranty

Delivery by forwarding agent to the factory in Germany

Rodpfxecwamxs Aa Eol

(Optional installation by our technicians on site)

Listing

Gifhorn

Gifhorn

1,258 km

FDM 3D Printer

StratasysFortus 900mc UPG F900 Gen 3- L0503

Call

Condition: refurbished (used), functionality: fully functional, machine/vehicle number: L0503, Year of construction: 2015, operating hours: 38,589 h, The Fortus 900mc 3D Printer is one of the most precise and powerful FDM printers on the market. With the largest build size among all Fortus® systems, this 3D printer is designed to meet the most demanding manufacturing requirements.

The build volume of the Fortus 900mc by Stratasys measures 914.4 x 609.6 x 914.4 mm, covering a wide range of 3D printing applications. The selectable layer thicknesses of 0.178mm, 0.254mm, 0.330mm, and 0.508mm allow for precise adjustments to suit your specific part requirements.

For optimal operation of this Stratasys 3D printer, an additional washing station is needed. The Stratasys Fortus 900mc uses the soluble support material SR30 or a Break-Away support material, enabling the creation of intricate models, including undercuts and holes, while reducing the need for post-processing.

The FDM 3D printer Fortus 900mc works seamlessly with the popular, free GrabCAD software, making it accessible even for inexperienced users to swiftly and easily fabricate their projects.

Make the most of this Stratasys FDM 3D printer model with iSQUARED materials such as ABS, ABS-ESD, ABS-CF, ASA, PC-ABS, PC, ULTEM 9085, and ULTEM 1010. The cartridges for building and support materials each hold either 1510 cm³ or 3020 cm³, ensuring uninterrupted printing.

This printer can be installed anywhere without the need for specific setup conditions. No special ventilation is required, as the Fortus systems do not produce harmful vapors, chemicals, or waste.

Download the provided site preparation guide to understand the space and connection requirements of the Stratasys Fortus 900mc.

This printer is part of the Certified Pre-Owned (CPO) program.

Rsdpfx Asvmpk Hsa Esl

Certified Pre-Owned 3D printers are used 3D printers that have been fully refurbished, serviced, and then verified through a 24-hour test print by our experts. If you opt for installation and training by one of our certified service technicians, you will also receive a 6-month warranty on your 3D printer. Additionally, we can provide you with all the accessories and consumables, tailored to your purchased 3D printer, from a single source.

This means that you take no risks with your purchase.

Listing

Hessisch Lichtenau

Hessisch Lichtenau

1,244 km

Steel cast grey cast iron alignment and welding plate, heavily ribbed, heavy-duty alignment plate

1600x1005

Call

Condition: used, Steel and cast iron straightening and welding plate, heavily ribbed

heavy-duty straightening plate

Length 1600 mm

Width 1005 mm

Thickness 280 mm

Rsdpedzqbaefx Aa Eol

Plate thickness approx. 85 mm throughout

- Center hole Ø 245 mm, 400/800 mm

- Threaded holes M 20, approx. 55 mm deep

- Through holes Ø 27 mm

Weight approx. 2.5 t

Good condition

Former press table – presumably machined parallel on both sides

Listing

Gifhorn

Gifhorn

1,258 km

FDM 3D Printer

StratasysFortus 900mc - L0404

Call

Condition: refurbished (used), functionality: fully functional, machine/vehicle number: L0404, Year of construction: 2015, The Fortus 900mc 3D Printer is one of the most precise and powerful FDM printers on the market. With the largest build size among all Fortus® systems, this 3D printer is designed to meet the most demanding manufacturing requirements.

The build volume of the Fortus 900mc by Stratasys measures 914.4 x 609.6 x 914.4 mm, covering a wide range of 3D printing applications. The selectable layer thicknesses of 0.178mm, 0.254mm, 0.330mm, and 0.508mm allow for precise adjustments to suit your specific part requirements.

For optimal operation of this Stratasys 3D printer, an additional washing station is needed. The Stratasys Fortus 900mc uses the soluble support material SR30 or a Break-Away support material, enabling the creation of intricate models, including undercuts and holes, while reducing the need for post-processing.

The FDM 3D printer Fortus 900mc works seamlessly with the popular, free GrabCAD software, making it accessible even for inexperienced users to swiftly and easily fabricate their projects.

Make the most of this Stratasys FDM 3D printer model with iSQUARED materials such as ABS, ABS-ESD, ABS-CF, ASA, PC-ABS, PC, ULTEM 9085, and ULTEM 1010. The cartridges for building and support materials each hold either 1510 cm³ or 3020 cm³, ensuring uninterrupted printing.

This printer can be installed anywhere without the need for specific setup conditions. No special ventilation is required, as the Fortus systems do not produce harmful vapors, chemicals, or waste.

Download the provided site preparation guide to understand the space and connection requirements of the Stratasys Fortus 900mc.

This printer is part of the Certified Pre-Owned (CPO) program.

Certified Pre-Owned 3D printers are used 3D printers that have been fully refurbished, serviced, and then verified through a 24-hour test print by our experts. If you opt for installation and training by one of our certified service technicians, you will also receive a 6-month warranty on your 3D printer. Additionally, we can provide you with all the accessories and consumables, tailored to your purchased 3D printer, from a single source.

This means that you take no risks with your purchase.

Redpfx Ajvmpivoa Eol

We make it easier for you to find: "sumab"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Sumab (184)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month