Used Sterilizer for sale (216)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Duxford

Duxford

585 km

Oxoid Tryptone Soya Broth 5Kg

Oxoid LtdTryptone

Call

Year of construction: 2025, condition: used, 5Kg Thermo Scientific™ Tryptone Soy Broth (Soybean Case in Digest Medium EP/USP/BP/JP) (Dehydrated)

New in original packaging

Dated for use by end January 2026

Hnedpfxexv Azge Afnoh

Representing a price reduction of around 80% from the manufacturers retail price list

Soybean Casein Digest (SCD), also known as Soybean-Casein Digest Medium or Tryptic Soy Broth (TSB), is a general-purpose nutrient medium used for cultivating a wide range of microorganisms, including bacteria and fungi. It's especially valuable because it's rich in nutrients derived from enzymatic digests of soybean meal and casein (milk protein)

Used By

1. Pharmaceutical Industry

- Sterility testing of pharmaceutical products (especially injectables and ophthalmic solutions).

- Microbial limit testing of raw materials, finished products, and water.

- Environmental monitoring (e.g., surface swabs, air sampling).

2. Medical Device Manufacturers

- Used for sterility testing of surgical instruments, implants, catheters, etc.

3. Hospitals & Clinical Laboratories

- For culturing bacteria and fungi from clinical specimens.

- Used in blood culture bottles to detect septicemia.

4. Food and Beverage Industry

- To test for microbial contamination in food products.

- Used for hygiene monitoring in food processing environments.

5. Biotechnology and Research Laboratories

- General purpose medium for growing a variety of microbes in research.

- Useful in antibiotic sensitivity testing or microbiome studies.

6. Cosmetic Industry

- For microbial limit testing and product safety validation.

Listing

Duxford

Duxford

585 km

Envair ISO1 -304 Mobile Isolator safety cabinet

EnvairISO1 -304

Call

Condition: used, This listing is introducing 8 No Envair Mobile Isolators of different specifications currently held in our stock

The units are in full working condition and ready for immediate use

Envair Mobile Isolator

Envair Technology is a UK-based manufacturer specializing in clean air and containment solutions for the healthcare, biotechnology, and pharmaceutical industries. Their product range includes a variety of isolators designed to provide controlled environments for handling hazardous substances, ensuring both operator and product safety.

Applications

Envair isolators are widely used in a variety of applications including

Hospital Pharmacies: For preparation of TPN, CIVAS, and aseptic dispensing.

Pharmaceutical Laboratories: Handling of HPAPIs and sterile compounding.

Sterility Testing: Secure, controlled environments for product testing.

R&D Facilities: Safe containment during experimental or early-stage developmen

Key Features of Envair Isolators

Positive and Negative Pressure Models: Envair offers both positive pressure isolators protect the product from contamination and negative pressure isolators to protect the operator from hazardous substances

Compliance with GMP Standards: Many Envair isolators meet EU GMP Grade A and ISO 5 classifications, ensuring sterile, controlled environments.

Customizable Designs: Envair provides bespoke solutions tailored to specific client needs, including unique dimensions and technical requirements.

Hsdpfexv Dhbjx Afnenh

Advanced Containment Technology: Isolators are equipped with automated pressure decay leak tests, electromagnetic interlocks for transfer chambers, and integrated decontamination systems.

User-Friendly Controls: Most units include intuitive touchscreen interfaces and PLC-based systems for simple and efficient operation.

Growing Need for Containment with HPAPIs

Demand for personalised medicines containing High Potent Active Pharmaceutical Ingredients (HPAPIs)—particularly in newer super-potent oncology, cardiovascular, and diabetes treatments—is increasing rapidly. These medicines often require shorter turnaround times, forcing pharmaceutical process manufacturers to develop faster, more agile workflows. In such high-risk, high-value settings, a GMP-compliant environment is not optional—it’s critical.

It’s easy to overlook the fact that the people developing, manufacturing, and dispensing these complex drugs are at risk of exposure to harmful, sometimes lethal, compounds. Their safety is paramount, given the essential role they play in maintaining a reliable supply of advanced therapeutics.

Expertise in HPAPI Handling for CMOs & CDMOs

Envair has specialist expertise in helping Contract Manufacturing Organisations (CMOs) and Contract Development and Manufacturing Organisations (CDMOs) safely handle HPAPIs—even within existing non-contained facilities.

Their isolator systems are designed, manufactured, and installed to meet rigorous containment performance levels below 1μg/m³ (OEB 5). Each system is custom-engineered for the specific site and process step—whether it’s weighing, mixing, milling, spray drying, or packaging.

Applications

Hospital Pharmacies: For preparation of TPN, CIVAS, and aseptic dispensing.

Pharmaceutical Laboratories: Handling of HPAPIs and sterile compounding.

Sterility Testing: Secure, controlled environments for product testing.

R&D Facilities: Safe containment during experimental or early-stage development

Listing

Duxford

Duxford

585 km

CAS

Biomat 2CAS Biomat 2 Microbiological Safety Cabinet

Call

Condition: used, This listing is for the CAS Biomat 2 Microbiological Safety Cabinet with Stand

The unit is in full working condition and is ready for immediate use

The BioMat 2 is a Class II microbiological safety cabinet—also known as a biosafety cabinet—designed to protect the user, the sample (or product), and the environment during handling of potentially hazardous or sterile biological materials

Key Features & Capabilities

Protection & Compliance

Meets the European standard EN 12469:2000 for microbiological safety cabinets

It shields both the operator and the product through an inward air curtain (front sash) and sterile downflow over the work surface. Aerosols and contaminants are filtered through HEPA filters before being exhausted or recirculated

Construction & Safety

Built with a 1.5 mm mild steel outer shell and 304 stainless steel interior. Side panels are made from 5 mm UV-resistant toughened glass

Include safety alarms, airflow monitoring, and robust sealing under negative pressure to prevent leaks

Hnodpfx Afsxhfkbeneh

Listing

Duxford

Duxford

585 km

Avestin EmulsiFlex-C5 for homogenizer with sealed toolings and spares

AvestinEmulsiFlex-C5

Call

Condition: used, This listing is for the Avestin EmulsiFlex-C5 for homogenizer with sealed toolings and spares

The unit is in full working condition and is ready for immediate use

Hodpfxsxhgaws Afnjnh

EmulsiFlex-C5 High Pressure Homogenizer

The Avestin EmulsiFlex-C5 is a high-pressure, pneumatically powered homogenizer designed for laboratory-scale applications. It is ideal for processing small to medium sample volumes, from 7 mL up to 5 L/h, depending on the pressure applied.

How It Works: High Pressure Homogenisation

High pressure homogenisation is an efficient and easy-to-use technique for cell disruption and liposome/emulsion processing.

The principle involves pumping the sample through a valve with a small aperture. The sample transitions from very high pressure (up to 30,000 psi) on the pump side to atmospheric pressure on the outlet side. This sudden drop in pressure creates intense shear forces, disrupting cell membranes or dramatically reducing liposome/emulsion sizes.

For cells, the pressure-induced shear forces rupture the membranes, effectively lysing the cells.

For liposomes and emulsions, this process reduces their size from micron to nanometer range, often resulting in uniform particles with narrow size distributions.

Unique Features of the EmulsiFlex-C5

Dynamic Homogenising Valve

The C5 uses a dynamic homogenising valve, which maintains constant pressure during sample processing. This consistency ensures the formation of highly uniform liposomes and micro-emulsions, with tight particle size distributions.

Efficient Cell Disruption

Most cells (including E. coli) can be lysed in a single pass, minimizing over-processing and reducing the risk of protein denaturation or degradation.

Pressure Range: Adjustable from 500 to 30,000 psi

Flow Rate: 1–5 L/h depending on pressure

Minimum Sample Volume: 7 mL

Holdback Volume: Less than 1 mL

Temperature Control: Can be used with ice baths, external chillers, or in cold rooms

Autoclavable: Easy cleaning and sterilization (SIP-compatible)

Compact Size: 430 × 160 × 320 mm, 25 kg

Power Source: Requires compressed or bottled air. For most applications (e.g., E. coli disruption or liposome formation), 100 psi air pressure is sufficient.

Applications

Disruption of bacterial, yeast, algal, insect, or mammalian cells

Nano-sized liposome and emulsion formation

Particle size reduction in pharmaceuticals, cosmetics, and food products

Liposomal drug delivery systems

Efficient homogenisation for biochemical and biophysical research

Listing

Duxford

Duxford

585 km

Amersham Pharma 35L BPG Cromatography Column

Amersham Pharma35L BPG

Call

Condition: used, This listing is for the Amersham Pharma 35L BPG Cromatography Column

The unit is in full working condition and is ready for immediate use

BPG stands for Bio‑Process Glass or BioProcess Glass (sometimes called BPG columns). They are process‑scale chromatography columns used in biopharmaceutical / downstream protein purification.

Originally from Amersham / Pharmacia, now under GE Healthcare / Cytiva brands.

Hnodpexhdw Hofx Afnsh

Made to be hygienic, scalable, reproducible, for use in situations where high cleanliness, sterility, and regulatory compliance matter (e.g. GMP)

A BPG column (short for BioProcess Glass column) is a process-scale chromatography column designed specifically for downstream purification in biopharmaceutical manufacturing — particularly for the purification of proteins, antibodies, and other biologics

Discover more used machines

Listing

Duxford

Duxford

585 km

BWT LOOPO WFI Storage and Distribution System

BWTLOOP0

Call

Condition: used, This listing is for 1 of 2 BWT LOOPO WFI Storage and Distribution System.

The unit is in full working condition and is ready for immediate release.

Overview

This BWT LOOPO system is a high-performance Water for Injection (WFI) storage and distribution solution, designed for reliable and hygienic operation in pharmaceutical and biotech environments.

Hnodoxhdxwjpfx Afnjh

Mounted on a robust stainless steel skid, the unit includes a high-grade stainless steel storage tank, engineered for ambient temperature WFI applications. The system features Siemens HMI controls for intuitive operation and precise system monitoring.

Key Features

- WFI Storage & Distribution at Ambient Temperature

- 30 kW Power Capacity

- Siemens HMI Touchscreen Interface

- Fully skid-mounted for compact and efficient installation

- Stainless steel construction throughout – skid and tank

- Ideal for pharmaceutical-grade applications

- Designed for continuous circulation to prevent stagnation and microbial growth

Technical Specifications

- System Type: Ambient WFI Storage & Loop

- Construction: Stainless Steel (Skid & Tank)

- Control System: Siemens HMI

- Power Supply: 30 kW

- Installation Type: Skid-Mounted

- Year of Manufacture: 2016

Applications

- Pharmaceutical manufacturing

- Biotech production facilities

- Cleanroom and GMP environments

- Laboratories requiring sterile WFI distribution

Listing

Duxford

Duxford

585 km

Charles Austin Capex 8C Diaphram Pump

Charles AustinCapex 8C

Call

Condition: used, This listing is for a 1 of 2 Charles Austin Capex 8C Diaphram Pump.

Hnsdpfx Afjxxx U Ijnoh

The unit is in full working condition and is ready for immediate release.

The Charles Austin Capex 8C is a highly efficient diaphragm pump designed to deliver a clean, oil-free vacuum and pressure source tailored for laboratory benchtop use. With its durable alloy casing and advanced engineering, the Capex 8C sets a new standard in versatile laboratory vacuum and pressure solutions.

Features:

- Oil-Free Operation: Ensures a clean environment, making it suitable for sensitive applications like microbiology and IVF treatments.

- Quiet Running: Designed for low noise levels, ideal for use in laboratories without disrupting ongoing work.

- Compliant with IEC 1010: Meets electrical safety standards, ensuring safe operation in laboratory settings.

- Versatile Applications: Perfect for vacuum and pressure-assisted filtration, residue analysis, gas monitoring, and evacuating rotary evaporators or desiccators.

- Lightweight Design: Easy to transport and reposition, enhancing usability across different workstations in a lab.

Key Specifications:

- Maximum Flow Rate: 8 L/min

- Vacuum Level: 240 mbar (excellent for sensitive applications)

- Pressure Capability: 200 kPa

- Motor Type: Shaded pole motor for quiet and efficient operation

- Dimensions: 282 mm (W) x 214 mm (D) x 137 mm (H)

- Weight: 3.75 kg (lightweight and portable)

Multipurpose Applications:

- Microbiology Experiments: Ideal for creating a sterile environment during sample handling.

- Embalming Procedures: Provides reliable pressure and vacuum for fluid transfer.

- IVF Treatment: Ensures a clean, controlled environment for sensitive biological processes.

- Waterjet Pump Replacement: A reliable alternative for general laboratory duties.

- Aspiration and Filtration: Effective for removing particles and contaminants from samples.

- Beauty Therapy: Used for vacuum treatments in cosmetic procedures.

Listing

Duxford

Duxford

585 km

GE Axichrom Master 300-1000 Control Tower + GE AxiChrom 300/300 mm Chromatography Column

GE HealthcareAxichrom

Call

Condition: used, This listing is for a GE Axichrom Master 300-1000 Control Tower + GE AxiChrom 300/300 mm Chromatography Column.

The unit is in full working condition and is ready for immediate release.

The GE AxiChrom Master 300-1000 Control Tower and GE AxiChrom 300/300 mm Chromatography Column offer an advanced, scalable solution for automated column packing in biopharmaceutical purification and process development. Designed for seamless integration and ease of operation, this system enhances workflow efficiency, optimizes chromatography resin performance, and supports GMP compliance for manufacturing applications.

Key Features:

GE AxiChrom 300-1000 Master Control Tower:

Automated Column Control: Preprogrammed methods for packing, unpacking, priming, and maintenance to improve uptime.

Touch Screen Interface: Easy-to-use operator interface for precise control.

Integration with UNICORN & Automation Systems: Supports Profibus integration with UNICORN or DeltaV Distributed Control System for batch record tracking and regulatory compliance.

Multi-Column Management: A single AxiChrom Master unit can control up to ten chromatography columns.

Intelligent Packing Wizard: Guides automated priming, packing, and unpacking of chromatography columns.

GE AxiChrom 300/300 mm Chromatography Column:

Automated Column Packing: Ensures verified packing methods for efficient resin performance.

Scalable Design: Adaptable from process development to full-scale production.

Optimized for Modern Chromatography Resins: Supports cutting-edge purification techniques.

Easy Sanitization: Designed for GMP environments, ensuring safe and sterile operation.

Closed-System Connectivity: Can integrate with slurry tanks and chromatography systems for improved process control.

Specifications:

Column Model: GE AxiChrom 300/300 mm

Column Diameter: 300 mm

Column Height: 300 mm

Voltage: 415V

Hertz: 50Hz/60Hz

Control Tower Model: GE AxiChrom Master 300-1000

Width: 670 mm

Depth: 630 mm

Height: 1090 mm

Foot Print: 630 x 670 mm

Weight: 90 kg

EMC: IEC/EN 61326-1, Emission according to CISPR 11, Group 1, class A, CFR 47 FCC Part 15B, class A

Voltage: 380 - 480 V

Frequency: 50/60 Hz

Air Supply: 5.5 - 7 bar g. Clean dry air

Benefits:

Automated & Efficient: Reduces manual intervention, improving process consistency and productivity.

Scalable & Flexible: Ideal for process development and full-scale biomanufacturing.

Regulatory Compliance: Designed for GMP environments with complete regulatory documentation.

Seamless Integration: Connects to UNICORN software, DeltaV, and other automation systems.

Multi-Column Control: One AxiChrom Master can manage up to 10 chromatography columns.

Applications:

This system is ideal for biopharmaceutical purification, including:

Hsdsxxycajpfx Afnonh

Monoclonal Antibody (mAb) Production

Vaccine & Biologic Drug Manufacturing

Recombinant Protein Purification

Gene Therapy & Cell Therapy Processing

With its combination of automated control, intelligent packing, and scalable chromatography, the GE AxiChrom Master 300-1000 Control Tower + GE AxiChrom 300/300 mm Chromatography Column is a powerful asset for biopharmaceutical manufacturing and large-scale purification applications.

Listing

Duxford

Duxford

585 km

Gilson Pipetman L P10mLL 1-10ml Pipette

GilsonPipetman L P10mLL 1-10ml

Call

Condition: used, This listing is for the Gilson Pipetman L P10mLL 1-10ml

The unit is in full working condition and is ready for immediate use

The Gilson Pipetman L P10mLL is a precision liquid handling instrument designed for laboratories requiring reliable and ergonomic pipetting in the 1–10 mL volume range. Ideal for both routine and high-precision applications, this pipette features advanced design enhancements for improved comfort, control, and durability.

Key Features:

Adjustable Volume Range: 1–10 mL for a wide variety of applications

Plastic Tip Ejector: Corrosion-resistant, ideal for working with harsh or volatile chemicals

Ergonomic Design: Lightweight and balanced to reduce fatigue during extended use

Volume Locking System: Prevents accidental volume changes during pipetting

Fully Autoclavable: Ensures sterility and easy decontamination

2D Identification Code: Laser-marked DataMatrix for traceability and inventory management

Exceptional Accuracy and Precision: Built to meet ISO 8655 standards

Applications:

Cell culture and media preparation

Hjdpfxjxv Drtj Afnonh

Buffer and reagent transfers

Clinical, research, and industrial laboratorie

Listing

Duxford

Duxford

585 km

MMM Group Vakulab HL Medical Autoclave

MMM GroupVakulab HL

Call

Condition: used, This listing is for the MMM Group Vakulab HL Medical Autoclave.

The unit is in full working condition and is ready for immediate use.

Overview

The Vakulab HL autoclave from MM Group Medical is a high-performance, GMP-compliant sterilizer designed for the safe, reliable, and validated sterilization of laboratory instruments, equipment, and materials. Specifically engineered for use in pharmaceutical manufacturing, biotechnology facilities, and research laboratories, the Vakulab HL combines advanced vacuum-assisted steam sterilization with robust stainless steel construction to ensure consistent results in even the most demanding applications.

Key Features

Advanced Steam Sterilization

Pre- and Post-Vacuum Cycles: Ensures efficient steam penetration and rapid drying

Optimized Steam Distribution: Uniform sterilization across all load types

Programmable Cycles: Fully adjustable parameters for different sterilization needs

GMP & Cleanroom Ready

Double-Door Pass-Through Design (optional): For installation between clean and non-clean areas

Stainless Steel Chamber & Piping: High-grade AISI 316L for corrosion resistance and hygienic operation

Integrated Monitoring: Real-time cycle control with full batch documentation capability

Operational Safety & Control

User-Friendly HMI: Touchscreen interface for programming and monitoring

Automatic Door Operation: With safety interlocks to prevent accidental opening under pressure

Built-In Diagnostics: Self-check functions for preventive maintenance

Technical Specifications

The Vakulab HL is a vacuum-assisted steam sterilizer available in multiple chamber volumes, typically ranging from 300 to 1,000 liters. The sterilization process operates at temperatures between 121 °C and 134 °C, controlled via a PLC-based system with an intuitive touchscreen human-machine interface (HMI). The chamber is constructed from AISI 316L stainless steel, ensuring corrosion resistance and compliance with GMP hygienic standards.

A water-ring or liquid-ring vacuum pump enables pre-vacuum and post-vacuum phases for thorough air removal and effective drying. Door configurations can be single or double-door in either sliding or hinged formats, with safety interlocks to prevent opening under pressure. The autoclave requires standard utility connections for steam, water, compressed air, and electricity. It is designed to meet EN 285, PED, ISO 9001, and GMP compliance requirements, and can be validated to ISO 17665 sterilization standards.

Hsdpfx Ajxv Dvfofnjnh

Applications

Pharmaceutical Manufacturing: Sterilization of equipment, components, and containers

Biotechnology: Sterilization of fermentation vessels, culture media, and instruments

Research Laboratories: Sterilization of glassware, tools, and lab consumables

Hospitals & Clinical Settings: Safe sterilization of surgical instruments and textiles

System Components

High-grade stainless steel chamber with polished finish

Vacuum pump system for pre- and post-cycle air removal

Steam generation and distribution system

Control panel with PLC and HMI touchscreen

Integrated temperature and pressure sensors for validation

Quality & Compliance

Manufactured in accordance with GMP guidelines

Complies with EN 285 and ISO 17665 sterilization standards

Full FAT/SAT/IQ/OQ/PQ support for validation in regulated environments

Designed for integration into cleanroom and production facilities

Benefits

Consistent, Validated Sterilization for a wide range of load types

Flexible Confi...

Listing

Duxford

Duxford

585 km

3M Zeta Plus 16EZA Encapsulated System Holder

3MZeta Plus 16EZA

Call

Year of construction: 2014, condition: used, This listing is for a 3M Zeta Plus 16EZA Encapsulated System Holder

The unit is in excellent working condition and is ready for immediate release.

The 3M Encapsulated System Holder is engineered to support Zeta Plus depth filtration and related downstream purification processes with optimal ergonomics, hygiene, and operational efficiency. It is specifically designed for biopharmaceutical and biotechnology applications where sterile, high-throughput filtration is required.

Hjdexl Dy Njpfx Afnonh

This system holder accommodates encapsulated filter capsules—eliminating the need for a stainless-steel housing—and offers a pivoting, ergonomic frame that enhances operator safety and eases filter change-outs.

Key Features

Pivoting Holder Design – The housing pivots between horizontal (waist-height) for loading/unloading and vertical for filtration mode, reducing operator strain and minimizing fluid spills during replacement.

Vertical Flow Path Retained – Preserves the proven vertical flow design ideal for depth filtration with 3M Zeta Plus filters and compatibility with 3M polisher or chromatographic clarifiers.

Torque-Limiter Sealing – Built-in torque limiter ensures the capsule shell is properly sealed before operation, protecting against leaks or misassembly.

Encapsulated Shell Architecture – Eliminates the need for an external stainless-steel cartridge housing, thereby reducing facility clean‑in‑place (CIP) or validation overhead.

Shell Options – Offers translucent polycarbonate shells for visual liquid level monitoring or polyphenylene oxide shells capable of sterilization and sanitization.

Multiple Flow Configurations Supported – Enables Bottom-In / Bottom-Out and Top-In / Bottom-Out modes to optimize media usage and filter performance.

Scalable Modules – Available in pilot and full-production configurations, facilitating scale‑up from lab to manufacturing scale within a unified system design.

Technical Specifications

Parameter Description

Model / Part No. Housing 16EZA1

Flow Path Vertical flow design, compatible with multiple flow directions

Shell Materials Polycarbonate or polyphenylene oxide options (sterilizable)

Holder Orientation Pivoting between horizontal (load/unload) & vertical (operational)

Sealing Mechanism Torque‑limiter style sealing indicator

Operational Scale Supports systems from small pilot scale up to production scale (0.5 L to >2,500 L)

Filtration Compatibility 3M Zeta Plus depth filters, 3M Polisher ST, 3M Emphaze AEX Hybrid Purifier, 3M Harvest RC, etc.

Footprint Compact vertical footprint; reduced spatial demand in filtration suites

Applications

Clarification of mammalian cell cultures prior to downstream purification

Protection of downstream membranes and chromatography resins via depth filtration

Clarification of bacterial, yeast, or insect cell lysates

Removal of host cell proteins (HCP), DNA, endotoxins, and particulates

Pre‑polishing or polishing after capture chromatography

Viral clearance modes in downstream workflows

Benefits & Value Proposition

Enhanced Ergonomics & Safety – The pivoting design reduces the need to lift used capsules overhead, lowering risk of spills and operator fatigue.

Lower Validation Burden – Because the system is fully encapsulated, no external housing cleaning or validation is needed in the customer’s site.

Operational Versatility – Flexibility in shell types, flow configurations, and scale continuity from pilot to production.

Visual Process Monitoring – Translucent shell...

Listing

Duxford

Duxford

585 km

Scilog SciTemp Single Use Temperature Sensor

ScilogSciTemp

Call

Condition: used, This listing is for a Scilog SciTemp Single Use Temperature Sensor.

The unit is in full working condition and is ready for immediate release.

The Scilog SciTemp Temperature Sensor is an innovative, pre-calibrated, and single-use temperature sensing solution tailored for the biopharmaceutical manufacturing industry. It offers high-precision temperature monitoring in a compact and disposable format, making it an excellent choice for applications that demand reliability and ease of use.

Key Features:

Pre-Programmed with Unique ID: Each sensor is barcoded with a unique identifier, facilitating easy traceability and efficient data documentation when integrated with SciLog SciDoc software.

Factory Calibration Data: Calibration information is stored on each sensor’s chip, ensuring out-of-the-box, plug-and-play functionality. This means you can start using the sensor immediately without additional setup.

Temperature Range: Operates effectively within a temperature range of 4°C to 70°C, making it suitable for various biopharmaceutical processes.

Gamma-Stable Memory Device: Each sensor features a gamma-stable memory device that securely stores all calibration and sensor-specific information, ensuring data integrity over time.

Multiple Sizes Available: Offered in five different sizes to accommodate various applications and tubing configurations.

Advantages:

Hodpfx Afexx Aausnonh

Single-Use Design: The convenient single-use format eliminates the need for cleaning and sterilization, significantly reducing preparation time and the risk of contamination.

Ease of Use: With pre-calibrated and pre-programmed features, the sensor is straightforward to deploy, minimizing training requirements and operational complexity.

High-Precision Measurement: Ensures accurate temperature data documentation, crucial for compliance and quality assurance in biopharmaceutical manufacturing.

Time and Resource Efficiency: The plug-and-play functionality saves valuable time and resources, allowing for quicker implementation in fast-paced environments.

Scalable Design: Accommodates various tubing sizes, providing flexibility for different processes and setups.

Listing

Duxford

Duxford

585 km

Laboklav 25MV Autoclave Refurbished

Laboklav25MV

Call

Condition: used, This listing is for a refurbished Laboklav 25MV Autoclave

Laboklav 25MV Refurbished Autoclave provides reliable steam sterilization, compact vertical design, user-friendly controls, and efficient, safe performance for laboratories and clinics

Incl. commissioning in UK. (outside the UK is possible also, please request and we will try and accommodate)

Horizontal device, 25l, glass lid

Hsdpfx Afjxx Anrjnsnh

Sterilisation temp. 98-135°C

Outer dimensions (w x h x d in mm) 440 x 540 x 660

Chamber dimensions (Ø x d in mm) 265 x 465

Steam generator 2kW

Fast re-cooling by air

Vacuum incl. pre- and postvacuum, heating during post vacuum

1N 230V, 50Hz, 16A

Refurbished according to manufacturer's specifications:

Reconditioning of pressure vessel incl. pressure test, maintenance incl. spare parts (filter, valves, seal, etc.)

According to requirements: Update of cable tree, steam generator, control system and software to the current status. Test runs to ensure and check functionality

Listing

Duxford

Duxford

585 km

Laboklav 55M Autoclave Refurbished

Laboklav55M

Call

Condition: used, This listing is for a manufacturer refurbished Laboklav 55M Autoclave

The Laboklav 55M refurbished autoclave is a compact and reliable steam sterilization solution for laboratories requiring consistent performance and safety. Designed for efficient sterilization of media, instruments, and laboratory materials, it offers precise temperature and pressure control in a space-saving footprint. Fully refurbished and tested, the Laboklav 55M delivers dependable operation for research, medical, and industrial laboratory environments at a cost-effective price

Incl. commissioning in UK. (outside the UK is possible also, please request and we will try and accomodate)

Vertical device, 55l, can be changed to horizontal version (stand required)

Sterilisation temp. 98-135°C

Outer dimensions (w x h x d in mm) 740 x 765 x 600

Chamber dimensions (Ø x d in mm) 410 x 460

Steam generator 3,3kW

Fast re-cooling with double jacket

Hodpfx Aoxx An Sjfnsnh

1N 230V, 50Hz, 16A

Refurbished according to manufacturer's specifications:

Reconditioning of pressure vessel incl. pressure test, maintenance incl. spare parts (filter, valves, seal, etc.)

According to requirements: Update of cable tree, steam generator, control system and software to the current status. Test runs to ensure and check functionality

Listing

Duxford

Duxford

585 km

2014 Mueller PyroPure P7310 Pure Steam Generator

MuellerPyroPure P7310

Call

Year of construction: 2014, condition: used, This listing is for 1 of 2 Mueller PyroPure P7310 Pure Steam Generator.

The unit is in full working condition and is ready for immediate release.

This Unit was installed new in 2015 by Freestead Process Technology.

The “Turned on Time”of the unit is 65,000 hours, but as this unit is 1 of 2 generators in an alternating system it does not indicate the "Steam Production Time". The sites steam requirements were low therefore the unit is in immaculate condition.

They have full maintenance records backed up on their electronic technical system supplied as an extra by Freestead.

This Unit is fitted with a Allen Bradley Compact Logix PLC and Panel View plus 1000 HMI's

The Unit is supplied with-

⦁ Feed water pump system

⦁ Pure steam condensate sampling system

⦁ Pure steam analyser

⦁ Stainless steel sheathing and frame

⦁ Feed water analyser

⦁ Degasser

The Mueller PyroPure P7310 Pure Steam Generator is a high-performance system designed to produce pyrogen-free pure steam suitable for the most demanding applications, such as pharmaceutical production, biotechnology processes, and healthcare sterilization. Built to meet or exceed U.S. Pharmacopoeia (USP) standards, the P7310 combines precision engineering, advanced technology, and robust materials to ensure consistent performance and reliability. They are CE marked and compliant with 3.1B material certification.

The terms pure steam and clean steam are often used interchangeably in the pharmaceutical industry. However, not all equipment marketed as clean steam generators are up to the task of producing WFI quality pharmaceutical pure steam. Mueller pure steam generators use a tangential nozzle to provide separation of impurities from incoming feed water, producing pyrogen-free steam that, when condensed, meets USP requirements for water for injection.

Key Benefits

Superior Steam Quality:

Produces pyrogen-free steam that meets USP requirements, ensuring safety and regulatory compliance.

Optimized for critical applications like autoclaves, clean room humidification, and steam-in-place (SIP) sterilization.

Achieves a 5 Log reduction in contaminants, which corresponds to a 99.999% reduction in microbial populations. This level of reduction ensures the highest degree of sterilization, making it ideal for pharmaceutical and biotechnology applications where absolute purity is critical.

Hjdpfx Ajxv Af Sefnenh

Efficient Design:

External evaporator allows easy access for inspection and maintenance, reducing downtime.

Separation column has no internal components requiring maintenance, eliminating potential for bacterial growth.

Efficient heat transfer with a double-tube sheet evaporator minimizes stress cracking and maximizes performance.

Ease of Maintenance:

All critical components can be serviced with only 24" of clearance around the system.

Fully drainable design prevents standing water, reducing contamination risks.

Polished 316/316L stainless steel construction ensures durability and easy cleaning.

Enhanced Operational Features:

Minimal instrumentation is required, reducing complexity and operational costs.

Simplified control with an Allen-Bradley PLC system, compatible with Ethernet for integration with facility systems.

Certified elastomers (USP Class VI) provide enhanced compatibility with feed water and product.

Specifications

Performance:

Pure Steam Capacity: from 0 to 700 kg/hr at optimal feed water conditions.

Operating Pressure Range: Pure steam output pressure up to 50 psig.

Mater...

Listing

Duxford

Duxford

585 km

Oxoid Tryptone Soya Broth 10Kg

Oxoid LtdTryptone

Call

Year of construction: 2025, condition: used, 10Kg Thermo Scientific™ Tryptone Soy Broth (Soybean Case in Digest Medium EP/USP/BP/JP) (Dehydrated)

New in original packaging

Dated for use by end January 2026

Representing a price reduction of around 80% from the manufacturers retail price list

Soybean Casein Digest (SCD), also known as Soybean-Casein Digest Medium or Tryptic Soy Broth (TSB), is a general-purpose nutrient medium used for cultivating a wide range of microorganisms, including bacteria and fungi. It's especially valuable because it's rich in nutrients derived from enzymatic digests of soybean meal and casein (milk protein)

Used By

1. Pharmaceutical Industry

- Sterility testing of pharmaceutical products (especially injectables and ophthalmic solutions).

- Microbial limit testing of raw materials, finished products, and water.

- Environmental monitoring (e.g., surface swabs, air sampling).

2. Medical Device Manufacturers

- Used for sterility testing of surgical instruments, implants, catheters, etc.

3. Hospitals & Clinical Laboratories

- For culturing bacteria and fungi from clinical specimens.

- Used in blood culture bottles to detect septicemia.

4. Food and Beverage Industry

- To test for microbial contamination in food products.

- Used for hygiene monitoring in food processing environments.

5. Biotechnology and Research Laboratories

Hjdpfx Ajxv A Sfefnenh

- General purpose medium for growing a variety of microbes in research.

- Useful in antibiotic sensitivity testing or microbiome studies.

6. Cosmetic Industry

- For microbial limit testing and product safety validation.

Listing

Duxford

Duxford

585 km

Watson Marlow 630S Peristaltic Pump

Watson Marlow630S

Call

Condition: used, This listing is for 1 of 3 Watson Marlow 630S Peristaltic Pumps

These units are in full working condition and ready for immediate use

A peristaltic pump moves fluid through a flexible tube by sequentially compressing the tube (like a wave) which pushes the fluid forward. Because only the inner surface of the tube contacts the fluid, the pump mechanism is isolated from the fluid — this is useful for:

Handling corrosive, abrasive or sterile fluids

Avoiding contamination (the pump body doesn’t contact the fluid)

Easy maintenance (replace the tubing rather than the pump’s internal components)

Watson‑Marlow is a well-known maker of such pumps in lab, process, pharmaceutical, chemical, water treatment, and industrial settings.

Typical applications / use cases

Because of the flexibility, purity, and control of peristaltic pumps, the 630S is used in:

Hnodpexhdtbjfx Afneh

Chemical dosing / metering (acid, base, reagents)

Pharmaceutical / biotech processes

Water / wastewater treatment

Food & beverage (for sterile or food-contact fluids)

Laboratory and pilot-scale processing

Listing

Duxford

Duxford

585 km

Walker Safety Cabiets All-In-One Fumigation Unit

Walker Safety CabinetsAll-In-One

Call

Condition: used, This listing is for a Walker Safety Cabiets All-In-One Fumigation Unit.

The unit is in full working condition and is ready for immediate release.

The Walker Safety Cabinets All-In-One Fumigation Unit is an innovative and compact solution for fumigating safety cabinets of all makes and models. Designed with efficiency and convenience in mind, this unit combines a built-in boiler and a carbon filtration system into one easy-to-use device.

Key Features:

- Compact Design: Height: Less than 200 mm, allowing it to fit inside a typical safety cabinet opening without the need to open the door further.

- Integrated System: Combines a boiler and carbon filtration system, ensuring comprehensive fumigation in a single device.

- Capacity: Maximum capacity of 30 ml of formaldehyde and 30 ml of water, making it effective and economical for fumigation processes.

- Carbon Filtration: Replaceable Carbon Granules: Requires replacement after each use to ensure optimal performance.

- Fresh Supply: Carbon granules are inexpensive and readily available, with a typical shelf life of approximately 18 months.

- Walker Safety Cabinets ensures quick delivery of replacement granules for uninterrupted operation.

- Benefits: Versatile Compatibility: Effective for fumigation of all safety cabinet brands and models.

- Efficient Operation: The compact, integrated design minimizes space requirements while maximizing performance.

Hsdpfjxxx R Nsx Afnenh

- Cost-Effective Maintenance: Affordable and easy-to-replace carbon granules keep operating costs low.

Applications:

- The All-In-One Fumigation Unit is ideal for laboratories and facilities that require effective and convenient fumigation of safety cabinets, ensuring a safe and sterile work environment.

Listing

Wald

Wald

1,366 km

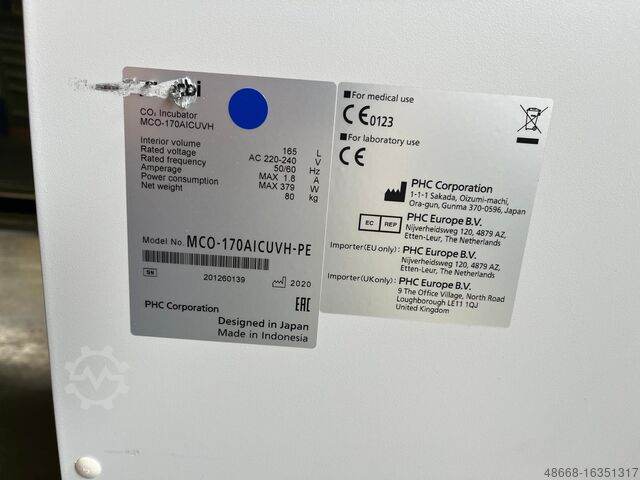

CO2 incubator cabinet H2O2

PHCbiMCO-170AICUVH-PE

Call

Year of construction: 2021, condition: used, PHCbi MCO-170AICUVH-PE CO2 incubator cabinet H2O2 decontamination

Temperature: AT +5 ~ +50, ±0.1 °C

Temperature uniformity: ±0.25 °C

Hodpotxakxsfx Afnsnh

CO2 control range and fluctuation: 0 ~ 20, ±0.15 %

Year of construction: 2021

Dimensions: 650mm x 620mm x 1000mm ( outside )

480mm x 500mm x 650mm ( inside )

Weight: approx. 80 kg

PHCbi

Creating successful cell cultures requires an incubator that offers a high level of precision and safety and is easy to use. IncuSafe offers a variety of cell culture incubators that utilize advanced technologies for unparalleled temperature and CO2 (and in some models O2) control when processing different cell cultures. These deliver long-term performance, are highly reliable and efficient.

- inCu-saFe® interior (proactive contamination control, copper-enriched stainless steel alloy): combines the germicidal properties of copper and the corrosion resistance of stainless steel.

- SafeCell UV proactive contamination control: the UV lamp isolated from the cell cultures decontaminates the circulating air and the water in the water tray without harming the cell cultures.

- H2O2 decontamination technology: PHCbi's unique high-speed decontamination system uses gaseous H2O2, enabling time-saving and documented decontamination in the chamber with a high degree of safety. Electronic door lock that automatically locks the chamber during the decontamination phase.

- Dual hot air sterilization (+ 180 °C). No interference and uninterrupted operation with stacked incubators during the sterilization cycle (model: MCO-170AICUVD-PE).

- Long-term good performance, optimal cell viability and successful experiments. It also enables precise control of CO2 concentration and temperature with easy operation and maintenance.

- Patented DHA direct heating and air jacket system*: high-precision temperature control for advanced temperature stability and fast temperature recovery times after opening the door.

- Fast CO2 recovery times: with the PID controller and the dual infrared sensor, an ultra-fast CO2 recovery time is achieved without overheating. Even after opening the door several times.

- The unique solid-state O2 zirconium oxide sensor in the multigas incubators enables precise control of physiological oxygen concentrations to simulate in vivo conditions

Description has been adopted.

You are welcome to come by for a viewing.

We will be happy to arrange a cost-effective forwarding agent for you.

organize!

You will receive a proper invoice.

A net invoice can also be issued for foreign customers. Prerequisite is a valid VAT number.

Subject to prior sale.

Visit our store and have a look at our other offers.

Company names and trademarks are the property of their owners and are used only to identify and describe the products.

Deviations from technical data and errors in the description of the article may occur and are reserved.

Listing

Wald

Wald

1,366 km

CO2 incubator cabinet H2O2

PHCbiMCO-170AICUVH-PE

Call

Year of construction: 2020, condition: used, PHCbi MCO-170AICUVH-PE CO2 incubator cabinet H2O2 decontamination

Temperature: AT +5 ~ +50, ±0.1 °C

Temperature uniformity: ±0.25 °C

CO2 control range and fluctuation: 0 ~ 20, ±0.15 %

Year of construction: 2020

Dimensions: 650mm x 620mm x 1000mm ( outside )

480mm x 500mm x 650mm ( inside )

Weight: approx. 80 kg

PHCbi

Creating successful cell cultures requires an incubator that offers a high level of precision and safety and is easy to use. IncuSafe offers a variety of cell culture incubators that utilize advanced technologies for unparalleled temperature and CO2 (and in some models O2) control when processing different cell cultures. These deliver long-term performance, are highly reliable and efficient.

- inCu-saFe® interior (proactive contamination control, copper-enriched stainless steel alloy): combines the germicidal properties of copper and the corrosion resistance of stainless steel.

- SafeCell UV proactive contamination control: the UV lamp isolated from the cell cultures decontaminates the circulating air and the water in the water tray without harming the cell cultures.

- H2O2 decontamination technology: PHCbi's unique high-speed decontamination system uses gaseous H2O2, enabling time-saving and documented decontamination in the chamber with a high degree of safety. Electronic door lock that automatically locks the chamber during the decontamination phase.

- Dual hot air sterilization (+ 180 °C). No interference and uninterrupted operation with stacked incubators during the sterilization cycle (model: MCO-170AICUVD-PE).

- Long-term good performance, optimal cell viability and successful experiments. It also enables precise control of CO2 concentration and temperature with easy operation and maintenance.

- Patented DHA direct heating and air jacket system*: high-precision temperature control for advanced temperature stability and fast temperature recovery times after opening the door.

- Fast CO2 recovery times: with the PID controller and the dual infrared sensor, an ultra-fast CO2 recovery time is achieved without overheating. Even after opening the door several times.

- The unique solid-state O2 zirconium oxide sensor in the multigas incubators enables precise control of physiological oxygen concentrations to simulate in vivo conditions.

- Condensation control: this prevents unwanted condensation in the chamber and possible contamination.

Description has been adopted.

You are welcome to come by for a viewing.

We will be happy to arrange a cost-effective forwarding agent for you.

organize!

You will receive a proper invoice.

Hjdpfx Afjtxaczonenh

A net invoice can also be issued for foreign customers. Prerequisite is a valid VAT number.

Subject to prior sale.

Visit our store and have a look at our other offers.

Company names and trademarks are the property of their owners and are used only to identify and describe the products.

Deviations from technical data and errors in the description of the article may occur and are reserved.

Listing

Wald

Wald

1,366 km

CO2 incubator cabinet H2O2

PHCbiMCO-170AICUVH-PE

Call

Year of construction: 2020, condition: used, PHCbi MCO-170AICUVH-PE CO2 incubator cabinet H2O2 decontamination

Temperature: AT +5 ~ +50, ±0.1 °C

Temperature uniformity: ±0.25 °C

CO2 control range and fluctuation: 0 ~ 20, ±0.15 %

Year of construction: 2020

Dimensions: 650mm x 620mm x 1000mm ( outside )

480mm x 500mm x 650mm ( inside )

Weight: approx. 80 kg

PHCbi

Creating successful cell cultures requires an incubator that offers a high level of precision and safety and is easy to use. IncuSafe offers a variety of cell culture incubators that utilize advanced technologies for unparalleled temperature and CO2 (and in some models O2) control when processing different cell cultures. These deliver long-term performance, are highly reliable and efficient.

- inCu-saFe® interior (proactive contamination control, copper-enriched stainless steel alloy): combines the germicidal properties of copper and the corrosion resistance of stainless steel.

- SafeCell UV proactive contamination control: the UV lamp isolated from the cell cultures decontaminates the circulating air and the water in the water tray without harming the cell cultures.

- H2O2 decontamination technology: PHCbi's unique high-speed decontamination system uses gaseous H2O2, enabling time-saving and documented decontamination in the chamber with a high degree of safety. Electronic door lock that automatically locks the chamber during the decontamination phase.

- Dual hot air sterilization (+ 180 °C). No interference and uninterrupted operation with stacked incubators during the sterilization cycle (model: MCO-170AICUVD-PE).

- Long-term good performance, optimal cell viability and successful experiments. It also enables precise control of CO2 concentration and temperature with easy operation and maintenance.

- Patented DHA direct heating and air jacket system*: high-precision temperature control for advanced temperature stability and fast temperature recovery times after opening the door.

- Fast CO2 recovery times: with the PID controller and the dual infrared sensor, an ultra-fast CO2 recovery time is achieved without overheating. Even after opening the door several times.

- The unique solid-state O2 zirconium oxide sensor in the multigas incubators enables precise control of physiological oxygen concentrations to simulate in vivo conditions.

Description has been adopted.

You are welcome to come by for a viewing.

Hjdpfx Astxarcjfnonh

We will be happy to arrange a cost-effective forwarding agent for you.

organize!

You will receive a proper invoice.

A net invoice can also be issued for foreign customers. Prerequisite is a valid VAT number.

Subject to prior sale.

Visit our store and have a look at our other offers.

Company names and trademarks are the property of their owners and are used only to identify and describe the products.

Deviations from technical data and errors in the description of the article may occur and are reserved.

Trust Seal

Dealers certified through Machineseeker

Listing

Switzerland

Switzerland

1,630 km

Used Aseptic Fllling Line SIPA GEA for milk up to 48.000 bph

AERZEN

Call

Condition: used, Year of construction: 2018, operating hours: 900 h, machine/vehicle number: LC524, Used Aseptic Filling Line SIPA GEA for Milk up to 48,000 bph

Hedpsyhcivsfx Afnsnh

GEA ASEPTIC BLOW FILL SYSTEM ABF 2.0

Fully aseptic blowing, filling and capping system featuring H2O2-based preforms sterilization.

Introduction to the Aseptic Filling Line SIPA GEA for Milk up to 48,000 bhp

The used aseptic filling line SIPA GEA for milk up to 48,000 bottles per hour delivers a highly efficient and technologically advanced solution for the packaging industry. Specifically, this system ensures high-quality standards and food safety by using machines from 2018. Moreover, it processes milk in 235 ml bottles with plastic screw caps and a 38 mm neck. The line has only 900 operating hours.

SIPA SFR 24 EVO Blow Molding Machine of SIPA and GEA aseptic line

The SIPA SFR 24 EVO blow molding machine, manufactured by GEA in 2018, produces high-quality bottles from PET preforms. As a result, it maintains continuous and uninterrupted production, ensuring efficiency. In addition, the SFR 24 EVO model optimizes energy consumption and shapes containers with precision, making it ideal for high-performance lines like the Used Aseptic Filling Line SIPA GEA for Milk up to 48,000 bph.

GEA Filling Machine

The GEA filling machine, also from 2018, controls the core of the system. Since it fills milk in an aseptic environment, it preserves the organoleptic and microbiological properties of the product. Furthermore, the SIPA and GEA aseptic line doses the product with precision and operates reliably, reducing waste and improving overall efficiency. Consequently, it enhances productivity while maintaining strict hygiene standards.

Arol Capping Machine for Secure Sealing

The Arol capping machine, built in 2018, securely seals bottles with plastic screw caps. Likewise, it ensures a tight closure and matches the 38 mm neck perfectly. As a result, its integration into the line guarantees fast and uniform capping, preventing leaks and maintaining product integrity.

Aerzen GM25S Compressor

The Aerzen GM25S compressor, from 2018, powers the blow molding process. In particular, it supplies high-quality compressed air, which the machine requires for shaping PET bottles. Notably, its efficiency and reliability support seamless production. Therefore, it plays a crucial role in maintaining high-speed output.

Operational Condition and Limited Use

The Used Aseptic Filling Line SIPA GEA for Milk up to 48,000 bph processed only around a hundred production cycles, keeping the machines in excellent condition. Thus, the limited use ensures optimal performance and minimizes wear, making this system nearly new in operational terms. Additionally, well-maintained components extend the machine’s lifespan, reducing the need for costly replacements.

Line Efficiency and Performance

The Used Aseptic Filling Line SIPA GEA for Milk up to 48,000 bph combines high-performance machines designed specifically for milk processing. Consequently, it enables fast and efficient production while meeting strict aseptic standards. Moreover, the line reaches speeds of up to 48,000 bottles per hour, making it a strategic choice for producers competing in high-demand markets. Similarly, it supports companies looking to improve productivit...

Listing

Nicaragua

Nicaragua

1,630 km

Used UHT Milk Preparation Room Tetra Pak 4000 L-h

Call

Condition: used, Year of construction: 2006, machine/vehicle number: LC562, Used UHT Milk Preparation Room Tetra Pak 4000 L-h

Operating Capacity and Product Versatility

The Used UHT Milk Preparation Room Tetra Pak 4000 L-h delivers optimized aseptic thermal processing for dairy and beverage applications. Specifically, the unit operates at variable flow rates from 2000 to 4000 liters per hour, making it suitable for plain milk, flavored milk, drinking yoghurt, and condensed milk. Furthermore, with program adjustments, the same line also processes fruit juices, nectars, and soft drinks. As a result, this flexibility makes it ideal for multi-product operations. The plant currently remains in storage, and as such, is ready for relocation and installation in a new production facility.

In-Line Aseptic Homogenization

Hodsyhbudjpfx Afnjnh

The Used UHT Milk Preparation Room Tetra Pak 4000 L-h includes an aseptic homogenizer manufactured by Tetra Pak, model Tetra Alex, year 2006. In particular, this unit, positioned downstream of preheating, operates in sterile conditions to ensure the breakdown of fat globules and uniform dispersion of solid and liquid phases. Consequently, it helps preserve the emulsion stability of flavored milk and yoghurt drinks. Moreover, the inline aseptic design reduces contamination risk after thermal processing. Therefore, it maintains the product’s physical and chemical consistency throughout downstream stages. In addition, the robust construction simplifies cleaning and routine maintenance.

Clean-in-Place (CIP) System

The line integrates a CIP (Clean-in-Place) system supplied by Gemak in 2009, which consists of four dedicated tanks: nitric acid, caustic soda, hot water, and rinse water. Notably, the system automatically sanitizes all product-contact surfaces under controlled parameters. In doing so, it ensures compliance with hygiene standards across multiple cleaning phases. Additionally, it manages solution recovery and water usage optimization across all cleaning circuits. As such, the CIP system in the Used UHT Milk Preparation Room Tetra Pak 4000 L-h minimizes downtime and supports continuous production. Above all, it protects product integrity between production cycles.

Thermal Treatment and Holding Time Control

The sterilization process relies on a holding coil supplied by Tetra Pak in 2006, designed to maintain the product at the target temperature for the required time. When paired with a tubular UHT heat exchanger, this coil enables indirect and uniform thermal processing. Thus, the system ensures accurate residence times and optimal microbial reduction. Likewise, the unit maintains organoleptic properties through consistent thermal transfer. Therefore, the Used UHT Milk Preparation Room Tetra Pak 4000 L-h delivers reliable processing for both dairy and plant-based applications.

Deaeration and Sterile Storage

The system includes a Tetra Pak deaerator from 2006, which removes dissolved oxygen and unwanted gases before the UHT process. Accordingly, it improves product shelf-life and minimizes oxidative degradation. Furthermore, the deaerator connects directly to a 3500-liter sterile tank, model Alsafe, also by Tetra Pak (2006). Because of this connection, the product transfers in a closed, sterile environment. In turn, this configuration preserves product sterility after treatment and maintains aseptic conditions up to the filling stage.

Technical Conclusion

In summary, the Used UHT Milk Preparation Roo...

Listing

Netherlands

Netherlands

1,630 km

Used aseptic tank Tetrapak 2010 - 13.000 liters

Tetra Pak®

Call

Year of construction: 2010, condition: used, machine/vehicle number: TNK7, Technical Specifications & Performance Data

This aseptic storage tank is engineered for hygienic storage and buffering of sensitive liquid food products in beverage production and industrial packaging environments. Manufactured by Tetra Pak in 2010, it is ideal for second hand facilities upgrading or expanding an existing used bottling line with reliable aseptic capacity. Two units are available, each offering substantial storage volume with robust sanitary construction.

Type: Aseptic storage tank for liquid food products

Manufacturer: Tetra Pak

Year: 2010

Nominal capacity (per tank): 13,000 liters

Maximum product weight:

Construction: High-quality stainless steel, sanitary design

Valve system: Cluster valves for controlled, hygienic product flow

Quantity available: 2 units (per-tank specification)

Application: Aseptic storage of milk, flavored milk, juices, and liquid dairy products

Advanced Automation & Control Systems

The tank integrates seamlessly into automated aseptic processes. Cluster valves enable precise, automated product routing with minimized contamination risk and simplified cleaning transitions. The design supports CIP (Cleaning-in-Place), ensuring efficient sanitation cycles and repeatable hygienic performance across production shifts. The aseptic configuration is engineered to protect product integrity and maintain sterility from upstream processing through downstream filling and packaging machinery.

Production Line Integration Capabilities

This aseptic tank is designed to interface with UHT processing lines, fillers, and other bottling equipment within a used bottling line or new installation. It enables stable buffering between processing and filling, improving uptime and throughput in beverage production. The sanitary connections and cluster valve manifolds simplify tie-ins to existing pipelines and control strategies, facilitating integration into multi-product operations in dairy and juice applications.

Machine Condition & Maintenance History

Hodeyhbm Tspfx Afnsnh

These second hand tanks come from a professional food and beverage environment and are presented as ready for operation, consistent with Tetra Pak’s durable hygienic engineering. The aseptic configuration and CIP-ready design support ongoing sanitary maintenance programs and long service life in industrial packaging settings.

Operational Performance & Versatility

Optimized for liquid dairy and juice products, the tank maintains sterility to help preserve product quality and shelf life prior to filling. The stainless steel construction, sanitary welds, and aseptic valves support stringent hygiene protocols. This configuration is well-suited for producers seeking dependable storage capacity to stabilize production, reduce changeover risks, and align processing cadence with filling schedules across beverage production lines.

Installation Requirements & Site Preparation

Installation typically requires appropriate floor space, access for piping to upstream/downstream equipment, and utilities compatible with aseptic processes. The tank supports CIP connections for caustic and rinse media, and the valve cluster accommodates ...

Listing

Georgia

Georgia

1,630 km

Used complete filling Krones CSD PET line – 22.000 bph

GEA

Call

Condition: used, Year of construction: 2010, operating hours: 47,000 h, machine/vehicle number: LC582, Used Complete Krones CSD PET Bottling Line – 22,000 BPH – Overview

This second hand, ultra-clean Krones CSD PET bottling line is a complete, high-efficiency solution for beverage production and industrial packaging across carbonated soft drinks, cider, sparkling water, still water and CO2-mixed juices. Built by Krones and GEA in 2010 and kept in production with OEM service, the line delivers up to 22,000 bottles per hour (0.5 L) and 18,000 bph (1.5 L), combining a Contiform S12M blow molder directly coupled to an ultra-clean isobaric filler-capper bloc. It is a market-ready used bottling line designed for reliability, hygiene, and quick format changeovers in PET.

Technical Specifications & Performance Data

Manufacturer: Krones and GEA

Year of manufacture: 2010

Working hours: approx. 47,000

Nominal capacity: 22,000 bph (0.5 L) | 18,000 bph (1.5 L)

Products handled: carbonated soft drinks, cider, sparkling water, still water, juices with CO2

Filling technology: Ultra-clean, isobaric, volumetric PET filling

Current product: Apple juice with water and CO2

Neck finishes: PCO 1810, PSO 28 mm, 1810/1881 short neck

Controls: Siemens Simatic S7 PLC platform

Main Equipment Scope

CIP: Krones VarioClean F AUT fully automatic CIP system, 4 x 5000 L, 30 m³/h

Process: GEA TDS plant with flash pasteurizer, mixer, carbonator, degasser and process tanks

Preforms: Preform tipper/kipper and feeding conveyors; Krones Contifeed RS preform feeding system; Prejet Linear preform cleaning unit

Caps: Cassner cap feeding with cap rinsing and sterilization

Blow molder: Krones Contiform S12M, directly connected to the ultra-clean bloc (no air conveyor)

Filler/Capper bloc: Krones Volumetric VODM-PET 2.160-66-103 with integrated capper; Krones Vario Dos filler-bloc cleaning

Coding and inspection: Domino DDC 3 laser coder; Krones Checkmat 731 FM-X+L filling level inspector; Krones Checkmat 731 EM label inspector

Conveying and testing: SYNCO bottle conveyors; Krones Flowliner bottle leak tester

Labeller: Krones Contiroll OPP 720-15, double roll-feed wrap-around labels with hot glue

Secondary packaging: Krones VarioPro FS shrink–tray packer; Krones Multico S packet conveyors; Twin Pack handle applicator

Pack coding: Leisinger Jet 3 ink coder

Palletizing: Krones Robopox Modulpal (2016)

Advanced Automation & Control Systems

Line Control & PLC

Siemens Simatic S7-series PLC for coordinated line control, interlocks and diagnostics

Integrated filler-bloc cleaning via Krones Vario Dos for validated ultra-clean cycles

Recipe and parameter management supporting fast changeovers between PET formats

Quality Assurance & Traceability

Laser date coding (Domino DDC 3) on primary packaging; inkjet coding (Leisinger Jet 3) on packs

In-line inspection with Krones Checkmat systems for fill level and label presence/position

Leak detection via Krones Flowliner for container integrity

Production Line Integration Capabilities

Hnodpfx Aoyhbmtofneh

Upstream (Preforms to Bottles)

Automated preform handling: tipper, conveyors and Krones Contifeed RS for steady feed

Preform cleaning (Prejet Linear) to protect blowing ...

We make it easier for you to find: "sterilizer"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Sterilizer (216)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you