Used Sound Enclosure for sale (2,078)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Duxford

Duxford

585 km

Watson Marlow 620S/R Peristaltic Pump

Watson Marlow620S/R

Call

Condition: used, This listing is for 1 of 7 Watson Marlow 620S/R Peristaltic Pumps

The units are in full working condition and ready for immediate use

Gbodpfxjxhdx Do Afnsh

Design & Functionality

The 620S/R model is part of the 600 Series of cased peristaltic pumps featuring a brushless DC motor equipped with digital keypad control (620S) and a sturdy NEMA 2 / IP31 vented, wipe‑down enclosure suited for dry industrial environments ,It operates at dual voltage (100–120 V or 200–240 V, 50/60 Hz) and includes features like MemoDose for one-shot dosing and wireless guard-switching for safety

The casing is chemically resistant, with powder-coated die-cast aluminium construction and an easy-to-clean membrane keypad

Pump Performance

Flow range: 0.00026 to ~4.23 gpm (equivalent to ~0.001 to 16 L/min) with the 620R pump head

With newer 620RE LoadSure heads, the flow increases up to ~4.76 gpm (0.004–18 L/min)

Pressure capability: Up to approximately 60 psi (4 bar) with the appropriate head and tubing

Control accuracy: Exceptional 2,650:1 turndown ratio, fine speed control from 0.1 to 265 rpm in selectable increments (0.1, 0.5, 1, 2, 5, or 10 rpm), with 0.1% speed accuracy

Pump Heads & Tubing

The model supports the following interchangeable pump heads:

620R Mk II (continuous tubing, two rollers)

620RE and 620RE4 (LoadSure elements, two or four rollers)

These heads are compatible with various tubing materials (e.g., Marprene™, Bioprene™, Sta‑Pure™, silicone) and sizes (typically 6.4 mm to 17 mm inner diameter)

The 620RE and RE4 heads feature retractable rollers for easier cleaning (CIP/SIP) and rapid loading

AFAB Lab Resources - Used Lab Equipment

Physical Attributes & Construction

Ingress Protection: IP31 (NEMA 2) for the standard 620S/R; there are IP66/NEMA 4X variants (e.g., 620SN/R) for environments requiring better dust and water resistance

Weight: Around 19.6 kg (with 620R/RE head) to 20.1 kg (with 620RE4)

Sound level: Less than 70 dB(A) at 1 m—relatively quiet for continuous industrial operation

Advanced Features

MemoDose: Delivers precise single-shot volumes—ideal for dosing applications

Ramp function & non‑drip: Ramp improves handling of delicate fluids, preventing splashes/frothing, while non-drip minimizes residual drips at dose end (noted in related Di versions but often included in feature suites)

Data export: Some models (e.g. 620S/RE) support RS‑232 export of batch records—important for GMP compliance

Listing

Duxford

Duxford

585 km

Fisher Scientific FB120 Sonic Dismembrator

Fisher ScientificFB120

Call

Condition: used, This listing is for a Fisher Scientific FB120 Sonic Dismembrator.

The unit is in full working condition and is ready for immediate release.

Gbedpfx Aexxx Unsfnoh

This unit is supplied with a Fisherbrand Sound Enclosure.

The Fisher Scientific FB120 Sonic Dismembrator is a versatile device designed for efficient analysis and sample preparation, particularly suited for small volumes. Whether for cell disruption, protein extraction, or DNA shearing, this sonic dismembrator ensures consistent, reproducible results across a wide range of applications.

Key Features:

- Manual and Programmable Operation: Offers both manual control and programmable settings for enhanced flexibility, allowing you to set specific processing parameters from 1 second to 10 hours for tailored sample preparation.

- Volume Range: Capable of processing volumes from 0.2 to 50 mL, making it ideal for small-scale experiments.

- Power and Performance: Operates at 120 watts, ensuring efficient sample processing with precise energy application.

- Pulse Mode Functionality: Features a pulse mode that allows for intervals from 1 second to 59 seconds, providing control over the intensity and duration of sonication.

- Energy Display: Real-time monitoring of energy output in watts and joules, giving insight into the processing conditions.

Specifications:

- Voltage Options: Available in two configurations:

- 110/117 V, 50/60 Hz

- 220/230 V, 50/60 Hz

- Dimensions: 13.5 x 8 x 6 in. (34.29 x 20.32 x 15.24 cm), designed for compact laboratory spaces.

Listing

Shrewsbury

Shrewsbury

376 km

Moulder with 9 Spindles

WEINIGUnimat 23 EL

Call

Condition: good (used), Year of construction: 1998, functionality: not functional, machine/vehicle number: 88208, working width: 230 mm, planing height: 120 mm, spindle diameter: 40 mm, planing width: 220 mm, working height: 120 mm, total width: 220 mm, total height: 120 mm, spindle speed (min.): 6,000 rpm, extraction nozzle diameter: 150 mm, planer shaft diameter: 40 mm, input current: 400 A, table width: 230 mm, blade shaft diameter: 40 mm, Equipment: motor brake, Weinig Unimat 23 EL Planing & Moulding Machine with 9 Spindles, No: 88210 Year 1998

In good condition, with safety enclosure and Accoustic Sound & Safety Booth.

Good HP, B11, R11, L11, R11, L11, T11, B22(Rip Saw Head) T11, B11 all kw.

2m. Infeed Table.

Pneumatic Pressure to Feed Rollers.

Wax Pump.

Feed Speed from 6-36m/min.

Gedpfx Asx Elagsfnebh

Some Planing Heads are on the machine.

With full documentation.

Can be viewed at The Old Basket Works, Lyng Road, Burrowbridge, Somerset TA7 0SG

Photos available on WhatsApp.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Metzingen

Metzingen

1,339 km

Gear Testing Machine

KLINGELNBERGR 30

Call

Condition: excellent (used), Year of construction: 2007, max. wheel diameter 400 mm

weight of the machine ca. 4 t

Q U O T A T I O N

We are pleased to offer you ex our stock, subject to prior sale, and error in technical data :

KLINGELNBERG

Single- and double-flank rolling test machine with structure-borne sound testing

model R 30

year 2007 _____

Workpiece outer diameter min. / max. 36 / 300 mm

Center distance between workpiece and counter wheel 135 - 290 mm

Spindle speeds max. 3.000 rpm

Drive torque max. up to 2196 rpm 20 Nm

Drive torque max. 2196 – 3.000 rpm 14,7 Nm

Spindle drive 4,62 kW

Total drive approx. 10 kW - 400 V - 50 Hz

Total weight approx. 4.000 kg

Accessories / Special Features:

• The machine is a universal rolling tester designed for the following testing procedures:

Gbjdpfx Afjxvdryjnjh

o Single-flank rolling test

o Double-flank rolling test

o Structure-borne noise testing in single and double-flank contact

o Helix testing in double-flank contact

• WINDOWS PC control for measurement data acquisition and analysis with the

NoisyS32 testing software

• SIEMENS control panel for operating the machine and evaluating the test cycles

• Complete enclosure with electrically monitored sliding doors

• Attached control cabinet, various accessories, operating instructions

• Unfortunately, the license dongle for activating the measurement software is currently missing. We hope to receive it from the supplier of the machine.

Condition : very good condition ! Almost unused !

Soon : Please click here to view a video of the machine running :

!

Delivery : immediately available, FCA Metzingen

Payment : 100 % Net, after conclusion of contract, before loading

We always have a large selection gear machines – CNC or conventional - available. Please let us know your requirements.

Listing

Shrewsbury

Shrewsbury

376 km

End Matching machine for flooring

FriulmacRandomat E

Call

Condition: excellent (used), Year of construction: 2001, functionality: fully functional, machine/vehicle number: 32664, collet bore: 40 mm, saw blade diameter: 220 mm, main saw diameter: 220 mm, overall weight: 1,200 kg, table length: 5,000 mm, positioning accuracy: 0.1 mm, table width: 250 mm, working range: 250 mm, pressure: 6 bar, type of input current: three-phase, total width: 250 mm, cutting width (max.): 250 mm, compressed air connection: 6 bar, cutting diameter: 220 mm, extraction nozzle diameter: 120 mm, working height: 30 mm, Friulmac Randomat E 001 Serial No: 32644 Year 2001 in excellent condition specially made for End Matching all types of wood flooring.

Gbjdex Ec Hnjpfx Afnjh

Fitted with a Sound & Safety Enclosure with front sliding doors and an entrance door at each end.

2 x 4kw motors do the cutting of the tongue & groove.

Will machine random or fixed lengths from 250m/m up to 6m. long.

6m. Long Infeed Belt Conveyor, and a 6m. Long Outfeed Belt Conveyor.

Siemens Simatic OP7 Control System.

Complete with documentation for Operating and Programming.

Listing

Haps

Haps

973 km

Suction vehicle

MANTGS 35.400 8X2-4 BL WIEDEMANN SUPER 1000

Call

Condition: excellent (used), mileage: 133,000 km, power: 294 kW (399.73 HP), first registration: 12/2016, fuel type: diesel, axle configuration: 8x2, fuel: diesel, brakes: engine braking, color: blue, driver cabin: day cab, gearing type: mechanical, number of gears: 16, emission class: euro6, total length: 11,610 mm, total width: 2,550 mm, total height: 3,700 mm, loading space volume: 15 m³, Year of construction: 2016, Equipment: ABS, air conditioning, central locking, cruise control, electric window regulation, fog lights, navigation system, power mirror, - Brake booster

- Remote-controlled central locking

- Refrigerator

- Air suspension

- Air horn

- Radio/CD player

- Reversing camera

- Sun visor

- Toolbox

- Xenon lighting

- Central lubrication

Gjdpfxex Tvn Ro Afnebh

Manufacturer: WIEDEMANN

Model / Sales designation: SUPER 1000 15

Equipment number: D/BAM/1666/T

Factory No.: X OW 1000 1494

Year of manufacture: 02.12.2016

Equipment: Suction / pressure tank body

ADR

Sludge compartment – variable size, rear closure floor and front torispherical head made from stainless steel, material 1.4404, sludge tank in stainless steel, material 1.4404, auxiliary tipping device, sludge tank lid/ADR, sludge tank lid – hydraulically opening, central locking pneumatically operated, level indicator with scale at the tank bottom, lower suction connection with gate valve DN 125 reduced to DN 100, lower suction connection pneumatically actuated, upper suction connection with gate valve DN 125 reduced to DN 100, hydraulic telescopic piston, display of 3 pre-set piston positions, ADR equipment, tank code L4BH (without heat recovery), splash partition in stainless steel 1.4301, vacuum pump type CVS VACUSTAR 1600 – DN 100, overfill protection, vacuum pump cooling, oil separator and silencer, vacuum pump flushing device, vacuum system piping, safety fittings and fittings DN 125, suction hose reel 25 m DN 125, special spiral suction hose 25 m / DN 125, oil-resistant, transport hose reel 40 m DN 80 (side-mounted), suction and high-pressure (HP) boom, retractable suction and HP boom, water compartment – variable, water filling device, hand washing device, warm, level control – Plexiglas sight glass for water compartment, high-pressure pump type URACA P 345-60, HP system protection, high-pressure reel 220 m DN 25 or 180 m DN 32, at the boom, high-pressure hose 180 m DN 25, rubber (GrüloKan 250), large automatic winding device, pressure roller – large HP reel, meter counter, high-pressure reel 80 m DN 13, hydraulic, high-pressure hose 80 m DN 13, rubber (GrüloKan 250), water shortage protection, pneumatic system, three-stage hydraulic system, centralized lubrication system, hydraulic winch, electrical system, reversing camera system with 2nd camera, engine can be started from control panel, PLC/CAN-BUS control, control cabinet with display, radio remote control with display, equipment cabinet with single flap – one side, insert tubes for suction hoses, pump room sound enclosure, full side paneling, toolbox approx. 800x500x500 mm, stainless steel, 3 work lights (LED), 2 revolving warning lights – flashing version, operating hour meter for HP pump; operating hour meter for vacuum pump, compressed air connection, spring cable pull, ladder, ladder holder, shovel, broom, and manhole hook

Next inspection dates:

General inspection (HU): 01 / 2026

Section 57b test: 05 / 2025

Safety inspection (SP): 07 / 2025

GGVSEB/ADR inspection: 02.01.2026

Tank inspection: 12 / 2027

German registration

In very good condition!

Immediately operational

Transmission

Transmission: ZF, 16-speed manual transmission

Axle configuration

Front axle 1: steered

Front axle 2: steered

Rear axle 1: steered

Weights

Unladen weight: 21,952 kg

Payload: 10,048 kg

Gross vehicle weight: 32,000 kg

Functionality

Body make: Wiedemann Super 1000...

Listing

Stockport

Stockport

404 km

Heavy Duty Granulator

GenoxGXC1200T

Call

Year of construction: 2025, condition: new, functionality: fully functional, rotor diameter: 660 mm, rotor width: 1,200 mm, Genox GXC1200T Series - Heavy Duty Granulator suitable for processing various materials including plastics, wood, rubber etc.

90kW Drive Motor with outboard rotor bearings (110kW & 132kW drive options are available), heavy duty precision machined rotor, and 480rpm operating speed as standard.

1,200mm wide x 660mm diameter cutting chamber with a choice of either a 10 knife/5 row or 14 knife/7 row V Cutting Rotor, or our heavy duty, high inertia Cascade Rotor with 60 x rotor knives. Two rows of counter knives are mounted in the chamber and as an option a third row can be mounted in the throat of the machine to increase cutting efficiency.

All knives are manufactured from Vacuum Heat Treated D2 Tool Steel.

Gbsdpfx Afjx Ardwonjh

Hydraulic assisted chamber and screen access with integrated safety interlocks, and a setting jig is supplied for pre-setting of knives off the machine to enable quick, simplified knife changes.

Output size is controlled by replaceable screens mounted beneath the rotor shaft - sizes supplied as required (4mm-50mm).

A sound attenuation enclosure is available as an option to minimise operational noise if required.

We can provide infeed conveyors and product conveying systems as required to transfer product in to bulk storage bags if required.

Listing

Stockport

Stockport

404 km

Heavy Duty Granulator

GenoxGXC1600T

Call

Year of construction: 2025, condition: new, functionality: fully functional, rotor diameter: 660 mm, rotor width: 1,600 mm, Genox GXC1600T Series - Heavy Duty Granulator suitable for processing various materials including plastics, wood, rubber etc.

110kW Drive Motor with outboard rotor bearings (132kW & 160kW drive options are available), heavy duty precision machined rotor, and 480rpm operating speed as standard.

1,600mm wide x 660mm diameter cutting chamber with a choice of either a 5 row or 7 row V Cutting Rotor. Two rows of counter knives are mounted in the chamber and as an option a third row can be mounted in the throat of the machine to increase cutting efficiency.

All knives are manufactured from Vacuum Heat Treated D2 Tool Steel.

Hydraulic assisted chamber and screen access with integrated safety interlocks, and a setting jig is supplied for pre-setting of knives off the machine to enable quick, simplified knife changes.

Output size is controlled by replaceable screens mounted beneath the rotor shaft - sizes supplied as required (4mm-50mm).

A sound attenuation enclosure is available as an option to minimise operational noise if required.

We can provide infeed conveyors and product conveying systems as required to transfer product in to bulk storage bags if required.

Gsdpox Arc Hofx Afnjbh

Listing

Stockport

Stockport

404 km

Heavy Duty Granulator

GenoxGXC1200

Call

Year of construction: 2025, condition: new, functionality: fully functional, rotor diameter: 520 mm, rotor width: 1,200 mm, Genox GXC1200 Series - Heavy Duty Granulator suitable for processing various materials including plastics, wood, rubber etc.

75kW Drive Motor with outboard rotor bearings (90kW & 110kW drive options are available), heavy duty precision machined rotor, and 520rpm operating speed as standard.

1,200mm wide x 520mm diameter cutting chamber with a choice of either a 10 knife, 5 row V Cutting Rotor, or our heavy duty, high inertia Cascade Rotor with 60 x rotor knives. Two rows of counter knives are mounted in the chamber and as an option a third row can be mounted in the throat of the machine to increase cutting efficiency.

All knives are manufactured from Vacuum Heat Treated D2 Tool Steel.

Hydraulic assisted chamber and screen access with integrated safety interlocks, and a setting jig is supplied for pre-setting of knives off the machine to enable quick, simplified knife changes.

Output size is controlled by replaceable screens mounted beneath the rotor shaft - sizes supplied as required (4mm-50mm).

A sound attenuation enclosure is available as an option to minimise operational noise if required.

We can provide infeed conveyors and product conveying systems as required to transfer product in to bulk storage bags if required.

Gsdpfxox Arcyo Afnjbh

Listing

Stockport

Stockport

404 km

Heavy Duty Granulator

GenoxGXC800

Call

Year of construction: 2025, condition: new, functionality: fully functional, rotor diameter: 520 mm, rotor width: 800 mm, Genox GXC800 Series - Heavy Duty Granulator suitable for processing various materials including plastics, wood, rubber etc.

55kW Drive Motor with outboard rotor bearings (75kW & 90kW drive options are available), heavy duty precision machined rotor, and 520rpm operating speed as standard.

800mm wide x 520mm diameter cutting chamber with a choice of either a 10 knife, 5 row V Cutting Rotor, or our heavy duty, high inertia Cascade Rotor with 40 x rotor knives. Two rows of counter knives are mounted in the chamber and as an option a third row can be mounted in the throat of the machine to increase cutting efficiency.

All knives are manufactured from Vacuum Heat Treated D2 Tool Steel.

Hydraulic assisted chamber and screen access with integrated safety interlocks, and a setting jig is supplied for pre-setting of knives off the machine to enable quick, simplified knife changes.

Gbsdpfxjx Arcgo Afnjh

Output size is controlled by replaceable screens mounted beneath the rotor shaft - sizes supplied as required (4mm-50mm).

A sound attenuation enclosure is available as an option to minimise operational noise if required.

We can provide infeed conveyors and product conveying systems as required to transfer product in to bulk storage bags if required.

Listing

Stockport

Stockport

404 km

Granulator

GenoxGXC1000

Call

Condition: new, Year of construction: 2025, functionality: fully functional, nominal power: 55 kW (74.78 HP), rotor diameter: 520 mm, rotor width: 1,000 mm, Genox GXC1000 Series - Heavy Duty Granulator suitable for processing various materials including plastics, wood, rubber etc.

75kW Drive Motor with outboard rotor bearings (90kW, 110kW & 132kW drive options are available), heavy duty precision machined rotor, and 520rpm operating speed as standard.

1000mm wide x 520mm diameter cutting chamber with a choice of either a 10 knife, 5 row V Cutting Rotor, or our heavy duty, high inertia Cascade Rotor with 50 x rotor knives. Two rows of counter knives are mounted in the chamber and as an option a third row can be mounted in the throat of the machine to increase cutting efficiency.

Gbedsx Arb Nspfx Afnjh

All knives are manufactured from Vacuum Heat Treated D2 Tool Steel.

Hydraulic assisted chamber and screen access with integrated safety interlocks, and a setting jig is supplied for pre-setting of knives off the machine to enable quick, simplified knife changes.

Output size is controlled by replaceable screens mounted beneath the rotor shaft - sizes supplied as required (4mm-50mm).

A sound attenuation enclosure is available as an option to minimise operational noise if required.

We can provide infeed conveyors and product conveying systems as required to transfer product in to bulk storage bags if required.

Listing

Stockport

Stockport

404 km

Heavy Duty Granulator

GenoxGXC2000G

Call

Condition: new, Year of construction: 2025, functionality: fully functional, overall weight: 15,500 kg, rotor diameter: 800 mm, rotor width: 2,000 mm, power: 250 kW (339.91 HP), rotational speed (max.): 480 rpm, Equipment: rotational speed infinitely variable, Genox GXC2000G Series - Heavy Duty Granulator suitable for processing various materials including plastics, wood, rubber etc.

250kW Drive Motor with outboard rotor bearings (200kW - 315kW drive options are available), heavy duty precision machined rotor, and 480rpm operating speed as standard.

Gjdpfxex Arbpe Afnobh

2,000mm wide x 800mm diameter cutting chamber with a choice of either a 5, 7 or 9 row V Cutting Rotor. Two rows of counter knives are mounted in the chamber and as an option a third row can be mounted in the throat of the machine to increase cutting efficiency.

All knives are manufactured from Vacuum Heat Treated D2 Tool Steel.

Hydraulic assisted chamber and screen access with integrated safety interlocks, and a setting jig is supplied for pre-setting of knives off the machine to enable quick, simplified knife changes.

Output size is controlled by replaceable screens mounted beneath the rotor shaft - sizes supplied as required (4mm-50mm).

A sound attenuation enclosure is available as an option to minimise operational noise if required.

We can provide infeed conveyors and product conveying systems as required to transfer product in to bulk storage bags if required.

Listing

Herrenberg

Herrenberg

1,310 km

Generator

SDMOJ33 – 33 kVA - 470 Liter Dieseltank

Call

Condition: new, Year of construction: 2022, functionality: fully functional, overall weight: 1,458 kg, fuel type: diesel, tank capacity: 470 l, color: blue, power: 26.4 kW (35.89 HP), output voltage: 400 V, output frequency: 50 Hz, type of output current: three-phase, continuous power: 24 kW (32.63 HP), continuous power (apparent): 30 kVA, total length: 2,100 mm, total width: 950 mm, total height: 1,630 mm, rotational speed (max.): 1,500 rpm, motor manufacturer: John Deere, type of cooling: water, fuel: diesel, fuel tank capacity: 470 l, Equipment: documentation/manual, mobile diesel tank, ❇️ KOHLER SDMO J33 – 33 kVA Diesel Emergency Generator • NEW (MY 2022) • John Deere Engine • 470 L Tank • ATS VERSO 200

I am selling a brand-new, unused industrial standby generator by KOHLER SDMO, model J33, including a large 470-liter diesel tank and a genuine KOHLER VERSO 200 ATS transfer switch for automated mains/generator switching.

The generator originally comes from civil protection stock and has never been put into operation.

It is in as-new condition, both technically and visually.

⸻

✅ Technical specifications (according to rating plate)

• Model: KOHLER SDMO J33

• Year of manufacture: 2022

• Engine: John Deere industrial engine (water-cooled)

• Output:

• 30 kVA / 24 kW (PRP – Prime Power)

• 33 kVA / 26.4 kW (ESP – Emergency/Standby Power)

• Voltage: 400/230 V – 3-phase – 50 Hz

• Speed: 1500 rpm

• Power factor (Cos φ): 0.8

• Generator protection class: G3

• Weight: 1,458 kg

• Noise level: 74 dB (1 m), 62 dB (7 m), 56 dB (15 m)

⸻

✅ Features / Equipment

• Very large tank capacity: 470 L (special equipment!)

• Sound-insulated enclosure (canopy)

• APM303 controller (with auto mode, start/stop, display, alarm function)

• Battery charger & engine preheating

• John Deere engine – extremely reliable & long-lasting

• Schneider Electric emergency stop & safety components

• Complete Mennekes socket combination

• Forklift pockets & top lifting hook

• Initial inspection performed & documented

⸻

✅ Included (high added value!)

KOHLER SDMO VERSO 200 – Automatic Transfer Switch (ATS)

• Automatic mains/generator changeover switch

• 4-pole

• Ideal for buildings, commercial operations, agriculture, critical infrastructure

• Like new, unused

⸻

✅ Ideal usage scenarios

• Agriculture

• Commercial & industrial operations

Godpox N A T Eofx Afnobh

• Municipalities

• Fire departments / Civil protection agencies

• Data centers, refrigeration systems

• Building technology

• Emergency power supply for businesses or larger residential complexes

⸻

✅ Transportation

• Pickup in 71083 Herrenberg

• Forklift available for loading

• Shipping via freight carrier possible (at buyer’s expense)

⸻

✅ Tax information

No VAT shown according to §19 UStG (small business exemption regulation).

⸻

⚠️ Note

This is a genuine industrial generator – not a cheap import from the Far East. Brand quality by KOHLER SDMO + John Deere engine + 470-liter tank + ATS panel = extremely value-retaining combination.

Listing

Borken

Borken

1,034 km

Temperature test chamber

CTSTSR-30/1000

Call

Condition: good (used), CTS

Type: TSR-30/1000

Water-cooled

The type designation of the CTS enclosure series is made up as follows:

z. e.g. type TSR -30/1000

1) T means: Temperature

2) S means: stress screening

3) R means: external conditioning

4) -30 means: lower temperature -30 °C

5) 1000 means: 1000 liter test chamber volume

Technical performance data:

A) TSR-30/1000 basic device without hose connections,

i.e. when used as a stand-alone temperature test chamber

Temperature tests:

Temperature range -40°C to +180°C

Final temperature -45°C

Temperature deviation ≤ ±0.3 K in time

Temperature change rate according to IEC 60068-3-5

Heating 6.0 K/min

Cooling 5.0 K/min

Heat radiation

Gbedpfxsrivfce Afneh

approx. 5000 W at +20°C

approx. 4200 W at ± 0°C

approx. 3000 W at -20°C

The technical data refer to an ambient temperature of +25 °C,

rated voltage 400V, without test material, without irradiation and without additional equipment.

Air volume flow

approx.2000m³/h

B) TSR-30/1000 basic unit with hose connections,

for connection to an external test room provided by the customer

Temperature tests:

Temperature range -30°C to +170°C

Temperature deviation ≤ ±0.1 to 0.5 K in time

Average rate of temperature change,

measured with short-circuited circuit

Heating 4.0 K/min

Cooling 4.0 K/min

in the range from +150°C to -10°C

The technical data refer to an ambient temperature of +25 °C,

rated voltage 400V, without test material, without irradiation and without additional equipment,

measured with short-circuited circuit

Attention: The external test chamber provided by the customer must be absolutely tight and appropriately insulated,

any feed-throughs must be optimally sealed on site.

Dimensions:

Test volume 1000 liters

Air circulation connection Ø 200 mm

Test chamber dimensions Height 900 mm Width 1000 mm Depth 1100 mm

External dimensions Height 1950 mm Width 1270 mm Depth 2245 mm

Technical design:

Refrigeration unit:

water-cooled, low-noise, fully hermetic

Infinitely variable capacity adjustment through

electronic monitoring and control system,

environmentally friendly refrigerant R404A

Door:

Fully opening door, door hinge on the left,

one-handed operation, lockable.

Shelf:

Stainless steel, support surface 970 x 980 mm

Max. load per shelf 35 kg

Total load with max. shelf load 100 kg

Test area lighting: Halogen lamp 20 W, 12 V

Control:

- 32 bit controller

- LCD control panel

Operating data:

Electrical connection 400 V +6/-10 %, 3/N, 50 Hz

Rated power 13.3 kW

Protection class IP 22

Sound pressure level < 60 dB(A)

Weight approx. 850 kg

The following information is for your safety as a buyer!

The following points are carried out on our offered chambers in advance:

1. functional check and replacement of necessary components

2. if necessary, refilling with legally compliant refrigerant

3. leak test with certificate

4. after successful inspection, the chambers are subjected to a documented test run.

Condition: used

Scope of delivery: (see picture)

(Changes and errors in the technical data, specifications are reserved!)

We will be happy to answer any further questions you may have on the phone.

Listing

Radom

Radom

1,994 km

Folding machine

Horizon PF P-330Folding Machine with Base

Call

Condition: good (used), Horizon PF P-330 Folding Machine with Base

The machine is in very good condition and 100% functional.

This folding machine is ideal for digital printing. Quick and easy to set up – automatic cassette adjustments and paper size detection. A huge advantage is the vacuum feed – a compressor is included.

The machine handles all types of paper perfectly.

Made in Japan.

Technical specifications:

Minimum format: 125 x 130 mm

Maximum format: 310 x 432 mm

Paper weight: 40 to 180 g/m²

Infeed stack height: 50 mm

Six folding options: half-fold, quarter-fold, Z-fold, C-fold, altar-fold, etc.

Folding speed: 200 sheets/min per hour, 12,000 sheets/h

Dimensions: 1060 x 553 x 670 mm

Weight: 45 kg

Power supply: 230V

Gbjdpfx Aeyg D Udofnsh

The machine includes: an external compressor in a sound-absorbing enclosure, an instruction manual, and a large-format accessory.

Listing

Zdziechowice

Zdziechowice

1,823 km

Welding fume extraction, welding extraction

Mobilny odciąg dymu spawalniczego

Call

Condition: new, Year of construction: 2025, functionality: fully functional, suction capacity: 1,100 m³/h, Welding Fume Extraction, Dust Extraction, Self-Cleaning, Pneumatic with Vacuum Filter.

This unit is designed for the extraction and purification of dry dust generated during welding, grinding, polishing, casting, and cutting of metals and plastics. It features a three-stage filtration system with integrated primary filter element regeneration. Contaminated air passes through a metal pre-filter (spark arrestor), a main filter cartridge, and a discharge filter made from activated carbon-impregnated fleece. The regeneration of the main filter element, which utilizes compressed air to clean the filter cartridge from accumulated contaminants, is equipped with its own 10-liter compressed air tank. The unit is recommended for applications requiring continuous extraction and filtration of airborne pollutants. Extraction arms with a reach of 3 or 4 meters are recommended as accessories.

Gbodpfx Aenabuzjfneh

The illustrated EC model is characterized by the following features:

- Fan with brushless EC motor and 0.78 kW inverter, sound-insulated

- Advanced next-generation EC motor design – ensures energy efficiency, precise speed control, and quiet operation

- Reliable induction motor – robust and reliable solution that guarantees high performance and trouble-free operation even under demanding conditions

Maximum Capacity: 1,100 m³/h

Automatic filter cartridge cleaning

Self-supporting extraction arm (L = 3.0 m, d = 160 mm, hood diameter 315 mm)

Three filtration stages:

• Coarse pre-filter (30% metal content, G2)

• Main cartridge filter with 99% separation efficiency for particles ≥ 0.5 µm

• Coarse final filter (70% activated carbon, G4)

PTFE membrane filter (filter class F9)

Coarse dust container below pre-filter

Grid and dust container below main filter

Welded steel enclosure with powder coating

Noise level: 64 dB(A)

Various configurations available to meet customer requirements.

Applications:

- Welding shops

- Metalworking industry

- Grinding and polishing stations

- Plastics processing and machining

This unit is ideal for environments that require constant and effective filtration of dry dust from the air.

Made in Poland.

The listed price applies to the model shown.

Machine warranty: 12 months

Listing

Trondheim

Trondheim

1,548 km

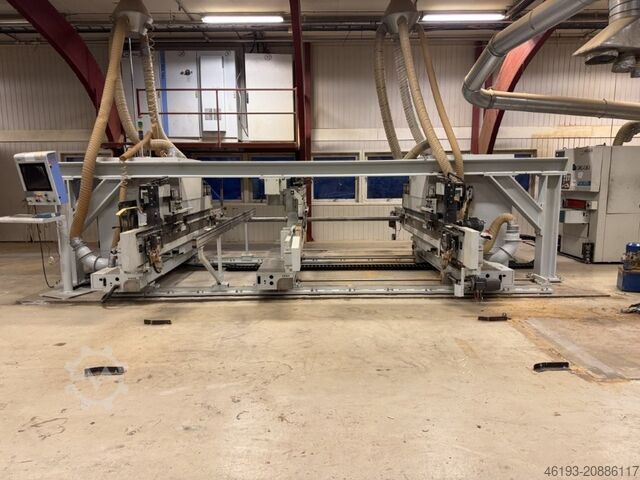

Double end tenoner

HOMAGFPL 626/03/40/W/3K

Call

Condition: ready for operation (used), Year of construction: 2009, functionality: fully functional, Equipment: documentation/manual, HOMAG FPL 626/03/40/W/3K

Double-sided HOMAG format processing machine for solid wood flooring in cross-feed through-feed operation.

Fixed reference side left, movable side right .

Technical data:

Feed speed, infinitely adjustable: 10–40 m/min

Format overhang: 3 mm (note profile depth)

Format thickness: 10–23 mm

Gjdpox Spxgofx Afnjbh

Format length in front of lugs: max. 140–250 mm

Infeed length min: 2,400 mm

Infeed length max: 4,000 mm

Working height to top of chain: 950 mm

Pneumatic connection: 7–8 bar

Standard Milling Unit SF20, 6.6 kW – Format Section - F.01 (1323) - 1 × left, 1 × right

For grooving and rebating from the top/bottom as well as from the side, in counter-rotation.

• 1 milling motor, 6.6 kW, 100 Hz, 6,000 rpm

• Motor shaft Ø35 × 70 mm with keyway

• Swivel range: 90°, manual

• Cross-slide with electro-pneumatic control for plunge milling

• Directional switch for rotation direction

• Extraction hood

• Groove position: minimum distance 10 mm from chain track or top pressure

• Maximum tool diameter: 200 mm

• Without tools

• Electronic frequency inverter with motor braking function

• Manual horizontal and vertical adjustment via spindle and counter

Free Space for additional milling unit - 715 mm – Standard Milling Unit - F.04 (1318) - 1 × left, 1 × right

• Including extension of sound enclosure and extraction connection ports

• Without electrical pre-installation

FOR MORE TECHNICAL SPECIFICATION PLEASE READ ATTAGED DOCUMENTS in PDF format.

This machine stands in south Norway on it orginal place. The company is now closed but it is possible to inspect the machine.

Rekman Maskin & Service since 1986

Listing

Roreto

Roreto

1,518 km

COMBI MACHINE (SIZING & EDGE BANDING)

IMACombima /K /II /950 /F /R75 /R1.3

Call

Condition: excellent (used), Double side - Independent Machine (or 1st and/or 2nd in a line)

Edges (band in rolls) thickness (Min/Max) mm 0,4 / 3

Edges thickness in strips/lippings max) mm 1,3

Panels thickness (min/max) mm 10 / 45

Working width (min/max) mm 244 / 2300 ca.

Numerical Control /Software ICOS Open

Adjustable feeding speed (m/min ) 8 - 40

Without Transmission bar (Master & Slave system)

Safety and sound-proof enclosures/cabins

Distance (center-axes) of the Disappearing Dogs (mm) 270

SIZING PART (for each side):

Pre-Milling unit 75.30 (Kw 6,6 x 2)

EDGE-BANDING PART (for each side):

Glueing Unit (P.U.R. Glue + Quick Melt system) 04.1570 + 283.205

Edge coils supporting unit (reels N°) 6

Snipping (end-cutting) unit 08.42 (Kw 0,2 x 2) 40 m/min

Fine Trimming unit 08.055 (Kw 0,66 x 2) 0°-30°

Multi Function Unit (Profile contour Trimming unit) MFA 08.342 (Kw 0,66 x 2) max 25 m/min

Corner Rounding unit (Contour Trimming) 08.465 (Kw 0,18 x 4) max 20 m/min

Buffing unit 08.617-2 (Kw 0,18 x 2)

Gedpfx Ajfi Tkvefnjbh

Free space

Listing

Roreto di Cherasco

Roreto di Cherasco

1,518 km

DOUBLE END TENONER

CELASCHI (SCM Group)TSA 200 N

Call

Condition: excellent (used), Independent machine (standing alone) and/or Universal machine (First & Second in a line)

Electronic Programmer

With separate electric and command panel

Safety and sound-proof enclosure

No. 1 Vertical column to support the working units

Min. useful working width (mm) 220

Max. useful working width (mm) 3000

Min. useful working tickness (mm) 6

Max. useful working tickness (mm) 60

Gbedpfx Aegz Alxsfnjh

Distance between center-axes of the disappearing dogs (mm) 400

Adjustable (min/max) feeding speed (m/min) 4-24

Total installed power Kw 40

No. 3 Working groups (for each machine's side):

1 Jumping Scoring Unit Kw 2,2 / Kw 3,2

1 Hogging Unit Kw 5,5 / Kw 7,3 (RPM 3000 / 6000)

1 Jumping Milling Unit Kw 4 / Kw 5,8 (RPM 3000 / 6000)

Listing

Roreto

Roreto

1,518 km

COMBI MACHINE (SIZING & EDGE BANDING)

BIESSEStream SB2 9.5

Call

Condition: excellent (used), Universal DOUBLE-SIDE SIZING & EDGE BANDING MACHINE (for both 1st and 2nd pass)

Edges (tape) thickness in rolls (min/max) mm 0,3 - 3

Panels thickness (min/max) mm 10 - 60

Working width (min/max) mm 240 - 2700

Numerical Control /Software SINITRA

Adjustable feeding speed (m/min ) 10 - 40 (INVERTER C.N.)

Safety and sound-proof enclosures/cabins

Distance (center-axes) of the Disappearing Dogs (mm) 500

SIZING PART (for each side):

Anti-chipping Milling Unit AS 10 (Kw 5,8)

N° 2 Hogging Units (1 Top + 1 Bottom) DT 10 (5,8 + 5,8) - Spraying unit (Anti-sticking liquid)

EDGE-BANDING PART (for each side):

Godeu Tg Uqepfx Afnebh

Glueing Unit (Hot Melt + Quick Melt Unit) SP30 (High Melt + Edge Guide Z-axe)

Band Pressure zone (N.C. adjustment) . Edge coils supporting unit (No. 6 reels)

Snipping (end-cutting) unit IT 90-S (Kw 0,3 x 2) speed 28m/min. 0 - 25°. PNEU

Fine Trimming unit (Multi-profile, by N.C.) RF 30 (Kw 0,65 x 2) 0 - 25°

Multi Function Unit (Profile contour Trimming unit) AR 80 (Kw 0,3 x 2) max 25 m/min - ROTAX motors with automatic tool change (8+8 position store)

Profile Scraping unit (Multi-profile, by N.C.) RB 30

Glue scraping unit RC 20 + Spraying Unit (for polishing liquid)

Buffing unit SZ 30 (Kw 0,37 x 2)

With ‘hopper’ for panels (useful height mm 80), as a buffer, to speed up the work cycle

Listing

Roreto

Roreto

1,518 km

COMBI MACHINE (SIZING & EDGE BANDING)

BIESSEStream SB2 9.5

Call

Condition: excellent (used), Universal DOUBLE-SIDE SIZING & EDGE BANDING MACHINE (for both 1st and 2nd pass)

Edges (tape) thickness in rolls (min/max) mm 0,3 - 3

Panels thickness (min/max) mm 10 - 60

Working width (min/max) mm 240 - 2700

Numerical Control /Software SINITRA

Adjustable feeding speed (m/min ) 10 - 40 (INVERTER C.N.)

Safety and sound-proof enclosures/cabins

Working line (work units support tables), manual adjustment

Distance (center-axes) of the Disappearing Dogs (mm) 500

SIZING PART (for each side):

Anti-chipping Milling Unit AS 10 (Kw 5,8)

N° 2 Hogging Units (1 Top + 1 Bottom) DT 10 (5,8 + 5,8)

Spraying unit (Anti-sticking liquid)

EDGE-BANDING PART (for each side):

Glueing Unit (Hot Melt + Quick Melt Unit) SP30 (High Melt + Edge Control EC 40)

Band Pressure zone (N.C. adjustment) . Edge coils supporting unit (No. 6 reels)

Snipping (end-cutting) unit IT 90-S (Kw 0,65 x 2) speed 28m/min. 0 - 25°. PNEU

Fine Trimming unit (Multi-profile, by N.C.) RF 40 (Kw 1 x 2) 0 - 25°

Multi Function Unit (Profile contour Trimming unit) AR 80 (Kw 0, 65 x 2) max speed 25 m/min - ROTAX motors with automatic tool change (tools)

Gedjhvahhspfx Afnsbh

Milling grooving Unit 2 x FB 30 (Kw 5 x 2) 0 - 90°

Profile Scraping unit (Multi-profile, by N.C.) RBK - 503 (2 POSITIONS)

Glue scraping unit RC 20 + Spraying Unit (for polishing liquid) + Buffing unit SZ 30 (Kw 0,37 x 2)

Trust Seal

Dealers certified through Machineseeker

Listing

Roreto

Roreto

1,518 km

SOFTFORMING DOUBLE SIDE EDGEBANDER

BIESSEStream SB1 11.0 SOFT

Call

Condition: excellent (used), DOUBLE-SIDE SIZING & EDGE BANDING MACHINE - First (1st) machine in a line

Edges (tape) thickness in rolls (min/max) mm 0,3 - 3

Gbodpfxot N Ix Rs Afnoh

Panels thickness (min/max) mm 10 - 60

Working width (min/max) mm 270 - 1200

Numerical Control /Software SINITRA

Adjustable feeding speed (m/min) 10 - 40 (INVERTER C.N.)

Safety and sound-proof enclosures/cabins

Working line (work units support tables), manual adjustment

SIZING PART (for each side):

No. 2 Hogging Units (1 Top + 1 Bottom) DT 10 (Kw 5.8 x 2)

Free space for Milling unit FS

Milling unit (vertical join trimming) ES30 + ER30 (Kw 5 x 2) 0° - 90°

Softforming Milling unit SF 10 (2 x Kw 2,4) 0° - 45°

Spraying unit (Anti-sticking liquid)

EDGE-BANDING PART (for each side):

Glueing Unit (Hot Melt + Quick Melt Unit) SP3/SF, SP40 (HighMelt + Edge Control EC 40)

Lamps to heat the workpieces side (infrared heater) RP 10

Band Pressure zone (N.C. adjustment)

Pressing rollers (revolver) both for straight and shaped edges (softforming) Soft PF40 (4 positions) mm 800 (Cesoia CI10+CS10+RL10) + Edge coils supporting unit (No. of reels) 6

Rough Milling unit RS 10 (Kw 1,3 x 2)

Fine Milling unit Softforming RF 10 / SF (Kw 0,65 x 2)

Fine Milling unit (Multi-profile) RF 30 (Kw 0,65 x 2)

Milling grooving Unit FB 30 (Kw 4,5 x 2) 0 - 90°

Profile edge scraping unit (Multi-profile) RB 30

Glue scraping unit RC 05 / Soft

Spraying Unit (for polishing liquid) + Buffing unit SZ 30 (Kw 0,37 x 2)

Listing

Roreto

Roreto

1,518 km

SOFTFORMING DOUBLE SIDE EDGEBANDER HOMAG

HOMAGKFL 620 / 23 / QE / 30 SOFTFORMING

Call

Condition: excellent (used), Double-side Sizing & Edge Banding - Independent Machine (1st &/or 2nd in a line)

Edges (tape) thickness in rolls (min/max) mm 0,3 - 3

Edges thickness in stips / lippings (min/max) mm 0,4 - 12

Panels thickness (min/max) mm 8 - 100

Gjdpfx Ajtt Iudsfnjbh

Working width (min/max) mm 240 - 3000

Numerical Control Power Control PC22 (Windows XP) Software woodCommander

Adjustable feeding speed (m/min) 10 - 40

Safety and sound-proof enclosures/cabins

Distance (center-axes) of the Disappearing Dogs (mm) 400

SIZING PART (for each side):

Pre-Milling unit (2 x Kw 6,6)

Free place

LEFT SIDE only: 2 x Milling grooving rotating unit (2 x KW 6,6)

EDGE-BANDING PART (for each side):

Glueing Unit (Hot Melt + Quick Melt Unit) E34

Pressing rollers (revolver) both for straight and shaped edges (softforming) GL sextuple

Edge coils supporting unit (No. of reels) 1

Snipping (end-cutting) Unit WK14 (2 x 0,8 KW) 25 m/min (0°-30°)

Fine Trimming Unit (2 x 0,55 KW) 0°-30°

Corner-rounding unit FF12 (4 motors) WD70 20 m/min

Profile edge scraping unit PN20

Finish processing unit (Glue scraper + Buffing unit) FA 11

Listing

Roreto

Roreto

1,518 km

DOUBLE END TENONER

HOMAGNFL 26/4/30

Call

Condition: excellent (used), Independent machine (standing alone) and/or Universal machine (First & Second in a line)

Numerical Control ( CNC) NC 21, Software Homatic

Safety and sound-proof enclosure

No. 3+3 Vertical columns to support the working units

Min. useful working width (mm)

Max. useful working width (mm) 3000

Gedpfx Afsh Nx U Nonjbh

Max. useful working tickness (mm) 100 (ca.)

Max. depth of the panel (mm) for automatic infeed 1250

Distance between center-axes of the disappearing dogs (mm) 1000

Adjustable (min/max) feeding speed (m/min) 8 - 25 (ca.)

No. 4 Working groups (for each machine's side):

1 Jumping Scoring Unit (1 x Kw 1,5 ca.)

1 Hogging Unit (1 x Kw 4,5 ca.)

1 Jumping Milling Unit (1 x Kw 4,5 ca.)

1 Free Space

Listing

Roreto

Roreto

1,518 km

DOUBLE END TENONER

SCMConcept 2000

Call

Condition: excellent (used), Independent machine (standing alone) and/or Universal machine (First & Second in a line)

Godpfx Aoifz H Nsfnobh

Electronic Programmer

Safety and sound-proof enclosure - OPTIONAL

No. 4+4 Vertical columns to support the working units

Min. useful working width (mm) 150 (ca.)

Max. useful working width (mm) 3100 (ca.)

Max. useful working thickness (mm) 180 (ca.)

Distance between center-axes of the disappearing dogs (mm) 500 (ca.)

Adjustable (min/max) feeding speed (m/min) 8-40 (ca.)

No. 8 Working groups (for each machine's side):

1 Jumping Scoring Unit

1 Hogging Unit

1 Jumping Milling Unit

1 Milling-Shaping unit

1 Corners Rounding unit (contour trimming) with 2 vertical motors

1 Belt sanding unit (with abrasive disc)

1 Belt sanding units (with abrasive papers)

We make it easier for you to find: "sound enclosure"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Sound Enclosure (2,078)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month