Used Optimizing for sale (3,172)

Germany

Germany Optimizing Cross-Cut Saw

DIMTERS50 Opticut

Juszczyn

Juszczyn Optimization cross cut line

Grecon DimterOptiCut 304R

Leipzig

Leipzig Optimization cutting saw

STROMABTR-600 MATRIX-6000

+44 20 806 810 84

Leipzig

Leipzig Optimization cutting saw

STROMABTR-500 MATRIX-6000

Leipzig

Leipzig Optimization cutting saw

STROMABTR-450 MATRIX-6000

Discover more used machines

Leipzig

Leipzig Optimization cutting saw

STROMABWS1

Leipzig

Leipzig Optimization cutting saw

WINTEROPTIMAX 100

Gelderland

Gelderland Optimizing cross-cut saw

StromabCT 800

Mediniai Strėvininkai

Mediniai Strėvininkai Optimization cross cut line

StromabCT 800

Malax

Malax Pallet Block Cutter Machine

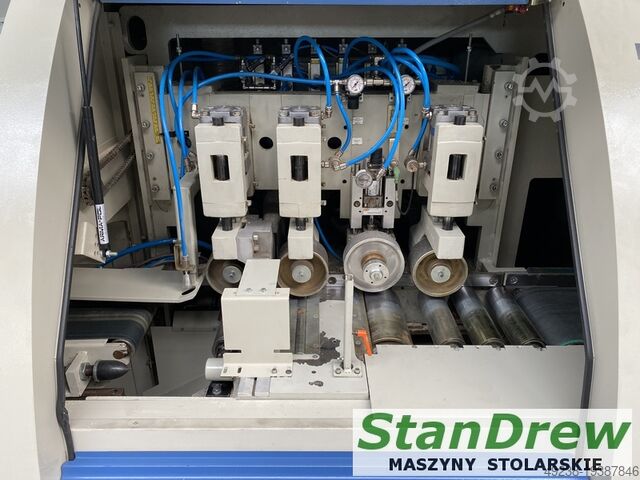

MychromeOPTIMIZING BLOCK CUTTER OKKR-2006

Cosne-Cours-sur-Loire

Cosne-Cours-sur-Loire Cross-cut line optimization

WEINIGOpticut 704 L

Treviso

Treviso Innovative optimizing cross-cutting saw

SALVAMACNEW SALVAPUSH 2000

Treviso

Treviso Optimizing cutting saw

SALVAMACSALVACUT 5000

Osielec

Osielec Weinig stacker optimization saw

WEINIG

Langenberg

Langenberg Optimization cross-cut system

DimterOpticut 450

Dubiny

Dubiny Length optimization machine

WEINIGOPTICUT150

Germany

Germany Upright panel saw including optimization

Holz-HerSector 1257

Miechucino

Miechucino GreCon Dimter OPTICUT 350 optimizer

WEINIGDimter Opticut 350 R

Miechucino

Miechucino Optimizer GreCon Dimter OPTICUT 204 R

GreCon DimterOPTICUT 204

Miechucino

Miechucino Weinig Dimter OptiCut S 90 optimizer

Weinig DimterOptiCut S 90

Aalen

Aalen Optimization cutting saw

SALVAMACSalvapush 2000 Version 4100

Domnești

Domnești Cross-cut optimization line

Paul MaschinenfabrikC11 MKL

Järvakandi

Järvakandi CNC full optimization cross cut saw line

Paul11 MKL

Cavedine

Cavedine Optimization of the cross-cutting line

CursalTRVE 450

Kanzach

Kanzach Optimization crosscut saw

Weinig Dimter350 - 4

Used Optimizing (3,172)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84