Used Cross Sanding Machine for sale (66,441)

Juszczyn

Juszczyn Edge sanding machine

COMECLN2G/8P+CA

Hallstadt

Hallstadt Edge sanding machine

HolzkraftKSO 150 F PRO

Hallstadt

Hallstadt Edge sanding machine

HolzkraftKSO 150 M PRO

+44 20 806 810 84

Hallstadt

Hallstadt Profile and strip sanding machine

HolzkraftS 220

Wioska

Wioska Wood shredder, cross-cutting machine for wood residues

HOLZMAKappautomat HRZ 540

Discover more used machines

Deutschlandsberg

Deutschlandsberg Single-piece wood sanding machine

HESSJunior

Rodgau

Rodgau Edge sanding machine

WegomaKS 2250

Germany

Germany Edge sanding machine

WegomaKS 2640

Czech Republic

Czech Republic Edge sanding machine

DE STEFANIMVT 1000

Gebhardshain

Gebhardshain Edge sanding machine

WegomaKS2250

Egenhofen

Egenhofen Edge sanding machine

RehnenJunior R1

Germany

Germany Sanding machine

StähleGloria/Saturn E 180 RF

Wijchen

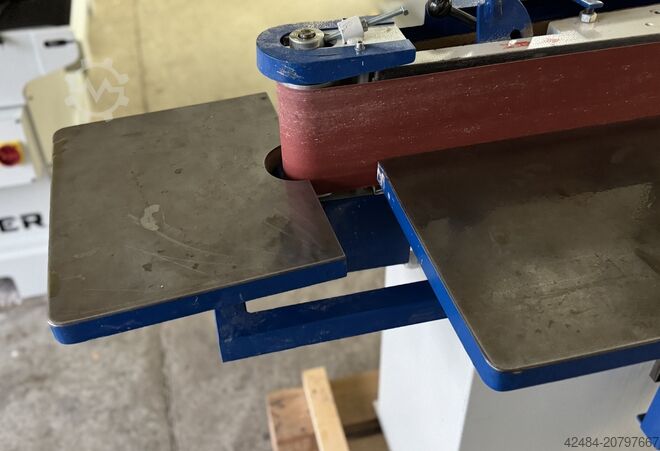

Wijchen Sanding machines Löwer FA 4 S

LöwerFA 4 S

Wien

Wien Edge sanding machine

Langzauner

Leipzig

Leipzig Sanding machines for edge

WINTERKSM-3000 ECO

Leipzig

Leipzig Sanding machines for edge

WINTERKSM-2600 ECO

Leipzig

Leipzig Sanding machines for edge

WINTERKSM-2260

Leipzig

Leipzig Sanding machines for edge

WINTERKSM-3000-S

Leipzig

Leipzig Longbelt sanding machine

WINTERLBS-3000

Leipzig

Leipzig Sanding machines for edge

WINTERKSM-2600

Leipzig

Leipzig Sanding machines for edge

WINTERKSM-2740 ECO

Leipzig

Leipzig Longbelt sanding machine

WINTERLBS-2500

Leipzig

Leipzig Dowel cross-cut and chamfering machine

WINTERFS-36

Leipzig

Leipzig Dowel cross-cut and chamfering machine

WINTERDCC-220

Bischofszell

Bischofszell CROSS AND LONGITUDINAL CUTTING MACHINE

BÖWE310 (5517)

Used Cross Sanding Machine (66,441)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84