Used Transformers for sale (695)

Rosny-sous-Bois

Rosny-sous-Bois Transformer

france transfo630 kva

Ennepetal

Ennepetal Transformer

MITSUBISHI3PH 53.5 kVA TR-YU

Borken

Borken Transformer Kernprüfanlage isolation tra

Betschart SwissKPA 15 Prüfanlage

+44 20 806 810 84

Tönisvorst

Tönisvorst Three-phase transformer

Siemens4AP 4303-2 LB

Tönisvorst

Tönisvorst Three-phase transformer (28031)

Siemens4 AP 4420-OCB

Discover more used machines

Cloughoge

Cloughoge Cast Resin Transformer

Trihal786630-01

Wiefelstede

Wiefelstede Transformer 300 VA

LAPP MikronDT 300 VA WF 51C

Wiefelstede

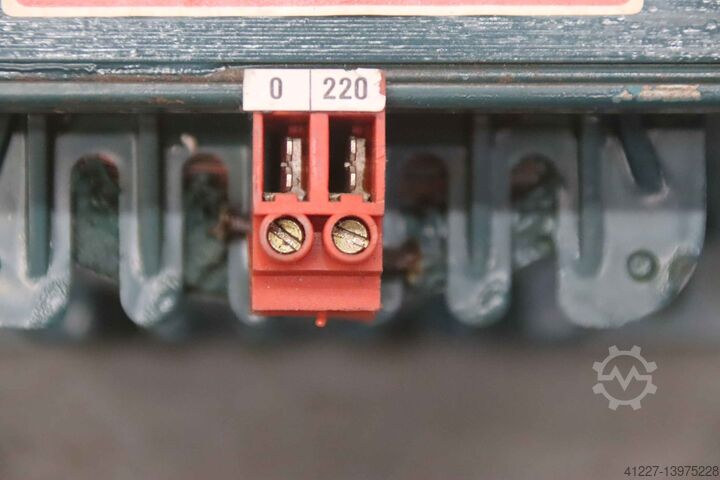

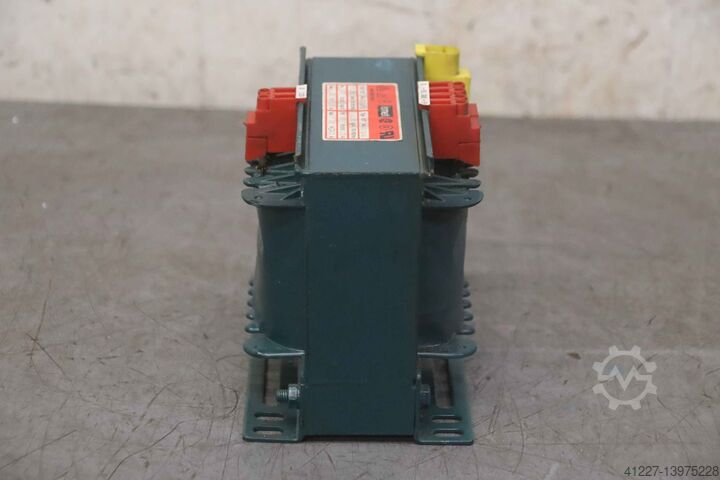

Wiefelstede Transformer 0.384 kVA

IsmetDAW

Wiefelstede

Wiefelstede Transformer 0.5 kVA

ismetCST

Wiefelstede

Wiefelstede Transformer

ismetKAWN-G 2,5

Wiefelstede

Wiefelstede Transformer

ISTDr.C 1100-80

Wiefelstede

Wiefelstede Single-phase isolation transformer 230 V

ismetKSTK 2500

Wiefelstede

Wiefelstede Transformer 650 VA

GME HACOSTMU PPES 30135

Wiefelstede

Wiefelstede Transformer 300 kVA

RohdeSPAR YNAO

Wiefelstede

Wiefelstede Transformer

Schad SintecISK-DK 30.32

Wiefelstede

Wiefelstede Transformers 5,5 kVA 2 pieces

EMB Wittlich2x DTST 7,5

Wiefelstede

Wiefelstede Transformer

ISTC 1100-80

Wiefelstede

Wiefelstede Transformer 1.6 kVA

ELMEE14-A542H

Wiefelstede

Wiefelstede Transformer

Bosch Mikron100-911637 WF 51C

Wiefelstede

Wiefelstede Transformer 160 VA

Legrand42304

Wiefelstede

Wiefelstede Single phase isolation transformer 42V

Foster1 FT22 82

Wiefelstede

Wiefelstede Transformer 160 VA

MücoEST 160

Wiefelstede

Wiefelstede Ignition transformer

KromschröderE 4718/54

Wiefelstede

Wiefelstede Transformer

Günter KirchNGG

Wiefelstede

Wiefelstede Transformer 0.384 kW

GST Schneider13GST108 GV2-RT05

Used Transformers (695)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84