Used Test Machinery for sale (80,755)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Germany

Germany

1,336 km

Citizen Miyano BNE-51MSY, year 2018, internal number 231432

Citizen MachineryBNE-51 MSY

Call

Condition: used, Year of construction: 2018, machine/vehicle number: IntNr231432, CNC short turning machine – Citizen Miyano BNE-51MSY

Year of manufacture: 2018

Condition: Very good, fully operational

Availability: At short notice

Brief description

For sale is a Citizen Miyano BNE-51MSY CNC short turning lathe in MSY configuration featuring main and counter spindles, as well as a Y-axis. This machine is ideal for precise and cost-effective complete machining of complex turned and milled parts in series production.

Equipment / Highlights

- Fixed headstock (short turning)

- Main spindle + counter spindle

- Y-axis

- 2 tool turrets, each with 12 stations

- Driven tools

- Simultaneous machining capability

- High rigidity and process reliability

Technical data

- Max. bar capacity: Ø 51 mm

- Max. turning diameter: approx. 165 mm

- Max. turning length: approx. 380 mm

Gtedpfx Afox Tg Sgjnsu

- Main spindle speed: up to approx. 5,000 rpm

- Counter spindle speed: up to approx. 5,000 rpm

- Control: Mitsubishi MELDAS

- Machine weight: approx. 8,000 kg

The machine is fully functional, both electrically and mechanically.

Complete technical documentation available.

The machine can be inspected under power by prior appointment.

Subject to technical changes, errors, and prior sale!

Listing

Wiesbaden

Wiesbaden

1,197 km

Machining center

Yeong Chin Machinery Industries Co. Ltd. (YCM)NXV-1020A

Call

Condition: new, Year of construction: 2023, travel distance X-axis: 1,020 mm, travel distance Y-axis: 520 mm, travel distance Z-axis: 540 mm, workpiece weight (max.): 6 kg, feed rate X-axis: 20 m/min, feed rate Y-axis: 20 m/min, feed rate Z-axis: 20 m/min, rapid traverse Z-axis: 32 m/min, rapid traverse X-axis: 48 m/min, rapid traverse Y-axis: 48 m/min, spindle speed (max.): 12,000 rpm, table load: 500 kg, YCM vertical machining center model NXV-1020A

Fanuc control MXP-300FB+

Screen size 15"

12,000 revolutions

30 tools

Godpfjrfdckjx Afnetu

20 bar internal cooling

Hinged belt chip conveyor

Spindle oil cooler

Oil separator

Steep taper 40 - DIN-69871A or BBT-40

Machine-side cable preparation for 4th axis connection

Demonstration machine at a special price

Sale only possible in Germany and Austria

Listing

Quakenbrück

Quakenbrück

1,085 km

High-Pressure Pasteurization Unit

Hiperbaric Machinery EquipmentWAVE 6000/55

Call

Year of construction: 2007, operating hours: 2,000 h, condition: used, functionality: fully functional, cylinder diameter: 200 mm, pressure (max.): 6,000 bar, machine/vehicle number: 600/55, High-Pressure Food Processing Machine (HPP System) – Wave 6000/55

This high-pressure food pasteurization system (HPP) is a unit designed for batch processing of packaged food using hydrostatic pressure. The machine is fully operational, well maintained, and suitable for research, product development, and low-to-medium volume industrial production.

High-pressure processing (HPP) offers significant advantages for food manufacturers seeking to improve product safety, quality, and shelf life without the use of heat or preservatives. By applying up to 600 MPa of hydrostatic pressure to already packaged products, HPP inactivates harmful pathogens such as Listeria monocytogenes, Salmonella, and E. coli while preserving the natural taste, texture, nutrients, and color of the food. This makes HPP an attractive technology for clean-label formulations. In addition, the process typically doubles or even triples the shelf life of many refrigerated foods, reducing waste and improving distribution flexibility. Because HPP is a post-packaging treatment, recontamination risks are minimized, enabling manufacturers to meet stringent food safety standards in domestic and export markets. The technology is suitable for a wide range of products, including meat, seafood, juices, plant-based foods, ready-to-eat meals, and high-value chilled items.

Gtsdpfx Afex E Utijnju

The system offers a treatment chamber volume of 55 L, reaching pressures up to 6,000 bar (600 MPa), with automatic basket loading/unloading and an integrated intensifier. It is ideal for enhancing food safety, extending shelf life, and enabling clean-label product concepts.

Technical Details

Model: Wave 6000/55

Chamber layout: Horizontal

Chamber dimensions: Ø 200 mm × 2,000 mm

Chamber volume: 55 L

Total equipment length: 8,020 mm

Maximum working pressure: 6,000 bar (600 MPa)

Pressure medium: Water, free of additives

Processing water temperature: +5 °C to +30 °C

Pressure-build time (0–6,000 bar): 3.9 min

Intensifiers: 1 integrated

Electrical power: 47 kW (50 Hz)

Loading/unloading system: Automatic

Total weight: ~20,000 kg

Condition and Use Cases

The machine is in very good condition and suitable for:

Meat, seafood, ready-to-eat meals

Dairy, beverages, plant-based products

Shelf-life extension and pathogen reduction

R&D, validation trials, pilot production

Cycles completed (as of Jan 2025): 20,000

Included with the High Pressure Food Processor WAVE 6000/55:

High-pressure vessel made of stainless steel, wire-wound with high-resistance cable; horizontal layout with 55 L useful volume

Yoke constructed from high-quality steel layers, double-primed and painted

Stainless steel vessel plugs

Support beds

Hydraulic power unit with vessel opening/closing mechanisms

Integrated intensifier (1 unit)

High-pressure stainless steel piping for intensifier–vessel connection

Water filtration system (5 µm)

Temperature probe for monitoring processing water via the client fluid circuit

Tactile touch screen for automatic and manual operation (interface in German)

Electrical control cabinet

SCADA system for control and data recording

Internet communication module for remote service

Instruction manual

The machine has been used for reasearch purposes and has only done ~20.000 cycles. It is assumed the average cycle length is 6minutes = 2,000 hours

All technical specifications and details are provided without guarantee. Subject to prior sale and possible errors or omissions.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Iszkaszentgyörgy

Iszkaszentgyörgy

1,993 km

Cnc EDM Spark machine

NEUAR Precision Machinery Co. LtdCNC-C50E2

Call

Condition: like new (used), Year of construction: 2020, operating hours: 2,000 h, functionality: fully functional, machine/vehicle number: HU50610, Controller 15" touch screen with Windows Operation System Interface

Table size 630 x 360 mm

Dimension of tank LxWxH = 940 x 550 x 350 mm

X travel 400 mm

Y travel 300 mm

Z travel 300 mm

Distance between the table and chuck 100 ~ 400 mm

Max weight of electrode 11/50 kgs

Max weight of wpc on table 500 kgs

Max Output power 50A

Best surface quality of work 0,08 Ra

Input power 10 kVA

Dielectric capacity 300 litre

Dimensions of the machine LxWxH = 1320 x 1380 x 2150 mm

Weight 1450 kgs

Gjdpowktkkofx Afnstu

Accessories, features

- No. of filters 3 pcs.

- C axis (max loading 11 kg)

- Dielectrictank

- Machine mouths

- Manuals

- Handtools

Listing

Székesfehérvár

Székesfehérvár

2,009 km

5 axis vertikal machining center

Yeong Chin Machinery Industries Co. Ltd. (YCM)FX380A

Call

Condition: good (used), Year of construction: 2018, functionality: fully functional, Controller FANUC MXP-200FC

Table size D380 mm

Table load max 200 kg

X travel 700 mm

Y travel 520 mm

Z travel 480 mm

A axis +30/-120 degree

C axis 0-360 degree

Spindle speed 12000 rpm

Tool holder type BBT40

Rapid speed 36/36/24 m/min

Feedrate 1 - 100000 mm/min

Max tool diameter and length D78 x 280 mm

Max tool weight 6 kgs

Spindle power 22,5 kW

ATC magazin 30-fold

Power required 46 kVA

Gedjr I Az Tspfx Afnetu

Accessories, features

- CTS

- integrated 4/5 axis

- Coolant unit

- Chip conveyor

- Mist collector

- external hydraulic

- manuals

The machine is still under power and can be inspected in function. Ready to buy.

Discover more used machines

Listing

Austria

Austria

1,819 km

Plate Shear - Mechanical

HM MachineryHM JBS 2000/3

Call

Condition: used, Year of construction: 2016, gebraucht

2016

9737

prompt, Zwischenverkauf v

9800 €

1

8330 €

2025 mm

3 mm

500 mm

4 kW

Godpfx Afewiq Iwonotu

2500 mm

1720 mm

1200 mm

1100 kg

Manual back gauge 500 mm

Foot pedal

Side stop

4 table support arms

Light barrier protection at the rear of the machine

Stroke counter

Sheet ejection to the front for small parts

Operating manual in English with EC declaration of conformity

Listing

Weert

Weert

979 km

Cable stripper cable stripping machine KM13

Jeffra Machinery & supportKM13

Call

Year of construction: 2023, condition: new, functionality: fully functional, This machine, type KM13, cuts electrical cables from 20 to 120 mm in diameter. The different diameters are easily adjusted by turning the hand wheel up and down. The machine has a speed of 25 mtr/min. The dimensions are: length 600 mm, width 600 mm and height 1600 mm. The weight of this machine is about 200 kg. This machine is powered by a 380V-50HZ, 3KW electric motor with a gearbox cabinet. The cable is cut from 2 sides so the copper core falls out easily.

Spare parts such as blades, drive, bearings etc can also be supplied. If required we can also perform maintenance on these machines A machine that is ready to use and easy to operate.

If you want to try it, please bring cable.

Godpsq E Ti Hefx Afnetu

Listing

London

London

590 km

Beer tank

Hangzhou Kuangbo Machinery EquipmentKBBFT1300A 2000L Beer Tank

Call

Condition: excellent (used), Year of construction: 2021, functionality: fully functional, machine/vehicle number: KB-20211022002, 1 x Hangzhou Kuangbo Machinery Equipment Co. Ltd 2000L beer tank, previously used as a brite tank but can be used as an FV.

Technical Specification:

Model - KBBFT1300A.

Serial number - KB-20211022002

Date of manufacture - 2021.

Capacity - 2000 litres.

Notes: All 1.5inch Tri Clamp connections other than DIN PRV port on top, manway door, and larger triclamp

Features: Port on top for dry hopping etc. 2x thermowells, one for a thermometer at front and one for temp sensor in back & a CIP arm on the RHS, with sprayball.

Gtsdpewl H Niefx Afnou

Listing

Thisted

Thisted

1,144 km

Blow molding machine

Coleman machineryKEM-B-2 Bottle blow molding machine

Call

Condition: used, DM-01225-PET-Blowing

Semi-automatic PET bottle blowing machine Capacity: 1,000 BPH

2 units of blowing machines

1 preform heating tunnel

Godpsx I Rcljfx Afnotu

Equipped with 2 x 0.5 L bottle mold

Capacity: 1,000 pcs/hour, Cavities: 2 x 2 for 500 ml bottles

Air pressure compressor

Air dryer

Donalcon air filters

Listing

Wysoka

Wysoka

1,676 km

Double wide belt sander

Qindao Haohailong Woodworking MachineryBSG2613C

Call

Condition: excellent (used), Year of construction: 2019, Double-sided grinder

Production date: 07.2019

New not used.

1) Net weight: 15000 kg

2) Dimensions: 2200 x 3100 x 3050 mm

3) Higher grinding speed

4) High precision

Gsdpfxet Dmmce Afnjtu

Technical specifications

1) Grinding width (max): 1300 mm

2) Grinding thickness: 5-150 mm

3) Grinding length:> 700 mm

4) Abrasive belt speed: 25 m/s

5) Abrasive belt dimension: 1350 x 2800 mm

6) Total motor power: 163.25 kW

7) Grinding head motor: 75 kW x 2

8) Motor for feeding: 11KW

9) Lift motor: 0.75 kW

10) Brush motor: 0.75 kW x 2

11) Feeding speed: 10-30 M/min

12) Power supply: 380 V 50 Hz

13) Working pressure: 0.6-0.8 MPa

14) Extraction capacity: 24000m³/h

a. Thickness of sanding boards in large range: 5-150mm.

b. Machining plate thicknesses greater than 25mm with good quality.

c. The upper and lower conveyor pressure roller adopts double power transmission, so that the transmission efficiency is increased and smooth operation is maintained. It can ensure grinding with high accuracy and good surface quality.

d. To meet the needs of different plate processing, they used variable frequency and adjustable speed system and variable speed motor for conveying.

e. Siemens electrical parts were selected as the main parts with long service life.

Listing

Peskojai

Peskojai

1,899 km

Belt Press for Juice

ProFruit MachineryPOWERPRESS 300

Call

Year of construction: 2026, condition: new, functionality: fully functional, Belt press POWERPRESS 300 is designed for pressing fruit, berry and vegetable mash. Fruit mash is supplied on the belt which presses it against shafts.

The obtained juice flows into a small collection tank under the press with filtration sieve on top. Then the external pump or juice collection tank with pump transfers the juice from the press to a desired storage tank or straight to ROCKET pasteurizer for further processing. The pressing process is continuous.

Capacity: 300 kg/h

The most cost-efficient belt press in the market!

The most evolutionary feature of our Belt press POWERPRESS 300 is one huge pressing shaft, which lets the machine to maintain the longer pressing time (belt length is 4900 mm) and huge shaft dimensions squeezes the juice efficiently by saving the costs and space.

The juice yield of apples using our belt press is ~65-75 %. The yield highly depends on freshness and variety of fruits.

There is a filtration sieve integrated into the juice collection tank. Because of that the belt press 300 filtrates the juice even during the pressing stage providing cleaner and purer product.

The belt press includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves service costs.

Gtsdpfot Rft Uox Afnsu

Adjustable fruit inlet lever lets fruit mash supply onto the shaft easily.

Crushed fruit mash can be supplied from MAXIMILL or straight from a bucket or basket.

After work, belt press should be manually washed with a water stream. A full washing process takes around 15 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

Belt tension is adjustable.

The machine is made entirely of stainless steel and has adjustable feet.

Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Listing

Peskojai

Peskojai

1,899 km

Automatic Bag in Box Filler

ProFruit MachineryMAXIFLOW

Call

Year of construction: 2026, condition: new, Machine provides fully automatic filling process for webbed Bag in Box bags. After inserting the first bag, machine removes the cap, fills the liquid and caps the bag. Then it releases the filled bag and takes another one for filling. This way the filling process is continuous and operator only needs to take the filled bag out of machine.

To fill separate Bag in Box or Pouch bags, insert a package into the filler and press START button – machine automatically removes the tap, vacuums the bag, fills it with liquid and closes the bag.

Capacity: ~2000 l/h

-Perfect for filling various liquids: from juice, wine, milk to broth, oil, soap, etc.

-Easy-to-use mechanism does all the work automatically. In addition to that, bags can be supplied to machine manually (separate bags or pouches) or automatically (bags in web).

-Suitable for both hot and cold filling.

-Machine fills Bag in Box bags in sizes 1–30 L, Stand up Pouch packages in sizes 0,75–5 L.

-Machine fills packages with tap closure. It is also possible to fill packages with different closures on request.

-Laser safety mechanism protects limbs by automatically stopping & cancelling the filling process in case of an accident.

-Machine is made from stainless steel materials (AISI 304).

-Touch-screen control panel and multi-language menu grant easier work.

Gtjdsq Nl A Repfx Afnju

-The error of repeatability of volumes is only ± 0,3 %.

-Additional filling table is possible, which slides beneath the main table for filling bags of bigger volume (from 20 to 30 L).

-The filler is easy to clean after work with external and CIP cleaning.

-Working surface of the table consists of conveyor rollers which are exceptionally easy to clean.

-All parts have IP 65 water protection.

Listing

Peskojai

Peskojai

1,899 km

Belt press

ProFruit MachineryPOWERPRESS 3000

Call

Year of construction: 2026, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous.

Gtedpfeq Nl Aqjx Afnsu

Capacity: 3000 kg/h.

The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

-The juice yield of apples using our belt press 3000 is ~75 %.

-There is a filtration sieve integrated into the juice collection tank. It filtrates the juice providing clearer and purer product.

-The belt presses work automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

-The belt press 3000 includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

-Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

-After work, belt press should be manually washed with a water stream. A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

-Belt tension is adjustable.

-Machine is made entirely of stainless steel and has adjustable feet for more convenient use.

-Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Listing

Peskojai

Peskojai

1,899 km

The Mobile Juice Production Line

ProFruit MachineryMobile Line

Call

Condition: new, Year of construction: 2026, The Mobile Fruit Processing Line is designed to conveniently accommodate all the machines necessary for juice production and a smooth work process. It contains:

-Fruit and vegetable washer elevator mill MAXIMILL 3000

-Belt press POWERPRESS 1500

-Transporter for leftover mash

-Stainless steel tanks

-Diesel pasteurizer

-Semi-automatic Bag in Box filler

-Juice filters

Gsdpfx Afoq Nl Afenotu

-Sink with a stainless steel table

Capacity: 1500 kg/h.

Other available capacities: 400 kg/h, 800 kg/h, 1200 kg/h.

Features:

-The mobile juice line conveniently contains all the machines required for fruit processing & juice production.

-Requires only 1 person to operate the whole line.

-Mobility is the biggest advantage which eliminates costs for premises and provides the ability to change location.

-The juice yield from apples is ~75 % .

-All machines are interconnected and controlled automatically.

-The mobile juice production unit includes a Bag in Box filler which fills the juice into both Bag in Box and Stand up Pouch packages.

-The mobile juice line can be customized on client’s request.

-The line is easy to operate and maintain.

-The mobile fruit processing line is installed in a specially made trailer which can be easily opened for work and shut when needed.

-The biggest advantage of our Mobile Fruit Processing Line is the ability to produce juice anywhere you like. This way the client avoids additional expenses for premises and gets the ability to change work location.

Mobility is the key aspect here which provides the client with more possibilities, such as developing a juice pressing service business at various apple farms or different towns.

Listing

Peskojai

Peskojai

1,899 km

Juice Pasteurizer - Filler

ProFruit MachineryROCKET

Call

Year of construction: 2026, condition: new, Pasteurizer-Filler Rocket is used for the pasteurization of juice and other liquid products and filling it to bottles or Bag in Box packaging. The machine has a built-in heating boiler. Inside of it there is a tubular heating spiral made from stainless steel. The liquid comes into the tubular spiral which is surrounded by hot water. The heat from the water heats up the liquid and eliminates the bacteria. If the boiler temperature rises more than set, an automatic temperature sensor turns off the heaters. Juice temperature is monitored manually.

Capacity: 150 – 200 l/h

Maximum heating temperature – 90 ºC.

-A tubular spiral made of hygienic thin-walled stainless steel.

-Spiral is integrated into the boiler which provides saving of space and prevention of heat loss when pumping the water into external heat exchanger. This saves the heating energy up to 15-20%.

-Pasteurizer has an automatic water temperature control with a digital thermostat.

-Safety sensors for dry run protection. Pasteurizer does not start until the water level is correct.

-Easily interchangeable filling heads to Bag in Box or bottle.

-Bag in Box filling table with scales for weight monitoring.

-Bag in Box closing handle is moved by a spring – this ease the opening and closing process.

-Automatic bottle filling – filling will stop when bottle is full.

Gedpeq Nlz Tofx Afnstu

-Bottle filling table is adjustable according to bottle dimensions.

-Manual juice temperature monitoring by digital thermometer.

-Fast and easy cleaning.

Listing

Peskojai

Peskojai

1,899 km

Electric Pasteurizer ECOHEAT

ProFruit MachineryECOHEAT 500

Call

Year of construction: 2026, condition: new, The liquid comes into the tubular spiral surrounded by hot water which is heated by three electrical heating elements. The heat from the water heats up the liquid and eliminates the bacteria.

Available outputs: 300 L/h, 500 L/h

The pasteurizer is suitable to heat various liquids, including viscous liquids: juice, puree, wine, broth, milk and other.

The maximum heating temperature of electric pasteurizer is 90 º C (194 °F).

Juice comes into the tubular spiral which is surrounded by hot water.

Tubular spiral is made of stainless steel.

The boiler has an integrated spiral. This provides saving of space and also prevention of heat loss when pumping the water into external heat exchanger. As a result, this technology saves the heating energy up to 15-20 %.

Gtjdpfx Ajizbcnjfnsu

The heating power is 30 kW.

Electric pasteurizer has a touch-screen panel with digital thermostat which provides an automatic water temperature control.

Automatic regulation of liquid temperature ensures an easy way to change the filling temperature on digital display.

The pasteurizer is fast and easy to clean. It can be washed by CIP cleaning together with our Bag in Box fillers.

Machine has pivoting wheels.

The pasteurizer is easy to clean and maintain.

Electric pasteurizers work in perfect synergy with our Bag in Box fillers. They have a special connection between them which prevents liquid from overflowing and ensures easy work.

Listing

Emmingen-Liptingen

Emmingen-Liptingen

1,349 km

Fully automatic mask machine

Lian Rou machineryLR-DM-85-P 20G34

Call

Condition: excellent (used), Year of construction: 2020, functionality: fully functional, machine/vehicle number: LR2009MAHEDEDM100PO1, type of input current: AC, total width: 1,150 mm, total length: 2,850 mm, total height: 1,900 mm, overall weight: 1,100 kg, outer diameter of label roll: 550 mm, inside diameter of label roll: 76 mm, input voltage: 380 V, compressed air connection: 6 bar, For sale is a fully automatic mask machine DM-85-P (CE version) with 380V connection – suitable for masks Type II and IIR.

The mask machine is designed to process multi-layer fabrics into various masks by means of forming folds, ultrasonic welding, ear loop welding, and nose wire welding. The fully automatic mask machine Lianrou LR-DM-85-P is a late-generation model and is also a patented product by LIAN ROU.

Compared to traditional disposable mask machines, it offers the following advantages: First, the LR-DM-85-P requires only one unit to complete the entire mask production process, which significantly reduces the space required for the production line; second, it features an integrated production design with an aesthetically clean and organized structure.

Godpoya Hdbefx Afnjtu

Most importantly, it is equipped with a range of reliable safety features, thus ensuring a safe operating environment for the operator. In summary, this machine stands out for its excellent cost-performance ratio and high reliability.

Technical data / Notes:

Model: DM-85-P

Design: Electric-Pneumatic

Voltage: 380V

Certification: CE

Manufacturer’s documentation and wiring diagrams included

If interested, please get in touch – viewing by appointment possible.

Listing

Misterton

Misterton

492 km

Fish slicer

CP Food machineryLong slicer

Call

Condition: like new (used), Stainless horizontal fish slicer with adjustable thickness, adjustable stroke and speed.

Gtsdpedz Tcbjfx Afnou

Listing

Gargždai

Gargždai

1,914 km

Rotational Juice Filter

ProFruit MachineryRotational Juice Filter

Call

Year of construction: 2026, condition: new, Machine works well with various fruit, berry and vegetable juice and pulp. During the work process, the juice enters the machine through the spinning filtration sieve. This way excess pulp and sediments stay in the sieve and filtered juice enters the juice collection tank. The sieve spins continuously so juice can flow without interruptions.

Output: 1000 L/h.

Gedpsizbawefx Afnotu

Conical form of the filter facilitates the work process so the pulp is collected and removed easily.

The washing of the filter is rarely needed because of convenient conical filter form. That is why washing can be done once per day.

Rotational juice filter has an integrated juice collection tank which collects the juice.

Juice collection tank has an automatic pump and liquid level control. When the tank is full, the pump automatically turns on and transfers the juice for further processing.

Machine is made entirely from stainless steel.

Rotational juice filter is mounted on wheels.

Machine is especially simple to use and easy to maintain.

This filter is often used after our DESTONE destoning & pulping machine to remove the pulp from the berries or other fruits and achieve uniform quality juice or puree.

Listing

Gargždai

Gargždai

1,914 km

Juice filtration

Profruit MachineryDouble juice filters

Call

Year of construction: 2026, condition: new, Mechanical double juice filters are made of stainless steel. The set includes two parallel stainless steel filters that can work separately one from each other. The double juice filters filtrate the juice and eliminate various thick particles in it. This provides particularly clean juice. The valves of the filters can also be shut off separately during the washing process or for other purposes.

Available mesh: 60 µm, 200 µm, 300 µm, 400 µm, 500 µm.

Connection D25.

Capacity: 2000 L/h.

Stainless steel ensures longevity as well as quality of the product.

Stainless steel filters are easy to clean after using.

Gtsdpehu Aafjfx Afneu

Listing

Gargždai

Gargždai

1,914 km

Belt press for juice

Profruit machineryPOWERPRESS 800

Call

Year of construction: 2026, condition: new, Belt presses POWERPRESS 800 are designed for pressing fruit, berry and vegetable mass. Fruit mass is placed on the belt which presses it against cylinders.The obtained juice flows in the collection trays under the belt presses. Pressing is continuous.

Capacity: 800 kg/h

The most evolutionary feature of our belt press POWERPRESS line is integrated pump and juice collection tank into the press itself. That means that you save money and do not need an additional juice collection tank and pump which otherwise would use much space and money.

There is a filtration sieve integrated into the juice collection tank. Because of that the machine filtrates the juice even during the pressing stage providing cleaner and more pure product.

Godpehu Ab Djfx Afnjtu

Entirely made of stainless steel.

Has adjustable feet.

The belt presses function automatically. When the tank of the mass is full, all other machines which come before belt press turn off automatically. When the juice tank is full, juice pump pumps the juice into the tanks.

Includes High pressure washer.

Has an integrated pump.

Belt tension is adjustable.

Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

The cleaning of the belt is automatic with high pressure cleaner, scraper and brush.

Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

Trust Seal

Dealers certified through Machineseeker

Listing

Gargždai

Gargždai

1,914 km

Diesel Pasteurizer

ProFruit MachineryHEAT 500

Call

Year of construction: 2026, condition: new, Diesel/gas pasteurizer 500 heats up the liquid before the filling process. The liquid comes into the tubular spiral which is surrounded by hot water. The heat from the water heats up the liquid and eliminates the bacteria.

One of our highest machinery achievements is our energy-saving solution integrated into our pasteurizers. It saves the heating energy up to 15-20 % and results in incredibly low heating costs. Calculations show that it costs up to 2 Euro Cents to pasteurize 1 liter of liquid.

Gtsdpfx Afeflrk Isnju

Capacity per hour – 400-600 L of 80 ºC (176 °F) heated juice.

- The pasteurizer is suitable to heat various liquids, including viscous liquids: juice, puree, wine, broth, milk and other.

- The maximum heating temperature of diesel pasteurizer is 90 ºC (194 °F).

- Our pasteurizers are equipped with highest quality German diesel and gas burners GIERSCH.

- The heating power is 53 kW.

- Pasteurizers’ heating chambers are covered with special heat-insulating paint which preserves high temperature for a longer time and increases heating capacity.

- Diesel/gas pasteurizer has a digital thermostat which provides an automatic water temperature control.

- Automatic regulation of juice temperature ensures an easy way to change the filling temperature on digital display.

- The pasteurizer is fast and easy to clean. It can be washed by CIP cleaning together with our Bag in Box fillers.

- Machine can use diesel or gas on client’s request.

- The boiler has an integrated spiral. This provides saving of space and also prevention of heat loss when pumping the water into external heat exchanger. As a result, this technology saves the heating energy up to 15-20%.

- Diesel/gas pasteurizer has pivoting wheels.

- Diesel/gas pasteurizers work in perfect synergy with our Bag in Box fillers. They have a special connection between them which prevents liquid from overflowing and ensures easy work.

Listing

Gargždai

Gargždai

1,914 km

Semi-automatic Bag in Box Filler

ProFruit MachinerySEMIFLOW Filler

Call

Year of construction: 2026, condition: new, Machine fills packages automatically. Just insert the bag or pouch into the Bag in Box filler and pull the handle. After the package is filled, return the filling handle into start position and cap the bag.

Capacity – 250 pcs. of 3 L bags/h

Perfect for filling various liquids: from juice, wine, milk to broth, oil, soap, etc.

Gsdpfx Afjflriuenetu

Fills Bag in Box bags in sizes 1–30 L, Stand up Pouch packages in sizes 0,75–5 L.

Suitable for both hot and cold filling.

Machine fills both Bag in Box and Stand up Pouch packages with a tap.

The filler can have an optional detachable buffer tank for hot filling. It is mounted conveniently on the side of the machine for better inspection and easier washing process. The buffer tank also reduces liquid foaming during hot filling process.

The buffer tank has an integrated liquid level control inside for regulation of overspill and level in the tank. Buffer tank also comes with a connection to our pasteurizer.

Error of volume repeatability is just ± 0,5 %.

The filler pre-vacuums the bags and pouches before filling.

Comes with touchscreen panel and multi-language menu.

Easy-to-adjust filling table allows easily fill different volumes of Bag in Box & Stand up Pouch packages.

Working surface of the table consists of conveyor rollers which are easy to clean and help for the smooth slide of the bags and pouches.

The filler is easy to clean after work with external and CIP cleaning.

Our Bag in Box fillers work in perfect synergy with our Pasteurizers HEAT. They have a special connection between them which prevents liquid from overflowing and ensures easy work.

We also offer fully automatic Bag in Box filler AUTOFLOW.

Listing

Gargždai

Gargždai

1,914 km

Screw conveyor

ProFruit MachineryScrew conveyor

Call

Year of construction: 2026, condition: new, The leftover fruit, berry or vegetable mash enters the loading hopper of the screw conveyor. The screw inside the machine is continuously turning and this way transports the mash from the loading hopper to the exit outlet at the top of the machine. The mash exits the machine.

Screw conveyor is made of stainless steel.

Gtjdpfx Afoizbffenou

Machine has a closed tunnel.

Conveniently transports leftover pressed mash from press.

Listing

Gargždai

Gargždai

1,914 km

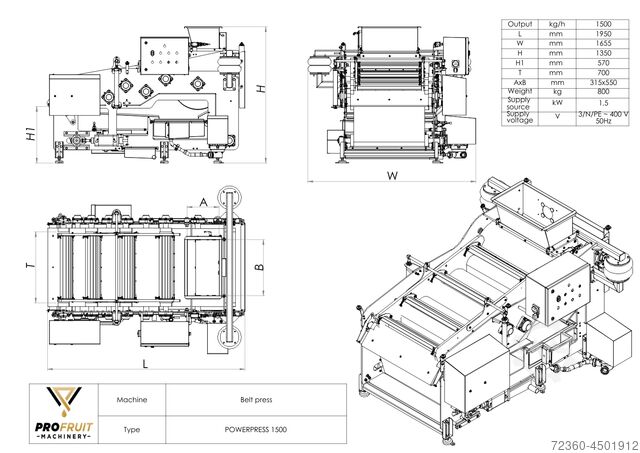

Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 1500

Call

Year of construction: 2026, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous.

Capacity: 1500 kg/h.

- The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

- The juice yield of apples using our belt press 1500 is ~75 %.

- There is a filtration sieve integrated into the juice collection tank. It filtrates the juice providing clearer and purer product.

- The belt presses work automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

- The belt press 1500 includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

- Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

- After work, belt press should be manually washed with a water stream. - A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

- Belt tension is adjustable.

- Machine is made entirely of stainless steel and has adjustable feet.

Gsdpfxeflpp Ej Afnstu

- Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

We make it easier for you to find: "test machinery"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Test Machinery (80,755)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month