Used Statistics Of The Ent for sale (86,849)

Neukamperfehn

Neukamperfehn Roller conveyor Roller conveyor

Bito / Segmentlänge: 1.580 mmSegmentbreite: 38 mm

Alfdorf

Alfdorf Heavy duty trailer

Stapler Center Fritz GmbHTPW 20 AL - AS

Cestona

Cestona Tangential grinding machine

KENTKGS-250AHD

+44 20 806 810 84

Wiefelstede

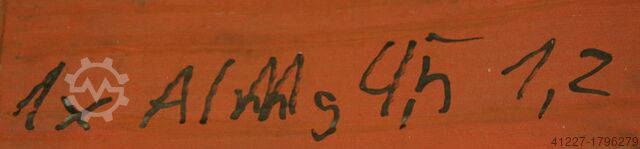

Wiefelstede Welding wire 1.2 mm, weight 7 kg/roll

ElisentalSG-AlMg5

Remscheid

Remscheid Component

SC Rulmenti SA BarladSC Rulmenti SA 23056 MBKW33 Pendelrollenlager - ! -

Discover more used machines

Wekerom

Wekerom Entecon conveyor flowveyor cable conveyor, aerodynamic transport.

Entecon

Neukamperfehn

Neukamperfehn Roller conveyor Roller conveyor

Bito / Segmentlänge: 2.460 mmSegmentbreite: 38 mm

Alfdorf

Alfdorf Load telescopic crane

Stapler Center Fritz GmbhTele 8000

Tönisvorst

Tönisvorst Clamping Units

Zentrierspitzefest + mitlaufend

Wiefelstede

Wiefelstede Thread cutting die

Central3/8"-1"

Borken

Borken Drying cabinet / heating cabinet

Thermo Scientific VötschUT 6420 300 °C

Neukamperfehn

Neukamperfehn High-bay warehouse Pallet rack traverse

Mecalux / Traversentyp: 2C-S 1315Lichte Weite: 3.595 mm

Alfdorf

Alfdorf Heavy duty trailer

Stapler Center Fritz GmbHTPW 40 AL-PA-AW

Wiefelstede

Wiefelstede Clamp

EntrelecVerschiedene Typen

Neukamperfehn

Neukamperfehn High-bay warehouse Pallet rack traverse

Dexion P 90 / Traversentyp: SLB 110|15 /lichte Weite: 2.900 mm

Alfdorf

Alfdorf Platform Industry Transport Trolley

Stapler Center Fritz GmbHTPW 10 AL - AS

Wiefelstede

Wiefelstede Solid rubber tires

Continental7.00-15 SC10

Neukamperfehn

Neukamperfehn Heavy duty casters

TENTEDurchmesser Rad: ca. 125 mm

Alfdorf

Alfdorf Trailer, Heavy Duty Trailer

Stapler Center Fritz GmbHTPW 20 AL-AS

Neukamperfehn

Neukamperfehn Machine step Steel stairs Steel stairs

Maschinentritt Stahltreppe StahltreppenBautreppe / Höhe: ca. 515 mm

Alfdorf

Alfdorf Heavy duty trailer

Stapler Center Fritz GmbHTPW 20 AL - AS No Making

Neukamperfehn

Neukamperfehn High-bay warehouse steel panels shelf

SSI Schäfer / f. Rahmentiefe 950mmRahmenprofil: ca. 300 x 40 x 20 mm

Alfdorf

Alfdorf Heavy duty trailer

Stapler Center Fritz GmbHTPW 16 AL - AS

Neukamperfehn

Neukamperfehn Plug-in shelving

META / 12x Fachbodenträger ClipsTyp: META FIX + META CLIP

Neukamperfehn

Neukamperfehn Steel panels shelf

SSI Schäfer / f. Rahmentiefe 950mm /passend für Traversenlänge 2.700 mm

Used Statistics Of The Ent (86,849)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84