Used Envelope for sale (167)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Topole

Topole

1,694 km

Parcel Sorter

Bell & Howell

Call

Condition: excellent (used), Year of construction: 2014, About the Machine

The Sorter solution consists of a high speed processing system capable of the following:

• Ergonomically designed manual induction prep section for 2-operators that will allow

efficient processing:

• 5,000 pieces per hour (pph) in barcode reading mode with a single operator. This

mode does not require orientation of the product and will be used for the reject

processing of parcels back into the Parcel Manager- (extreme pieces must be

oriented).

• 5000 pph for labeling and OCR mode with two operators. This mode requires the

operator to orient and bring the product to the edge.

• Automated product gapping with minimal skewing

• In-motion weighing and dimensioning

• Top read, full piece image, omni-directional camera solution with complimentary dual

barcode reading and OCR address reading software

• High speed linerless print and apply labeling system with stand.

• Sorting, consisting of:

• Multiple parcel sized outputs into 1 meter (39 in.) containers

• Bin Confirmation sensors

• Tray label printers

• Overhead system displays for the operators

The system is design to handle throughputs up to 5,000 pph.

Parcel Specifications

The system can handle various types of parcel products including but not limited to envelopes, corrugated boxes, polybags, cellophane covered boxes, soft packs, and vacuum-sealed products.

The table below specifies the range of product for the Parcel Manager system. Feeding limitation includes high aspect ratio, the proportional relationship between its width and its height, pieces and pieces with significantly irregular surfaces. The product can be fed and processed in either portrait or landscape orientation.

Below the specifications for packages that the Parcel Manager can handle.

Parcel Specifications

Length (distance along transport path) min. 150 mm (5.9 in.) max. 600 mm (23.6 in.)

Hedpfxoixz Iqj Ag Uong

Width (distance perpendicular to transport path) min. 100 mm (3.9 in.) max. 300 mm (11.8 in.)

Height/thickness (distance above transport bed) min. 5 mm (0.196 in.) max. 160 mm (6.3 in.)

Weight min. 0.014 kg (0.03086 lb) max. 13.6 kg (30 lb)

Listing

Czech Republic

Czech Republic

1,679 km

Vertical Machining Centre

HurcoVMX 30i

Call

Condition: ready for operation (used), Year of construction: 2014, travel distance X-axis: 760 mm, travel distance Y-axis: 510 mm, travel distance Z-axis: 610 mm, controller manufacturer: HURCO, controller model: WINMAX GEN 5, total height: 2,747 mm, table width: 1,020 mm, table length: 510 mm, table load: 1,350 kg, overall weight: 5,000 kg, spindle speed (max.): 12,000 rpm, spindle motor power: 13,500 W, number of slots in tool magazine: 40, tool weight: 7,000 g, product length (max.): 2,180 mm, number of axes: 3, General Data

Machine weight 5000 kg

Measurements height 2747 mm

Measurements depth 2439 mm

Control Unit

Brand HURCO

Main Drive

Spindle Speed 12000 RPM

Spindle motor power 13.5 kW

Tool taper SK 40

Number of axis 3

Movement

X-Axis Movement 760 mm

Z-Axis Movement 610 mm

Y-Axis Movement 510 mm

Dimensions

Machine Length 2180 mm

Table

Table Width 1020 mm

Hjdpfjx D Hu Hjx Ag Ueng

Table Length 510 mm

Table load 1350 kg

Tools

Slots in storage 40

Max weight 7 kg

Media

Internal cooling yes

This 3-axis Hurco VMX 30i was manufactured in 2014. It features a 760x510x610 mm working envelope, a 1020x510 mm table, and a high-speed spindle at 12000 rpm with SK40 taper. The machine includes a 40-piece tool changer and a chip conveyor. Renishaw probes enhance precision. If you are looking to get high-quality milling capabilities, consider the Hurco VMX 30i machine we have for sale. Contact us for more information about this machine.

Application Types

Milling

Listing

Heemskerk

Heemskerk

872 km

Mail processing machinery system mailing

Winkler + DünnebierBB300 Buhrs BB 300 10K

Call

Condition: used, Year of construction: 2013, functionality: fully functional, We have a Buhrs W+D BB300 10K 6 stations envelope inserting system with camerasystem available. DL up to C4 envelopes. This machine is built in 2013.

This system needs to come in in our workshop so we are now still able to offer it as-is and/or after our complete maintenance programm.

Year of built 2013

Hnsdpjxl Uq Ejfx Ag Ueg

6 station base

Configuration:

Buhrs BB300 - 10K

6 station base

4 rotary feeders

1 HF3 vacuum friction feeder

Divert bin

Turning module

Alignment module

Conveyor belt

Autoloader envelope station

This system is already equipped with a camerasystem for matching with two camera's.

More and other feeders possible.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Saarbrücken

Saarbrücken

1,149 km

Coordinate measuring machine

Mahr MultisensorOMS1000 (Refurbished) mit Garantie

Call

Condition: refurbished (used), Year of construction: 2025, operating hours: 20 h, functionality: fully functional, measuring range X-axis: 1,000 mm, measuring range Y-axis: 1,000 mm, measuring range Z-axis: 350 mm, workpiece weight (max.): 50 kg, warranty duration: 12 months, total height: 1,950 mm, type of input current: AC, total width: 1,900 mm, total length: 2,020 mm, travel distance X-axis: 1,000 mm, travel distance Y-axis: 1,000 mm, travel distance Z-axis: 350 mm, overall weight: 5,800 kg, input voltage: 230 V, compressed air connection: 6 bar, year of last overhaul: 2025, Equipment: documentation/manual, lighting, type plate available, Reference Measuring Device Mahr OMS 1000 Multisensor

The all-round measuring device for the broadest range of components or pallet measurements

Factory-refurbished premium multisensor measuring center with warranty, rebuilt in 2025.

INCLUDES latest software update, 18 months of free software update service, free lifetime software hotline and user support.

Delivery with factory service or freight forwarding, worldwide.

Online or on-site demonstrations with customer parts available, application-specific consultation by accredited Profitech metrology laboratories during project planning.

Full service possible:

– Delivery, installation, commissioning, accuracy acceptance according to standards, certification, and comprehensive acceptance documentation. Customized training and education programs also available as online courses.

Rental, hire-purchase, or financing possible directly through Profitech and without a financial institution. Measuring device can be configured individually to customer requirements.

Measurement accuracy: E1 = 1.3 + L / 400µm

E2 = 0.9 + L / 600µm

E3 = 2.2 + L / 300µm

Measuring range: approx. 1000 x 1000 x 350 mm

Includes optical sensor (camera & laser)

Renishaw TP200 probe system incl. Standard Force Module

CNC control incl. hand control panel

27-inch flatscreen monitor

Evaluation station incl. Windows 10 operating system (Windows 11 available on request)

New Opticheck 3D 5.0 software

Active vibration damping (pneumatic) suitable for production-related measurements

Optical sensor:

• Pure grayscale image processing

• Fast, digital image processor

• Automatic feature and edge filter

Hnodoxbpgtepfx Ag Ueg

• Error documentation via program-controlled video image storage

• Multifunctional multi-window technology

• White telecentric transmitted light

• Coaxial reflected light

• 3D multi-sensor head

Laser Sensor:

Laser preparation for laser autofocus. Software-controlled intensity regulation for adaptation to different materials.

Software:

• Full version WITHOUT subscription model or maintenance contract

• User-friendly, interactive programming

• Symbolic representation of the program structure

• Multitasking enables parallel measuring and evaluation

• Powerful basic editor for customer-specific programs

• Automatic sensor calibration

• Geometry elements: point, line, circle (envelope, best-fit and circumscribed circle), ellipse, plane, cylinder, cone, sphere

• Geometry functions: intersection, distance, angle, perpendicular, symmetry

• Form & position tolerances: straightness, roundness, flatness, cylindricity, parallelism, perpendicularity, inclination, position, symmetry, concentricity, run-out, total run-out, flatness run-out, total flatness run-out

• Maximum material condition (MMC)

• Up-to-date tolerance tables according to common DIN standards

• Software module for creating any factory-specific tolerance tables

Listing

Wagna

Wagna

1,843 km

Inserting Machine

CMC200/Easy

Call

Year of construction: 2004, condition: good (used), machine/vehicle number: 1826, inserting machine

CMC 200/Easy

envelopes from C6 to C4

including conveyor belt and vacuum pump

Installation area approx. 460 x 210 cm

Machine number: 1826

Hjdpsnuc Tnofx Ag Ueng

Manual in german and english

Sparepartsbook

wire diagram

some Spareparts und tools inkluded

Discover more used machines

Listing

Győr

Győr

1,927 km

Digital Ultrasonic Flaw Detector Set

ShowRangeSRFD2600

Call

Condition: used, functionality: fully functional, ShowRange SRFD2600 Digital Ultrasonic Flaw Detector Set.

The rugged SRFD2600 is designed for the severe environment. Its domestically unique omniseal design enables it to resist the damp, sandstorm, dust, and pollution in all sorts of environmental extremes ranging from ocean to desert.

The full screen function enables the echo wave displaying area to cover the entire screen so that the operator will have the maximal view.

The solid waveform :add the waveform visual contrast and omission will hardly happen during the fast testing.

The bulk memory can store up to 1000 data sets,including waveforms, curves,and parameters(including the traditional 1000 channels)

Through echo wave-echo wave thickness measurement:the zero calibration can be avoided, and the net thickness of the base material can be directly measured through the coating.

Wave Crest Memory: the real-time envelope can display the highest wave of the flaw and record the maximum value of the flaw to help the exact positioning and fast testing of the flaw as well as the qualitative analysis by the envelope waveform.

Hnodjttrc Aopfx Ag Ujg

Automatic Gain: automatically adjust the gain to the pre-set amplitude height.

Warning Function: afferent echo/lost wave alarm

Real-time Clock: automatically record the date and time of the stored waveform.

Display Freeze: catching the waveform and the sound path data at any moment and removing the hatch after freezing to measure the echo wave parameters.

Flaw Positioning: real time displaying sound path S, horizontal height X, depthY, and wave height H.

Good working condition. Please check out our other listings as well.

Auction

Auction ended

Sachsen

Sachsen

1,416 km

Direct printing machines

AS-OrbitNeopost

Year of construction: 2022, condition: ready for operation (used), functionality: fully functional, paper width (max.): 520 mm, paper height (max.): 762 mm, resolution (max.): 600 dpi, machine/vehicle number: 63507120672, production capacity: 40,000 unit/h, Submission of a bid obliges the buyer to collect the item within the stipulated period, no later than 31/12/2025!

TECHNICAL DETAILS

Printing technology: Inkjet

Number of print units: up to 4

Hjdpoxyf E Aofx Ag Usng

Number of ink cartridges: 12

Print resolution: 600 dpi

Print speed: 40,000 addresses/hour

Print area: 762 × 152 mm

Paper formats

Min. paper size: 85 × 40 mm

Max. paper size: 762 × 520 mm

MACHINE DETAILS

Dimensions & Weight

Dimensions (L × W × H): 1,476 × 58 × (810 – 915) mm

Weight: 131 kg

EQUIPMENT

Feeder for filled envelopes or finished brochures

Double tabber for sealing self-mailers or applying labels

Vacuum transport belt

Direct printing system with 6 print heads (IR possible)

Belt delivery at a 90° angle

Listing

Germany

Germany

1,508 km

Inserting machine

BöweTurbo 22

Call

Condition: used, Complete machine:

- 5510 sheet feeder

- 4720 Reader module with VEKTOR camera

- 4810 Mounting module

- 6015 Folding module

- 4507 Sequencer module,

- 4806 pre-assembly module,

- 5552 Insert module

- 5552 Insert module

- 501 Base unit module

- 5571 Envelope feeder module,

- 7512 Bypass module

- 5535 Stacker module

- Bicos 2009 operating system

Hnjdpfsqzhr Isx Ag Ujg

- ANV/DBDI PC for the control integrity system.

Reading: VEKTOR camera

Can read all types of barcodes, OCR, Datamatrix, barcodes and OME.

Bicos version 2009 and ANV/DBDI version V 9.1.5.0

The entire system is configured to read Datamatrix.

All modules are tested and packaged.

Meter readings can be requested.

Listing

Alkmaar

Alkmaar

876 km

Dozen vouw en lijm machine

ROPIFK-3500

Call

Condition: used, Year of construction: 2000, Compact foldergluer machine for folding carton boxes

Able to process straightline boxes, crashlock boxes and envelopes.

Maximum feeding width 50cm, maximum feeding length 40cm.

Paperweights 120 to 400 gr/m2

Hnodpfx Asxb Dabog Ujg

Speed up to 10.000 pcs/hour

Overstock machine

Listing

Wien

Wien

1,818 km

Inserting machine

INTIMUSTSI-2.0 S / 2.5 S

Call

Condition: refurbished (used), Refurbished envelope inserting machines TSI 2.0/2.5, identical to Quadient DS-40i

Hodpfx Ajx Eiwmeg Uong

Listing

Heerhugowaard

Heerhugowaard

877 km

Filling machine and sealing machine

Can filling and seamingmonobloc

Call

Condition: ready for operation (used), Can diameter range: 50 mm - 100 mm

Can height range: 28mm - 120mm

Capacity: up to 200 cans per minute

Tooling for approx.: 73mm

No. or seaming heads: 6

No. of filling pistons: 16

Single knive member separator

Driven lifters

Hodjwnriaspfx Ag Uong

Siemens touchscreen

Listing

Germany

Germany

1,293 km

Enveloping Machine

Grützmacher/Bell & HowellRubin C5/CEXP-6RC

Call

Condition: ready for operation (used), Year of construction: 2006, Two inserting machines are available. 1) Grützmacher Rubin C5, max. mechanical output: 7500pieces/h, envelope format range: C6-C5, min. insert size: 99mm/148mm, max. insert size: 148mm/210mm, max. filling thickness: 5mm. 2) Bell and Howell CEXP-6RC, year of manufacture: 2006, max. mechanical output: approx. 10000cycles/h, envelope format range: C6-C5, max. insert dimensions X/Y: 110mm/220mm. Machine dimensions X/Y/Z: approx. 2200mm/950mm/1250mm, weight: approx. 1000kg. Documentation available. An on-site inspection is possible.

Hodpfext Rmxex Ag Uong

Listing

Leinfelden-Echterdingen

Leinfelden-Echterdingen

1,322 km

FGT Graphic Machinery - DigitalPress

XeroxVersant 3100

Call

Condition: good (used), Year of construction: 2018, Xerox Versant 3100 - 06/2018 🌟

We're excited to present a fantastic deal for this high-performance, pre-owned Xerox Versant 3100 digital printing machine! 🎉 Perfect for professional print environments, this machine is packed with essential features for efficiency and top-quality output. 📈✨

Technical Specifications and Included Features:

- 🌡 Cooling/Decurling Module: Keeps prints smooth and flat for a polished finish.

- 🎯 Full-Width Array: Achieves automatic, precise color calibration and image alignment.

- 🚀 EFI Fiery NX Controller (External): Delivers high-speed processing and enhanced color accuracy.

- 🎨 EFI ES 2000 Spectrophotometer: Ensures consistent, professional color matching.

- 📄 Dual High-Capacity Paper Trays: (2 x 2,000 sheets) for extended print runs and efficiency.

- 📏 Extended Output for XLS Format: Handles sheets up to 660 mm in length, ideal for a variety of formats.

- ✉️ Envelope Kit for Paper Trays: Versatile paper handling, including envelope printing.

- 📚 Production Ready Finisher with Booklet Maker: Includes booklet-making and 2/4-hole punching.

- 🔥 Fiery FS200 Pro System: High-powered processing for demanding print jobs.

- 🎨 Graphics Art Package: Equipped with Image Viewer, Compose, and Impose tools.

- 🎛 Color Profiler Suite: For advanced color profiling and management.

Hnedpeu Ik Ugsfx Ag Ueg

Listing

München

München

1,508 km

Inserting system

MÜLLER9006

Call

Condition: excellent (used), Year of construction: 2010, Very nice inserting system for DL, C5 and C4 envelopes which has only 1 mil cycles, 2D Data Matrix camera reading code, accumulator, double fold unit, turnover and shingling conveyor.

Hedpfjh H Iuajx Ag Uong

Listing

Lauda-Königshofen

Lauda-Königshofen

1,312 km

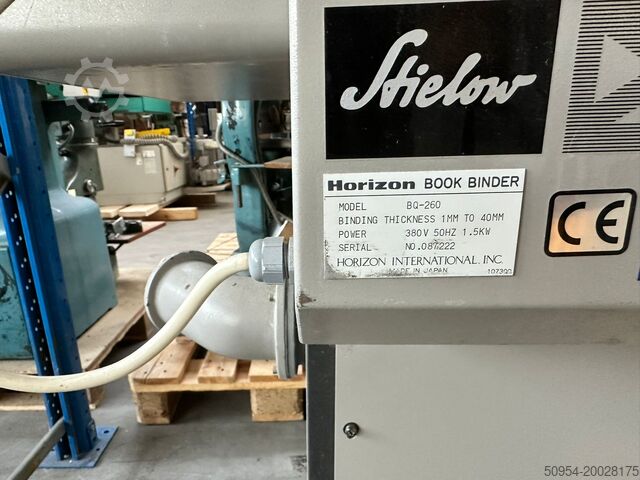

Adhesive Binder

HorizonHorizon BQ-260

Call

Condition: good (used), machine/vehicle number: 087222, Horizon Perfect Binder BQ-260, 1 station, hotmelt glue, envelope feeder, machine number 087222, in good condition, immediately available.

If interested, we are happy to provide information on further machines available at our facility.

Hnodpjxdh Etsfx Ag Usg

You are welcome to view the machine at our premises by appointment.

Listing

Bacău

Bacău

2,603 km

CNC VTL ,2 heads ,2 discmagazines

REMSCR 50 CNC 2S

Call

Condition: new, Year of construction: 2026, Vertical Turning center SCR 50 2S

Turning Center’s Specifications

Nominal Turning Envelope

Faceplate Diameter 4.500 mm

Machining Diameter

Optional 4.700 mm – with the CE Enclosure - 5.300 mm ( without )

Machining Heights 2.100 mm /3500 mm

Work Piece Weight 30.000 kg / 50T

Nominal Turning Travels

X & U - Axis Ram Carriage

From -100 mm

To 2.600 mm

Z and W - Axis Ram 1.250 mm / 1700 mm

Faceplate Diameter

4.500 mm/Normal face plate with T-slots

Jaw chucks height 200 mm

Work Table Speed: 0-50rpm

Power Continuous S1 96 kW / 2X75kW

Torque Continuous S1 130,000 Nm / 320,000Nm

Turning main drive mechanism Gear box reducer ZF and belt transmission

Z & W - Axis Ram

Turning Ram - Left and Right side

Ram Size 250 by 250 mm or bigger

Tool holder type KM 63

Tool Storage (ATC)

No. of Tool storage 2 Tool Storage, left and right sides

Stations qty 12 stations per each tool storage

Stations type Turning toolholder

ATC turning capabilities:

Maximum Singular Tool Weight – turning toolholder

Maximum tool weight 50 kg

Maximum tool size 250 x 150 mm X 700 mm

Axes Drives

X and U - Axes Ram Carriage

Power Continuous S1 6.5 kW

Thrust Continuous S1 45,000 N

Z-Axis Ram

Power Continuous S1 6.5 kW

Thrust Continuous S1 45,000 N

Axes Rates

X, U And Z, W-Axes Feed Rates 0.02 to 6,000 mm/min

X, U And Z, W-Axes Rapid Rates 6,000 mm/min

Coolant System

Coolant Tank Capacity 2,000 L

Coolant Pressure / Flow Rate:

-external coolant (turning)

Hnedpfxjhh Dnxs Ag Uog

-internal

Filtration unit:

-type

-accuracy

6 bar at 100 LPM

40 bar at 60 LPM

Chips conveyor

Conveyor type Hinged (Hardox material)

Width The conveyors should have a width of 600 mm

CNC Control

-type

-producer Sienumerik One Siemens / Fanuc oiF

Listing

Heerhugowaard

Heerhugowaard

877 km

Filling machine

LubecaLW792 clincher and can filler

Call

Condition: ready for operation (used), Can format can be round as well as oval or rectangular.

Hnsdpfjvy Tt Sox Ag Uog

Suitable for food cans. Several sizes available.

Listing

Aalen

Aalen

1,378 km

Sanding machine

LoewerLeistomat SD Video

Call

Condition: new, Number of sanding units 8 st.

sanding width 180 (260) mm

Sanding height max. 160 mm

Dimensions (L/W/H) 3065x1600x1900 mm

weight of the machine ca. 1500 kg

LÖWER Leistomat SD

-----

Automatic fine grinding machine for wood grinding (smoothing, defibering and

Edge breaking) or intermediate sanding of profiled window bars. With soft disc

Technology for the visible surfaces as well as automatically safe profile and

Width adjustment.

- 2 lamella roller units on the side, each 0.75kW, L=120mm, D=200mm

1 softisc unit Ø=200mm above 0.75kW,

1 slat roller unit L=200mm top 0.75kW,

1 soft disc unit Ø=200mm bottom 0.75kW,

1 slat roller unit L=200mm bottom 0.75kW,

2 lamella roller units on the side, each 0.75kW, L=120mm, D=200mm

- Linear guidance of all grinding units

Linear ball bearing sets on hardened shafts

- time-controlled immersion of all lamella roller units

directly above the incoming workpiece edges. By the

It is possible to immerse the aggregates deeper into the profiles

to be able to deliver.

- Motorized workpiece thickness adjustment of the machine

Hnsdpfx Agsvnv Uhj Ueg

- variable grinding flap speed via frequency converter

for adjusting the grinding intensity using frequency converters

(separate for discs, surface rollers and side rollers)

- Disc aggregates as soft discs with Velcro fastener for

Grinding wheels (wood pulp)

- Feed via three lower and one upper conveyor belts and

Spring-loaded pressure rollers with infinitely variable speed 4-15m/min

- Parameters that can be set using the touch panel are workpiece thickness,

Workpiece width (left side units individually), immersion depth

Side units, spindle speed, feed speed

- Saving the parameters as machine programs in program mode

- Working in automatic mode with non-contact

Workpiece width detection and profile detection as well as automatic

Adjustment of the sanding units to the workpiece width and the

Profile shape (workpiece height is set in advance)

- pneumatically clocked driven feed roller, automatic

Clamping of the workpiece and feeding in after unit adjustment

- Red/green indicator lights to indicate operational readiness

- shortest workpiece length 380mm

- Transport belt width 200mm

- max. workpiece width 180mm (260mm in the envelope process)

- Workpiece height 12-160mm

- Suction connection 4 x 100mm and 2x80mm diameter

- Sensor-controlled tool blow-off directly on the discs

- Length (case) x width x height (mm): 3065x 1600 x 1900

Complete length: 4365mm (including roller conveyor with integrated

workpiece width detection)

- Weight: 1500kg

- Operating voltage 400V, 50Hz, 3P, air connection 6 bar

- CE version

-----

Price of the above machine on request!

-----

Special accessories with additional costs:

Set of replacement slats for Leistomat SD-200

consisting of

Area aggregates:

30 strips EH45 / 200 - 7 (rolls)

30 strips EH45 / 200 - 20 (rolls)

Folding units:

96 strips M55 / 120 - 4

SmartFlex slat disc Ø200 solid

with 30 grooves 50mm long

Set of replacement slats for SmartFlex slat disc

consisting of

60 strip M35 / 50 K 180-7 p

Sandpaper disc VB for soft disc

D=200mm grit 220

with velor backing (Velcro), pack of 100.

Sandpaper disc VB for soft disc

D=200mm grit 280

with velor backing (Velcro), pack of 100.

-----

Price of the above-mentioned special accessories on request!

-----...

Listing

Burgas

Burgas

2,880 km

Industrial robot

KUKAKRC2 KR 150 2006 MODEL ROBOT

Call

Condition: excellent (used), Year of construction: 2006, load capacity: 150 kg, arm reach: 2,700 mm, The KUKA KR 150 is a 6-axis industrial robot designed for high-precision and high-speed applications. With a 150 kg payload capacity and a wide working envelope, it delivers reliable performance in tasks such as welding, assembly, handling, and machining.

Model: KR150 L130

Condition: Used

Year: 2006

Included: Manipulator + KRC2 + KCP2 Teachpendant + All Wire Sets

Please get in touch with us for a quote and also the refurbishment options. As PLC Merkezi EOOD, we have more than 300 robots in our inventory and deal with the brands of KUKA, ABB, FANUC and Motoman.

Hedpfx Agew Nat Ie Uong

(Source: Kuka's Website)

Listing

Taufkirchen

Taufkirchen

1,516 km

Inserting machine

Pitney BowesDI600

Call

Condition: like new (used), Year of construction: 2022, functionality: fully functional, Equipment: documentation/manual, Stapler Systemform SI4400 / Pitney Bowes DI600

Including base cabinet

Full inspection and overhaul in the 1st quarter of this year

Counter reading: 70419

Serial number: 440355

Technical data:

Automatic feed stations for unfolded documents: 2 / expandable to 4

Automatic feeding stations for inserts (envelope format): 1 / expandable to 2

Paper width: 127 - 229mm

Paper length: 175 - 406mm

Paper weight for unfolded paper: 60-120 g/m²

Max. Thickness of inserts in envelope format: 2mm

Fold types: Single, wrap, Z and double parallel folds

Speed/h 4000

Stacking capacity per document station max. with 80g/m² : 325

Stacking capacity per insert station max. with 80g/m² : 300

Stacking capacity of the envelope station: 300

Envelope formats: C6/5, C5, Din Long

Options included

Hedjr Eqglspfx Ag Uong

Cascade function (automatic tray change when tray is empty)

Quick start with automatic format recognition

Collective fold with up to 5 sheets

Daily mail station

Number of program memories: 20

Large display with graphic, icon and text display

Automatic counter / preset counter for envelopes

Automatic double sheet detection

Automatic error management

OME reading

Online connection for franking machine

Listing

Borken

Borken

1,027 km

Robot assembly station, dosing station

EpsonG10-854SR

Call

Condition: excellent (used), Epson G10-854SR Robot Assembly Station Dispensing Station

The assembly station is divided into the following sub-stations: 3.1 Dispensing Area, 3.2 Assembly Area KK+SW, and 3.3 Assembly Area Front. (KK = heatsink, SW = front wall bracket)

St.3.1: Dispensing Area

- A workpiece carrier (WT) with mounted chassis and circuit boards is conveyed via the transfer belt into the dispensing area.

- The WT is stopped at the lift-positioning unit (HuPo), raised off the belt, and secured in place

- The X-Y-Z handling system moves the dispensing head to the designated position and initiates the dispensing process.

- Once dosing is completed successfully, the handling system moves to the home position and the WT is placed back onto the conveyor

- Transfer continues into the assembly area KK+SW (prerequisite: no WT in placement position)

St.3.2: Assembly Area KK+SW

- A WT transported from the dispensing area enters the KK+SW assembly area via the transfer belt.

- It is stopped at the lift-positioning unit (HuPo), raised from the conveyor, and fixed in place; during this, the chassis side panels of the partially assembled component are aligned

- Simultaneously, the positioning of the KK and SW tray is carried out

- Both a KK tray stack (12) and a SW tray stack (12) are manually placed onto each respective infeed conveyor outside of the safety enclosure

- The two safety shutters are opened and the loaded tray stacks are conveyed into the gripping position of their respective stackers

- The safety shutters are then closed

- The respective grippers pick up the corresponding tray

- Using the Z-axis, trays are singled and transported upwards (above the actual pick-up height)

- To center and stabilize the trays, a centering support is positioned beneath each tray using the X-handling system.

- Using the stacker Z-axis, each tray is placed onto its centering support

- The trays are now ready for component pick-up

- The SCARA robot with a multi-gripper picks up the KK from the tray and places it in an intermediate alignment position (to compensate for inaccuracies in the pick-up and establish a fixed gripping point for assembly)

- The KK is scanned, picked up again, and if the scanner result is OK, installed onto the WT

- Non-OK KKs are placed in a non-OK container

- The multi-gripper on the SCARA robot then picks up the SW from the tray and places it in the alignment position

- The SW is picked up again and installed onto the WT

- Continue with Assembly Area Front

Technical Data

Design: SCARA (4-axis robot)

Payload: nominal 5 kg, maximum 10 kg

Horizontal reach: 850 mm

Vertical reach: Axis 3: 420 mm

Hnjdpsibx S Nofx Ag Usg

Rotational range: J4: +/- 360°

Horizontal repeatability: +/- 0.025 mm

Vertical repeatability: J3: +/- 0.01 mm

Rotational repeatability: J4: +/- 0.005°

Maximum work envelope: Axis 1: +/- 152°, Axis 2: +/- 152.5°, Axis 3: 420 mm, Axis 4: +/- 360°

Maximum operating speed: J1,J2: +/- 11,000 mm/s, J3: +/- 2,350 mm/s, J4: +/- 2,400°/s

Permissible inertia: nominal 0.02 kg*m², maximum 0.25 kg*m²

User cabling, electrical: 1x D-Sub 9 pin, 1x D-Sub 15 pin

Z-axis: Outer diameter: 25 mm

Press-in force: 250 N

Weight: 48 kg

Control: EPSON RC180

Mounting type: Ceiling

IP protection class: IP20

Power and signal cables: 3 m

Additional assembly modules in other sizes – new and used – can be found in our shop!

International shipping costs on request.

Trust Seal

Dealers certified through Machineseeker

Auction

Auction ended

Hessen

Hessen

1,199 km

Horizontal machining center

HellerMCT 160

Condition: ready for operation (used), Year of construction: 2003, functionality: fully functional, travel distance X-axis: 450 mm, travel distance Y-axis: 450 mm, travel distance Z-axis: 450 mm, spindle speed (max.): 10,000 rpm, TECHNICAL DETAILS

Working Area

Working envelope (X/Y/Z): 450 × 450 × 450 mm

Maximum workpiece height: 700 mm

Pallet size: 320 × 320 mm

Maximum pallet/table load: 300 kg

Spindle

Number of spindles: 2

Tool spindle: 10,000 rpm, 95 Nm

Hjdpfxewx Er Ns Ag Ueng

Speed extension: 18,000 rpm

Tool interface: HSK 63

Feed

Acceleration: 10 m/s²

Rapid traverse: 60 m/min

Chip-to-chip time: 2.6 s

Tool Magazine

Tool positions: 2 × 60

Tool magazine with 60 positions: included

MACHINE DETAILS

Weight

Machine weight: approx. 14 t

Control

Control system: Siemens Sinumerik 840D

EQUIPMENT

Double-spindle, 4-axis horizontal machining center

4 machine pallets

Renishaw probe

Infrared receiver for probe, Renishaw model Vaf72a0p

Operator panel at workpiece setup station

Operator panel at tool setup station

Workpiece setup stations manually rotatable

Hydraulic workpiece clamping, 60 bar

Pneumatic support control at workpiece setup stations

Automatic swing door

Extended coolant supply 70 bar / 1,500 l

VF 250 coolant chiller

Work area flushing

Emulsion mist extraction

Roto-Clear

Automatic setup sequence

Automatic teardown sequence

Run-time and quantity recording

Status lamp, 3 colors

Modem for remote diagnostics

Control cabinet lighting

Listing

Bischofszell

Bischofszell

1,398 km

DIGITAL PRINTER

XEROXCOLORPRESS 1000 / Colour 1000

Call

Year of construction: 2011, condition: excellent (used), machine/vehicle number: 3130055185, with Freeflow Printserver and Clear Toner

Counter (m): 7.3

Colors: 4 + varnishes

Format : A7 – A3+ (SRA3)

Equipment / Additional information:

Image Resolution: 2400 x 2400 dpi VCSEL ROS

Productivity/Print Speeds—AWM

• 80/100 ppm (8.5" x 11"/A4 letter), all weights

55–350 gsm (15 lb Bond to 130 lb Cover)

• 4800/6000 full process color A4 (letter) 4/0 impressions

per hour

• 44/50 ppm (11" x 17"/A3–12" x 18"/SRA3), all weights

55–350 gsm (15 lb Bond to 130 lb Cover)

• 2400/3000 (11" x 17"/A3–12" x 18"/SRA3 tabloid) 4/0

impressions per hour and 4800/6800 (8.5" x 11"/A4) IMP

Paper Format/Sizes

• Maximum Sheet Size: 13" x 19.2" (330 x 488 mm)

• Minimum Sheet Size: 7.2" x 7.2" (182 x 182 mm), tray

Hjdpfjh Nvm Djx Ag Ueng

inserter kit supports for 4" x 6" (102 mm x 152 mm);

see Optional High Capacity Feeder

• Maximum Print Area: 12.83" x 19.05" (326 mm x 484 mm)

• Maximum Print Image Assurance: 12.48" x 19.05"

(317 mm x 484 mm)

Machine can staple, punch, fold & front cut

Complete machine with software & RIP

Brochures, flyers, business cards

Envelopes can also be printed

Various spare materials:

Contains 1 bottle Blaue, 1x yellow, 1x blue, 1x red

1x Kit Beet Assy – FSR Module IEC

1x Chamonix Waste Tonner Bottle

2x Tonner Waste Container

10x Cartridge M 006R01472

3x Cartridge C 006R01471

4x Cartridge K 006R01470

2x Cartridge Y 006R01473

7x Staple Cartridges 008R12925

1x Belt Assy-IBT 064K93191

8x Fuser Belt Assembly

1x Chamonix Deutemle

1x MM Assy-1

5x Copy Cartridge

4x Chamonix Corotion Assy

Listing

Taufkirchen

Taufkirchen

1,516 km

With integrated DS200 C4

NeopostDS-1200

Call

Condition: used, Machine description:

8K/hour inserting processing speed (Upgradeable to 10K/hr or 12K/hr)

Hsdpfx Agjrkmiij Ueng

Base Unit

1 High-Capacity Sheet Feeder (2 Mobile Trolleys each with 5,000 sheet capacity)

Reading Unit with 2D Barcode Reader which can read any type of code, 1D or 2D

Accumulator Unit

Folding Unit

Insert Feeder Station for BRE or enclosure insert

3 input envelope channels for C56, C5 and C4 sizes

2 output channels for filled envelopes, 1 output conveyor for C56 and C5, the other one for C4

The system can run all the 3 different type of jobs, C56, C5 and C4 in the same time

The system run with Quadient license to see in real time in the Quadient Application the production for each channel.

Vertical Stacker stacks filled envelopes and can be controlled intelligently to stack in separate lines

"plug & play" mobile trolley system. Mobile Trolley's roll right to printer for 1-Touch Loading into DS-1200!

Unlimited Programmable jobs automate most all system job changeovers (i.e. track, envelope size, separation, fold size, etc.) for the easiest job changeover (30 seconds) in the industry! The IMOS technology can also provides "Integrated Integrity" to record every movement of each document all the way until they are securely inserted into the envelope!

Listing

Borken

Borken

1,027 km

Continuous scale Volume measuring system

BizerbaCWL Eco flex

Call

Year of construction: 2008, condition: excellent (used), Bizerba CWL Eco flex continuous scale with Sick VMS520 volume measuring system

Bizerba CWL Eco flex continuous scale

Dynamic weight detection with volume determination

The CWL Eco flex can be integrated almost effortlessly into existing parcel shipping, sortation systems and feeding lines.

Bizerba WM-CWL flex Conveyor scale

Model: CWL Eco in Motion

DE-09-MI006-PTB018

Max 60 kg

Min 0,4 kg

230 V

Hnsdjmgax Uopfx Ag Ujg

Sick VMS520 Volume Measuring System

Special features

- Non-contact, active measuring method

- Measurement of length, width and height of cuboid objects

- Measure length, width and height of objects with almost any shape

- Works with a wide range of surface structures and on various flat conveyor systems

- Flexible system configurations

- Calculation of the small enveloping cuboid (box volume)

- Calculation of real volume

Device components

Sick VMD520-2000 Volume measuring device

Sick CLV 490 Stationary barcode scanner

Year of manufacture: 2008

Further articles - new and used - you will find in our store!

International shipping costs on request!

We make it easier for you to find: "envelope"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Envelope (167)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month