Used Enclosures for sale (630)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Oberhausen

Oberhausen

1,044 km

Bench drill

LAGUNBM 3RT

Call

Condition: new, BRAND NEW MACHINE

HEIDENHAIN TNC 640 digital path control

HEIDENHAIN package (motors, measuring systems, and handwheel)

X-axis: 3,000 mm

Rsdeq I Ncqopfx Aa Esl

Y-axis: 1,300 mm

Z-axis: 1,500 mm

Rotary table: 1,600 x 1,200 mm

Maximum workpiece weight: 6,000 kg

Automatic universal diagonal swivel head 1° x 1° (optional with fixed ram Ø 210 mm)

Spindle taper: SK-50 DIN 69871/A

Max. spindle speed: 6,000 rpm (oil-cooled)

Max. spindle motor power: 53 kW

ICS – internal coolant supply – 36 bar

Rapid traverse X,Y,Z: 30 m/min

Positioning accuracy: 0.015 mm

Repeatability: 0.010 mm

ATC – tool changer: 40 positions (vertical / horizontal change)

2 x longitudinal hinge-type chip conveyors

Perimeter enclosure (open top)

Only inquiries from Germany will be answered.

Listing

Guiseley

Guiseley

434 km

Spiral Freezer

CFS18-12-130

Call

Condition: excellent (used), Year of construction: 2003, 460mm width stainless steel wire mesh belt

2070mm Drum width

6580x4700 Outer dimensions

Ammonia 110kw Evaporator

Enclosure and floor included including doors

120m usable belt

Rjdpoxn S E Eefx Aa Eel

810mm infeed height

2280mm discharge height

More photos and specs available on request

Listing

Albstadt

Albstadt

1,342 km

Tool and Cutter Grinder

Adelbert Haasmultigrind HT

Call

Condition: good (used), Year of construction: 2005, operating hours: 114,129 h, functionality: fully functional, machine/vehicle number: 2820, Control: Siemens Sinumerik

Software: Haas Software 7.3

Number of axes: 6 (X, X3, Y, Z, C, A)

Rsdpfxewpqkrj Aa Esl

Grinding spindle:

- Infinitely variable up to 8,000 rpm

- Haas short taper

- Grinding wheel diameter max. Ø200 mm

Workpiece spindle:

- Up to 1,000 rpm

- Center height 175 mm

- Collet 3409

- SK50 tool taper

- Through hole Ø28.5 mm

- Workpiece weight up to 2.5 kg

- Indexing accuracy +/- 3.5 angular seconds

- Input increment 0.001°

Workpiece support:

Linear axis X3 with bushing holder

Feed drives:

- Linear axes with ball screw spindles

- Direct position measurement with resolution 0.0001 mm

Workpiece dimensions (drills):

- Ø 0.8 - 15.0 mm

- Overall length 20 - 380 mm

- Grinding length 10 - 360 mm

- Workpiece weight max. 2.5 kg

Chain magazine:

- 42 stations

- Ø 0.8 - 15.0 mm

- Length 80 - 250 mm

- Workpiece weight max. 1.5 kg

Stack magazine:

- Suitable for stack magazine for indexable inserts

CCD area camera measuring system:

- Tool indexing and positioning by cooling channel (from Ø 0.8 mm)

- Measurement of opening angle

- Indexing of multi-flute drilling and reaming tools

Renishaw probe:

- Touching off workpiece length / tool tip

- Scanning flute lead angle

- Positioning in a coolant hole at the tool tip

Electrical connection:

- 63A pre-fuse

- Supply voltage 400 V

- Frequency 50 Hz

- Control voltage 24 V

- Rated power 21 kW

Weight: 8 t

Incl.:

- Control cabinet cooling: water-water heat exchanger

- Fire protection system: Kraft and Bauer extinguishing system

- Extraction: Büchel Smog-Hog SH 2000/T

- Dressing unit (stationary dresser)

- Workpiece retainer

-----

Operating procedure for drills:

- Manual loading of the chain magazine outside the machine enclosure

- Workpiece feeding by automatic handling system

- Workpiece clamping by automatic collet chuck

- Positioning of workpieces in the working area

- Workpiece machining

- Automatic return of the workpieces on a driven discharge conveyor

Operating procedure for solid carbide indexable inserts:

- Manual loading of the stack magazine in the working area

- Workpiece feeding by automatic handling system

- Automatic clamping using special clamping device

- Positioning of workpieces in the working area

- Workpiece machining

- Automatic return of finished workpieces to the storage system

Drill grinding:

- Grinding flute profile

- Grinding point

- Grinding outer contour

- Grinding relief

- Grinding circumferential margin

- Cylindrical grinding

Indexable insert grinding:

- Grinding seating surface and pin

-----

There are two additional identical machines for sale!

Listing

Waldlaubersheim

Waldlaubersheim

1,171 km

Laser cutting machine

TRUMPFTruLaser 3030 L49 4KW Fiber

Call

Condition: used, functionality: fully functional, Year of construction: 2015, Machine

- Enclosed machine frame

- Automatic pallet changer in longitudinal direction

- Torque drive in combination with linear direct drives

- Enclosed beam guidance using fiber optic cable (LLK)

- Machine cooling unit (water-air)

Rjdpfxsxw Uryo Aa Eel

- Integrated control cabinets with interior lighting

- Power supply to TruDisk via the machine

- Longitudinal conveyor belt

- Work area lighting

- Positioning laser diode

- Oil spray device

- PierceLine

- FocusLine

- NitroLine

- PlasmaLine

- Automatic nozzle cleaning

- Transport and assembly device

TRUMPF Laser

- Solid-state laser TruDisk with 1 fiber optic output

- Laser cooling unit (water-air)

- Excitation via pump diodes

- Laser power control

Cutting Unit

- Universal cutting unit with fully adaptive lens system

- Single cutting head strategy

- Protective glass against lens contamination

- Protective glass condition monitoring

- ControlLine: height control and sheet metal edge detection

Control

- Advanced workshop programming (TruTops via network access)

- Fast repeat production

- 17" touch color screen

- Integrated technology data

- Automatic shut-off

- Programmable selection of cutting gas/pressure

- ContourLine

- Microweld

- FastLine

- FlyLine

- AdjustLine

- Teleservice via Internet

- Integrated e-shop

Data Transfer

- USB interface

- RJ-45 network socket

Safety

- CE marking

- Light barriers

- Multi-chamber extraction system

- Compact dust extractor

- Machine enclosure with certified viewing window (right door)

- Roll-up roof

Special Equipment:

• 3001 on TruDisk 4001

• Extended pallet extraction

• Dust protection device panel

• Viewing window left

• Side viewing windows right

• Storage interface

• Brightline Fiber

• Titanium cutting package

• Brass cutting package

• Copper cutting package

• Nozzle changer

Listing

Łódź

Łódź

1,864 km

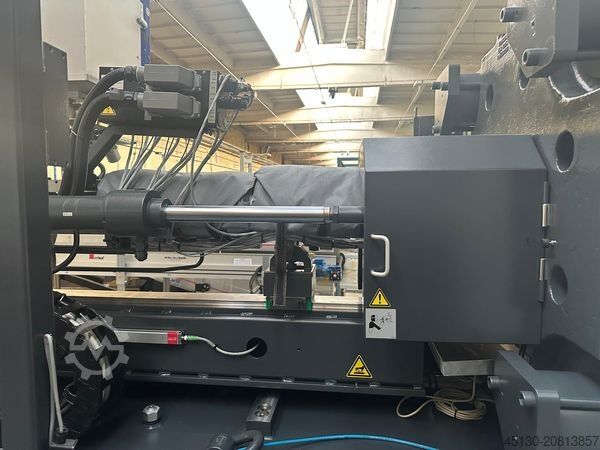

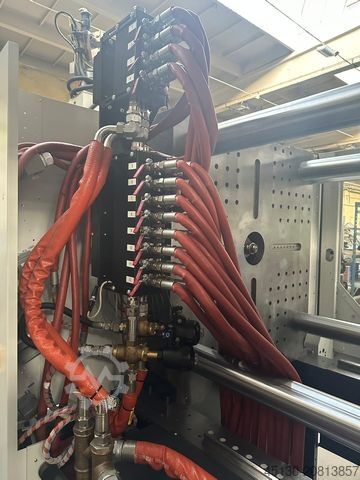

Injection molding machine

EngelVictory 2550/400 Tech Ecodrive

Call

Condition: excellent (used), Year of construction: 2017, Engel Victory 2550/400 Tech Ecodrive with Sepro Industrial Robot Success 22 / Hybrid Machine / Operating Hours: approx. 300 h in automatic mode

Year of manufacture: 2017

Injection unit:

Screw diameter: 80 mm

Shot weight: approx. 1450 g

Injection pressure: 1640 bar

Dosage volume: 1558 cc

Clamping unit:

Clamping force: 400 t

Tie bar spacing: 0x0 mm

Platen size: 1320x1100 mm

Rodpfxjx Nhfme Aa Eel

Ejector: hydraulic

Clamping unit: hydraulic

Control system: CC 300 - Touchscreen

Additional equipment:

Machine in perfect technical condition, like new

Tie-barless, hybrid machine: energy-efficient and very quiet

Operating hours: approx. 300 in automatic mode

Euromap 67

Robot interface

Control with air valve

Hydraulic core pull x 3

Injection unit is wear-resistant and corrosion-resistant

Both clamping and injection units are servo-driven

Proportional valve on injection unit – precise injection

Magnetic quick mold change system Stäubli QMC 122/V3, integrated into the machine control (platens feature their own additional control system) – available at extra cost

Sepro Industrial Robot Success 22

Year of manufacture: 2018

5-axis robot

Touch screen control panel

Robot safety package

Robot with adapter, conveyor belt, and safety enclosure

Purchase of robot and conveyor belt available at additional cost

Dimensions:

Weight: 26,600 kg

Length/Width/Height: 7.70x2.34x2.30 m

All machines offered are started and tested by our service technicians before sale.

A video of the technical tests of the selected machine can be provided, or you can participate in live technical tests at our company in Łódź.

Price: On request

Listing

Oberkochen

Oberkochen

1,377 km

4 side moulder

WEINIGUnimat 23 E

Call

Condition: used, Number of spindles 6 St.

Working width 230 mm

Working height 120 mm

Length of the planing table 2000 mm

Feed motor 4 kW

Feed speed 5-24 m/min.

1 WEINIG Unimat 23 E Planer and moulder

-----

6 spindles (with 2 rigth spindles, reinforced motors, 8,000 rpm, ATS control

Machine will be cleaned and functionally checked before delivery

Working width 20 - 230 mm

Working height 8 - 120 mm

1st spindle (bottom) 5.5 kW (motor replaced)

-----

Diameter 40 mm

Speed ??6,000 rpm

Tool swing diameter 125 - 180 mm

Rebating unit including tool

Hardened table insert in front of 1st (bottom) spindle

2nd spindle (right) 12.1 kW (motor replaced)

-----

Shared motor with left vertical spindle

Diameter 40 mm

Speed ??8,000 rpm

Tool swing diameter 112-250 mm

Max. Tool diameter behind stop plane 203 mm

Max. groove depth 35 mm

Axially travel 80 mm

Rjdpfx Aasxz Hh Uo Eel

3. Spindle, left

-----

Shared motor with 2nd spindle

Diameter 40 mm

Speed ??8,000 RPM

Tool swing diameter 112-200 mm

Max. groove depth 35 mm

Axially travel 80 mm

Pressure shoe in front of left spindle, including

spring-loaded lateral roller pressure

4. Spindle, right 8.3 kW (motor replaced)

-----

Diameter 40 mm

Speed ??8,000 RPM

Tool swing diameter 112-250 mm

Max. tool diameter behind stop plane 203 mm

Max. groove depth 35 mm

Axially travel 80 mm

5. Spindle, top 7.5 kW

-----

Diameter 40 mm

Speed ??8,000 rpm

Tool travel 112-200 mm

Max. groove depth 35 mm

Axially travel 45 mm

Split pressure shoe in front of upper spindle, adjustable to the tool travel

and pivoting away from the tool, spring-loaded.

6. Lower spindle 4.0 kW

-----

Diameter 40 mm

Speed ??6,000 rpm

Tool travel 112-250 mm

Max. groove depth 15 mm

Axially travel 45 mm

Spindles in general

-----

All groove spindles with high concentricity.

Lubrication points for the axial spindle movement.

Feed system

-----

Motor with mechanical brake, 4 kW

Mechanical feed infinitely variable 5-24 m/min.

Feed roller in front of the first lower tool

pneumatically controlled up/down,

Durofer pointed tooth rollers (Weinig patent) with

depth limiter and self-cleaning

Adjustment travel of the feed rollers relative to the left

spindle, axial 35 mm

Machine electrical system

-----

Operating voltage 440 V (voltage range 380 - 420 V), 50 Hz.

Machine frame, tables and stops

-----

Infeed table 2.0 m long (incl. jointing guide)

Manual Waxilit pump for table de-resin removal

One driven rubber roller (spring-loaded in the outfeed table)

Two driven rollers in the machine table, hardened

Machine operation

-----

Pressure shoe in front of the upper spindle with mechanical digital display.

Extraction after the upper spindle with mechanical digital display.

ATS/System, automatic 2-axis positioning for spindles 3 and 5

Minimum working height 12 mm

Electric height adjustment of the upper spindles

and the feed

Central lubrication points on the front of the machine

Electronic digital displays on spindles 3 and 5 (axial), spindle 6 (radial)

and spindle 4 (axial and radial)

Safety and noise reduction

-----

Full safety enclosure

Easily hinged safety hood with window. Covers the e...

Listing

Oberhausen

Oberhausen

1,044 km

Bed type milling machine

LAGUNBM 3

Call

Condition: new, travel distance X-axis: 3,000 mm, travel distance Y-axis: 1,300 mm, travel distance Z-axis: 1,500 mm, rapid traverse X-axis: 30,000 m/min, rapid traverse Y-axis: 30,000 m/min, rapid traverse Z-axis: 30,000 m/min, position of the milling head: Universal-Diagonal-Fräskopf, spindle speed (max.): 6,000 rpm, table width: 1,100 mm, table load: 10,000 kg, table length: 3,100 mm, torque: 1,178 Nm, power: 31 kW (42.15 HP), Equipment: rotational speed infinitely variable, FACTORY NEW BED MILLING MACHINE

Control and Motors:

HEIDENHAIN TNC 640 digital path control

HEIDENHAIN package (motors, measuring systems, and handwheel)

Rodsh Ekrtspfx Aa Ejl

IKZ:

Internal coolant supply, 36 bar

Additional Equipment:

ATC tool changer with double gripper, 24 positions

Double hinge belt chip conveyor (longitudinal), one front and one rear

4th axis preparation (rotary table)

Perimetric enclosure

Accuracies:

Positioning accuracy: ± 0.015 mm

Repeatability: ± 0.008 mm

Only inquiries from Germany will be answered.

Listing

Germany

Germany

1,228 km

CNC machining center

HolzfraeseHP 1890

Call

Condition: used, Year of construction: 2019, Used machine

Year of manufacture: 2019

Only 110 operating hours!

Equipment and technical data:

Travel ranges:

- X = 1800 mm

- Y = 900 mm

- Z = 80 mm

Made from 18 mm Koskisen panels

Redpfxsw Nadyo Aa Eel

Milling bed made of 19 mm MDF as sacrificial plate with guide rails and T-slot nuts for clamping.

Chassis with reinforcements, filled with polymer concrete, designed for transport by pallet truck or forklift.

Mechanical set consisting of profile rails including linear guides and ball screws (2010 and 1605) for all axes.

Shaft couplings and high-performance grease for lubricating the carriages; also includes energy chains with connection sets.

Control set comprised of a Triple Beast controller for controlling 3 axes, with Ethernet interface.

Leadshine drive for the fourth motor. Four stepper motors, 5.0A, 3Nm each with motor cables, as well as a 48V 6.7A switching power supply, LED board for breakout board, ribbon cable and proximity sensors; small parts such as wire leads, ferrules, control cables, heat shrink tubing, and cable lugs. Fully pre-installed in an aluminum enclosure including electrical kit and emergency stop.

- 21.5 inch built-in monitor, including mini PC with Windows 7, Rhino 5.0 CAD software, Estlcam G-code generator, Beamicon2 control software, as well as mouse and keyboard, all pre-installed in an ergonomic console.

Tool length sensor for determining tool length and adjusting the active reference point.

Special equipment:

- High-frequency spindle with 2.2 kW, including clamping nut, frequency inverter, line filter, brake resistor, and collet set.

- PC with 8 GB RAM and AMD processor

- Rhino 5.0 CAD software for creating both simple 2D data and 3D solids

Availability: short-term

Location: Flörsheim

Listing

Germany

Germany

1,293 km

Screw Compressor

BAUER WOLFRATSHAUSENC20 Super Silent (C20-10-SS)

Call

Condition: ready for operation (used), Year of construction: 1989, Offered are 2 screw compressors with the following features per unit: Power: 15kW, pressure: 10bar, volume flow: 1950l/min (1.95m3/min), speed: 2930rpm, including sound enclosure, 1) year of construction 1989, operating hours: approx. 38100h, 2) year of construction 1986, operating hours: approx. 10600h. Inspection possible by appointment.

Rodpfx Aasx Hffxe Ejl

Listing

Stockstadt am Rhein

Stockstadt am Rhein

1,220 km

Universal machining center

AxileG8

Call

Condition: as good as new (ex-display), Year of construction: 2025, functionality: fully functional, AXILE G8 – High-Performance 5-Axis Machining Centre for Maximum Precision

The AXILE G8 belongs to the top tier of modern 5-axis machining centres and is specifically engineered for demanding precision applications. Its integrated gantry design, high dynamic rigidity, and advanced automation options make it ideal for tool and mould making, aerospace, medical engineering, as well as complex single-part and small batch manufacturing.

Technical highlights

• 5-axis gantry construction for superior stability and minimal vibrations

• High-dynamic linear drives / precision ball screws (depending on configuration)

• Robust spindle (18,000–20,000 rpm, HSK-A63) with high power density

• Swivel/rotary table with direct drive, perfect for simultaneous 5-axis machining

• Large operating envelope for complex workpieces

• Tool magazine capacity: 40–120 positions, depending on specification

• Available with Siemens or Heidenhain control (depending on version), ergonomic and user-friendly

• Rigid portal construction for optimal thermal stability and consistent precision

Typical technical data (model dependent)

• X-axis: approx. 670 mm

• Y-axis: approx. 820 mm

• Z-axis: approx. 600 mm

• Table diameter: approx. 600 mm

• Table load capacity: up to 500 kg

• Spindle speed: 18,000 – 20,000 rpm

Redpfx Aaoxxh A Ij Ejl

• Tool holder: HSK-A63

• Magazine size: 40 / 60 / 120 tools

• Control: Heidenhain TNC 640 or Siemens 840D sl

(Values may vary according to year of manufacture and configuration.)

Equipment & options

• Full simultaneous 5-axis machining

• Through-spindle coolant (IKZ)

• Automatic tool measurement and breakage detection

• Renishaw probing systems

• High-pressure coolant system

• Chip conveyor and internal enclosure rinsing

• Modern safety enclosure & automation interfaces

Application areas

The AXILE G8 is ideal for:

• Tool & mould making

• Aerospace

• Medical technology

• Automotive prototyping

• Mechanical engineering & precision component manufacturing

Description

This 5-axis machining centre stands out for its combination of dynamics, rigidity, and ultra-precise machining performance. Thanks to the gantry structure, the machine remains extremely stable even during long runtimes and high feed rates. Advanced thermal management ensures consistent accuracy, and the modern control system provides efficient programming and quick set-up times.

The AXILE G8 is the perfect solution for companies seeking a reliable, powerful, and future-proof 5-axis machine.

Currently, machines with Siemens and Heidenhain controls are in stock, also available with a 600mm table size.

Listing

Łódź

Łódź

1,864 km

Injection molding machine

KraussMaffeiKM 250-2000 CX Blue Power

Call

Condition: excellent (used), Year of construction: 2019, Krauss Maffei KM 250-2000 CX Blue Power with Sepro Industrial Robot SR S5-35HL S4 Trans

Year of manufacture: 2019

Injection Unit:

Screw diameter: 70 mm

Shot weight: 980 g

Injection pressure: 1877 bar

Metering volume: 1077 cm³

Clamping Unit:

Clamping force: 250 t

Tie bar spacing: 630x630 mm

Platen dimensions: 995x1050 mm

Ejector: hydraulic

Clamping unit: hydraulic

Control: MC6 – touchscreen

Additional Equipment:

Very good technical condition

Rodpfxex Nhfae Aa Esl

Operating hours: approx. h in automatic mode

Euromap 67

Robot interface

Air valve with vacuum measurement x 1

Air valve x 1

Hydraulic core pull x 3

Pneumatic core pull x 1

Hot runner control x 16

Hardened injection unit – bimetallic

Energy-efficient machine – equipped with a system of 3 variable displacement hydraulic pumps

Parallel movements

Proportional valve on injection unit – precise injection

Additional oil filtration pump

Sepro Industrial Robot SR S5-35HL S4 Trans

Year of manufacture: 2015

5-axis robot: 4 axes driven by servomotors (electric): X, Y, Z, B; C axis

Touch screen control panel

Robot safety package

Robot with adapter, conveyor belt, and safety enclosure

Purchase of robot and conveyor belt available at an extra charge

Dimensions:

Weight: 20,100 kg

Length/Width/Height: 6.50x2.20x2.30 m

All machines offered are started up by our service technicians before sale.

A video of the technical tests of the selected machine can be provided or it is possible to participate in live technical tests at our facility in Łódź.

Price: On request

Listing

Sankt Leon-Rot

Sankt Leon-Rot

1,259 km

Tooth flank grinding machine

KlingelnbergViper 500 W

Call

Condition: like new (used), Year of construction: 2020, operating hours: 18,000 h, functionality: fully functional, As-new Gear Grinding Machine KLINGELNBERG VIPER 500 W

All-inclusive machine equipped for internal and external gearing

Equipped with a special converter from EUR kW to US standard connection (simplified global connection)

Available due to restructuring at a high-tech family-run company (no automotive production)

Working Area and Capacities

Max. workpiece diameter: 500 mm

Max. grinding stroke: 500 mm

Working area over table (min.–max.): 300 – 800 mm

Distance between spindle center and table (min.–max.): 442 – 1042 mm

Module (generating grinding module): 0.5 – 22

Swivel angle (min.–max.): –180° to +45°

Grinding System

Grinding wheel diameter (min.–max.): 221 – 350 mm

Grinding worm diameter (min.–max.): 221 – 350 mm

Max. grinding wheel width: 75 mm

Max. grinding worm width: 150 mm

Grinding spindle power: 37 kW

Max. grinding wheel speed: 6000 rpm

Table and Feeds

Table diameter: 400 mm

Table bore Ø × depth: 100 × 500 mm

Max. table speed: 1000 rpm

Max. axial feed: 20,000 mm/min

Max. radial feed: 12,000 mm/min

Max. tangential feed: 20,000 mm/min

Connections and Dimensions

Total connected load: 60 kVA

Machine dimensions (L × W × H): 4220 × 3120 × 2526 mm

Filter unit dimensions (L × W): 3490 × 2250 mm

Net weight approx.: 19,300 kg

Machine Configuration – VIPER 500 W

Base Machine and Options

VIPER 500 W base machine

Preparation for internal grinding arms

Internal grinding unit V5 for straight or helical internal gears

Measuring system for profile, lead, and pitch of external gears

Measuring system for profile, lead, and pitch of internal gears V5

Touch Trigger Phasing System

Power supply with ESR voltage drop compensation

100 mm table adapter

Preparation for hydraulic clamping devices

Hydromechanical unit for drawbar clamping systems

Grinding oil filtration system with band filter 100

Fire extinguishing system

Automatic work area door

Cleaning system with spray gun

Crane/hoist integrated into enclosure

Isolation transformer

Voltage stabilizer and isolation transformer

Signal light/beacon tower

Software Packages

Gear PRO software

Software for grinding of spline shafts

Software for testing of spline shafts

BIAS control software for gear grinding

CBN grinding wheel software

ADI dressing process optimization

DLC lifetime monitoring for dressing tools

Flexible profile correction for grinding operations

Consumables

Endless filter band

Assembly/disassembly aid for filter band 100

Diamond dressing rollers

Rsdpoxx T N Tefx Aa Eol

CVD dressing roller D200 R1 for profile grinding

CVD special dressing roller for generating grinding

Grinding wheels

Grinding wheel D350 B60 for profile grinding

Grinding wheel D350 B45 for profile grinding

Profiled grinding wheel D350 B150 for generating grinding

Distance rings/intermediate plates

4 intermediate plates B100

22 intermediate plates B60

30 intermediate plates B45

37 intermediate plates B30

Additional Components

Grinding wheel flange without intermediate plate

Set of standard probes / measuring probes

Additional Options

Warranty extension from 12 to 24 months

Closed Loop 1.0 basic version

Interface for external automation

Listing

Oberhausen

Oberhausen

1,044 km

Portal milling machine

STARVISIONDH 2012

Call

Condition: new, travel distance X-axis: 2,000 mm, travel distance Y-axis: 1,200 mm, travel distance Z-axis: 800 mm, feed rate X-axis: 30,000 m/min, feed rate Y-axis: 30,000 m/min, feed rate Z-axis: 30,000 m/min, table length: 1,900 mm, table width: 1,100 mm, spindle speed (max.): 6,000 rpm, table load: 4,000 kg, position of the milling head: Vertikal, torque: 1,356 Nm, spindle nose: SK 50 - DIN 69871A, Equipment: rotational speed infinitely variable, BRAND NEW GANTRY MILLING MACHINE

Control and Motors:

HEIDENHAIN TNC 640 Digital Path Control

HEIDENHAIN Package (motors, measuring systems, electronic handwheel)

Spindle Performance:

Maximum spindle motor power: 30 kW

ICS:

Internal coolant supply, 70 bar

Additional Equipment:

Tool changer with double gripper, 60 positions

Dual worm conveyor (longitudinal)

Hinged belt swarf conveyor (transversal)

Preparation for 4th axis (rotary table)

Full enclosure, closed at the top

Accuracies:

Positioning accuracy: ± 0.025 mm

Repeatability: ± 0.020 mm

Redoq Ixc Tspfx Aa Ejl

Only inquiries from Germany will be answered.

Listing

Germany

Germany

1,228 km

CNC machining center with plate storage

Holz-HerDynestic 7532 10.5 automatic mit Store-Master 511

Call

Condition: used, Year of construction: 2019, Used machine

Year of manufacture: 2019

Equipment and Technical Data:

- For classic nesting processing with wear plate

- Machine frame of welded construction with ground and hardened prism guides for the gantry, unit head, and consoles

- Gantry-type traveling column

- Helical rack and pinion drive in X and Y axes, ball screw in Z axis for precise positioning

- Working dimensions:

- Max. support area on nesting table:

X = 3100 mm, Y = 1560 mm

- Max. traverse paths:

X = 4695 mm, Y = 2100 mm, Z = 293 mm

- Max. clearance height over DYNESTIC table:

Z = 100 mm from table top (without wear plate)

- Maximum programmable speed

Rodpfx Aaewka Upj Ejl

Vector speed: 128 m/min

X = 80 m/min, Y = 100 m/min, Z = 25 m/min

- DYNESTIC table:

- Fixed, continuous processing table with grid layout

- Continuous grooves in X and Y directions

- Groove spacing: 50 mm

- Includes 25 meters of sealing cord for clamping the wear plate

- Vacuum fields: Single-circuit vacuum system

- Drilling unit 7877:

- 19 spindles

- Drive power: 1.7 kW

- 13 vertical spindles:

- Individually selectable

- Arranged in U-shape

- 5+4 in X direction, 4 in Y direction

- 32 mm spacing

- Max. drill diameter: 35 mm

- Total drill length: 70 mm from screw-on end (depending on panel thickness)

- Spindle stroke: 70 mm

- Rotational direction: alternating clockwise/counterclockwise

- Speed (max): 1000 - 4400 rpm, infinitely variable

- Tool holder: M10 thread, 11 mm fit

- Without tool, without holder

- 6 horizontal spindles:

- 2 double drill spindles in X direction

- 1 double drill spindle in Y direction

- Tool holder: M10 thread, 11 mm fit

- Max. total drill length: 63 mm from screw-on end

- Without tool, without holder

- Milling unit 7842:

- Power: 12.0 kW (S6)

- Max. speed = 1000 - 24,000 rpm, infinitely variable

- Max. power at 12,000 to 24,000 rpm

- Air-cooled

- With HSK-F 63 tool holder

- With right-hand threaded nut (for right-hand rotating tools)

- With collet chuck for HSK shank

- Ceramic ball bearings (hybrid bearings)

- Tool weight max. 6 kg (incl. holder)

- Tools: milling and grinding tools max. Ø 160 mm

- Safety enclosure according to CE standard

- Side and rear safety fence

- Vacuum pump: 500 m³/h, dry-running

- Personnel safety ensured by light barriers in the front machine area

- Hand-held control device for remote operation of the machine with the following functions:

- Start/stop of the processing program

- Control of processing cycle speed

- Reset button

- Manual feed/rapid traverse for all axes

- EMERGENCY STOP

- CAMPUS V7 CAD/CAM software 1x machine license consisting of:

- CAMPUS NC-HOPS:

- Graphic variant system with WOP and CAD/CAM features for creating part variants using macro technology

- CAMPUS MT-Manager

- CAMPUS Workcenter

- CAMPUS DXF interface

- Automatic central lubrication

- Automatic lubrication at defined intervals

- Additional sealing against dust via pressurization in each guide carriage

Listing

Güllesheim

Güllesheim

1,123 km

Laser engraving machine

SEI GIOTTO I-SCAN Graviermaschineinkl. Sonderbau Laserklasse 4

Call

Condition: like new (used), Year of construction: 2017, Laser System Mercury SEI Giotto I-SCAN – used / as-new condition

For sale: Mercury SEI Giotto I-SCAN laser machine

This system is ideally suited for precise engraving applications in industry and trade.

Technical data:

Type: Mercury SEI Giotto I-SCAN

Laser processing system with I-SCAN technology

High-precision processing of various materials (e.g. plastic, wood, acrylic, paper, textiles, and more)

Suitable for engraving

Robust construction, reliable operation

Condition: as new / fully functional

Immediately ready for use, including setup and aluminium frame (programmable sliding table with enclosure – Laser Class 4)

Including SICK safety laser scanner

Inspection & Test:

Redpfow Rp Udox Aa Eel

On-site inspection by arrangement possible.

Laser power: 300W

Includes Icaro Backlight software

Listing

Germany

Germany

1,293 km

Toggle Press - Double Column

SCHULERKB 2-1000-1,25-315

Call

Condition: used, Year of construction: 1997, pressure 1000 t

distance between columns 1260 mm

stroke 315 mm

no. of strokes 10, 21 - 42 /min

distance table/ram, max. stroke up, adjustment up 1295 mm

table surface area 1250 x 800 mm

table height over floor 670 mm

side window 830 mm

capacity of ejector in table 63 t

ejector stroke of ejector in table 75 mm

capacity of ejector in ram 16 t

stroke of ejector in ram 23 mm

ram surface 1250 x 800 mm

ram adjustment 20 mm

feeding length transfer 0 - 250 mm

closing travel of each rail programmable 0 - 140 mm

no. of strokes of the transfer 42 /min

power requirement 135,0 kW

weight 120,0 t

Dimensions (WxDxH) 5,9 x 4,8 x 7,95 m

Rodpfx Ajvuukusa Eol

height above floor 6,95 m

height beneath floor 1,0 m

with DC drive, pneumatic clutch, motoric ram adjustment, pneumatic counterbalance in ram, mechanical ejector in table (pneumatically controlled), mechanical ejector in ram, ram interlocking, die clamping system in table and ram, motoric oil circular lubrication, grease lubrication

control of the press: Siemens S 5

- CNC 2-Achs-Transfer (Fabrikat Dreher, Type STV-D Modell 350/100-SO, Bj. 2008), Steuerung Siemens S 7

- cleaning system (make Beyss, yom. 1989)

as is where is, WITHOUT putting into operation, stored in dismantled condition

The press was previously installed in a soundproof enclosure, which is not part of the scope of delivery

Video at seller's site before dismantling available

Listing

Łódź

Łódź

1,864 km

Injection molding machine

KraussMaffeiKM 200-1400 CX

Call

Condition: excellent (used), Year of construction: 2018, Krauss Maffei KM 200-1400 CX with Krauss Maffei LRX Easy Control 100 Robot / Operating hours: 12,000 h in automatic mode

Year of manufacture: 2018

Injection Unit:

Screw diameter: 60 mm

Shot weight: 617 g

Injection pressure: 2007 bar

Dosage volume: 679 ccm

Clamping Unit:

Clamping force: 200 t

Tie bar distance: 560x560 mm

Platen size: 915x915 mm

Ejector: hydraulic

Clamping unit: hydraulic

Control system: MC6 – touchscreen

Additional equipment:

Very good technical condition

Operating hours: 12,000 h in automatic mode

Euromap 67

Robot interface

Air valve with vacuum measurement x 1

Hydraulic core pull x 3

Pneumatic core pull x 3

Rodpfx Aaex Nhdis Eel

Control system for hot runner zones x 10

Hardened injection unit – bimetallic

Energy-efficient machine – features a system with 3 variable displacement hydraulic pumps

Parallel movements

Proportional valve on injection unit – precise injection

Machine manufactured in December 2018, delivered to customer in 2019

Krauss Maffei LRX Easy Control 100 Robot

Year of manufacture: 2019

4-axis robot: 3 axes driven by servo motors (electric); axis C – pneumatic

Touch control panel

Safety package for robot

Robot with interface, conveyor belt, and safety enclosure

Purchase of robot and conveyor belt at additional cost

Dimensions:

Weight: 11,500 kg

Length/Width/Height: 6.10x2.20x2.30 m

All machines offered are started up by our service technicians before sale.

It is possible to receive a video of the technical tests for the selected machine, or to participate in live technical demonstrations at our premises in Łódź.

Price: Upon request

Listing

Siegen

Siegen

1,146 km

Travelling column milling machine

SoraluceSLP-8000

Call

Condition: reconditioned (used), Year of construction: 2016, travel distance X-axis: 6,500 mm, travel distance Y-axis: 1,800 mm, travel distance Z-axis: 1,300 mm, feed length X-axis: 10,000 mm, feed length Y-axis: 10,000 mm, feed length Z-axis: 10,000 mm, rapid traverse X-axis: 35 m/min, rapid traverse Y-axis: 35 m/min, rapid traverse Z-axis: 35 m/min, spindle speed (max.): 7,000 rpm, spindle speed (min.): 20 rpm, table length: 8,000 mm, table width: 1,100 mm, RepairFIT by Dornhöfer

The difference.

Including installation & commissioning!

Redpfxjxvx Amo Aa Eel

Year of manufacture: 2016

Capacities / Travel distances:

Longitudinal (X): 6,500 mm

Vertical (Y): 1,800 mm

Cross (Z): 1,300 mm

Table size:

Length: 8,000 mm

Width: 1,100 mm

Number of T-slots on the table surface: units: 7

Width of T-slots: 22 mm

Distance between slots: 140 mm

Paintwork:

RAL 7021 (black grey)

RAL 7035 (light grey)

ref F-38 (DanobatGroup Blue)

Tool holder: ISO 50, DIN 69871 AD

Pull stud: DIN 69872 Type A

Main drive:

Drive power: 100% duty cycle 43 kW

Spindle speed range:

Max. spindle speed: 20 – 7,000 rpm

Torque: 900 Nm

Feeds: X, Y, and Z axis mm/min 2 – 10,000

Max. rapid traverse speed: X, Y, and Z axis 35,000 mm/min

Base area SLP8000: (without enclosure) 13.0 x 4.5 m

Overall height: approx. 4.4 m

Weight: approx. 34,000 kg

Heidenhain TNC 640 HSCI

Automatic milling head, Diagonal H207

Adapter angle milling head SK50 with Hirth gearing

Automatic tool changer, 60 magazine places

Chip conveyor

Preparation / integration of NC rotary table

Adaptive control

ACCURA HEADS

Coolant system 2

RepairFIT is our proven solution for a profitable entry into our product lines.

The machines offered in this line are procured by us through a strict selection process and undergo a thorough inspection (Deep-Dive Check). After intensive cleaning, any identified defects or faults are professionally repaired by our expert service team.

Listing

Ireland

Ireland

166 km

Surface grinding machine

METALLKRAFTFSM 2550

Call

Condition: excellent (used), Year of construction: 2018, functionality: fully functional, grinding length: 500 mm, grinding width: 250 mm, total height: 1,800 mm, total length: 2,250 mm, total width: 1,400 mm, feed rate X-axis: 25 m/min, grinding wheel diameter: 205 mm, table length: 500 mm, type of input current: three-phase, table width: 250 mm, grinding wheel width: 19 mm, spindle speed (max.): 2,900 rpm, overall weight: 1,350 kg, grinding spindle motor power: 1,500 W, rotational speed (max.): 2,900 rpm, grinding spindle speed: 2,900 rpm, power: 1.5 kW (2.04 HP), grinding wheel speed: 2,900 rpm, input voltage: 400 V, disc diameter: 205 mm, Metallkraft FSM 2550 Surface Grinder

Machine Type: Surface Grinder with NC Controlled Vertical Feed

Year: 2018

Control: NC Control

Condition: Very Good

Includes

NC Controlled Vertical Feed

Table Enclosure Guard

Electro-Magnetic Chuck

Wheel Dresser

Coolant Equipment

Halogen Light

DRO

Auto-Lube

Technical Specifications

Grinding Wheel Diameter: 180 to 205mm

Redpfjv Iq Shjx Aa Esl

Grinding Wheel Width: 19 to 13mm

Grinding Wheel Bore: 31.75mm

Spindle Speed: 2900rpm

Table Dimensions: 500 x 250mm

X Axis Travel Speed: 5-25m/min

Drive Motor Power: 1.5kW

Electrical Connection: 400V/3Phase/50Hz

Machine Dimensions: 2250x1400x1800mm

Machine Weight: 1350kg

Listing

Grafenberg

Grafenberg

1,338 km

Deep hole drilling machine TBM 50-2-1000

SFTTieflochbohrmaschine TBM 50-2-1000

Call

Condition: excellent (used), This machine was overhauled in 2025 and is therefore in like-new condition!

Technical data:

- Min. drilling diameter 16 mm

- Max. drilling diameter 35 mm

- counter boring 65 mm

- Max. drilling depth 1,400 mm using BTA method

- Required machine footprint approx. 6,100 x 3,100 mm

- Max. machine height 2,400 mm

- 2 separate drilling units, mounted on base machine bed, spindle distance 600 mm

Redewq I Iqjpfx Aa Esl

- Flat guideways

- Feed drive via ball screw and feed gearbox

- Rapid traverse speed 4,000 mm/min

- Feed speed max. 230 mm/min

- Drive power per drilling spindle: 11 kW (2 pieces)

- Infinitely variable speed up to max. 6,000 rpm

- Hydraulically attachable tailstock with counter run

- Tailstock manually movable on base plate with T-slots

- Enclosure with sliding doors

- 1 steady rest each

- 1 rotating clamping bell holder, basic holder each

- 2 pre-centering devices each

- Drilling depth control via cams and limit switches

- CNC control SFT and FU, connection 380 V / Rated current 80 Amp.

- Each unit has its own control and own feed motor

With this machine you actually receive 2 single-spindle machines,

as each spindle is operated separately with its own control and feed motor.

Listing

Wöllstadt

Wöllstadt

1,217 km

Carton packaging machine E

Kartonierer 2024 E

Call

Condition: new, Year of construction: 2023, operating hours: 10 h, !! We would be happy to advise you!!

Model name ////: Rotection cartoner

Features ////: Double servo feed control, with hot melt station, safety enclosure and safety technology

Production orientation ////: Horizontal

Conveyor system ////: Fan conveyor belt

Carton feed ////: top with active conveyor belt

Operator display ////: Touchscreen

Drives & control ////: 8 servo motors and PLC control

Box length ////: 150-300 mm

Box width ////: 120-260 mm

Packaging height ////: 50-100 mm

Speed ////: 40-60 boxes/min. depending on box size and product weight

Recommended cardboard box ////: pre-folded boxes, 250-350g/m³

Consumption ////: approx. 9.5KW

Rsdpsr E Dpaofx Aa Eol

Power supply ////: 380 V / 50 Hz/ 3-phase

System weight ////: approx. 1000 kg

System dimensions ////: approx. 4257 x 1605 x 1823 mm

System material ////: "304 stainless steel with surface treatment"

Hot melt station ////: Required, optional Nordson or Robatech

Trust Seal

Dealers certified through Machineseeker

Listing

Łódź

Łódź

1,864 km

Injection molding machine

Sumitomo DemagSystec 350/720-2300

Call

Condition: excellent (used), Year of construction: 2012, Sumitomo Demag Systec 350/720-2300 / Production Line with Wittmann-Demag DR833 Robot

Year of manufacture: 2012

Injection Unit:

Screw diameter: 70 mm

Shot weight: 1103 g

Injection pressure: 1877 bar

Dosage volume: 1212 cm³

Clamping Unit:

Clamping force: 350 t

Tie bar distance: 720x720 mm

Platen size: 1040x1060 mm

Ejector: hydraulic

Clamping system: toggle lever

Control system: NC5

Additional equipment:

Euromap 67

Robot interface

5x air valves

1x hydraulically operated core pull with proportional valve

5x hot runner controls

Hardened injection unit – bimetal

Moog proportional valve on the injection unit – high-precision injection

Parallel movements

Central lubrication

3 variable-capacity hydraulic pumps

Integrated printer

Machine has been regularly serviced by authorized Sumitomo Demag technicians

Rjdpfxex Nhb Uo Aa Ejl

Robot Wittmann-Demag DR833

Year of manufacture: 2011

4-axis robot: 3 axes driven by servomotors (electric), Y-axis telescopic; C-axis pneumatic, A-axis movement

Axis travel: X-900, Y-1600, Z-3000

Touch control panel

Robot safety package

Robot with adapter, conveyor belt, and protective enclosure

Purchase of the robot and conveyor belt at additional cost

Dimensions:

Weight: 15,750 kg

L x W x H: 8.26 x 2.01 x 2.27 m

All offered machines are started up by our service technicians prior to sale.

It is possible to obtain a video of technical tests for the selected machine, or to participate in live technical tests at our facility in Łódź.

Price: On request

Listing

Łódź

Łódź

1,864 km

Injection molding machine

Sumitomi DemagSystec 350/720-2300

Call

Condition: excellent (used), Year of construction: 2015, Sumitomo Demag Systec 350/720-2300 / Production line with Wittmann-Demag DR853 robot

Year of manufacture: 2015

Injection unit:

Screw diameter: 70 mm

Shot weight: 1103 g

Injection pressure: 1,877 bar

Dose volume: 1,212 ccm

Clamping unit:

Clamping force: 350 t

Tie bar spacing: 720x720 mm

Platen size: 1,040x1,060 mm

Ejector: hydraulic

Clamping unit: toggle lever

Control: NC5

Additional equipment:

Euromap 67

Robot interface

Control with air valve

Control with hot runner x 5

Injection unit hardened - bimetallic

Moog proportional valve on the injection unit – precise injection

Rjdpfx Aasx Nhbbj Eol

Parallel movements

Central lubrication

3 hydraulic pumps with variable output

Built-in printer

Machine regularly serviced by authorized Sumitomo Demag service

Wittmann-Demag DR853 robot

Year of manufacture: 2016

6-axis robot: 5 axes driven by servo motors (electric): X, Y-telescopic, Z, B, C

Axis travels: X-1,200, Y-2,400, Z-4,000

Touch control panel

Safety package for robots

Robot with adapter, conveyor belt and protective enclosure

Purchase of robot and conveyor belt at extra cost

Dimensions:

Weight: 15,750 kg

Length/Width/Height: 8.26x2.01x2.27 m

All machines offered are started up by our service technicians prior to sale.

It is possible to obtain a video of the technical tests of the selected machine or to participate in live technical tests at our company in Łódź.

Price: On request

Listing

Łódź

Łódź

1,864 km

Injection molding machine

Sumitomo DemagSystec 100/420-310

Call

Condition: excellent (used), Year of construction: 2013, Sumitomo Demag Systec 100/420-310 with Sepro SR SDR11 S3 TRANS robot / Hybrid Machine

Year of manufacture: 2013

Injection unit:

Screw diameter: 35 mm

Shot weight: 149 g

Injection pressure: 2024 bar

Dosage volume: 168 ccm

Clamping unit:

Clamping force: 100 t

Tie bar spacing: 420x420 mm

Platen size: 600x600 mm

Ejector: hydraulic

Clamping unit: hydraulic

Control system: NC5

Additional equipment:

Hybrid machine: high-speed, energy-saving, and very quiet

Operating hours: approx. 38,000 h in automatic mode

Robot interface

Air valve x 2

Hydraulic core pull x 1

Hardened injection unit - bimetallic

Main motor of the machine - servo motor driven by inverter - energy saving

Built-in printer

Machine was regularly serviced by authorized Sumitomo Demag service

Robot Sepro SR SDR11 S3 TRANS

Redpfjx Nhaqex Aa Ejl

Year of manufacture: 2013

5-axis robot: 3 axes driven by servomotors (electric); axes A and C (rotation) - pneumatic

Touch control panel

Robot safety package

Robot with adapter, safety enclosure

Robot acquisition available at an additional cost

Dimensions:

Weight: 4400 kg

Length/Width/Height: 4.20x1.40x2.00 m

All machines offered are started up by our service technicians before sale.

It is possible to obtain a video of the technical tests of the selected machine, or to take part in technical live tests at our facility in Łódź.

Price: On request

Listing

Łódź

Łódź

1,864 km

Injection molding machine

Arburg270C 400-70 e²

Call

Condition: excellent (used), Year of construction: 2016, Arburg 270C 400-70 e² with Arburg Multilift Robot / Hybrid Machine

Year of manufacture: 2016

Injection Unit:

Screw diameter: 22 mm

Shot weight: 31 g

Injection pressure: 2000 bar

Dosage volume: 34 ccm

Clamping Unit:

Clamping force: 40 t

Tie bar spacing: 270x270 mm

Platen size: 446x446 mm

Ejector: hydraulic

Clamping unit: hydraulic

Control system: SELOGICA - Touchscreen

Additional Equipment:

Hybrid machine: energy efficient and extremely quiet

Euromap 67

Robot interface

Air valve x 2

Hydraulic core pull x 1

Injection unit hardened - bimetallic

Main machine motor - servo motor with inverter drive - energy saving

Proportional valve on injection unit – precise injection

Self-sealing nozzle

Arburg Multilift Select 6 kg traverse robot

Year of manufacture: 05.2016

5-axis robot: 3 axes driven by servo motors (electric); axes B and C

Travel paths in axes: X-600, Y-800, Z-1000

Robot with adapter, conveyor belt, and safety enclosure

Purchase of robot and conveyor belt available at extra cost

Dimensions:

Weight: 2210 kg

Length/Width/Height: 3.18x1.43x1.98 m

Redpox Ng D Ijfx Aa Ejl

All machines offered are started up by our service engineers before sale.

It is possible to receive a video of the technical tests of the selected machine or to participate in live technical tests at our company in Łódź.

Price: On request

We make it easier for you to find: "enclosures"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Enclosures (630)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you