Second-hand machinery for sale (2,431)

Sort results

- Lowest price Highest price

- Latest listings Oldest listings

- Shortest distance Farthest distance

- Latest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Latest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Latest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation A to Z

- Designation

- designation Z to A

- Designation

- Model A to Z

- Model

- Model Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest running time

- Runtime

- Relevance

- Relevance

Auctions

Auction

Auction ended

Bayern

Bayern

1,385 km

Automation system for injection molding

WITTMANNW833PRO

Year of construction: 2016, Condition: excellent (used), Functionality: fully functional, Automation system of the Wittmann brand was newly installed in 2016 and used on a Netstal Synergy 2000.

All documents, operating instructions, maintenance plans, measurement diagrams etc. included as well as control modules, power supply units and control panels.

The Wittmann Picker can be used as a stand alone.

TECHNICAL DETAILS

travel X / Y / Z: 900 / 1800 / 3000 mm

payload: 15 kg

Scope of delivery: robot, console, support V/2614-3104, adapter, conveyor system standard MB belt, SE protective enclosure incl. safety door with SIPA

MACHINE DETAILS

Dkolnjpm Htgo Shu Eol

dimensions plant (LxWxH): 6560 x 4423 x 4154 mm

Robot weight: 560 kg

Mains connection: 3PH/N/PE

mains voltage: 400 V

tolerated voltage fluctuations: up to 10%

connected load: 11 kVA

frequency: 50-60 Hz

tolerated frequency fluctuations: up to 2%

supply line fuse: 16 A

air pressure: max 6 bar

maintenance of system functions: up to min 5 bar

Auction

Auction ended

Bayern

Bayern

1,385 km

Jig

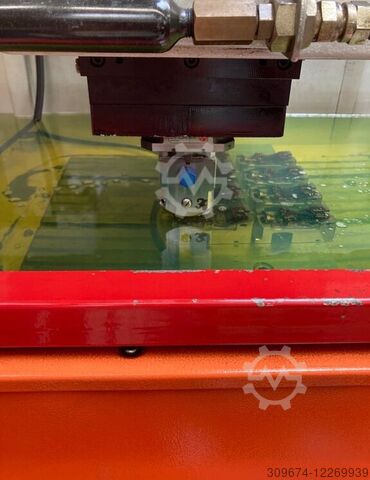

CHARMILLESRoboform 35 P Roboter Automation

Year of construction: 2001, Condition: good (used), Functionality: fully functional, Machine extensively overhauled worth EUR 18,000

Optional configuration QCRI 54/8: available, see pictures

placement automation: available, see video

Pressure flushing: 1 x through workpiece 1 x through electrode, 2 x lateral

Suction flushing: 1 x through workpiece

Central lubrication system automatically via NC in all axes

TECHNICAL DETAILS

Travel (X, Y, Z): 350, 250 300 mm

Max man. Feeding speed: 900 mm/min

Weight of electrodes: max. 20 kg

Weight of workpieces: max. 40 kg

Magazine configuration: 54/8

electrodes: 54 pieces

Electrode dimensions: 70 x 70 x 200

Djlnjn Arnxj Shu Eekl

Plates: 8 pieces

workpiece dimensions: (4x) 320 x320 x 270 mm, (4x) 320 x 320 x 170 mm

work table: 500 x 400 mm

T-slots: 3 x 12 mm

distance of grooves: 125 mm

Available clamping systems: Erowa IST 3R Macro Megatool GPS 70

MACHINE DETAILS

Dimensions (H x L x W): 2400 x 1900 x 1690 mm

Auction

Auction ended

Kujawsko-Pomorskie

Kujawsko-Pomorskie

1,732 km

Lead/traction spindle lathe

PorebaTR-135 B1/5M

Condition: refurbished (used), Year of construction: 1986, Functionality: fully functional, machine/vehicle number: 1102-1284, turning diameter over cross slide: 1,000 mm, turning diameter over bed slide: 1,350 mm, turning length: 5,000 mm, rotational speed (max.): 630 rpm, workpiece weight (max.): 11,000 kg, Comprehensive overhaul in 2025 - as good as new! Guarantee: 12 months on spare parts and electrics

Highlights

- Refurbished universal lathe with the latest technology

- Powerful motor with 22/41 kW power and 21 spindle speeds

- Turning diameter of up to 1,650 mm in the bridge recess

- Versatile feed options for precise machining

- Expandable equipment with digital measuring systems, steady rests and MULTIFIX steel holders

- Meets CE / WOT acceptance conditions and Polish standards

TECHNICAL DETAILS

Center distance / turning length: 5,000 mm

Turning diameter over bed: 1,350 mm

Turning diameter over slide: 1,000 mm

Turning diameter in the bridge recess: 1,650 mm

Spindle passage diameter: 120 mm

Workpiece capacity

Max. workpiece weight between centers: 8,000 kg

Max. workpiece weight with 1 steady rest: 10,000 kg

Max. workpiece weight with 2 steady rests: 11,000 kg

Turning & feed data

Number of spindle speeds: 21

Speed range: 5 - 630 rpm

Number of feeds: 80

Longitudinal feed range: 0.07 - 10 mm/rev

Cross feed range: 0.035 - 5 mm/rev

Upper drawer feed range: 0.017 - 2.5 mm/rev

Motor & power

Motor drive for upper slide drawer: taper turning up to 450 mm length, 90° scale

Motor power: 22 kW / 41 kW (1. gear / 2nd gear)

MACHINE DETAILS

Total length: 7,500 mm

Width: 2,130 mm

Height: 1,550 mm

Total weight: 13,200 kg

EQUIPMENT

- Tailstock

- Coolant pump

- Chuck protection

- Tool holder

- Chip trays

ADDITIONAL EQUIPMENT (available for an additional charge)

- 3- or 4-jaw chuck (various diameters & variants)

- Digital measuring system for 2 axes (incl. display, assembly & calibration)

- Steady rests with rollers for the following clamping ranges: 40 - 400 mm / 400 - 700 mm / 450 - 900 mm

- MULTIFIX quick-change tool holder

Djlsvy U U Ron Shu Ejkl

Find out now

+44 20 806 810 84

+44 20 806 810 84

Create listing

*per listing / month

Auction

Auction ended

Oberösterreich

Oberösterreich

1,631 km

Plasma cutting machine

Swift CutPro 3000

Condition: excellent (used), Year of construction: 2019, Functionality: fully functional, machine/vehicle number: PR4-3000-07190386, sheet thickness aluminum (max.): 20 mm, sheet thickness steel (max.): 22 mm, travel distance X-axis: 3,000 mm, travel distance Y-axis: 1,500 mm, No reserve price - guaranteed sale to the highest bidder!

TECHNICAL DETAILS

Cutting area: 3000 x 1500 mm

Drives: 400 W AC OMRON servo motors

Plasma source Hypertherm: Powermax 105

Duty cycle: 80%

Dkjlnsvw Amco Shu Eol

100% duty cycle: 94 Amps

Maximum piercing capacities

Mild steel: 22 mm

Stainless steel: 20 mm

Aluminium: 20 mm

MACHINE DETAILS

Space requirement: 5.50 x 2.80 m

Machine dimensions: approx. 3.7 x 2.0 m

Transport dimensions: 3780 x 2115 x 1500 mm

Weight: 1.1 t

Box software: included

Operating hours: 265 arc hours

Auction

Auction ended

Woiwodschaft Pommern

Woiwodschaft Pommern

1,721 km

Forklift

Steinbock BossB1512-5A1

Condition: ready for operation (used), Functionality: fully functional, Year of construction: 1995, operating hours: 7,381 h, load capacity: 15,000 kg, lifting height: 3,520 mm, fuel type: diesel, mast type: standard, construction height: 3,380 mm, fork carriage width: 2,500 mm, fork length: 2,400 mm, TECHNICAL DETAILS

Load capacity: 15,000 kg

Load center: 1,200 mm

Lift height: 3,520 mm

Mast type: Standard

Overall height: 3,380 mm

Fork & structure data

Fork carriage width: 2,500 mm

Dolnjvy A U Ss Shu Ejkl

Fork length: 2,400 mm

Fork width: 200 mm

Fork thickness: 100 mm

Dimensions & weight

Overall length: 5,400 mm

Overall width: 2,650 mm

Net weight: 22,700 kg

Engine & drive

Fuel type: Diesel

Engine type: Perkins

Drive type: Diesel

Gearbox: Clark

Tires

Front: Pneumatic tires 12.00-20

Rear: Pneumatic tires 12.00-20

Condition

Overall condition: Ready for use and fully functional

Technical condition: Very good

EQUIPMENT

- Perkins diesel engine with Clark gearbox

- Side shift and tine adjustment device for flexible handling

- Full cabin with heating for comfortable working

- Pneumatic tires front and rear for optimal traction

- Side shift

- Tine adjustment device

- Heating

- Full cabin

Auction

Auction ended

Bayern

Bayern

1,387 km

3D metal printer

ALPHALASERAL3D-METAL 200

Condition: like new (used), Year of construction: 2022, operating hours: 70 h, Functionality: fully functional, machine/vehicle number: AL-001-0007, laser power: 200 W, travel distance X-axis: 100 mm, travel distance Y-axis: 100 mm, travel distance Z-axis: 100 mm, HIGHLIGHTS

- Very fine laser spot for the finest geometries

- Powerful laser

- High powder yield

- Reliable printing process thanks to intelligent AL3D-OS software

- Small footprint 600 × 617 mm

- Closed gas circuit for reduced gas consumption

- Low energy consumption

- Unpacking station: Clean separation of the sintered component from unused residual powder + collection of the residual powder for possible reuse

TECHNICAL DETAILS

Installation space size: d = 100 mm, h = 100 mm

Resolution: 50 µm

Laser & optics

Laser type/wavelength: fiber laser 200 W CW, 1070 nm

Focus diameter: 50 µm

Scanning speed: max. 5 m/s

Process parameters: Open access to all machine and process parameters

software

Operation: 15.6" touchscreen, keyboard and mouse possible

Connectivity: Ethernet; 2 × USB

Software: AL3D-OS, offline version for project creation

Remote access: TeamViewer

External software: Autodesk Netfabb, Materialise Magics, CIM Systems Pyramis

Software interface: Open interface for external postprocessors

File format: CAD import STL

Print preparation: Simple support generation; slicer integrated in software

Materials

Material: Metal powder, grain size fraction 10-45 µm

Alloys: Iron, nickel-based, cobalt-chromium, precious metals, reactive metals (others on request)

Component density: > 99 %

Layer thickness: 10 - 50 µm

MACHINE DETAILS

Machine dimensions

Weight: approx. 180 kg

W × D × H: 600 × 617 × 1,770 mm

Unpacking station dimensions

Weight: approx. 100 kg

W × D × H: 600 × 617 × 1,770 mm

Operating hours: 70 h

Electrics & connection

Electrical connection: 230 V, 50 Hz / 60 Hz, max. 16 A

Permissible humidity: max. 70 %

Permissible ambient temperature: 15 - 30 °C

Shielding gas/argon connection: 4.5 - 6 bar inlet pressure, Ø 6 mm hose connection

Dksln Sheu S H E Hju Esl

Gas consumption in operation: < 5 l/min

Gas consumption purge function: 20 l/min

Unpacking station

Vacuum cleaner connection: NW32 connection

EQUIPMENT

- 3D printer

- Unpacking station

- 9 print cartridges.

Auction

Auction ended

Germany

Germany

1,499 km

CNC turn-mill center

WFLM40 G x 3000

Condition: good (used), Year of construction: 2004, Functionality: fully functional, machine/vehicle number: 34101701, turning length: 3,000 mm, turning diameter: 520 mm, spindle speed (max.): 4,000 rpm, spindle bore: 77 mm, number of slots in tool magazine: 100, TECHNICAL DETAILS

Nominal speed: 3,000 mm

Center height above floor: 1,217 mm

Circulation Ø over slide at top: 520 mm

Circulation Ø over telescope left: 520 mm

Djln Shovrgcdou Ejkl

Circulation Ø over steady rest slide: 520 mm

Main drives (left/right)

Drive power: 29 kW

Torque max. 100% / 40% ED: 551 / 630 Nm

Main spindle left/right

Spindle head according to DIN / size: DIN 55026 / A8

Spindle diameter in the front bearing: 160 mm

Spindle bore: 77 mm

Spindle speed: max. 4,000 rpm

Slide at top

Longitudinal stroke: 3,150 mm

Face stroke: 600 mm (+580, -20)

Rapid traverse longitudinal / plane: 40 / 30 m/min

Feed force longitudinal / plane: 1,400 daN

Tool magazine

Tool positions: 100

Tool holder: HSK-A63

Turning-drilling-milling unit

Drive power: 15 kW

Max. torque: 125 Nm

Tool holder: HSK-A63

MACHINE DETAILS

Length: 9,475 m

Width: 4,875 m

Height: 3,120 m

Weight: 21,500 kg

Auction

Auction ended

Bayern

Bayern

1,393 km

Gear grinding machine

Gleason-PfauterG 320

Condition: excellent (used), Year of construction: 2002, Functionality: fully functional, Gleason Pfauter G320 CNC generating grinding machine + Promot Automation handling unit

Functionality and machine features

Generating grinding machine with 8 numerically controlled axes for machining gears with straight and helical teeth that can be produced by generating, including a dressable worm profile wheel.

Linear and rotary main axes are hydrostatic.

High-performance machine for finishing cylindrical gears with straight or helical involute teeth.

TECHNICAL DETAILS

Control: Siemens 840 incl. control panel

Module: 0.5-7.0

Workpiece diameter: 10 - 380 mm

Number of teeth: 10 - 600

Vertical slide stroke Z: 200 mm

Horizontal slide stroke X: 230 mm

Tangential slide stroke Y: 135 mm

Swivel angle of clamping head A: ± 45°

Stroke - tailstock center: 125 mm

Tangential slide stroke - dressing V: 180 mm

radial slide stroke - dressing U: 110 mm

C-axis (table rotation): 360°

rapid traverse speed - linear axes: 10,000 mm/min

Rotation speed: 3,000 rpm (infinitely variable)

Table rotation speed: 240 rpm

Table resolution: 0.001°

Processing feeds: stepless

Working feeds: infinitely variable

Grinding wheel diameter: 270 - 350 mm

Grinding wheel width: 104 mm

Grinding wheel bore: 160 mm

Delnstu T S Uj Shu Eekl

MACHINE DETAILS

Machine weight: 11,500 kg

Machine space requirement: approx. 3.7 x 2.4 x 2.75 m

Promot Automation space requirement: approx. 4.5 x 1.6 x 4.0 m

EQUIPMENT

- Promot automation

- Conveyor belt

- Cooling belt system

- Hydraulic unit

- Complete documentation

Auction

Auction ended

Germany

Germany

1,393 km

CNC lathe

EMCOHYPERTURN 45

Condition: used, Year of construction: 2016, Functionality: fully functional, machine/vehicle number: BF15103648, TECHNICAL DETAILS

WORKING RANGE

Travel in X/Y/Z: 160 /+40/-30 / 510 mm

Bar passage: max. 45 (51) mm

Turning diameter: max. 300 mm

Rotation diameter over bed 430 mm

Rapid traverse speed X/Y/Z 30 / 15 / 45 m/min

MAIN SPINDLE

Dkslstt D Adon Shu Esl

Speed: max. 7000 rpm

Drive power: max. 15 kW

Torque: max. 100 Nm

COUNTERSPINDLE

Speed: max. 7000 rpm

Drive power: max. 15 kW

Torque: max. 100 Nm

TOOL TURRET 1

VDI size: VDI 25

Number of tool positions: 12

Driven tools: 12

Speed: max. 6000 rpm

Drive power: max. 4 kW

Torque: max. 16 Nm

TOOL TURRET 2

VDI size: VDI 25

Number of tools: 12

Of which driven: 12

Speed: max. 6000 rpm

Drive power: max. 4 kW

Torque: max. 16 Nm

EQUIPMENT

- Chip conveyor

- Parts catcher

- Accessories shown

Auction

Auction ended

Ljubljana

Ljubljana

1,828 km

Heating tunnel

Petek ProcessTKO-1-12000-02

Condition: ready for operation (used), Year of construction: 2006, Functionality: fully functional, machine/vehicle number: 14705, temperature: 42 °C, No reserve price - guaranteed sale at the highest bid!

TECHNICAL DETAILS

Capacity: 12,000 bottles/hour

Temperature range: 0-42 °C

Equipment: Heat exchanger Ipros VT20V-12/CDSC-16

CE marking: Yes

Voltage: 400 V

Frequency: 50 Hz

Power consumption: 8 kW

Dslnjvnbr Es Shu Eskl

Packaging form: Custom-made pallet

Overall dimensions (metric): 5,000 x 2,500 x 1,800 mm - 2,000 kg

Auction

Auction ended

Baden-Württemberg

Baden-Württemberg

1,397 km

Vertical machining center

CHIRONFZ 08 K W Magnum

Condition: refurbished (used), Year of construction: 2004, operating hours: 5,000 h, Functionality: fully functional, travel distance X-axis: 450 mm, travel distance Y-axis: 270 mm, travel distance Z-axis: 310 mm, controller manufacturer: Siemens, controller model: 840D, rotational speed (max.): 15,000 rpm, TECHNICAL DETAILS

Travel X / Y / Z: 450 / 270 / 310 mm

Drilling capacity in St 60: 16 mm (indexable insert drill)

Thread cutting Milling capacity in St 60: M12, 60 cm³/min

Speed range: 20 - 15,000 rpm

Control: SIEMENS 840D

Spindle power at 100%/25% ED: 2.2 / 7.2 kW

Torque: 23 Nm

Rapid traverse X,Y / Z: 40 / 60 m/min

Workpiece changing device: 0 / 180°

Clamping surface: 2 x 550 x 300 mm

Thread and fitting hole grid: M16 x Ø 15H7 x 50 mm

Load weight: max. 200 kg per side

Weight difference: max. 50 kg between both sides

Workpiece changeover time: approx. 2.0 s

Tool places: 24 pieces

Tool taper: HSK A 40 DIN 69893

Tool diameter: max. 50 mm

Tool diameter with free adjacent positions: max. 100 mm

Tool length: max. 160 mm

Tool weight: max. 1.2 kg

Tool change time: 0.8 s (depending on control system)

Chip-to-chip time: approx. 2.2 s (depending on control)

MACHINE DETAILS

Operating voltage: 400 / 230 V, 50 Hz/N/PE

Compressed air: 6 bar ±1 bar

Ambient temperature: max. 40°

EQUIPMENT

- Moving column machine with workpiece changing device Guides with long-term grease lubrication

- Digital main drive with spindle with sealing air supply

- Tool clamping monitoring

- Automatic tool changer with robust, fully encapsulated pick-up chain magazine, with mechanical collision protection as well as,

Cone cleaning via blast air

- Look Ahead with dynamic pilot control, Bellshape acceleration ramp, software limit switch, access authorization

via key switch for tool corrections, NC program changes and machine parameters

- CHIRON Powersafe software package for the targeted switch-off of installed consumers

- Definable time for variable "warm-up" program

- Thermocontrol

Djln Sst R R A Ijhu Eokl

- Thermodrive

- Operating hours and piece counter on screen

- 230 V socket

- Socket for portable mini handwheel

- Splash guard cover

- Switch cabinet cooler

- Oil-free maintenance unit

- Installation elements

- Flushing gun

- Extraction connection Extraction Ø 150

- Machine preparation for IKZ

- CHIRON tool life monitoring

- Chip conveyor (scraper belt)

- Fixture flushing

- 4th + 5th NC axis, ready to plug in

- Documentation

Floor vehicle on site / electrician for dismantling can be provided by the seller for an additional charge.

Auction

Auction ended

Bayern

Bayern

1,522 km

Machining center with throughfeed

Format4creator 950

Condition: excellent (used), operating hours: 50 h, Functionality: fully functional, travel distance X-axis: 1,475 mm, travel distance Y-axis: 1,550 mm, travel distance Z-axis: 225 mm, rotational speed (max.): 24,000 rpm, CNC continuous feed center with clamp drive in X direction and fixed portal design in Y direction (without tools)

HIGHLIGHTS

Pressure cylinder: For holding the workpiece at zero reference

Height-adjustable workpiece support: Along the Y axis

Manual pressure device: For workpiece guidance

Stop reference cylinder: For workpiece referencing in X direction

Single pick-up space: Ergonomic tool change

Dkeln Sjvrzrgjhu Ejl

4-way linear changer: For the shortest changeover times and space for milling tools/units

TECHNICAL DETAILS

Drive: Digital drives (driven on one side)

Travel path X: 1,475 mm

Travel path Y: 1,550 mm

Travel path Z: 225 mm

Working area X / Y / Z: 3,500 / 950 / 80 mm

Milling spindle: 12 kW (S6)

Tool holder: HSK F63

Maximum speed: 24,000 rpm

Machine software package: Woodflash

Sensor measurement: workpiece length in X direction

Drill head

Model: DH 25 8H 1S

Number of spindles:

- 17 vertical spindles

- 8 horizontal spindles

- 1 grooving saw in X direction

MACHINE DETAILS

Operating hours: 50 h

EQUIPMENT

- CNC board

- Tool database

- Program editor

- Control management for 2 workstations (1 machine workstation + 1 external workstation)

- Wireless barcode readers

- Second stop cylinder for workpieces larger than X = 1,400 mm

- Extractable air cushion run-out table

- Automatic central lubrication

Auction

Auction ended

Germany

Germany

1,499 km

Press brake

DENERDD-M 10030

Condition: as good as new (ex-display), Year of construction: 2019, Functionality: fully functional, installation height: 590 mm, pressing force: 100 t, stand width: 3,250 mm, bending length: 3,050 mm, TECHNICAL DETAILS

Pressure: 100 t

Bending length: 3,050 mm

Column width: 3,250 mm

Y-axis stroke: 300 mm

Installation height: 590 mm

Control: Delem DA 66T

Speeds

Feed speed: 75 mm/s

Bending speed: 20 mm/s

Retraction speed: 75 mm/s

Dslsvrfufjn Shu Eokl

System: Y1 / Y2 servo-electronic

Punch clamp: hydraulic (WILA Premium)

Die clamp: hydraulic (WILA Premium), including motorized crowning

Back stop

System: "DENER"

Axes: X, R, Z1, Z2 axis

Safety equipment

Safety light curtain: FIESSLER AKAS LC II M Type 4 (manual) with box bending function

Tools

Rolleri Quick-change tools: segmented

Punch: TPR200.28.R1

Die: TMR100.12.30

Tool length: 3,050 mm

MACHINE DETAILS

Total power requirement: 11 kW

Machine weight: approx. 6.5 t

Space requirement (L x W x H): approx. 4.3 m x 2.0 m x 2.9 m

EQUIPMENT

- Rolleri quick-change tools (segmented)

- Safety light curtain FIESSLER AKAS LC II M

- Hydraulic punch and die clamping (WILA Premium)

- Motorized crowning

Auction

Auction ended

Bayern

Bayern

1,393 km

High-precision rack grinding machine

MägerleMFP 260

Condition: excellent (used), Year of construction: 2008, Functionality: fully functional, Commissioning took place in 2009

TECHNICAL DETAILS

Dkelnjttazfj Shu Eel

Model: MFP L 260 - 75

Control: Siemens 840D Sinumerik

Table clamping surface X / Z: 2202 / 352 mm

Longitudinal stroke: 2600 mm

Transverse stroke sanding support: 650 mm

Distance spindle to table: 806 mm

Head design: fixed, not adjustable

Grinding wheel dimension: Ø400 x 160 mm

Grinding wheel bore: 127 mm

Peripheral speed of grinding wheel: 35 / 50 m/s

Stroke speed longitudinal / transverse / vertical: 30 / 5 / 5 m/min

Resolution: 0.001 mm

MACHINE DETAILS

Machine weight: 21 t

Space requirement: 7.06 x 2.7 x 3.26 m

Drive power of grinding wheel: 75 kW

Total connected load: 113 kVA

Knoll coolant cleaning system Dimensions: 5.6 x 2.4 x 3 m

Knoll coolant cleaning system Weight: 2,000 kg

EQUIPMENT

- Handwheel included

- Complete documentation

Purchase price of the machine was € 1,450,000

Auction

Auction ended

Bayern

Bayern

1,396 km

CNC lathe

GildemeisterCTX 510 V

Condition: good (used), Year of construction: 2007, operating hours: 25,000 h, Functionality: fully functional, TECHNICAL DETAILS

Turning diameter: max. 465 mm

turning length: 1050 mm

Rotation diameter: 680 mm

Chuck diameter: 325 mm

x-path: 300 mm

z-path: 1,050 mm

C-axis: 360°

Control: Heidenhain Plus IT

Speed range: max. 3,500 rpm

Drive power: 33 kW

Torque: max. 630 Nm

Spindle bearing diameter: 120 mm

Spindle bore: 100 mm

Max. Bar diameter: 90 mm

Tailstock travel: 850 mm

Quill stroke: 150 mm

Tailstock holder: MK 5

Dkoln Shstt Du Nsu Ejl

Rapid traverse X / Z: 30 m/min

Number of tool positions: 12 positions

Tool holder: VDI 40

Driven tool stations: 12

Speed of driven tools: max. 4,000 rpm

Drive power of driven stations: 8.4 kW

Torque: max. 20 Nm

MACHINE DETAILS

Total power requirement: 50 kVA

Machine weight: 9,000 kg

Space requirement: 6.5 x 3.0 x 2.2 m

Spindle hours: 25,000 h

Auction

Auction ended

Germany

Germany

1,401 km

Vertical machining center

Deckel MahoDMC 635 V

Year of construction: 2008, Condition: good (used), Functionality: fully functional, machine/vehicle number: 1540503266A, TECHNICAL DETAILS

X axis: 635 mm

Y-axis: 510 mm

Z-axis: 460 mm

Control: Heidenaihn İTNC 530

Number of tools: 30

Tool holder: SK 40

Djln Shujng Amve Eskl

MACHINE DETAILS

on request

EQUIPMENT

Direct path measuring system X,Y,Z

Measuring probe Heidenhain TS640

Spindle conveyor

Operating mode 4

Auction

Auction ended

Wallis

Wallis

1,402 km

Stationary concrete mixing plant

Huggler SuhrZwangsmischer 1m3

Condition: ready for operation (used), Functionality: fully functional, Year of construction: 2009, No minimum price - guaranteed sale at the highest bid!

The system is a modular system and can therefore be quickly dismantled and reassembled.

Dkeln Shou Rc Nnju Esl

TECHNICAL DETAILS

Storage components

Ring-pan mixer: 1 m³

Pre-silo: 4.5 m³

Gravel silo: 2 pieces, 6 components each

Cement silo: 2 pieces, 3 chambers each

Chemical scale: Finke with 3 chambers

Software and maintenance

Software: Version from 2022, updated to the latest operating system

Base plates: Renewed in 2023

Mixer

Type: Forced action mixer

Model: Huggler

Capacity: 1 m³ hardened concrete

Gravel silo 1

Components: 4

Capacity K1: 20 m³

Capacity K2: 32 m³

Capacity K3: 32 m³

Capacity K4: 20 m³

Gravel silo 2

Components: 2

Capacity K5: 20 m³

Capacity K6: 20 m³

Cement silo 1

Type: 2-part silo

Cement 1 capacity: 20 t

Cement 2 capacity: 40 t

Cement silo 2

Type: 1-piece silo

Cement 3 capacity: 60 t

Admixture

Admixture weigher: Finke

Number of chambers: 3

Chamber capacity: 6 components, conveying system by pump

Year of construction

Gravel silo 1 and cement silo 1: 2009

Gravel silo 2 and cement silo 2: 2013

Other

Heating: Gravel silos equipped with electric heating

Pre-silo: 4 m³ hardened concrete

Control system: PC control system, conversion in 2022

Floor sealing plates: Renewed in 2023

Plant: Compact construction site plant with plug connections

Auction

Auction ended

Bayern

Bayern

1,522 km

Edge banding machine

FORMAT4tempora F800 60.12-2

Condition: excellent (used), Functionality: fully functional, workpiece length (max.): 140 mm, TECHNICAL DETAILS

Minimum workpiece length: 140 mm

Chain feed: 8 + 20 m/min

Aggregate equipment

Cross-cut saw unit: available

Radius scraper unit: available

Surface scraper: available

Flush and radius milling unit: available

Joining milling unit: available, with plunge-controlled diamond cutters

Doljvrzqcsn Shu Eokl

Polishing unit: available

Pressure unit: available

Special functions

End position damping: for cross-cut saw unit

Pneumatic-mechanical insertion lock: available

Spraying of release agent and cleaning agent: available

Cutter equipment: 60 mm

Glue and heating system

Infrared heating lamp: available

Glue basin: Teflon-coated

Auction

Auction ended

Germany

Germany

1,499 km

Machining center

Deckel MahoDMC 100 U

Condition: good (used), Year of construction: 2005, Functionality: fully functional, machine/vehicle number: 1148000080, travel distance X-axis: 1,000 mm, travel distance Y-axis: 1,000 mm, travel distance Z-axis: 1,000 mm, rotational speed (max.): 12,000 rpm, number of slots in tool magazine: 60, swivel angle C-axis (max.): 360 °, TECHNICAL DETAILS

X-travel: 1,000 mm

Y-travel: 1,000 mm

Z-travel: 1,000 mm

C-axis: 360°

Control: MillPlus IT Heidenhain

Tool magazine

Capacity: 60 slots

Spindle

Max. spindle speed: 12,000 rpm

Spindle mount: SK50 DIN 69871

Table

Clamping surface: 1,000 mm x 800 mm

MACHINE DETAILS

Total power requirement: 65 kVA

Machine weight: approx. 24.5 t

Space requirement: approx. 6.50 m x 5.20 m x 3.50 m

EQUIPMENT

- Pallet changer

- Electric handwheel HR410

- 4th operating mode

- BLUM Laser tool measurement

- Vibration sensor

Djlnovrfnfs Shu Eekl

- IKZ pressure level 40 and 80 bar

- Rotoclear

Air filter system

Coolant system 980 l

Chip conveyor

Auction

Auction ended

Bayern

Bayern

1,407 km

Press brake

BystronicXPERT 400 x 4100 TANDEM

Condition: ready for operation (used), Year of construction: 2009, Functionality: fully functional, pressing force: 800 t, travel distance X-axis: 700 mm, travel distance Z-axis: 2,900 mm, stroke distance: 665 mm, travel distance R-axis: 250 mm, surfacing fence length: 8,200 mm, TECHNICAL DETAILS

Pressure: 2 x 400 t

Bending length: 2 x 4100 mm

X-axis travel: 700 mm

R-axis travel: 250 mm

Z-axis travel: 2900 mm

Stroke: 665 mm

Projection: 400 mm

Installation height: 850 mm

Clearance between the uprights: 3600 mm

MACHINE DETAILS

Total output 30 kW

Weight 76,000 kg

Equipment/accessories:

- Operator terminal with 15" TFT-LCD flat screen, network card, Windows XP and MMC-Bybend software

- Tilt adapter and double articulated arm for control system

- Pressure reference for automatic compensation of side stand deflection

- Dynamic hydraulic crowning of the lower beam, DNC-controlled

- Automatic dynamic press pressure control

- Material thickness measurement

- Tool overload protection

- Temperature monitoring

- Stainless steel scale on the upper beam

- AKAS laser system, manually adjustable in height

- Electrically monitored side safety guards

- Rear safety guard with sliding door

- Integrated hour and stroke counter

- Linear guide on the lower beam with 2 parking spaces of 250 mm each

- Double guide on the upper beam

Dkjln Sovi I Ntohu Eol

- 2 x manually adjustable front support arms made of steel, length 1000 mm

- slim table T5, height 145 mm

- punch holder type "R" mechanical

- 2-axis back gauge with X and R

- Inclination adapter for operator terminal

Auction

Auction ended

Bayern

Bayern

1,406 km

Machining center

Deckel MahoecoMill 800 V

Condition: ready for operation (used), Year of construction: 2016, operating hours: 4,945 h, Functionality: fully functional, travel distance X-axis: 800 mm, travel distance Y-axis: 560 mm, travel distance Z-axis: 510 mm, spindle speed (max.): 12,000 rpm, number of slots in tool magazine: 30, TECHNICAL DETAILS

Control system: Siemens 840D SlimeLine

Travel X / Y / Z: 800 / 560 / 510 mm

Speed range: 12,000 rpm

Tool holder: SK40

Clamping surface: 1100 x 560 mm

Table load: max. 800 kg

Tool changer: 30 magazine positions

Dkoln Sst Ur Srehu Eel

MACHINE DETAILS

Switch-on time: 15,856 h

Spindle hours: 4,945 h

EQUIPMENT

- Chip conveyor

- IKZ

- Paper belt filter

- Documentation

Trust Seal

Dealers certified through Machineseeker

Auction

Auction ended

Germany

Germany

1,499 km

Bevel gear testing machine

OerlikonT50

Condition: good (used), Year of construction: 2001, operating hours: 31,789 h, Functionality: fully functional, machine/vehicle number: 291545, travel distance X-axis: 70 mm, travel distance Y-axis: 200 mm, travel distance Z-axis: 200 mm, gear diameter: 500 mm, helix angle: 90 °, 3-axis CNC testing machine for fully automatic hard and soft testing of spiral and hypoid bevel gears with an axis angle of 90°

TECHNICAL DETAILS

Bevel gear analysis: ROTEC T50 GA2

Color unit: Binks

X-axis: ±70 mm

Y-axis: 200 mm

Z-axis: 200 mm

CNC control: GE FANUC Series 160i-M

Technical specifications

Wheel diameter: max. 500 mm

Pinion diameter: max. 400 mm

Circular gear diameter: max. 500 mm

Axis angle: 90°

Speeds

Speed range R: 0 - 3,000 rpm

Speed range T: 0 - 5,000 rpm

Dkoln Shuovrd T Ts Eol

MACHINE DETAILS

Rated current: 30 kVA

Machine weight: approx. 6.2 tons

Space required: approx. 3.2 m x 2.5 m x 2.3 m

Auction

Auction ended

Bayern

Bayern

1,407 km

Laser Punch Press

TRUMPFTruMatic 6000 L - 1600

Condition: ready for operation (used), Year of construction: 2008, operating hours: 72,918 h, Functionality: fully functional, punching force: 22 t, laser power: 2,700 W, sheet thickness (max.): 6 mm, sheet thickness aluminum (max.): 4 mm, sheet thickness steel (max.): 8 mm, TECHNICAL DETAILS

Combined punching/laser operation: 2,585 x 1,650 mm

Punching mode: 3,085 x 1,740 mm

Laser operation: 3,085 x 1,650 mm

Outputs

Laser power: 140 - 2,700 W

Maximum sheet thickness: 8 mm

Cutting capacity for mild steel: 8 mm

Cutting capacity for aluminum: 4 mm

Cutting capacity for stainless steel: 6 mm

Maximum punching force: 220 kN

Active hold-down device (programmable in stages): 4.5 - 20 kN

Maximum workpiece weight: 230 kg

Speeds

Maximum positioning speed X-axis: 90 m/min

Dkoln Sevi I Ayjhu Eol

Y-axis: 60 m/min

Simultaneous (X and Y): 108 m/min

C-axis punching: 60 revolutions/min

Thread forming: 180 revolutions/min

Punching stroke sequence (E = 1): 900 1/min

Marking: 2,800 1/min

Tools

Linear magazine: 18 tools with 3 clamps

Tool change time: 1.5 - 5 s

Tool accuracy

Position deviation: ±0.10 mm

Average position spread: ±0.03 mm

Programmable slides for punched and laser parts (max.)

Size: 500 x 500 mm

TRUMPF CNC control: based on Siemens Sinumerik 840D

MACHINE DETAILS

Laser switch-on time: 72,918 h

Cutting time: 18,536 h

Space requirement (width x length): 7,900 x 9,100 mm

Height: 2,400 mm

Weight: 22,500 kg

Laser gas consumption CO2 / N2 / He: 1 / 6 / 13 l/h

Connected load: 73 kVA

Auction

Auction ended

Germany

Germany

1,499 km

Machining center

HERMLEC50U

Condition: good (used), Year of construction: 2006, Functionality: fully functional, travel distance X-axis: 1,000 mm, travel distance Y-axis: 1,100 mm, travel distance Z-axis: 700 mm, spindle speed (max.): 18,000 rpm, swivel angle A-axis (min.): -115 °, swivel angle B-axis (max.): 30 °, TECHNICAL DETAILS

Dkjln Sevrd Hyohu Eol

X-travel: 1,000 mm

Y-travel: 1,100 mm

Z-travel: 700 mm

A-axis: -115° / +30°

C-axis: 360°

Control: Heidenhain 530 i TNC

Spindle

Tool holder: HSK-A63

Main spindle speed: 18,000 rpm

Tool changer

Number of tools: 60

Table

Table size: 1,150 mm x 900 mm

Max. table load: 2,000 kg

MACHINE DETAILS

Total power requirement: 41.00 kW

Machine weight: approx. 22.00 t

Space requirement: approx. 6.50 x 3.00 x 3.70 m

EQUIPMENT

- Electric handwheel HR 410

- KSS Knoll / IKZ 40 bar

- chip conveyor

- Oil mist extraction Handte

Auction

Auction ended

Bayern

Bayern

1,407 km

Punch nibbling machine

TRUMPFTruMatic 5000 R

Condition: ready for operation (used), Year of construction: 2001, Functionality: fully functional, punching force: 22 t, sheet thickness (max.): 8 mm, travel distance X-axis: 3,000 mm, travel distance Y-axis: 1,500 mm, TECHNICAL DETAILS

Sheet thickness: 8 mm

Punching force: 220 kN

Working area: 3,000 x 1,500 mm

Control system: Siemens

MACHINE DETAILS

Machine weight: approx. 17,500 kg

Dkelsvi Iw Rsn Shu Esl

EQUIPMENT

- Scraper alternating position control

- Thread forming

- Marking - fast beading

- Slotting

- Multishear

- Multibend

- Offset resetting

- Roller tools

- Set-up cassettes

- Ball transfer table

We make the search easier for you

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

This may be of interest to you

Find out now

+44 20 806 810 84

+44 20 806 810 84

Create listing

*per listing / month