Used Veneers Process for sale (20,590)

Wellingborough

Wellingborough CNC PLATE PROCESSING MACHINE

PEDDINGHAUSFPB1800

Wellingborough

Wellingborough CNC PLATE PROCESSING MACHINE

PEDDINGHAUSFDB1500/3C

Willich

Willich Cnc-processing center

KORRADIVH 800

Willich

Willich Vertical processing machine

MICROCUTChallenger 2412

Mouvaux

Mouvaux Meat processing machine

NIJALPlieuse 1 piste PE1P

Discover more used machines

Eibergen

Eibergen Meat processing machine

Talsa stopbusH15

Germany

Germany Veneer press Ott

OttJU 65

Germany

Germany Cnc-processing center

HyundaiSPT-V100

Lambsborn

Lambsborn Veneer saw

ScheerFM3

Nattheim

Nattheim Veneer gluing machine

KuperFW/J 900

Germany

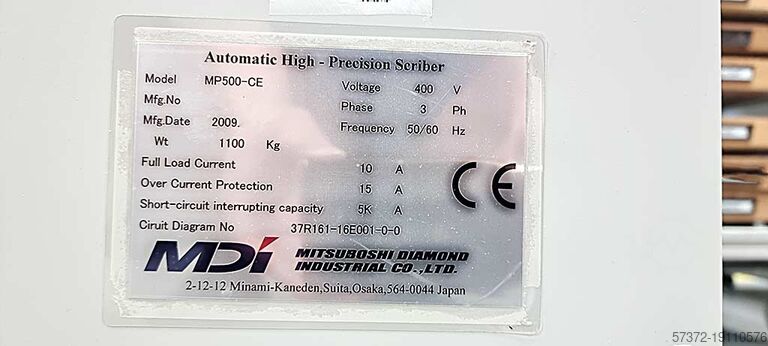

Germany CNC Glass Processing Machine

MDIMP500-CE

Germany

Germany Veneer Saw

ScheerFM 4-3100

Germany

Germany CNC Sheet Metal Processing Center

Salvagini

Germany

Germany Veneer Plant

Cremona

Germany

Germany Process Tank

Concept GMP/NordhausenIso

Germany

Germany Heel Processing Machine

Sabal/USMS60 ORO-KITHGS/320/DVSK-RC

Germany

Germany Sole Processing Machine

Elettrotecnica/Mollina & Bianci/InternationalPS/CS 90 TS

Germany

Germany Strip Edge Processing Plant

JuliusXF 1528

Germany

Germany Cable Processing Machine

MetznerTriathlon

Borken

Borken Multi-camera image processing system

KeyenceXG-7501P

Wijk bij Duurstede

Wijk bij Duurstede Plastic processing machine

RSS

Lambsborn

Lambsborn Veneer gluing machine

KuperFWJ900

Janville

Janville 10 000 L Process tank

Goavec SA-

Janville

Janville Process tank

WIMACH-MCuve agitée 2500 L

Janville

Janville 10000 L process tank

Goavec SA-

Used Veneers Process (20,590)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you