Used Pig Scales for sale (2,165)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Germany

Germany

1,084 km

Welding Table

GERD WOLFF3000 x 1500 x 200

Call

Condition: new, Year of construction: 2025, table length 3000 mm

table width 1500 mm

table height 200 mm

weight 1500 kg

Manufacturer: GERD WOLFF

Technical Details:

• Length 3000 mm

• Width 1500 mm

• Height 200 mm

• Weight 1500 kg

• Hole diameter 28 mm

• Hole spacing 100 mm

• Plate thickness: 25mm

Kodsuia Nmopfx Ag Usll

Advantages and Features:

• 3-day gas nitriding process

• Increased corrosion resistance

• Weld spatter adhesion protection

• Maximum load capacity

• Enhanced fatigue strength

• Improved vibration resistance

• Fine scale engraving

• Reinforcement with welded seams and ribs on the underside

• Optimal working height of 820-865 mm

• 8 height-adjustable support legs

• Available with a matching accessory set (optional)

Our welding tables are manufactured using HT 300 cast iron and are nitrided as

a whole after mechanical processing. Furthermore, they feature precise fine

scale engraving using laser technology.

To ensure adequate stability, our welding tables are reinforced with welded

seams and ribs on the underside (see illustrations). Additionally, they undergo

a 3-day gas nitriding process, enhancing their corrosion resistance, fatigue

strength, and vibration resistance, among other factors.

All our tables come with adjustable legs. The minimum height adjustment range

is 620 mm, while the maximum is 665 mm, allowing for a variable working height

of 820 to 865 mm.

Additional available dimensions:

• 1000 x 1000 x 200

• 2000 x 1000 x 200

• 1200 x 1200 x 200

• 1500 x 1000 x 200

• 1500 x 1500 x 200

• 1500 x 2000 x 200

• 2000 x 3000 x 200

• 3000 x 1500 x 200

• 3000 x 2000 x 200

• 4000 x 2000 x 200

Please note that the images are not to scale and are for illustrative purposes

only. Our welding tables are produced for our distribution brand "GERD WOLFF

Maschinenfabrik" by a reputable manufacturer.

3D Welding Table - 3D Clamping Fixtures - 3D Precision Welding Table

Listing

Ennepetal

Ennepetal

1,084 km

Bandsaw - Horizontal

GERD WOLFFKLY 2DT 650

Call

Condition: new, Year of construction: 2022, cutting diameter 660 mm

saw band length 9000 x 54 mm

cutting width 1,6 mm

Capacity 90° - round 660 mm

Klodpfx Agsugnynj Ujl

Capacity 90° - square 650 x 650 mm

Capacity 90° - rectangle 650 x 1080 mm

Capacity 45° - round 660 mm

Capacity 45° - square 650 x 650 mm

Capacity 45° - rectangle 650 x 670 mm

Capacity 30° - round 410 mm

Capacity 30° - square 410 x 410 mm

Capacity 30° - rectangle 650 x 410 mm

total power requirement 5,5 kW / 2775 Nm

weight of the machine ca. 7100 kg

dimensions of the machine ca. 2500 x 2200 x 4500 mm

The KSY 2DT 650 is a semi-automatic and column-guided horizontal bandsaw.

The machine also has a driven roller table, which is 2 metres long on the front

has a spray mist has a spray mist cooling system. Equipped with a linear

guided saw blade, the KSY 2DT 650 can perform precise and fast Mitre cuts.

Standard Specifications

- Swarf Brush

- Hydraulic Blade Guide

- Hydraulic Vice

- Hydraulic Blade Tension

- Automatic Angle Rotation

- PLC TouchScreen

- Blade Breakage Switch / Stop System

- Led Lighting

- Swarf Conveyor

- Carrying

- 2 Pieces 2 Meter Roller Table

- USB Connection Output

Optional Specifications

- Motorized system for roller table

- Laser Line

- Lubrication mist

- Extra double roller table

The pictures are for orientation only and do not represent a true-to-scale

image of the machine.

Listing

Germany

Germany

1,084 km

Swarf Conveyor

GERD WOLFFMaßanfertigung

Call

Condition: new, Year of construction: 2025, Please complete the attached form and return it to us by email for quotation preparation.

Hinged Belt Conveyors – Overview & Features

General

- Hinged belt conveyors can be manufactured according to purpose and dimensions.

- The design and belt system are robust and durable, provided regular maintenance is carried out.

- Most commonly used type of chip conveyor.

Applications

Transport of:

- Long, coarse, corrugated, and crumbly chips

- Materials such as transmission steel, tool steel, aluminum alloys, Teflon, Delrin, etc.

- Designed for conveying chips from the production process.

Kodpfx Ajuddbpjg Uoll

- Separation of cutting oil/coolant from the chips.

Versions

- Available with or without a tank for returning cutting oil/coolant to the system.

- Four standard chain pitches: 31.75 mm, 38.10 mm, 50.80 mm, 63.50 mm.

- Chain pitch selected according to the amount of chips to be conveyed.

- Conveyor width, length, motor, and gearbox are matched to the hourly conveying capacity.

- Coolant recycling is taken into account during the design.

Control

- Operation via control panel or CNC control of the machine tool.

- Control via plug-in connection possible.

Note: Images are for reference only and are not to scale.

Listing

Germany

Germany

1,084 km

Straightening- and Bending Machine

GERD WOLFFHP 10 - Horizontal

Call

Condition: new, pressure 10 t

stroke max. 200 mm

bending capacity max. - flat 150 x 6 mm

working feed 10 mm/sec

Control NC

Height of Toolings 150 mm

total power requirement 1,1 kW

weight of the machine ca. 400 kg

required space 500 x 900 x 1150 mm

The Gerd Wolff HP 10 is a hydraulic horizontal press machine with many

many possible combinations.

Whether it's bending tubes, punching profiles or cutting sheet metal, with the

right accessories the HP 10 is a multifunctional machine among presses.

Standard accessories

- ergonomic tool clamping table

- easy tool change

- hydraulic speed and pressure adjustment

- easily adjustable back gauge

- induction hardened support pins

- NC control

Highlights

- control panel with digital display

- Easy tool change

- hardened support pins

- hydraulic speed regulation

The HP 10 is manufactured for our sales brand "GERD WOLLF Maschinenfabrik",

by a renowned manufacturer from Türkiye.

Kledpfsuddi Hex Ag Uel

The pictures are for orientation only and are not true-to-scale representations

of the machine.

Listing

Ennepetal

Ennepetal

1,084 km

Bandsaw - Horizontal

GERD WOLFFKSY 550 X 700

Call

Condition: new, Year of construction: 2025, cutting diameter 550 mm

saw band length 6850 x 41 mm

cutting width 1,3 mm

Control Halbautomatisch

Cutting area - square 550 x 550 mm

Cutting area - flat 550 x 700 mm

Kedpfjuddkdjx Ag Uoll

total power requirement 4 kW / 1580 Nm kW

weight of the machine ca. 3775 kg

dimensions of the machine ca. 1850 x 1500 x 3450 m

TThe KSY 550 x 700 is a semi-automatic and column-guided horizontal bandsaw.

In addition, the machine has a driven roller table which is 2 meters long on

both the front and rear sides.

Optional Specifications

- Motorized System For Roller Table

- Laser Line

- Extra Double Roller Table

- PLC-Screen

- Anti-Vibration System

The pictures are for orientation only and do not represent a true-to-scale

image of the machine.

Listing

Ennepetal

Ennepetal

1,084 km

Straightening- and Bending Machine

GERD WOLFFHP 60 - Horizontal

Call

Condition: new, pressure 60 t

stroke max. 300 mm

bending capacity max. - flat 300 x 16 mm

working feed 10 mm/sec

Control NC

Height of Toolings 300 mm

total power requirement 5,5 kW

weight of the machine ca. 1530 kg

The Gerd Wolff HP 60 is a hydraulic horizontal press machine with many

many possible combinations.

Whether it is the bending of tubes, the punching of profiles or the cutting of

sheet metal - with the right accessories, the HP 60 is a multifunctional

machine among all presses.

Standard accessories

- ergonomic tool clamping table

- easy tool change

- hydraulic speed and pressure adjustment

Kledpfx Asxfb Ikog Uel

- easily adjustable back gauge

- induction hardened support pins

- NC control

Highlights

- control panel with digital display

- Easy tool change

- hardened support pins

- hydraulic speed regulation

The HP 60 is manufactured for our sales brand "GERD WOLLF Maschinenfabrik",

by a renowned manufacturer from Türkiye.

The pictures are for orientation only and are not true-to-scale representations

of the machine.

Listing

Ennepetal

Ennepetal

1,084 km

Press Brake - Hydraulic

GERD WOLFFCNC KANTO 200T - 8

Call

Condition: new, Year of construction: 2025, sheet thickness - max. 8 mm

pressure 200 t

chamfer lenght 3200 mm

engine output 15 kW

return speed 105 mm/min

working feed 9 mm/sec

x-travel 600 mm

Max. opening height 570 mm

Klodpfjxf Na Usx Ag Usl

control DELEM DA53T

GERD WOLFF KANTO 200T CNC Electro-Hydraulic Press Brake

CNC axis accuracy

1) Machine sliders (Y1, Y2) – synchronisation precision:

The slider movement axes control the bending depth and bending angle. The system consists of the control unit, two glass scales (Y1, Y2) installed on the work table, electro-hydraulic proportional valves and an amplifier. A closed control loop detects and controls the relative position of the slide and table as well as the speed and position of the slide. This ensures the synchronisation of the slide and maintains the bending depth and angle with high precision.

Positioning accuracy: ±0.02 mm

Repeatability: ±0.02 mm

2) Machine backgauge (X axis):

The forward/backward movement of the X-axis controls the dimensions of the sheet metal cut. The stop bar is driven by a servo motor and moves the crossbeam via a ball screw and linear guide. Operation is stable and precise.

Positioning accuracy: ±0.10 mm

Repeatability: ±0.03 mm

3) Mechanical compensation system (V axis):

The pull plate of the mechanical compensation is moved by a motor so that the compensation points are formed in an arc shape. The points perfectly compensate for the elastic deformation of the work table and slide to ensure angular constancy and straightness of the workpiece. Position sensors and CNC control ensure precise regulation.

Listing

Ennepetal

Ennepetal

1,084 km

Measurement equipment

HEIDENHAINLB 326-8500mm 249 942 01

Call

Condition: used, LB 326 - glass scale

Klsdpfxor I D Ime Ag Uol

Length: 8500mm

HEIDENHAIN LB 326

ID 249 942 01

Listing

Ennepetal

Ennepetal

1,084 km

Bending machine horizontal

SCHÄFER4-Walzen Rundbiegemaschine

Call

Condition: used, Year of construction: 1987, pressure / t

stroke / mm

table-size / mm

weight of the machine ca. 65000 kg

Make: Shepherd

Type: SVRM

4-roller bending machine:

Year of construction: 1986

Working width: 3000cm

Smallest pipe diameter with 600 mm roller: Ø 720 mm

Smallest tube diameter with 360 mm roller: Ø 460 mm

Sheet thickness up to (depending on the material): 50 mm

Kodsuddcaopfx Ag Uell

Material SA- 738 B Working width: 2500 mm

Material SA- 738 B Material thickness: 35 mm

conical bending:

Except for the top roller, all rollers can be moved in an inclined position for

conical bending. The roller positions can be read on display instruments. For

semi-automatic or fully automatic operation of the machine, the bearing jewels

of the rollers are equipped with scale bars and slide cams for limit switch

actuation. This allows the rollers to return to the same set position over and

over again, giving a very high level of uniformity in the shot wefts being bent.

Listing

Goldenstedt

Goldenstedt

1,114 km

Center Lathe

WEIPERT Voest AlpineW802

Call

Condition: used, Year of construction: 1985, greates pass round over bed 810 mm

swing diameter over face slide 560 mm

centre distance 00 mm

bed width 480 mm

slide valve travel 400 mm

upper head travel 180 mm

turning tool - shaft cross cut 32 x 25 mm

power capacity 22 kW

max. torque on the spindle 30 Nm

spindle head Gr. 11, DIN 55027

spindle diameter in front bearing 152,4 mm

spindle bore 106 mm

turning speed range 9 - 1800 U/min

turning speeds 24

longitudinal feeds: 0,092 - mm/U

face feeds 0,046 - mm/U

metric threading 0,5-112 mm

inch threading 1/4 - 56 G/1"

thread - module mm

thread - DP 1 - 224 Pitch

tailstock quill diameter 115 mm

quill stroke 225 mm

Kledpexn Ty Refx Ag Usl

taper of tail spindle MK 6

max. workpiece weight between centres 00 kg

max. workpiece weight -without tailstock 750 kg

3-jaw chuck Röhm, Ø

Overall size ca. 4600x1900x1600 mm

weight ca. 4300 kg

Number of feed stages and threads: 99

Accessories:

3-axis digital display

Mobile chip guard over the entire length (plexiglass)

Coolant device

Rapid traverse in Z and X axes

Multifix steel holder size C with 6 interchangeable cassettes

Bed stop with micrometer scale

Fixed steady rest - 300 mm

Taper sleeve for main spindle MK 6

Travelling center point (center point) MK 6

Bed guides in very good condition!

Listing

Bünde

Bünde

1,138 km

Center Lathe

TONGILTipl 4 SP / 3-A-Digi

Call

Condition: good (used), Year of construction: 1993, turning diameter over bed 400 mm

turning diameter over slide rest 210 mm

turning length 1060 mm

centre height 200 mm

spindle bore 58 mm

spindle taper: Camlock D 1-6

Drive 3,2/4,9 kW

Kodpfx Agjxtfx Ae Uoll

spindle turning speed range 16, von 55 bis 1600 U/min

feeds - longitudinal 0,039-0,541 mm/U

feeds cross 0,019-0,271 mm/min.

weight of the machine ca. 1,45 t

dimensions of the machine ca. 1900 x 870 x 1700 mm

High-quality machine with induction-hardened guideways, torsionally rigid bed,

main spindle made of chrome-nickel steel, surface-hardened and ground gears,

automatic circulating lubrication in the spindle housing, slip clutch in the

support, bed lubrication via hand pump, Siemens electrical system. Thread feeds

for metric, inch, module, and diametral pitch.

3-axis digital readout: 2 scales are mounted, the scale on the top slide

has been replaced but still needs to be mounted. The display unit is for

lathes and therefore, with the appropriate setting, adds the slide travel to

the top slide travel.

The machine was only used in a prototype workshop for sporadic applications.

Machine dealer with own stock of 1600 m².

Listing

Austria

Austria

1,192 km

EMCO Hyperturn 65 Powermill G2

EMCOHyperturn 65 Powermill G2

Call

Condition: ready for operation (used), Year of construction: 2022, spindle motor power: 29,000 W, spindle speed (max.): 5,000 rpm, overall weight: 620 kg, number of axes: 6, This 6-axis EMCO Hyperturn 65 Powermill G2 was manufactured in 2022. A highly productive CNC turn-mill center, it features a main spindle and subspindle both with a max torque of 250 Nm and speeds up to 5000 rpm. The milling spindle offers up to 12000 rpm. Includes a 40-position tool magazine, 12-position turret, and advanced Sinumerik ONE control system. If you are looking to get high-quality turning and milling capabilities consider the EMCO Hyperturn 65 Powermill G2 machine we have for sale. Contact us for more information.

• Main spindle (direct drive):

• Max. torque: 250 Nm

• Subspindle (direct drive):

• Max. drive power: 29 kN (as provided)

• Max. torque: 250 Nm

• Speed range: 0–5000 rpm

• Milling spindle (direct drive):

• Max. drive power: 37 kW

• Max. torque: 30 Nm

• Speed range: 0–12000 rpm

• Tool turret (direct drive):

• Max. drive power: 10 kW

• Max. torque: 30 Nm

• Speed range: 0–12000 rpm

• Kinematics and axes:

• Cross slide at the top with turning/milling spindle as motor spindle; hydraulic clamping during turning

• Y-axis travel: +/- 120 mm

• B-axis with direct drive: +/- 120°, hydraulic clamping

• Tooling:

• 40-position tool magazine, HSK-T63

• 12-position radial turret with direct drive, BMT55P tool interface

• Spindles and clamping:

• High-clamping cylinder with draw tube for main spindle

• Full clamping cylinder with partial hollow clamping 66 x 550 mm deep in counter spindle

• Programmable clamping pressure for main and counter spindle

• External feed flushing on main and counter spindle

• Mechanical holding brake on main and counter spindle

• C-axis for main and counter spindle

• Control and HMI:

• SINUMERIK ONE / OPERATE, EMCONNECT app-based UI

• 22" multi-touch display

• IPC with 240 GB

• SHOPTURN dialog programming

• 3D simulation and Drawing

• Residual material detection

• Unblocking from external memory

• CAD reader (DXF import)

• TRANSMIT and TRACYL for C-axis programming

• USB interface, Network drive (Ethernet)

• PC keyboard incl. HMI hotkey

• LED status bar

• Fluids and utilities:

• 2 coolant lines at 25 bar

• 2 flushing pumps at 4.3 bar

• Control cabinet air conditioning unit

• Cooling system for spindle motors, milling spindle, B-axis torque motor, and turret direct drive

• Hydraulic unit

• Machine light

• 8 leveling elements

• Feedback/measurement:

• Glass scales: X1 (incl. air system), Y1, Z1, X2 (HT65-PM-G2 / 840D-sl)

Additional equipment

• Chip management and filtration:

• Hinged belt chip conveyor, discharge height 1200 mm

• Belt filter system, 980 liters

• Dirty water pump

• Control/monitoring options:

• BAOD-SL electronic handwheel (portable, magnetic mount for Siemens controllers)

• EMCO tool breakage and wear monitoring / B40D-SL

Kedpfx Ajx D E Hbjg Uoll

• Wireless probe / HSK drill breakage control BK-MICRO

• 4-axis turning / balance cutting (SINUMERIK option)

• Alternative-end spindle speed (SINUMERIK option)

• Turret as tailstock (SINUMERIK option)

• Counter spindle as tailstock (SINUMERIK option)

• Bar feeder (specifications as provided):

• Bar length: 300–1200 mm

• Bar diameter: 10–104 mm

• Material support surface (front view): 800 x 1250 mm

• Material capacity: 12 bars with 65 mm diameter

• Max. load capacity: 400 kg (max. 74 kg/bar)

• Rectangular material: min. edge length 6 mm; max. circumference 105 mm

• Hexagonal material: SW 5 to 85 mm

• Round material:

Listing

Italy

Italy

1,192 km

Mitsubishi MV1200R

MitsubishiMV1200R

Call

Condition: ready for operation (used), Year of construction: 2018, overall weight: 2,722 kg, controller manufacturer: MITSUBISHI, controller model: M800, number of axes: 5, This 5-axis Mitsubishi MV1200R was manufactured in 2018 and features advanced capabilities such as X-Axis Travel of 15.7", Y-Axis Travel of 11.8", and Z-Axis Travel of 8.7". It includes a Mitsubishi M800 control, Auto Wire Threading, and a Chiller for enhanced performance. If you are looking to get high-quality wire EDM capabilities, consider the Mitsubishi MV1200R machine we have for sale. Contact us for more information about this machine.

Additional Equipment

• Auto Wire Threading

• Chiller

• Remote 360 Installed

• Round Diamond Guides Included

• 1GB Partition

• Wire Chopper

• Angle Master Advanced Tapering

• Angle Master Precision Taper Software

• CFAST Compact Flash Card

• Chiller Chopper

• DNC Hardware Ethernet FTP

• FS Power Supply

• High Precision Alignment Gauge

• Wire Alignment Gauge Included

Machine Benefits

Technical machine benefits:

• X-Axis Travel: 15.7"

• Y-Axis Travel: 11.8"

• Z-Axis Travel: 8.7"

• U/V Axis Travel: 2.4" x 2.4"

• Degree Taper Cutting: 15 @ 8"

• Glass Scale Feedback: X, Y, U, V

• Workpiece

• Precision: .000002"

Ksdpex D Ryyjfx Ag Usll

• Table

• Inside Tank Dimensions: 31.9" x 27.6"

Listing

Denmark

Denmark

1,192 km

TRUMPF Trulaser 7040

TRUMPFTrulaser 7040

Call

Condition: ready for operation (used), Year of construction: 2007, operating hours: 32,333 h, controller manufacturer: TRUMPF, This TRUMPF Trulaser 7040 was manufactured in 2007. It features a working area of X=2500 mm and Y=12000 mm, equipped with 2 laser heads and dual 3.2 kW power. Ideal for large-scale CO2 laser cutting tasks. Contact us for more information.

Kledpfjx D R Udox Ag Uel

Extra Information

• Working Area: X=2500 mm / Y=12000 mm

• Axes: 2 x 32 kW

• Laser Heads: 2

Listing

Ahaus

Ahaus

1,037 km

Pipe-Bending Machine

ERCOLINAHB 60 - MODELL "M"

Call

Condition: new, tube diameter 60.3 x 4.5 mm ST

tube diameter 60.3 x 5.4 mm ALU

tube diameter 2" x 3.91 mm GAS

bar material - diameter 35.0 mm

revolutions per minute 2.0 U/min

bending radius min. 10.0 mm

bending radius max. 270 mm

external diameter min. 5.0 mm

external diameter min. 1/8 Zoll

voltage 230 V

total power requirement 1.5 kW

weight 76.0 kg

range L-W-H 302 x 243 x 674 mm

Equipment:

- mandrel-less tube bending machine

Kjdpfox Urtlex Ag Uoll

- Model "M" = ELECTRO-HYDRAULIC SINGLE-PHASE

- high performance and compact design

- completely hydraulic machine

- bends 210° without the need to catch up

- no electronic control

- Ercolina patent n. 102017000142179

- control of the bending angle via adjustable angle scale

- mobile machine base

BENDING SEGMENT AVAILABLE AT AN EXTRA CHARGE

Listing

Italy

Italy

1,192 km

+GF+ Mikron Mill E 1200

+GF+Mikron Mill E 1200

Call

Condition: ready for operation (used), Year of construction: 2021, travel distance X-axis: 1,250 mm, travel distance Y-axis: 600 mm, travel distance Z-axis: 600 mm, controller manufacturer: HEIDENHAIN, controller model: TNC 620, table load: 1,500 kg, spindle speed (max.): 20,000 rpm, number of axes: 4, This 4-axis +GF+ Mikron Mill E 1200 was manufactured in 2021. It features a spindle speed of 20,000 rpm, HSK A63 tool magazine, and rapid traverses up to 40 m/min. The work table measures 1450 x 600 mm with a maximum load of 1500 kg. Additional features include a Lehmann 4-axis rotary table and a liftable chip conveyor. Consider the opportunity to buy this +GF+ Mikron Mill E 1200 vertical machining centre. Contact us for more information.

• Tool magazine: DT30, HSK-A63

• Rapid traverse: X/Y 40 m/min; Z 35 m/min

Klsdpsyb Sifefx Ag Ujl

• Table size: 1450 x 600 mm

• T-slots: 5

• Spindle cooling system – 20 kHz

• Linear scales: MILL E 1200 linear scales

• Machine status light

Additional equipment

• Liftable chip conveyor

• Chip trolley

• Washdown system

• Oil separator

• Remote electronic handwheel

• TS35.10 tool presetter (TNC 620)

• IRP40.02 HSK63A measuring system

• Lehmann 4-axis rotary table

Technical Specification

Taper Size HSK 63

Listing

Malakoff

Malakoff

896 km

Vertical machining center

DMG MORIEcomil 635 V

Call

Condition: used, Year of construction: 2013, functionality: fully functional, Equipment: chip conveyor, documentation/manual, rotational speed infinitely variable, DMG MORI Machining Center

Type 635 V ECOMILL

Year 2013

CNC DMG Siemens

With through-spindle coolant

With chip conveyor

Kodsx R Tqwopfx Ag Uoll

Equipped with linear scales on every axis

Comes with workpiece probe and tool probe

The screen operates with a computer mouse

Listing

Sittard

Sittard

996 km

Telescopic work platform

GenieZ 135 | 2008

Call

Condition: good (used), functionality: fully functional, Year of construction: 2008, operating hours: 6,227 h, power: 57.4 kW (78.04 HP), load capacity: 272 kg, mast type: telescopic, lifting height: 43,150 mm, lifting power: 272 kg/m, platform length: 2,440 mm, platform width: 910 mm, overall weight: 21,092 kg, transport length: 12,830 mm, transport width: 3,940 mm, transport height: 3,070 mm, construction height: 3,070 mm, fuel type: diesel, fuel consumption per hour: 10 l/h, fuel tank capacity: 151 l, tire size: 445/50D710, tire condition: 70 %, wheelbase: 4,110 mm, color: blue, Equipment: all wheel drive, === KEY SPECIFICATIONS ===

Year of manufacture: 2008

Operating hours: 6,227 h

Working height: 43.15 m

Maximum horizontal outreach: 21.26 m

Platform capacity: 272 kg

Platform dimensions (L × W): 2.44 × 0.91 m

Turntable rotation: 360° continuous

Platform rotation: Yes, 160°

Boom type: Articulated knuckle boom

Jib: Yes – 6.10 m (20 ft), 110° vertical rotation

Drive system: Diesel

Four-wheel drive: Yes (4WD)

Four-wheel steering: Yes

Tyres: Rough-terrain, foam-filled

Stabilisers: No (Mini X-Chassis system)

Engine power: 77 hp / 57.4 kW

Emission class: Stage IIIA

Machine weight: 20,261 kg

CE certification: Yes

=== HIGHLIGHTS ===

Carefully selected from reliable sources with verifiable history

CE-certified with full documentation included

Fully tested, serviced and ready for immediate use

Extensive technical documentation available

=== CONDITION ===

Excellent working condition – fully inspected, serviced and tested by certified professionals. Inspection available upon request.

=== LOCATION & DELIVERY ===

Located in Sittard, The Netherlands. Worldwide delivery available. Price €47 750 (EXW / excl. VAT).

This Genie ZX-135/70 (Z-135) offers one of the largest working envelopes in the industry: 43.15 m working height, 21.26 m outreach and full-time 4WD. Equipped with a 6.1 m jib, 160° platform rotation and 360° continuous turntable rotation, it delivers exceptional versatility for construction, industrial maintenance, port operations and large-scale projects. All machines from Collé Rental & Sales are CE-certified, fully inspected and ready for immediate use. Service history, inspection reports and spare parts available upon request.

Klsdpfx Agsx Ah Huo Uol

=== LOADING & TRANSPORT ===

Crane loading available upon request for smooth export handling. Flexible worldwide shipping arranged by the Collé logistics team.

Listing

Slovenia

Slovenia

1,192 km

MIKRON VCP 1350

MIKRONVCP 1350

Call

Condition: ready for operation (used), Year of construction: 2000, travel distance X-axis: 1,350 mm, travel distance Y-axis: 900 mm, travel distance Z-axis: 750 mm, controller manufacturer: HEIDENHAIN, controller model: TNC 426 M, total height: 3,150 mm, overall weight: 10,100 kg, spindle speed (max.): 24,000 rpm, tool weight: 8,000 g, number of axes: 3, This 3-axis MIKRON VCP 1350 was manufactured in 2000. It features a Heidenhain TNC 426 M control system, X-axis travel of 1350 mm, Y-axis of 900 mm, and Z-axis of 750 mm. The machine supports a maximum workpiece weight of 1,800 kg and includes a high-speed Step-Tec HSK-A63 spindle capable of 24,000 rpm. Ideal for precision machining with a tool magazine capacity of 46 tools. Contact us for more information about this machine.

Additional equipment

• High-speed precision machining capability

Machine Benefits

Technical Machine Benefits

• Equipped with a automatic spindle orientation and high-speed spindle (24000 rpm)

• Coolant system pressure: 30 bar (standard) / 40 bar (optional high pressure)

Ksdpfx Agoyarz Ej Ujll

• Tank capacity: 180 l (optional 600 l)

• Direct drive ac motor

• Measuring system: direct linear scales on all axes

• Clamping surface: 1425 x 860 mm

• Magazine capacity: 46 tools (standard), 92 tools (optional)

• Max. Magazine load: 200 kg

• Tool-to-tool change time: approx. 12 sec

• Available for inspection

Extra Information

Machine still under power

Dimensions

Machine Depth 4130 mm

Listing

Babberich

Babberich

984 km

Radial arm drill REFORM HEIDENHAIN RB 32

REFORM HEIDENHAINRB 32

Call

Condition: excellent (used), Year of construction: 2004, drilling capacity: 32 mm, column diameter: 200 mm, Heidenhain RADIAL ND 1200 R ;

HeidenHain scales

HeidenHain measuring probe for:

Rectangle target pattern

Frame target pattern

Circle target pattern

Line target pattern

Arm Length: 1000mm

Max. drill Ø cast: 32mm

Max. tap Ø: 30M

Stroke pinole: 240mm

Max. distance spindle - table:860mm

Min. distance spindle - table:320mm

Floor / table area: 1370 x 700mm

Speeds / ranges: 1220Rpm

Spindle Taper: 4ISO/Bt/Mk

Throat: 1000mm

Column sleeve: 200mm

Quill Ø: 50mm

Length: 1400mm

Kjdpfx Asx S H Nvog Usll

Width: 720mm

Height: 1900mm

Weight: 1200kg

Listing

Germany

Germany

1,192 km

OPS INGERSOLL High Speed Eagle V5

OPS INGERSOLLHigh Speed Eagle V5

Call

Condition: ready for operation (used), Year of construction: 2018, controller manufacturer: HEIDENHAIN, controller model: iTNC640, spindle speed (max.): 42,000 rpm, spindle motor power: 15,000 W, number of slots in tool magazine: 32, This 5-axis OPS INGERSOLL High Speed Eagle V5 was manufactured in 2018. It features a Heidenhain Control TNC 640, a high-frequency spindle with a speed range up to 42,000 rpm, and a 32-slot HSK-E40 tool changer. The machine offers a traversing speed of 30m/min and traversing paths of 550x400x400 mm. If you are looking to get high-quality milling capabilities consider the OPS INGERSOLL High Speed Eagle V5 machine we have for sale. Contact us for more information.

• Max. acceleration: 15 m/s²

Kljdjx D Ektspfx Ag Uel

• Max. traversing speed: 30 m/min

• Control cabinet ambient temperature: up to 33 °C (with heat exchanger)

• Traversing paths (X/Y/Z): 550 x 400 x 400 mm

• Drive system: Ball screw spindles with directly coupled AC servo motors

• Measurement system: Absolute glass scales on all axes

• Torque (S6 60%): 6.7 Nm

Trust Seal

Dealers certified through Machineseeker

Listing

Germany

Germany

1,192 km

MTcut UDS80H-5A

MTcutUDS80H-5A

Call

Condition: ready for operation (used), Year of construction: 2019, operating hours: 2,215 h, controller manufacturer: HEIDENHAIN, controller model: TNC 640, spindle speed (max.): 20,000 rpm, spindle motor power: 35,000 W, number of axes: 5, This 5 axis MTcut UDS80H-5A was manufactured in 2019. It features a 20,000 rpm spindle, 120 Nm torque, and 35 kW drive power. Equipped with a HSK63 tool holder, 96-position tool changer, and a Kessler rotary tilting table with an 800 mm diameter. Includes Heidenhain TNC 640 control, 15" TFT screen, and Ethernet connectivity. Ideal for precision machining with its Heidenhain glass scales and BLUM laser tool measurement. Contact us for more information about this machine.

• Operating hours: Control unit 6,904 h; Machine 5,480 h; Program runtime 2,215 h

• Spindle: 120 Nm torque, separate spindle cooling for constant temperature

• Tool interface: HSK63 with blow-out function

• Rotary table: 800 mm diameter; Kessler rotary tilting table with 2 A-axes and 1 C-axis, direct-drive torque motors

• Feedback: Heidenhain glass scales in all 5 axes

• Tool changer: 96 positions with double-arm gripper

• Control: 15" color TFT screen

• Connectivity: Ethernet interface, 2x USB ports

• Control functions: Plain text programming; short block processing time; create new program while another is running; proven Heidenhain machining cycles

• Electronic handwheel

• CE certified

Additional equipment

• Chip conveyor

Kedpfx Ajx D In Ujg Ujll

• Coolant system

• Internal high-pressure coolant 50 bar with belt filter system

• Coolant and compressed air gun

• BLUM laser tool measurement

• Heidenhain TS460 workpiece probe system for HSK63 with radio and infrared transmission

• Heidenhain KinematicsOpt including Heidenhain calibration sphere KKH 250

• Extraction system: Filtermist FX4002, air volume 1,250 m³/h

• Rotating viewing window

• Work area light

• Tool package

Technical Specification

Taper Size HSK 63

Listing

Denmark

Denmark

1,192 km

DMG MORI CTX Beta 800 4a

DMG MORICTX Beta 800 4a

Call

Condition: ready for operation (used), Year of construction: 2014, operating hours: 48,973 h, controller manufacturer: SIEMENS, controller model: 840 D, number of axes: 3, This DMG MORI CTX Beta 800 4a was manufactured in 2014. It features a Siemens 840 D control system, a counter spindle, and a bar machine package for enhanced versatility. The machine includes a 980-liter coolant system and a hinge type conveyor for efficient operation. If you are looking to get high-quality turning and milling capabilities, consider the DMG MORI CTX Beta 800 4a machine we have for sale. Contact us for more information about this machine.

• 2 x 16 fold Sauter star VID 30

• Siemens 840 D

• Excentric turning and milling operation

• TC alternating speed

• Counter spindle

• Glass scales Y1, Z1, Z2, Z3, X1, X2, X3

Kjdpsx D Nd Dsfx Ag Usll

Additional equipment

• 980 liter coolant with 8 bar/20 L and 20 bar/40 L programmed by M function

• Pater band filter

• Chuck rinsing device for main outside

• Chuck rinsing device for counter outside

• Coolant spray gun

• Hinge type conveyor

• Bar machine package

• Window cleaning with compressed air

• SK package for alu machining

• Tool breakage Artis CTM

Listing

Italy

Italy

1,192 km

OMV ACTIVE FIVE 3000

OMVACTIVE FIVE 3000

Call

Condition: ready for operation (used), Year of construction: 2008, travel distance X-axis: 3,000 mm, travel distance Y-axis: 1,800 mm, travel distance Z-axis: 850 mm, spindle speed (max.): 22,000 rpm, number of axes: 5, This 5-axis OMV Active Five 3000 was manufactured in 2008. It features a fixed table with a tilting head, Heidenhain TNC-530 control, and a travel range of 3000 x 1800 x 850 mm. The spindle operates at 22,000 rpm with a HSK63A taper and a 30-position tool changer. If you are looking to get high-quality milling capabilities, consider the OMV Active Five 3000 machine we have for sale. Contact us for more information.

• Head rotation: B 360° / A ±105°

Klsdpfsx D H Duex Ag Ujl

• Tool changer: 30 positions

• Table size: 3100 x 1100 mm

• Optical scales: Yes

• Options/Features:

• Torque motor head

• Laser tool presetting

• Laser measuring system

Listing

Janville

Janville

917 km

Vacuum mixer

Romaco – FrymakorumaDinex Lab

Call

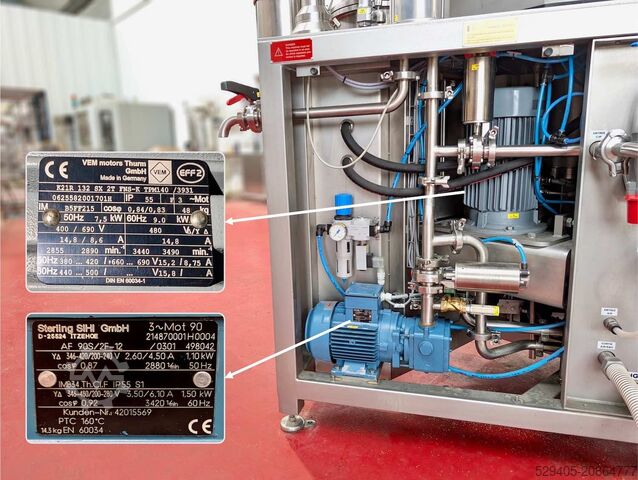

Condition: used, Year of construction: 2009, Manufacturer: Romaco - Frymakoruma

Model: Dinex Lab

Year: 2009

Type: Vacuum mixer for R&D or small-scale production

Application: liquid and/or viscous (semi-liquid) products = dispersion, homogenization, emulsion, grinding, and pumping of the product

Tank:

Ksdex R D Elopfx Ag Usll

Pressure: -1 / 0 bar

Volume: 18 L

Temperature: 130°C

Jacket:

Pressure: 6 bar

Volume: 2 L

Temperature: 180°C

Homogenizer: high-speed agitation

2 modes = Pumping with discharge / Dispersion with high shear force

Tool size: 100 mm

Rotor: 20 x 4 mm

Stator: 30 x 4 mm

VEM motor 7.5 kW / 2890 RPM

Scraper mixer: slow agitation

SEW 0.37 KW motor

Sterling SIHI LEMA 25 liquid ring vacuum pump

Power 1.1 KW - Max. 16 m³/h.

CIP (clean in place)

2 x feed hoppers, 1 of which is connected to the jacket with its piping

Air pressure: 6 bar

Water pressure: 6 bar

Temperature control regulator

Single-acting seal: reconditioned by Burgmann

Paper documentation

Weight: 750 kg

We make it easier for you to find: "pig scales"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Pig Scales (2,165)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you