Used Paper Bag Machinery for sale (77,157)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Gargždai

Gargždai

1,914 km

Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 1200

Call

Year of construction: 2024, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous.

Capacity: 1200 kg/h

The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

The juice yield of apples using our machine is ~75 %.

There is a filtration sieve integrated into the juice collection tank. It filtrates the juice providing clearer and purer product.

Machine works automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

The belt press includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

After work, belt press should be manually washed with a water stream. A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

Belt tension is adjustable.

Kwodpfx Asflppledtjt

Machine is made entirely of stainless steel and has adjustable feet.

The washing is simple, and all machinery parts are easily removable.

Interested in belt press only with different efficiency? Check out our other belt presses: POWERPRESS 400, POWERPRESS 800, POWERPRESS 1500.

Listing

Gargždai

Gargždai

1,914 km

Diesel Pasteurizer

ProFruit MachineryHEAT 1000

Call

Year of construction: 2024, condition: new, Diesel/gas pasteurizer pasteurizes various liquids before the filling process. The liquid comes into the tubular spiral which is surrounded by hot water. The heat from the water heats up the liquid and eliminates the bacteria.

One of our highest machinery achievements is our energy-saving solution integrated into our pasteurizers. It saves the heating energy up to 15-20 % and results in incredibly low heating costs. Calculations show that it costs up to 2 Euro Cents to pasteurize 1 liter of liquid.

Capacity per hour – 900-1250 L of 80 ºC (176 °F) heated juice.

The pasteurizer is suitable to heat various liquids, including viscous liquids: juice, puree, wine, broth, milk and other.

The maximum heating temperature of pasteurizer is 90 ºC (194 °F).

Our pasteurizers are equipped with highest quality German diesel and gas burners GIERSCH.

The heating power is 110 kW.

Pasteurizers’ heating chambers are covered with special heat-insulating paint which preserves high temperature for a longer time and increases heating capacity.

Kodpeflq Sgofx Adtewt

Diesel/gas pasteurizer has a digital thermostat which provides an automatic water temperature control.

Automatic regulation of juice temperature ensures an easy way to change the filling temperature on digital display.

The pasteurizer is fast and easy to clean. It can be washed by CIP cleaning together with our Bag in Box fillers.

The boiler has an integrated spiral. This provides saving of space and also prevention of heat loss when pumping the water into external heat exchanger. As a result, this technology saves the heating energy up to 15-20%.

Machine can use diesel or gas on client’s request.

Diesel/gas pasteurizers work in perfect synergy with our Bag in Box fillers. They have a special connection between them which prevents liquid from overflowing and ensures easy work.

Listing

Gargždai

Gargždai

1,914 km

Rotational Juice Filter

ProFruit MachineryRotational Juice Filter

Call

Year of construction: 2024, condition: new, Machine works well with various fruit, berry and vegetable juice and pulp. During the work process, the juice enters the machine through the spinning filtration sieve. This way excess pulp and sediments stay in the sieve and filtered juice enters the juice collection tank. The sieve spins continuously so juice can flow without interruptions.

Output: 1000 L/h.

Conical form of the filter facilitates the work process so the pulp is collected and removed easily.

The washing of the filter is rarely needed because of convenient conical filter form. That is why washing can be done once per day.

Rotational juice filter has an integrated juice collection tank which collects the juice.

Kodpfsizbawjx Adtewt

Juice collection tank has an automatic pump and liquid level control. When the tank is full, the pump automatically turns on and transfers the juice for further processing.

Machine is made entirely from stainless steel.

Rotational juice filter is mounted on wheels.

Machine is especially simple to use and easy to maintain.

This filter is often used after our DESTONE destoning & pulping machine to remove the pulp from the berries or other fruits and achieve uniform quality juice or puree.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Gargždai

Gargždai

1,914 km

Automatic Bag in Box Filler

ProFruit MachineryAUTOFLOW Filler

Call

Year of construction: 2024, condition: new, Machine fills packages fully automatically by pressing one button. Just insert a package into the filler and press START button – machine automatically removes the tap, vacuums the bag, fills it with liquid and closes the bag. The full filling process of 3 L bag takes ~7 seconds.

Capacity – 300 pcs. of 3 L bags per hour.

- Bag in Box filler AUTOFLOW is extremely versatile. It is perfect for filling various liquids: from juice, wine, milk, broth, oil, to cream, coffee, ice cream, soap, motor oil, chemicals, etc.

- Machine fills Bag in Box bags in sizes 1–30 L, Stand up Pouch packages in sizes 0,75–5 L. It is also possible to fill 220 L bags with a special filling gun.

- Suitable for both hot and cold filling.

- The filler can have optional interchangeable filling heads. This way with one filler you can fill bags with different closures, such as tap, milk tube, screw cap, simple cap, etc.

- Laser safety mechanism protects limbs by automatically stopping & cancelling the filling process in case of an accident.

- High-quality automatic filling head provides stable and smooth filling process.

- The filler can have an optional detachable buffer tank for hot filling. It is mounted conveniently on the side of the machine for better inspection and easier washing process. The buffer tank also reduces liquid foaming during hot filling process.

- The buffer tank has an integrated liquid level control inside for regulation of overspill and level in the tank. Buffer tank also comes with a connection to our pasteurizer.

- Error of volume repeatability is just ± 0,5 %.

- Filler comes with a touchscreen panel and multi-language menu.

- Easily adjustable filling table allows to easily fill different volumes of Bag in Box & Stand up Pouch packages.

Kwjdjflrkuspfx Adtot

- The filler is easy to clean after work with external and CIP cleaning.

- Our Bag in Box fillers work in perfect synergy with our Pasteurizers HEAT 1000. They have a special connection between them which prevents liquid from overflowing and ensures easy work.

Listing

Gargždai

Gargždai

1,914 km

Bag in box filler MINIFLOW

PROFRUIT MACHINERYMINIFLOW

Call

Year of construction: 2024, condition: new, A small, table version semi-automatic Bag in Box filler is an easy, economical and mobile solution for filling liquids into Bag in Box or Stand up Pouch packages. Insert the bag or pouch into the filler and pull the handle – the package is filled automatically. Return the filling handle into the start position, cap the bag and the filling process is finished.

Kwedsh S H A Iopfx Adtjt

- Capacity ~250 pcs. of 3 L packages (depending on the pump).

- The weight of the machine is only 50 kg so it is especially easy to move or transport from one facility to another.

- There are two options of the machine: with or without pump. When purchasing machine without pump, you can connect your own pump or fill the packages by gravity.

- Hot and cold filling of bags and pouches is possible from 0,5 liter up to 20 liters.

- The machine is suitable to fill both Bag in box and stand up pouch packages with a tap.

- Bag in Box filler pre-vacuums the bags and pouches before filling.

- Machine comes with touchscreen panel and a multi-language menu.

- Repeatability of volumes with an error of ± 0,5 %.

- Easy-to-adjust filling table for different volumes of bags and pouches.

- Working surface of the table consists of conveyor rollers which are easy to clean and help for the smooth slide of the bags and pouches.

- The filler is easy to clean after work with external and CIP cleaning.

- The filler is reliable, simple and easy to use and maintain.

Discover more used machines

Listing

Gargždai

Gargždai

1,914 km

Fruit Washer Elevator Mill

ProFruit MachineryMAXIMILL 1000

Call

Year of construction: 2024, condition: new, The fruit washer mill is made from stainless steel. Firstly, the operator of machine pours fruits and vegetables into the washing tub with clean water. Conveyor lifts the products up to the mill. During the lifting process, water nozzles spray the fruits and vegetables with clean water. The mill crushes the products after they reach the top of the conveyor. Finally, the fruit and vegetable mash comes out of mill.

Capacity – 1000 kg/h.

- The crushing head of the machine is round, so all the crushed mash goes directly out for further processing. This feature significantly helps when washing the head as there are no corners.

- Our round shape technology is superior to other producers’, because a lot of fruit mash gets stuck in the corners of square-shaped heads for hours and can cause juice fermentation!

- Machine has additional table in front of the basin for putting fruits or boxes on it. It facilitates the process of pouring the products into the basin.

Kedsflpfbepfx Adtswt

- V form washing basin helps fruits and vegetables move directly to the conveyor, therefore less fruit stay in the basin.

Integrated water-spraying system provides additional washing when lifting the fruits up the conveyor.

- Belt conveyor has a water drainage and speed regulation system.

- The speed of the belt conveyor is adjustable in the control panel.

- Optional replaceable cutting graters/sieves are available for different fruits and berries.

- The mill does not damage the fruit seed.

- Machine is easy to clean after using.

- Powerful 2.2 kW crushing engine can crush various fruits, berries and vegetables – from soft raspberries to hard apples, beets, etc.

- Machine is entirely made of stainless steel.

Listing

Gargždai

Gargždai

1,914 km

Fruit Washer Elevator Mill

ProFruit MachineryMAXIMILL 3000

Call

Year of construction: 2024, condition: new, The fruit washer elevator mill is made from stainless steel. Firstly, the operator of the machine pours fruits and vegetables into the washing tub with clean water. Conveyor lifts the products up to the mill. During the lifting process, water nozzles spray the fruits and vegetables with clean water. The mill crushes the products after they reach the top of the conveyor. Finally, the fruit and vegetable mash comes out of mill.

Capacity – 3000 kg/h.

Kwedoflpmkepfx Adtst

- The crushing head of the machine is round, so all the crushed mash goes directly out for further processing. This feature significantly helps when washing the head as there are no corners.

- Our round shape technology is superior to other producers’, because a lot of fruit mash gets stuck in the corners of square-shaped heads for hours and can cause juice fermentation!

- Machine has additional table in front of the basin for putting fruits or boxes on it.

- V form washing basin helps fruits and vegetables move directly to the conveyor, therefore less fruit stay in the basin.

Integrated water-spraying system provides additional washing when lifting the fruits up the conveyor.

- Belt conveyor has a water drainage and speed regulation system.

- Optional replaceable cutting graters/sieves are available for different fruits and berries.

- The mill does not damage the fruit seed.

- Powerful 4 kW crushing engine can crush various fruits, berries and vegetables – from soft raspberries to hard apples, beets, etc.

- Machine is entirely made of stainless steel and easy to clean after using.

Listing

Gargždai

Gargždai

1,914 km

Bath pasteurizer for bottles

ProFruit MachineryBath pasteurizer for bottles

Call

Year of construction: 2024, condition: new, Bath pasteurizer option is the perfect solution for post fill pasteurization of your bottled or canned products. 97 units of standard 0.75 L bottles easily fits in 4 baskets.

Our bath pasteurizers can be produced in two options:

1. Autonomous bath pasteurizer with electric heating elements and integrated control panel.

2. Bath pasteurizer as an option together with HEAT or ECOHEAT pasteurizers. Then water heating is done with our pasteurizer and the same control panel is used for controlling both devices.

Features:

Mounted on pivoting wheels.

Kodpfx Ajrif Smodtswt

Insulated heating bath to save the energy and temperature.

Can be used for glass bottles, jars, cans, any other heat resistant package.

Works with different products, like juices, jams, marmalades, puree, sauces, etc.

Automatic temperature and time control.

Water overflow protection.

Fast and easy loading and unloading of bottle trays.

Entirely made of stainless steel.

The bottles, cans, or jars are loaded into the trays and then trays are loaded into the bath. The desired pasteurization temperature and holding time settings can be set simply using the integrated control panel or on the HEAT or ECOHEAT pasteurizers.

At a start of process, bottles or jars are placed into the bath, then water is filled into the bath until it reaches bottle neck. Then pasteurizer is connected, temperature (max 90 C⁰) and time is set. Then it starts to heat up the water inside the bath. When set temperature is reached, timer turns on and pasteurization is started. In the meantime, in the new set of trays filled bottles can be loaded for a faster exchange process.

When timer ends, water out of the bath pasteurizer is released and bottles are unloaded.

As the temperature is only measured in the bath, it is important to monitor the core temperature of your product to ensure that adequate pasteurization has been achieved.

Listing

Gargždai

Gargždai

1,914 km

Screw conveyor

ProFruit MachineryScrew conveyor

Call

Year of construction: 2024, condition: new, The leftover fruit, berry or vegetable mash enters the loading hopper of the screw conveyor. The screw inside the machine is continuously turning and this way transports the mash from the loading hopper to the exit outlet at the top of the machine. The mash exits the machine.

Screw conveyor is made of stainless steel.

Machine has a closed tunnel.

Kwjdpfxoizbffj Adtst

Conveniently transports leftover pressed mash from press.

Listing

Gargždai

Gargždai

1,914 km

Bin tipper

Profruit MachineryUNLOADER 800

Call

Year of construction: 2024, condition: new, It is a first processing step during which machine transfers fruit, vegetable or berries to the next stages of processing: washing, sorting or crushing. Bin tipper lifts the box and pours out the products into sorting conveyor, AQUA or MAXIMILL.

Bin tipper is entirely made of stainless steel.

Machine has a hydraulic drive.

Controls of the machine are very simple: just put the box in and move the control handle to lift it up.

Kwedpfx Ajichbbsdtjt

Suitable for boxes with different dimensions. Max size: 120x120x85.

Loading power – 800 kg.

Listing

Gargždai

Gargždai

1,914 km

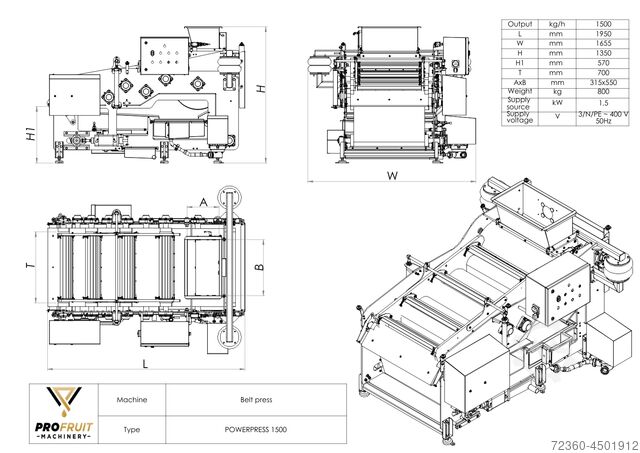

Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 1500

Call

Year of construction: 2024, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous.

Capacity: 1500 kg/h.

- The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

- The juice yield of apples using our belt press 1500 is ~75 %.

- There is a filtration sieve integrated into the juice collection tank. It filtrates the juice providing clearer and purer product.

Kodpsflpp Ejfx Adtowt

- The belt presses work automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

- The belt press 1500 includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

- Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

- After work, belt press should be manually washed with a water stream. - A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

- Belt tension is adjustable.

- Machine is made entirely of stainless steel and has adjustable feet.

- Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Listing

Gargždai

Gargždai

1,914 km

Semi-automatic Bag in Box Filler

ProFruit MachinerySEMIFLOW Filler

Call

Year of construction: 2023, condition: new, Machine fills packages automatically. Just insert the bag or pouch into the Bag in Box filler and pull the handle. After the package is filled, return the filling handle into start position and cap the bag.

Capacity – 250 pcs. of 3 L bags/h

Perfect for filling various liquids: from juice, wine, milk to broth, oil, soap, etc.

Fills Bag in Box bags in sizes 1–30 L, Stand up Pouch packages in sizes 0,75–5 L.

Suitable for both hot and cold filling.

Machine fills both Bag in Box and Stand up Pouch packages with a tap.

The filler can have an optional detachable buffer tank for hot filling. It is mounted conveniently on the side of the machine for better inspection and easier washing process. The buffer tank also reduces liquid foaming during hot filling process.

The buffer tank has an integrated liquid level control inside for regulation of overspill and level in the tank. Buffer tank also comes with a connection to our pasteurizer.

Kwedjflriuepfx Adtjt

Error of volume repeatability is just ± 0,5 %.

The filler pre-vacuums the bags and pouches before filling.

Comes with touchscreen panel and multi-language menu.

Easy-to-adjust filling table allows easily fill different volumes of Bag in Box & Stand up Pouch packages.

Working surface of the table consists of conveyor rollers which are easy to clean and help for the smooth slide of the bags and pouches.

The filler is easy to clean after work with external and CIP cleaning.

Our Bag in Box fillers work in perfect synergy with our Pasteurizers HEAT. They have a special connection between them which prevents liquid from overflowing and ensures easy work.

We also offer fully automatic Bag in Box filler AUTOFLOW.

Listing

Gargždai

Gargždai

1,914 km

Diesel Pasteurizer

ProFruit MachineryHEAT 500

Call

Year of construction: 2024, condition: new, Diesel/gas pasteurizer 500 heats up the liquid before the filling process. The liquid comes into the tubular spiral which is surrounded by hot water. The heat from the water heats up the liquid and eliminates the bacteria.

One of our highest machinery achievements is our energy-saving solution integrated into our pasteurizers. It saves the heating energy up to 15-20 % and results in incredibly low heating costs. Calculations show that it costs up to 2 Euro Cents to pasteurize 1 liter of liquid.

Capacity per hour – 400-600 L of 80 ºC (176 °F) heated juice.

- The pasteurizer is suitable to heat various liquids, including viscous liquids: juice, puree, wine, broth, milk and other.

- The maximum heating temperature of diesel pasteurizer is 90 ºC (194 °F).

- Our pasteurizers are equipped with highest quality German diesel and gas burners GIERSCH.

- The heating power is 53 kW.

- Pasteurizers’ heating chambers are covered with special heat-insulating paint which preserves high temperature for a longer time and increases heating capacity.

- Diesel/gas pasteurizer has a digital thermostat which provides an automatic water temperature control.

- Automatic regulation of juice temperature ensures an easy way to change the filling temperature on digital display.

- The pasteurizer is fast and easy to clean. It can be washed by CIP cleaning together with our Bag in Box fillers.

- Machine can use diesel or gas on client’s request.

- The boiler has an integrated spiral. This provides saving of space and also prevention of heat loss when pumping the water into external heat exchanger. As a result, this technology saves the heating energy up to 15-20%.

- Diesel/gas pasteurizer has pivoting wheels.

Kwodpfjflrk Isx Adtot

- Diesel/gas pasteurizers work in perfect synergy with our Bag in Box fillers. They have a special connection between them which prevents liquid from overflowing and ensures easy work.

Listing

Gargždai

Gargždai

1,914 km

Manual bottle filler GRAVITY

ProFruit MachineryGRAVITY

Call

Year of construction: 2024, condition: new, The manual bottle filler is specially easy to use. The filling mechanism works on the basis of gravity. The handle is pulled down and the strong stream of liquid flows out of the head.

Capacity – 600 pcs. of 0,5 L bottles per hour.

The bottle filler is completely made of stainless steel.

Gravitational mechanism provides a strong stream as well as easy and effective work.

Comes with a buffer tank for fluid.

Buffer tank has an integrated flowmeter which helps to follow the liquid level on the buffer tank.

Suitable for various liquids that are similar to water consistency such as juice, wine, vodka, etc.

Kwsdpfxsizbb Hs Adtet

Mounted on the pivoting wheels.

Listing

Gargždai

Gargždai

1,914 km

Juice filtration

Profruit MachineryDouble juice filters

Call

Year of construction: 2024, condition: new, Mechanical double juice filters are made of stainless steel. The set includes two parallel stainless steel filters that can work separately one from each other. The double juice filters filtrate the juice and eliminate various thick particles in it. This provides particularly clean juice. The valves of the filters can also be shut off separately during the washing process or for other purposes.

Available mesh: 60 µm, 200 µm, 300 µm, 400 µm, 500 µm.

Ksdpfx Ajhu Aafsdtowt

Connection D25.

Capacity: 2000 L/h.

Stainless steel ensures longevity as well as quality of the product.

Stainless steel filters are easy to clean after using.

Listing

Gargždai

Gargždai

1,914 km

Belt press for juice

Profruit machineryPOWERPRESS 800

Call

Year of construction: 2023, condition: new, Belt presses POWERPRESS 800 are designed for pressing fruit, berry and vegetable mass. Fruit mass is placed on the belt which presses it against cylinders.The obtained juice flows in the collection trays under the belt presses. Pressing is continuous.

Capacity: 800 kg/h

The most evolutionary feature of our belt press POWERPRESS line is integrated pump and juice collection tank into the press itself. That means that you save money and do not need an additional juice collection tank and pump which otherwise would use much space and money.

There is a filtration sieve integrated into the juice collection tank. Because of that the machine filtrates the juice even during the pressing stage providing cleaner and more pure product.

Entirely made of stainless steel.

Has adjustable feet.

The belt presses function automatically. When the tank of the mass is full, all other machines which come before belt press turn off automatically. When the juice tank is full, juice pump pumps the juice into the tanks.

Includes High pressure washer.

Has an integrated pump.

Belt tension is adjustable.

Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Kodpfxjhu Ab Dj Adtewt

The cleaning of the belt is automatic with high pressure cleaner, scraper and brush.

Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

Listing

Győr

Győr

1,929 km

Heavy duty laminator

Reliant Machinery Ltd.Powerbond-HPC 1800 Laminator System

Call

Condition: like new (used), Year of construction: 2016, operating hours: 210 h, functionality: fully functional, working width: 1,800 mm, type of cooling: water, This Reliant Powerbond HPC, 1800 mm width High Pressure Laminatint Line contain the following unites:

- Unit 1 Reliant Powerline non driven unwind unit

- Unit 1A Lightweight table designed to support sheets during feeding

- Unit 2 Reliant Powerline Powder Coating unit

- Unit 3 Reliant Powerline 3000 mm PTFE Conveyor

- Unit 4 Reliant Infrared Pre-Heating System

- Unit 4A Unwind shaft roll support for surface friction or centre unwinding

- Unit 5 Reliant Powerbond-HPC-180 Haevy Duty, High Pressure Laminating Machine

- Unit 5A Laminating Line Control Unit

- Unit 6 Reliant Powerline Centre Driven Rewind System

Kwjdpfxjv Tmxns Adtst

- Unit 7 Reliant Chiller Unit-I416

More details about the units can be found in the attached pdf file.

Loading of the machine on the transport vehicle is included in the price.

The transportation of the machine should be provided by the buyer.

Listing

Košťany nad Turcom

Košťany nad Turcom

1,942 km

Flexographic printing machine

Focus Label Machinery LtdE-FLEX 330 2S

Call

Condition: like new (used), Year of construction: 2021, operating hours: 300 h, functionality: fully functional, product width (max.): 330 mm, working width: 330 mm, EFLEX 330 2S (in operation since 2021, only on a partial shift basis; fewer than 300 printing hours):

Selling price: €350,000 + Accessories €20,000

Prices are EXW Košťany nad Turcom, Slovakia, and exclude VAT, (de)installation, and commissioning. The machine has been regularly maintained and is ready for sampling, customer testing, or production.

8-Colour UV Flexo Printing Press: Model eFlex 330-2 S

- Full Servo Drive Technology

- eFLEX 330 – 2 S with helical gear transmission

- 8 Colours + Extended Die Module

- 2 x Die Stations + Sheeter

DRYER OPTIONS

- 8 x IR Lamp & Hot Air Drying Systems

- 8 x UV Lamp System + Chill Rolls & Chiller

OTHER INCLUDED OPTIONS

- Pre-register

- Auto register

- 2nd Pass Capability

- Upgrade: Unwind Roll Lift

- Corona Treatment - Single Sided (2 kW)

- Web Cleaner (Double Sided) with anti-static

- Rail System

- Turn Bar with Delam-Relam (Rail mounted)

- Cold Foil (Rail Mounted)

- Sheet Stacker (Shingle Conveyor)

- Peel & Reveal

- Tint Roll with Air Mandrel

- Antistatic Unit (4 bars)

- Rotary Die Adaptors (1 Set)

Kwedpfx Adsrxrx Sstst

- Edge Trim Extraction (Venturi) – requires compressed air supply

- Reverse Rewind

- Video Inspection System (Double-Sided Viewing, E+L)

- FOCUS Video Plate Mounter Platemate

- Upgrade: Full-Length Rail

- Rail Mounted Snowball Waste Rewind

Accessories:

Gears (Helical Gearing) Print Cylinder Magnetic Base Die

84T (266.700mm) 8 x Print Cyl. 1 x Mag Cyl

96T (304.800mm) 8 x Print Cyl. 1 x Mag Cyl

99T (314.325mm) 8 x Print Cyl. 1 x Mag Cyl

105T (333.375mm) 8 x Print Cyl. 1 x Mag Cyl

117T (371.475mm) 8 x Print Cyl. 1 x Mag Cyl

88T (Rubber Sleeve) 1 x Varnishing Cyl.

69T (219.075mm) 1 x Mag Cyl.

+ 17 pcs Anilox Rollers

Listing

Debrecen

Debrecen

2,194 km

Decanter Centrifuge

YIXING HEAD SEPARATOR MACHINERY CO. LTD.LW250*1000

Call

Condition: like new (used), Year of construction: 2020, operating hours: 50 h, machine/vehicle number: LW250*1000, Decanter centrifuge manufactured in 2020, but put into operation in May 2021! The machine is in like new condition (used in total approx. 50 operating hours)!

The decanter is for sale due to a change in technology, it works flawlessly!

Manufacturer: YIXING HEAD SEPARATOR MACHINERY CO. LTD., CHINA

Year of manufacturing date: 2020

Serial Number: LW250*1000

Kwodpfxjpu A D As Adtot

Machine signal: 02-001

Decanter indication number: 2647

Sludge formation capacity of decanter: 500 kg/h

Main motor capacity: 7,5 KW

Vice motor capacity: 3 KW

Capacity: 1-5 m3/h

Netto weight of decanter: 1000 kg

Material of wetted parts:1.4404

Feed volume flow: 0,5t – 3t/h

Stainless steel Reference number: 2590

Listing

Italia

Italia

2,009 km

HIPAK

AutoBox MachineryHIPACK MULTICUT

Call

Year of construction: 2015, condition: used, Touch screen

HICUT quick set

Kwsdpfjwrr Hmsx Adtet

Crease pressure dial

Emergency shutdown system

Rear crease pressure regulator

WIDTH 2600

Listing

Kežmarok

Kežmarok

2,038 km

7 spindle fourside moulder

SK MACHINERY907S

Call

Condition: good (used), I sell the heavy duty fourside moulder SK MACHINERY 907S.

Element max. 240x150mm !

7 spindle configuration:

Ksdpfx Aopwdwbodtewt

Bottom 5,5kW (7,5HP) / 6000 rpm

Right 5,5kW (7,5HP) / 6000 rpm

Left 5,5kW (7,5HP) / 6000 rpm

Right 5,5kW (7,5HP) / 6000 rpm

Top 7,5kW (10HP) / 6000 rpm

Top 12kW (15HP) / 6000 rpm

Bottom 5,5kW (7,5HP) / 6000 rpm

Total power 62KW / 102 A

Total weight 5000kg.

Element max. 240x150mm !

Moulding heads with spiral knives fi.140x260x40mm included in price.

Electronic programmer for the working width and height adjustment of the pressure zone and top spinde, aka working height.

Feeding speed adjustable by inverter.

Zone pneumatic pressure system for feeding wheels.

Available immediately

Repair required: Bearings on one spindle which is already outside.

Trust Seal

Dealers certified through Machineseeker

Listing

Rumbula

Rumbula

2,082 km

Outdoor WPC PE profile production line

Zhangjiagang anda machinery co,.ltdYF-240

Call

Condition: like new (used), Year of construction: 2022, functionality: unexamined, machine/vehicle number: YF-240, type of input current: AC, Equipment: documentation/manual, In 2022 we purchased a new line, but the business direction changed and the line was never unpacked from the containers.

The line is stored in 40HQ*3pcs container and in one 20GP container.

Kwedpfexb R Aisx Adtot

Production capacity:220-300kg/hour

WPC production line is applied to produce wood plastic composite products, like WPC decking, WPC door frames, WPC skirting and so on.

by changing screw barrel and molds, it can produce both PE PP type WPC products and PVC type WPC products.

features of wpc production line:

- adopts double step production, first compounding & granulating, then extrusion

- adopts bimetallic screw barrel, high hardness, more wearable

- adopts parallel twin screw extruder for compounding & pelletizing, good exhausting effect, better plasticizing effect

Please view all the technical specification in attachments.

Listing

Mārupe

Mārupe

2,069 km

Electric pallet truck

Global Machinery; HOPEWT-BD-01

Condition: new, Year of construction: 2024, functionality: fully functional, Equipment: documentation/manual, emergency stop, type plate available, Last 4 pieces left. With running gear. New powerful 3T electric pallet trucks

Kwedpfx Asw Ulr Hodtot

Listing

Dievogala

Dievogala

2,070 km

Vertical Flow Pack machine

HUAYUAN MACHINERY

Call

Year of construction: 2008, condition: good (used), For sale vertical Flow Pack machine. Not used 2 years.

Power: 3,5 kW

Packing speed: from 15 psc/min to 30 psc/min

Kodpfx Adsibwk Hstjwt

If you have an questions on this, please do not hesitate to contact us.

Listing

Rīga

Rīga

2,074 km

Squeeze Dryer for washed plastic film

GENIUS Machinery CoDW300

Call

Condition: new, functionality: fully functional, power: 90 kW (122.37 HP), Year of construction: 2025, Plastic squeeze dryers are a vital part of plastic film washing lines.

Kedpfx Adewg Sd Ustowt

Washed films retain up to 30% moisture normally after exiting the wash process. High humidity will be affecting the efficiency and production of the following extrusion pelletizing process. Having a plastic squeeze dryer is a must to dehydrate the washed film, increase the density of recycled film and fibre materials, increase the capcity of the following extrusion process and further refine the quality of final plastic pellets.

Even the water-washed plastic film processed through a spin-dryer still contains over 10% moisture which would significantly reduce the productivity of the extruder and quality of pellets. The latest development for drying and recycling washed film are plastic film squeeze dryers which could reduce moisture to the minimum and the squeezed material only contains maximum 3%, and more usually 1%, residual moisture. Much cheaper to operate than hot air drying , and better result as the output materials are continuously agglomerated direct from washing lines with +40% fluids to dense free flowing agglomerate. In this form it is not necessary to have cutter compactor extruders, as the materials are so dry and dense they can be fed direct to extruders for pellet production.With over 30 years of producing recycling dryers and extruders GENIUS have sold more than 600 of these driers to the plastics recycling market. ..There are 4 models in the range with production between 250 kgs per hour up to 1200 kgs per hour.

We make it easier for you to find: "paper bag machinery"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Paper Bag Machinery (77,157)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month