Used Crossfield Scanner for sale (321)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Wiefelstede

Wiefelstede

1,085 km

Reflection light barrier

SickWT36-P410

Call

Condition: used, Reflection light barrier, reflection light scanner, light barrier, light scanner

-Manufacturer: Sick, retro-reflective sensor type WT36-P410

-Connector: DC 10-30V

Cpodeiiig Tspfx Agzsw

-Number: 2x sensors available

-Price per piece

-Total dimensions: 150/100/H35 mm

-Weight: 0.3 kg/pc.

Listing

Wiefelstede

Wiefelstede

1,085 km

Reflection light barrier

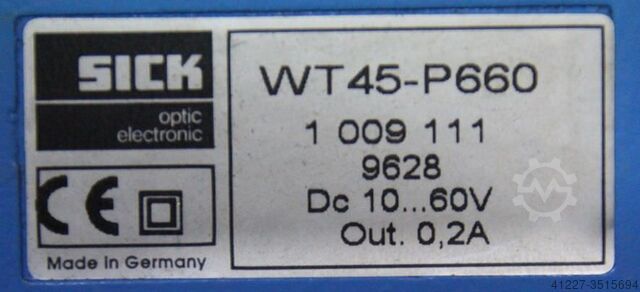

SickWT45-P660

Call

Condition: used, Reflection light barrier, reflection light scanner, light barrier, light scanner

-Manufacturer: Sick, retro-reflective sensor type WT45-P660

-Connector: DC 10-60V

-Number: 2x sensors available

-Price per piece

-Total dimensions: 105/60/H180 mm / 170/90/H110 mm

-Weight: 0.7/0.8 kg/pc.

Cododnllrepfx Agzepw

Listing

Wiefelstede

Wiefelstede

1,086 km

Flame detector

SiemensQR12B2.B180B

Call

Condition: used, Switchgear, control system, flame sensor, flame monitor, UV flame sensor, UV sensor

-Manufacturer: Siemens, UV flame scanner unused in original packaging

-Type: QR12B2.B180B

Codpfx Agoghihaezepw

-Dimension box: 155/115/H85 mm

-Weight: 0.2 kg

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Dinkelsbühl

Dinkelsbühl

1,378 km

Double mitre saw for steel

MECALVICO 3

Call

Condition: new, Year of construction: 2026, Comparable to: e.g. Emmegi

Double mitre saw for steel

Cutting length: 5,000 mm

Equipped with 7 NC axes for length positioning, outward and inward saw blade inclination, saw blade feed, and saw motor speed control

Torsion-free welded construction with longitudinal linear guideways

2 x saw motors, each 4.5 kW

Saw blade speed: 0–250 rpm

Saw feed motorized from rear to front

Feed speed infinitely adjustable

Motorized angle adjustment between 135° and 45°

Suitable for HSS circular saw blades, Ø 400 mm

Pneumatic protective covers

Water cooling with pump and coolant tank

Left saw unit fixed to the base frame, right unit motorized and traversable

Positioning accuracy: ± 0.15 mm

Max. traverse speed: 25 m/min

Length positioning compensates for saw angles and profile height

Each saw head fitted with three horizontal and vertical profile clamps; in the event of pressure loss, the horizontal cylinders remain clamped

Pneumatically swivelable material support between the saw heads

15” touchscreen

Single cut processing

Processing of cutting lists

Creation of cutting lists via keyboard

Import of cutting lists via USB flash drive or network interface

Corner cutting

Overlength cutting

Short cuts from 5 mm cutting length

Crosscuts

Available options:

Micro-spraying unit

Saw head inward inclination increased to 150°

Cpsdpfjyinu Hjx Agzsw

Label printer

Barcode scanner

Additional network interface and teleservice agreement

Listing

Hauzenberg

Hauzenberg

1,616 km

Engraving machine

LD-LaserLG-UV-Q15

Call

Condition: as good as new (ex-display), Year of construction: 2025, functionality: fully functional, shaft length: 355 mm, input voltage: 230 V, laser power: 20 W, UV Laser Engraving Machine with 20 Watt Laser Power

- Laser source with 355nm wavelength / 20 Watts

Demonstration machine, with minimal operating hours (approx. 15 hours)

- incl. Windows 64-bit PC system

- incl. 22" monitor

- everything fully installed and calibrated

- Engraving software in German

- 3D software (MM3D)

- very easy to operate

- switch on and start working

- UV laser source with 20 Watts for high-contrast and fast marking with extremely high resolution

- suitable for engraving almost all metals (stainless steel, brass, aluminium, etc.)

- suitable for engraving almost all plastics (including PVC, silicone, etc.)

- suitable for engraving real glass (including crystal glass)

- capable of cutting real glass

- heavy-duty industrial quality

- complete system / ready for immediate use

- working area approx. 500 x 600 x 600 mm (W x D x H)

- clamping surface with threaded inserts on a 50 mm grid

- LED workspace lighting

- 50 mm duct connection for fume extraction

- Engraving area approx. 150x150 / 200x200 / 300x300 mm (switchable)

- 3D scanner for marking surfaces of any shape

- incl. foot pedal to start the engraving process

Cpodpfxeflrnas Agzow

Sale to businesses only.

Delivery / consulting / sales only within Germany / Austria / Switzerland.

Please also ask about our attractive leasing/financing options.

Machine dimensions approx.:

Width: 800 mm

Height: 1800 mm

Depth: 1000 mm

Weight: approx. 150 kg

Listing

Berlin

Berlin

1,444 km

3D scan measuring system with robotic cell

Zeiss / GOMScanBox 4105 mit Atos Q 12M

Call

Condition: excellent (used), Year of construction: 2017, operating hours: 40 h, functionality: fully functional, input voltage: 230 V, total width: 1,600 mm, total length: 1,200 mm, total height: 2,100 mm, overall weight: 900 kg, workpiece weight (max.): 100 kg, For sale is a Zeiss ScanBox 4105 equipped with an Atos Q 12M 3D sensor, a high-precision optical 3D scanner designed for demanding measuring and inspection applications, fully automated within a robotic cell.

The robotic cell was manufactured in 2017 and retrofitted in 2024 with a new Atos Q 12M 3D sensor. The system has seen little use and is in nearly new condition. The robotic cell has logged only 40 operating hours (axis movement).

The sensor is fitted with the MV170 measuring volume. Included in the scope of delivery are a mobile controller and a tripod, as well as the original transport case for the sensor, allowing for flexible and manual use of the sensor outside the robotic cell.

The supplied software package includes Zeiss Inspect Professional and Zeiss Blade Inspect. All original manuals and documentation are also included.

Cpjdpfjyir Hysx Agzew

Listing

Wiesbaden

Wiesbaden

1,199 km

Engraving machine

SK LASER GmbHF100iW1 Faserlaser 100 W

Call

Condition: as good as new (ex-display), Year of construction: 2025, functionality: fully functional, machine/vehicle number: 1746, shaft length: 10,564 mm, laser power: 100 W, type of cooling: air, working range: 1,750 mm, overall weight: 205 kg, table height: 1,760 mm, table length: 12,000 mm, table width: 9,200 mm, Equipment: cabin, Used fiber laser system for laser marking, engraving, marking, and microstructuring on metals and plastics.

Ex-display machine, laser class 1, CE-compliant, Made in Germany.

Laser & Beam Source

- IPG Ytterbium fiber laser

- Power: 100 W

- Wavelength: 10564 nm

- Pulse energy: 0.2–1.0 mJ

- Cooling: Air-cooled, no external cooling required

- Power supply: 230 V / 50 Hz

- Scanner: X-Y galvanometer with mirror mount for 1064 nm

Note: Manufacturer’s lab values; actual values may vary depending on the application.

Scanner & Control

- F-Theta lens: f = 254 mm, anti-reflection protective glass

- Marking field: 175 × 175 mm

- Max. scan speed: 4 m/s

Industrial PC with Windows 11 Pro, SSD storage

- Controller cards for laser & scanner

- Digital & analog interfaces: RS232, Ethernet, USB

Cpedsyfvhgjpfx Agzow

- Custom adaptations optional

- 19" TFT color monitor, keyboard & mouse

- SK CONTROL software

- Industrial software for texts, logos, QR codes, variable data

- Intuitive user interface, logo/photo import via mouse click

- Job management and parameter library for reproducible quality

- Pilot laser displays laser position as red rectangle

Workstation 1 – SK LASER

- Enclosed laser class 1 workstation

- Combined sitting/standing workstation

- Aluminum profile housing, front door with laser safety glass, bright work lighting

- Dimensions: H 1760 × W 920 × D 1200 mm

- Stainless steel worktop with 25-mm hole grid, 710 × 400 mm

- Motorized Z-axis, travel 500 mm (gross)

- Rear door for oversized workpieces (when open: laser class 4)

- Extraction nozzle DN50 for fume extraction

- Redundant safety equipment: emergency stop, interlock, safety relay performance level 4

- Operating temperature: 15–35°C

- Connection load: 230 V / 50 Hz

Condition & Delivery

- Ex-display, tested machine

- Optionally: Delivery including commissioning within Germany

Listing

Wiesbaden

Wiesbaden

1,199 km

Engraving machine

SK LASER GmbHC60W1 – CO₂-Laser 60 W – Refurbished

Call

Condition: as good as new (ex-display), Year of construction: 2025, functionality: fully functional, shaft length: 10,600 mm, laser power: 60 W, type of cooling: air, total width: 800 mm, total height: 1,800 mm, total length: 1,700 mm, working range: 1,200 mm, warranty duration: 6 months, height adjustment type: electric, table height: 7,000 mm, table length: 4,000 mm, Equipment: cabin, Used CO₂ laser system for marking, engraving, and cutting plastics, wood, acrylic, paper, and more.

Refurbished, 6-month warranty, Made in Germany.

Technical Specifications

- Laser source: CO₂ laser, beam source refurbished in 2023

- Peak power: 60 W

- Wavelength: 9,600 nm

- Cooling: air cooling

- Power supply: 230 V / 50 Hz

- Scanner & optics

Cjdpfxeyfucvs Agzspw

- X-Y galvo scanner with mirror mount

- F-theta lens: F = 200 mm, anti-reflective protective glass

- Working area: 120 × 120 mm (other lenses available on request)

Machine & Work Area

- Fully enclosed workstation

- Dimensions (W/H/D): 910 × 255 × 200 mm

- Extraction port available (extraction system not included)

Control & Software

- Industrial PC

Marking software:

- Texts, logos, variable data

- Import of DXF, PLT, WMF, bitmap

- Intuitive, user-friendly interface

Scope of Delivery & Safety

- Complete machine, workstation

- 6-month warranty

- CE certified, TÜV-tested

Condition & Delivery

- Refurbished, technically tested

Offer valid ex works plus shipping, while stocks last

Listing

Mönchengladbach

Mönchengladbach

1,031 km

Coordinate measuring machine

AberlinkHorizon 800

Call

Condition: new, Year of construction: 2025, functionality: fully functional, Aberlink's Horizon CNC Coordinate Measuring Machine (CMM) sets new standards in metrology by using frictionless linear drives that ensure fast, smooth and silent movements.

Cpjdovwa Udjpfx Agzew

This technology minimizes wear and increases reliability, which reduces maintenance. The granite base and Y-axis rail make the most of the thermal stability of this material to ensure precise measurements.

The Horizon CMM is available in a range of sizes, with travels of X 800 mm, Y 1000 or 1600 mm and Z 600 mm, to suit different measurement requirements. Volumetric accuracy is (1.8 + L/350)µm with the TP20 probe, (1.7 + L/350)µm with the TP200 probe and (1.5 + L/350)µm with the SP25M scanner. The scale resolution is 0.1µm.

Thanks to the user-friendly Aberlink 3D measurement software, the training time is minimal, so that precise measurements can be carried out even without prior knowledge. Free software updates ensure that the system is always up to date.

Listing

Mönchengladbach

Mönchengladbach

1,031 km

Coordinate measuring machine

AberlinkHalo CNC

Call

Condition: new, Year of construction: 2025, functionality: fully functional, Aberlink's Halo CNC coordinate measuring machine (CMM) combines high precision with affordable metrology.

It features a bridge design and belt drive for the X, Y and Z axes, making it ideal for use in inspection departments and on the shop floor.

With travels of X 800 mm, Y 1000 or 1600 mm and Z 600 mm, the Halo CMM offers flexibility for various measurement requirements. The solid granite plate ensures high load-bearing capacity and stability.

Codpfxsvwa T Hj Agzspw

Thanks to the user-friendly Aberlink 3D measuring software, the training time is minimal, so that precise measurements can be taken even without prior knowledge. The volumetric accuracy is (2.1 + L/250)µm with the TP20 probe, (2.0 + L/250)µm with the TP200 probe and (1.8 + L/250)µm with the SP25M scanner.

The scale resolution is 0.1µm. The Halo CMM is a cost-effective solution for precise measurements in various industrial applications.

Listing

Randers

Randers

1,217 km

Aluminium cross cut saw

FOMINDUSTRIEPANDA 400

Call

Condition: excellent (used), Year of construction: 2013, Maximum saw blade : 400 mm

Digital angle display in degrees ( +/- 46 degree )

2 x pneumatic clamps

Cedpfxjxx Hwws Agzopw

Hydraulic blade feed

Engine size : 1,8 Kw

Digital display with touch screen

Hand held barcode scanner

6000 mm infeed with digital pusher

4000 mm manual outfeed with rollers

Listing

Bitburg

Bitburg

1,087 km

Machining center / nesting machine

Holzfräse BesslerAxolox

Call

Condition: as good as new (ex-display), Year of construction: 2024, Axolox 3021 CNC wood router - display machine available immediately -

in 19mm Forescolor, consisting of a router table (X-axis), gantry (Y-axis), Z-axis unit made of compact board, and a base frame, with adjustable machine feet. Router bed as a sacrificial board made of 19mm MDF. Table openings pre-prepared lengthwise and crosswise. Mechanical set consisting of profile guides including profile guide carriages, recirculating ball screws, and precision racks. All elements assembled, pre-lubricated, including a test run, and immediately ready for operation. The control set consists of control cables, energy chains, planetary gears, stepper motors, high-performance power amplifiers, power supply, and toroidal transformer, fully pre-assembled in the control cabinet, as well as sensors for each axis. Switching relays for automatic control of the existing extraction system.

Brush seals for dust protection, as well as CE-compliant safety devices with a mobile extraction system and a laser scanner mounted on one side for monitoring the work area, with a 275° and 5.5 m field range (positioning the machine in a corner of the room). A handheld control unit is equipped with all the necessary functions for operating the machine, including an emergency stop button and a deadman's switch. A tool length sensor is used to determine the tool length and change the active zero offset. A 2.2 kW high-frequency spindle includes a union nut, frequency converter, line filter, brake resistor, and collet set. A built-in monitor includes a mini PC with Windows 10 and Beamicon2 control software, as well as a mouse and keyboard, pre-installed in an ergonomic desk. A Rhino 7.0 CAD license and an Estlcam V11 CAM license, as well as all necessary documentation, will be sent by email prior to delivery.

- Milling bed designed as a vacuum table

consisting of six adjustable sub-elements. Cross table made of PE with an MDF cover plate. Vacuum pump from Becker with an output of 160 m³/h, with an oil-driven rotor. A 16 amp, 400 V AC plug is required for the vacuum pump's power connection. The customer must provide 3 mm HDF raw on both sides for the entire vacuum table

(3000 x 2100 mm) as a sacrificial plate. (Recommended use: machining coated chipboard)

- Tool set: 10 pieces

2 x 5 mm TAC double-flute cutters

8 x 4 mm solid carbide single-flute cutters

- Maintenance package:

Including a 150 ml grease gun, a 400 g cartridge of high-performance grease, a 500 ml can of silicone spray grease, and a grease nipple

- Clamping device

as an attachment for the existing high-frequency spindle. Suitable for slightly curved and particularly thin materials.

Location: From stock, 54634 Bitburg

- Available immediately -

Subject to prior sale

Cpsdpfx Agjwdny Tozow

Listing

Borken

Borken

1,027 km

6 kW short pulse laser source

TrumpfTruMicro 7050

Call

Condition: good (used), Trumpf TruMicro 6 kW Laser Source

High-performance disk laser with nanosecond pulses.

The high-performance nanosecond lasers of the TruMicro Series 7000 are based on disk laser technology and combine

short pulses and high pulse energies, even at high frequencies.

This allows you to remove layers and contaminants at maximum speed and reduce your cycle times.

Further optimize your processes by varying the repetition rate – while maintaining a constant pulse duration.

The short-pulse lasers of the TruMicro Series 7000 are the ideal tool for the efficient and economical cleaning of tire molds.

Large-area applications with high average power

Ablation, cleaning, annealing:

The lasers of the TruMicro Series 7000 demonstrate their full potential in large-area applications.

With pulse energies of up to 100 mJ, they achieve enormous layer removal rates.

A scanner ensures excellent power utilization.

Flexible laser light cables transport the light to its intended destination and facilitate laser integration.

Manufacturer: Trumpf

Type: TruMicro 7050 Laser Source

Power: 6 kW

Cooling: Water

System Input Power: 380–460 VAC, 3-phase

Laser Power: 750 W

Wavelength: 1030 nm

Pulse Energy: 80 mJ

Pulse Duration: 30 ns

Beam Quality: 20 mm

Csdpfexaktlsx Agzepw

Repetition Rate: 5 to 100 kHz

Fiber Diameter: 400 µm

IP Rating: 54

Dimensions (W x H x D): 1460 mm x 1350 mm x 730 mm

Financing through our bank is also possible.

komplett-konzept.leasingo.de

Find more items – new and used – in our shop!

International shipping costs available upon request!

Listing

Barbing

Barbing

1,505 km

Laser Sintering System

FarsoonSS403P-H

Call

Year of construction: 2023, operating hours: 10,700 h, condition: like new (used), functionality: fully functional, Build Cylinder Size: 2x 400x400x520 mm

Scanning Speed: 15,2 m/s

Scanner: High-precision three-axis digital galvo system

Laser: CO2 Laser, 1×100W

Max. Chamber Temperature: 190°C

Gewicht: ca. 3.000 kg

incl. 260kg FS3300 Powder

Cjdon Dxbyopfx Agzepw

incl. Chiller

incl. N2 Generator

incl. Breackout Station

Listing

Borken

Borken

1,034 km

Welding machine

BielomatikK3633/023 K3633 023

Call

Condition: excellent (used), Here we offer you a Bielomatik laser welding system.

Bielomatik laser welding system

Machine description:

The laser unit with integrated cooling for the laser is located in the lower left part of the machine frame.

The tools are mounted on a 2-station rotary table, which rotates 180 degrees with each cycle.

The work area with the welding station, the tool (on the rotary table) and the hold-down device for the product is located in the middle section of the machine frame.

The control cabinet is installed at the rear.

The welding station is protected against the insertion/removal area by a laser-tight cover.

The welding laser (the laser supply) is switched off when a maintenance door is opened.

The welding parts are loaded and removed manually. The welding process runs automatically.

Laser type: YLR-300-AC-Y11/IPG

The cell was used for laser welding various plastic parts (front frame).

For components measuring approx. 460 x 280 mm

Basic data

Equipment of the machine:

1 complete machine frame with cladding, substructure and protective devices, painted

Cpedpfx Agoqay Uvjzew

Adjustable machine feet, designed for transportation with forklift.

3 manual maintenance doors in the laser-safe processing area, each secured with guard door switch with guard locking.

4 manual maintenance doors underneath the machine table.

The control cabinet is permanently installed at the rear of the machine Laser system Fab. IPG

1 fiber laser 300 Wcw, at the fiber end, 1070 nm completely air-cooled.

1 power supply unit for laser unit, target beam laser and glass fiber

1 Vario-Scan for 3D welding contour

1 scanner - 20 aperture

Optics, F-Teta lens, focal length determines processing field and processing distance

2x basic tool Tool coding with transponder

Hold-down/clamping system for holding a mask with absolute path measuring system

With pneumatic clamping system for path-controlled pressing of one welding part at a time

Pneumatic air shower to protect the lens body Microbox PC427B incl. RTX (Siemens)

Pre-installed Siemens S7 software PLC

Profibus, Profinet, Ehternet, RS232 interface

15" touch panel for operating and entering data/parameters Machine lighting

Connection flange for on-site fume cupboard

Machine data:

Dimensions:

Machine W x D x H: approx. 2330 x 2350 x 2500mm

Control cabinet:

Firmly bolted to the machine frame

Space requirement BF x DF: 5400 x 5400mm

Technical Data:

Power supply:

Number of phases/rated voltage 3x400V 50Hz

Connected load 5KVA

Back-up fuse: 16A

Exhaust air:

Nominal diameter ∅160

Air volume 500-1000 m³/h

Weight approx. 2000 kg

Type: K3633/023

Condition: second-hand / used

(Changes and errors in the technical data, specifications are reserved!)

We will be happy to answer any further questions you may have on the phone.

Listing

Borken

Borken

1,034 km

Laser cutting and welding system

ScanlabPowerScan II 50i

Call

Condition: like new (used), Scanlab PowerScanII 50i

Aperture: 50 mm

Angle Encoder: Galvanometer scanner with analog position detector

Optics Wavelength Range (Standard): 9400 nm, 10600 nm

Max. Laser Power: 2500 W @ 9400 nm / 10600 nm

Typical Deflection Angle: ±0.35 rad (optical)

Dynamics

Number of Installed Tunings: 1

Typical Tuning: Fast-Vector Tuning

Tracking Delay: < 0.45 ms

Positioning Speed (f = 160 mm): 20 rad/s

Step Response (100% Full Scale):

1% Full Scale: 1.0 ms

10% Full Scale: 4.5 ms

Accuracy

Repeatability (RMS): < 4 µrad

Maximum Position Resolution: 18 bit for XY, 16 bit for Z*

Non-linearity: < 2.1 mrad / 44°

8-Hour Drift (after 30 min warmup):

Offset: < 50 µrad

Gain: < 50 ppm

Electrical / Control

Control: Galvanometer scanner, digital controller card

Control Interface (alternatives): digital SL2-100

Advanced Diagnostics: Yes (iDRIVE)

Supply Voltage: (48±2) V DC, up to 10 A each (20 A peak)

Mechanics

Scan Axes: 3-axis system with integrated varioSCAN

Housing Versions: Scan head

Connector Positions: Opposite beam exit

Weight (without lens, standard housing): 35 kg

Dimensions (L x W x H, standard housing, with varioSCAN): (433 x 268 x 266) mm³

Beam Offset: 72.72 mm

Other Features

Water Cooling: Yes

Air Cooling: Yes

Other Specifications

Operating Temperature: 25 °C ± 10 °C

Deflection Angle Deviation: < 5 mrad

Zero Position Deviation: < 5 mrad

Condition: used

Scope of delivery: (See picture)

(Specifications subject to change and errors excepted!)

Shipping & Collection:

Secure pallet shipping (upon arrangement) or local pickup possible.

Feel free to contact us by phone for further questions.

Csdpfxoxp Iw He Agzspw

Listing

Borken

Borken

1,034 km

Microwave drying balance

CEMTURBO SMART 5

Call

Condition: used, CEM

CEM Smart 5 Turbo Model 907990

Professional Microwave Moisture Analyzer for Moisture and Solids Analysis

Reliable Laboratory Analytics in Record Time

The CEM Smart 5 Turbo is a state-of-the-art microwave drying system for rapid and precise determination of moisture and solids content in a wide range of samples.

Ideally suited for applications in the food, chemical, pharmaceutical, and environmental industries, this device saves significant time while maintaining consistently high measurement accuracy.

Product features:

Turbo technology with Intellitemp™ – Optimal temperature control prevents burning or crust formation on the sample.

Fast analysis times – results within 60–180 seconds

High precision – measurement range from 0.1% to 99.9% moisture or solids

Versatile – suitable for solids, pastes, sludges, and liquids

User-friendly touchscreen operation

Interfaces – RS-232, USB, LIMS-compatible

Typical applications:

Cheese, dairy products, meat

Paints, coatings, plastics, polymers

Sludges, wastewater, organic residues

Creams, pastes, emulsions

Technical Data – CEM Smart 5 Turbo

Feature

Device type: Microwave moisture analyzer / moisture analyzer

Technology: Microwave drying with Intellitemp™ temperature control

Moisture range: 0.1% – 99.9%

Sample types: solids, liquids, pastes, sludges, emulsions

Cpodswv Ryyopfx Agzow

Analysis time: typically 1–3 minutes

Drying method: direct microwave radiation (non-rotating)

Temperature control: automatic (microwave-controlled, no fixed °C value)

Weighing unit: Optionally connectable external scale (resolution up to 0.001 g possible)

Display / Operation: color touchscreen, intuitive menu navigation

Data interfaces: RS-232, USB, network (LIMS-compatible)

Documentation: Barcode scanner & thermal printer (optional)

Power supply: 230 V / 50–60 Hz

Dimensions (W × D × H): approx. 41 × 44 × 37 cm

Weight: approx. 18 kg

Condition: used

Scope of delivery: (see picture)

(Subject to changes and errors in technical data and information!)

If you have further questions, we will gladly answer them by phone.

Listing

Borken

Borken

1,034 km

SLA printer

3D systemsiPro 8000

Call

Condition: excellent (used), 3D systems

Here we offer you a 3D printer.

Solid-state Nd: YVO4with triple frequency

Wavelength: 354.7nm

Nominal power at the laser head: 1450 mW (1000mW at the resin surface under

standard conditions)

Zaphyr TM coating system:

Process: Replaceable coating agent

Adjustment: Self-leveling and self-correcting

Production layer: Minimum 0.05mm Maximum 0.15mm

ProScan™ scanner

Edge detection (diameter at 1/e2): Nominal in standard mode 0.13mm

Detection of large lines Nominal: 0.76mm

Cedpfx Ajnkalgjgzspw

Maximum drawing speed

Edge detection: 3.5m/sec.

Detection of large lines: 25m/sec.

Build volume capacity:

RDM 750F: 650mm x 750mm x 550mm; 414l

Maximum part weight: 75kg

Power supply: 200-240VAC (alternating current), 50/60Hz single-phase, 30A

Ambient conditions

Temperature range: 20-26°C

Max. permissible fluctuation: 1°C per hour

Relative humidity: 20-50%, non-condensing

Space requirement:

Size (WxDxH), unpacked: 1260mm x 2200mm x 2280mm

Weight packed (no RDM): 1590kg

Type: iPro 8000

Condition: used

Scope of delivery: (See pictures)

(Changes and errors in the technical data, information is subject to change!)

We are happy to answer any further questions you may have over the phone.

Listing

Borken

Borken

1,034 km

High-performance solid-state disk laser

TrumpfTruDisk 4002 (4 C)

Call

Condition: used, Trumpf

TRUMPF TruDisk 4002 (4 C) High-Performance Solid-State Disk Laser with up to 4 kW Output

Type: TruDisk 4002 (4 C)

The TruDisk 4002 is a powerful, energy-efficient, and modular laser solution – ideal for industrial manufacturing environments with demanding requirements for quality, precision, and automation.

The combination of high power, excellent beam quality, and smart factory features makes it particularly attractive for modern production lines.

System type: TruDisk 4002 (4C)

Manufacturer: TRUMPF Laser GmbH + Co. KG

Year of manufacture: May 2012

Drawing number: 20-10-02-A3*

No additional tests were carried out in-house.

Operating hours could not be read out.

The laser operated flawlessly until decommissioning.

Technical features:

Output & wavelength: 80–4000 W at 1030 nm

Beam quality (BPP): typically 2 mm·mrad (up to 25 mm·mrad, depending on configuration)

Cjdpfx Aowzahdsgzjpw

Modular & compact: footprint < 1 m², modular design simplifies maintenance/service

Efficient energy & cooling systems: energy-saving modes, active power factor correction, pulse function to reduce consumption

Flexible cooling: integrated heat exchanger (5–28 °C), optional with compressor (up to 38 °C inlet temperature)

Reflection-resistant: special resonator design also suitable for highly reflective metals

Industry 4.0 capable: extensive sensor technology and data interfaces for condition monitoring, OPC UA, predictive maintenance

Application areas:

Scanner & hybrid welding (e.g. automotive body manufacturing, shipbuilding)

High-speed cutting, including on reflective metals

Flame cutting & surface processing

Laser cladding, hardening, deep penetration welding where high precision is required

Technical data:

Supply voltage: 380 V (-10%) to 460 V (+10%), 3AC + PE

Frequency: 50 – 60 Hz

Power consumption: 23 kW / 25 kVA

Rated current: 34 A at 400 V

Protection rating: IP 54

Short-circuit strength: Icn / SCCR 50 kA

Weight: 850 kg

Condition: used

Scope of delivery: (See picture)

(Specifications subject to change and errors excepted!)

We would be happy to answer any further questions by phone.

Listing

Borken

Borken

1,034 km

Bending machine

Bluhm Systemee-SolarMark FL

Call

Condition: not inspected (used), Bluhm Systeme marking lasers

Cpsdpfx Ageq Rtz Hozew

Here we offer you a Bluhm Systeme marking laser.

Bluhm Systeme marking laser fiber laser e-SolarMark FL Without function guarantee (untested)

Introduction:

The e-SolarMark FL10W and 30 W are class IV lasers in accordance with the lEC 825

and EN 60825 (standards for end-user applications). It is designed to be

integrated into a system or operated separately with a protective housing.

After installation, the laser system must meet the requirements for a protection class

product in accordance with the above-mentioned directives.

The e-SolarMark is a laser system for marking and engraving plastics,

metals and foils while stationary or in motion.

Technical specifications

e-SolarMark description

The e-SolarMark system consists of two main components:

1. the marking unit with laser head (scanning head) with focusing lens.

2. the control unit contains the power supply unit, electronic control system and firmware

for the system function, I/O slots inside.

The e-SolarMark includes a fixed galvo scanning head equipped with a lens for

a square marking field with standard dimensions of 70 X 70 mm

Laser specification in standard version

Laser Type---Fiber Laser

Laser output power---FL2 model: 19W; typical

Wavelength---1062 nm typical

Internal Modulation---20 to 80 kHz

Scanner Head Description:

Scan Head---Two galvanometric mirror scanners with hard,

highly reflective dielectric coating.

F-Theta

Lens types and their characteristics:

Lens marking field 70x70 mm to 300 x 300 mm

Focus distance B 192 mm

Working environment Conditions:

Relative humidity up to 80% non-condensing

Operating temperature 5 - 40°C

Recommended operating temperature 15-25°C

Dimensions W x H x D

Laser unit 122 x 108 x 495 mm

Control unit 520 x 380 x 215 mm

Cable length marking/control unit 3 m

Weight marking unit 5 kg

Weight of control unit 15 kg

Mains voltage

115/230 VAC. 50/60 Hz, single-phase.

Power consumption FL2 model 450W

Type: e-SolarMark FL

Condition: gebraucht / used

Scope of delivery: (see picture)

(Changes and errors in the technical data, specifications are reserved!)

We will be happy to answer any further questions you may have on the phone.

Listing

Borken

Borken

1,034 km

Laser cutting and welding system

ScanlabPowerScan II 50i

Call

Condition: like new (used), Scanlab PowerScanII 50i

Cpodpfxjxp Iybj Agzew

Aperture: 50 mm

Angle Encoder: Galvanometer scanner with analog position detector

Optics Wavelength Range (Standard): 9400 nm, 10600 nm

Max. Laser Power: 2500 W at 9400 nm, 10600 nm

Typical Deflection Angle: ±0.35 rad (optical)

Dynamics Number of Installed Tunings: 1

Typical Tuning: Fast-Vector Tuning

Tracking Delay: < 0.45 ms

Positioning Speed (f = 160 mm): 20 rad/s

Step Response (100% Full Deflection):

1% Full Deflection: 1.0 ms

10% Full Deflection: 4.5 ms

Accuracy:

Repeatability (RMS): < 4 µrad

Max. Positioning Resolution: 18 Bit for XY, 16 Bit for Z*

Nonlinearity: < 2.1 mrad / 44°

8-hr Drift (after 30 min):

Offset: < 50 µrad

Gain: < 50 ppm

Electrical / Control

Control: Galvanometer scanner, digital controller card

Control Interface (alternatives): Digital SL2-100

Advanced Diagnostics: Yes (iDRIVE)

Power Supply: (48±2) V DC, max. 10 A each (20 A peak current)

Mechanical

Scan Axes: 3-axis system with integrated varioSCAN

Housing Variants: Scan head

Connector Positions: Opposite to beam exit

Weight without Lens (standard housing): 35 kg

Dimensions (L x W x H, standard housing): (433 x 268 x 266) mm (with varioSCAN)

Beam Offset: 72.72 mm

Other Features

Water cooling: Yes

Air cooling: Yes

Other Specifications

Operating Temperature: 25 °C ± 10 °C

Deflection Angle Deviation: < 5 mrad

Zero Position Deviation: < 5 mrad

Condition: used

Scope of delivery: (See picture)

(Technical data subject to change. Information may contain errors!)

Shipping & Collection:

Secure pallet shipping (by arrangement) or local pickup possible.

For further questions, we will be happy to assist you by phone.

Trust Seal

Dealers certified through Machineseeker

Listing

Lauda-Königshofen

Lauda-Königshofen

1,312 km

Label Letterpress

ShikiPC 45/4

Call

Condition: good (used), label letterpress, 4 colors, 3 colors, 2 colors or 1 color, punching unit, 2 embossing plates, various mounting plates, laminator, UV - dryer, unwinder, slitter rewinder, scanner camera, in a good condition, available immediately

Cpjdpfx Aeiphigsgzsw

Listing

Wrocław

Wrocław

1,732 km

Magnet for lifting

MHS (VanRiet)

Call

Condition: used, Year of construction: 2017, functionality: fully functional, The bankruptcy administrator is offering for sale:

MHS (VanRiet) Sorter – dismantled and prepared for transport

E-commerce parcel sorter manufactured by VanRiet (Van Riet Material Handling Systems BV). Disassembled and ready for transport.

The sorter includes:

a) three roller conveyor lines with 72 shipping stations;

b) one roller conveyor line;

c) a removal line (belt conveyor) for excess cartons running parallel to each shipping line (3 lines) and the returns line (1 line); this leads outside the building to a compactor container (the container is not part of this listing);

d) one chute line for parcels to 46 locations, equipped with a scanner for determining the size and weight of individual parcels.

The sorter has a throughput of up to 6,000 parcels per hour. The valuation includes additional photographic documentation illustrating the technical condition of the appraised items as well as detailed components of the sorter.

The sorter operates by assigning and preparing parcels for shipment to specified courier companies. Goods should be packed either in a box or polybag. An operator scans the goods and prints a label for each box or polybag. Information about the box/container is sent from the sorter to the MHS (VanRiet) controller. Meanwhile, the operator loads the box/container onto the loading line. Products are conveyed downstream, then merged onto a single conveyor line. At the merger point, a scanner equipped with a camera identifies the item, measures its dimensions, and the product is then sorted to its designated output (pickup location for ready-to-ship parcels).

The MHS (VanRiet) sorter is suitable for handling products of various dimensions. It handles cartons with the following range of sizes: length 150–800 mm, width 100–600 mm, height 10–400 mm, and weight from 0.25 kg up to 32 kg. Polybags with the following range: length 200–550 mm, width 150–550 mm, height 13–400 mm, and weight from 0.25 kg up to 10 kg.

Cpodpfx Ajwaimysgzow

The MHS (VanRiet) sorter processes up to 6,000 parcels per hour, with shipments sorted into one of 46 directions. A diagram showing the general layout of the sorter is provided below. Lines 1–3 are outbound shipping lines, and line 4 (added in 2020) is used for processing returns.

Listing

Wiefelstede

Wiefelstede

1,085 km

Time recording device

BENZINGBDE-Terminal

Call

Condition: good (used), Time recording device, terminal

Cpedpfjb A Imtox Agzew

-Number: 1x time recording device available

Price: per piece

-with Datalogic touch 90 handheld scanner

Listing

Germany

Germany

1,447 km

Throughfeed machining center

WeekeOptimat BHX 500

Call

Condition: excellent (used), Year of construction: 2009, Weeke BHX 500 – Operator Side Right

Weeke Machining Center, each with one machining support above and below

Infeed table with automatic workpiece feeding and positioning

WORKPIECE DIMENSIONS

Min. workpiece length: 200 mm

Max. workpiece length: 2,500 mm

Min. workpiece width: 70 mm

Max. workpiece width: 1,000 mm

Min. workpiece thickness: 8 mm (2*4 mm)

Max. workpiece thickness: 80 mm

Max. workpiece stacking: 2 pieces

Machine configuration:

2V21 HIGH SPEED 7500

Vertical drilling unit arranged in both upper and lower machining supports, each with 21 drilling spindles (individually controllable with variable speed range).

2H4X/1Y

Horizontal drilling unit arranged in both upper and lower machining supports, each with 10 spindles individually selectable via program.

Each with 8 drilling spindles: in X-direction

Each with 2 drilling spindles: in Y-direction

N2 X-Y 90°

Grooving saw unit arranged in both upper and lower machining supports for machining operations in the X-Y direction, swiveling 90°.

Cutting depth: 30 mm

ADDITIONAL NOTE ON GROOVING SAW BLADE

Codpfsx S Hzlsx Agzopw

The saw blade width can be 8.4 mm. The cutting cross-section must not exceed 70 mm².

F2-ETP-6 KW

Milling unit arranged in both upper and lower machining supports, suitable for receiving shank tools.

Manual tool change.

Tool clamping: manual, Hydro quick-clamping system ETP 25

Rotation direction: right/left

Speed: 6,000 – 18,000 rpm, stepless programmable

Machining up to 3,000 mm

Infeed table with automatic workpiece feeding and positioning

Workpiece discharge area with cross belt conveyor and lifting arms

– Workpiece length measurement in the machine

– Movable operator terminal

– Barcode software incl. scanner

We make it easier for you to find: "crossfield scanner"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Crossfield Scanner (321)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month