Used Advance 3800 for sale (3,366)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Heteren

Heteren

958 km

Standard tractor unit

VOLVOFH 460 Globetrotter XL i-Save

Call

Condition: used, functionality: fully functional, mileage: 381,597 km, power: 338 kW (459.55 HP), first registration: 09/2022, fuel type: diesel, overall weight: 8,461 kg, axle configuration: 4x2, wheelbase: 380 mm, color: white, gearing type: automatic, emission class: euro6, Year of construction: 2022, number of cylinders: 6, cubic capacity: 12,777 cm³, steering wheel position: left, Equipment: full service history, power assisted steering, Features

I-See Predictive Cruise Control - Map based topography information

Cab: Globetrotter XL

Ksdpfx Agex Upzgs Uell

Battery system type: Single energy battery system (2 batteries)

Engine & Turbo Package: D13K460TC Turbo-compound diesel engine, 460hp, 2600Nm SCR and EGR

Gearbox: I-shift Automated 12-speed - GCW 60 tonne

Automatic transmission manual shift options: Standard transmission shift - I-Shift or Powertronic

Engine Brake Type: Volvo Engine Brake - Retardation D13K-375kW/D16-500kW

Advanced Emergency Brake System AEBS

Driver attention support

Driver comfort

Cab Climate Unit: Electrically controlled air conditioning with sun sensor

Driver Seat: Comfort 4: suspended - belt in seat

Passenger seat: Comfort 4: suspended - belt in seat

Top bunk: Height adjustable foldable top bunk 700 x 1900mm

Lower bunk: Lower bunk 815mm wide in the centre

Aux. cab heater: 1.8kW Air to air

Refrigerator: 33 litre under bunk mounted fridge / freezer with dividers

Technical specifications

Continental VDO 4.1 smart tachograph version 2 - legal demand from 21/08/2023

Front Axle Tyre Size: 315/70R22.5

Drive Axle Tyre Size: 315/70R22.5

Fifth Wheel Type: Jost JSK 37 cast fixed or sliding fifth wheel

Wheelbase: 3800 mm

Drive Axle Ratio: 2.31:1

Fuel tank - RHS: 610 LITRE, RIGHT SIDE FUEL TANK

Fuel tank - LHS: 650 LITRE, LEFT SIDE FUEL TANK

Plastic AdBlue Tank: 65 litre under/behind cab

Cruise Control: Eco fleet software - with speed 85, I-See and push button I-shift

Technology

Secondary Information Display: Secondary colour information display

FMS gateway: FMS gateway for Fleet Management System

Exterior

Headlamps: LED headlamps

Daytime Running Lights: V-shaped

Front fog lamps: Front fog lights - white

Cornering lights: Static corner lights - works with indicator at low speed to light up direction

Air Deflector - Roof: Roof air deflector

Side air deflector: Cab side air deflector - long tractor

Listing

Heteren

Heteren

958 km

Standard tractor unit

VOLVOFH 460 Globetrotter XL Varios i-Save

Call

Condition: used, functionality: fully functional, mileage: 444,664 km, power: 338 kW (459.55 HP), first registration: 05/2022, fuel type: diesel, overall weight: 8,441 kg, axle configuration: 4x2, wheelbase: 380 mm, color: white, gearing type: automatic, emission class: euro6, Year of construction: 2022, number of cylinders: 6, cubic capacity: 12,777 cm³, steering wheel position: left, Equipment: full service history, power assisted steering, Features

I-See Predictive Cruise: I-See Predictive Cruise Control - Map based topography information

Cab: Globetrotter XL

Battery system type: Single energy battery system (2 batteries)

Engine & Turbo Package: D13K460TC Turbo-compound diesel engine, 460hp, 2600Nm SCR and EGR

Gearbox: I-shift Automated 12-speed - GCW 60 tonne

Automatic transmission manual shift options: Standard transmission shift - I-Shift or Powertronic

Engine Brake Type: Volvo Engine Brake - Retardation D13K-375kW/D16-500kW

Advanced Emergency Brake System AEBS

Driver comfort

Cab Climate Unit: Electrically controlled air conditioning with sun sensor

Driver Seat: Comfort 4: suspended - belt in seat

Passenger seat: Comfort 4: suspended - belt in seat

Top bunk: Height adjustable foldable top bunk 700 x 1900mm

Lower bunk: Lower bunk 815mm wide in the centre

Aux. cab heater: 1.8kW Air to air

Refrigerator: 33 litre under bunk mounted fridge / freezer with dividers

Driver attention support

Technical specifications

Continental VDO 4.1 smart tachograph version 2 - legal demand from 21/08/2023

Front Axle Tyre Size: 315/60R22.5

Drive Axle Tyre Size: 315/60R22.5

Fifth Wheel Type: SAF-Holland/+GF+ SK-S 36.20 cast fixed fifth wheel

Wheelbase: 3800 mm

Drive Axle Ratio: 2.17:1

Fuel tank - RHS: 570litre aluminium diameter 710mm

Fuel tank - LHS: 900 LITRE, LEFT SIDE FUEL TANK WITH STEPS

Plastic AdBlue Tank: 65 litre under/behind cab

Cruise Control: Eco fleet software - with speed 85, I-See and push button I-shift

Technology

Secondary Information Display: Secondary colour information display

FMS gateway: FMS gateway for Fleet Management System

Ksdpfxex Upm As Ag Uoll

Exterior

Headlamps: LED headlamps

Daytime Running Lights: V-shaped

Front fog lamps: Front fog lights - white

Cornering lights: Static corner lights - works with indicator at low speed to light up direction

Air Deflector - Roof: Roof air deflector

Side air deflector: Cab side air deflector - long tractor

Listing

Heteren

Heteren

958 km

Standard tractor unit

VOLVOFH 460 Globetrotter XL i-Save

Call

Condition: used, functionality: fully functional, mileage: 449,384 km, power: 338 kW (459.55 HP), first registration: 08/2022, fuel type: diesel, overall weight: 8,461 kg, axle configuration: 4x2, wheelbase: 380 mm, color: white, gearing type: automatic, emission class: euro6, Year of construction: 2022, number of cylinders: 6, cubic capacity: 12,777 cm³, steering wheel position: left, Equipment: full service history, power assisted steering, Features

I-See Predictive Cruise Control - Map based topography information

Cab: Globetrotter XL

Battery system type: Single energy battery system (2 batteries)

Engine & Turbo Package: D13K460TC Turbo-compound diesel engine, 460hp, 2600Nm SCR and EGR

Gearbox: I-shift Automated 12-speed - GCW 60 tonne

Automatic transmission manual shift options: Standard transmission shift - I-Shift or Powertronic

Engine Brake Type: Volvo Engine Brake - Retardation D13K-375kW/D16-500kW

Advanced Emergency Brake System AEBS

Driver attention support

Driver comfort

Cab Climate Unit: Electrically controlled air conditioning with sun sensor

Driver Seat: Comfort 4: suspended - belt in seat

Kljdpfx Asx Upmpog Uel

Passenger seat: Comfort 4: suspended - belt in seat

Top bunk: Height adjustable foldable top bunk 700 x 1900mm

Lower bunk: Lower bunk 815mm wide in the centre

Aux. cab heater: 1.8kW Air to air

Refrigerator: 33 litre under bunk mounted fridge / freezer with dividers

Technical specifications

Continental VDO 4.1 smart tachograph version 2 - legal demand from 21/08/2023

Front Axle Tyre Size: 315/70R22.5

Drive Axle Tyre Size: 315/70R22.5

Fifth Wheel Type: Jost JSK 37 cast fixed or sliding fifth wheel

Wheelbase: 3800 mm

Drive Axle Ratio: 2.31:1

Fuel tank - RHS: 610 LITRE, RIGHT SIDE FUEL TANK

Fuel tank - LHS: 650 LITRE, LEFT SIDE FUEL TANK

Plastic AdBlue Tank: 65 litre under/behind cab

Cruise Control: Eco fleet software - with speed 85, I-See and push button I-shift

Technology

Secondary Information Display: Secondary colour information display

FMS gateway: FMS gateway for Fleet Management System

Exterior

Headlamps: LED headlamps

Daytime Running Lights: V-shaped

Front fog lamps: Front fog lights - white

Cornering lights: Static corner lights - works with indicator at low speed to light up direction

Air Deflector - Roof: Roof air deflector

Side air deflector: Cab side air deflector - long tractor

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Heteren

Heteren

958 km

Standard tractor unit

VOLVOFH 460 Globetrotter XL i-Save

Call

Condition: used, functionality: fully functional, mileage: 432,468 km, power: 338 kW (459.55 HP), first registration: 09/2022, fuel type: diesel, overall weight: 8,461 kg, axle configuration: 4x2, wheelbase: 380 mm, color: white, gearing type: automatic, emission class: euro6, Year of construction: 2022, number of cylinders: 6, cubic capacity: 12,777 cm³, steering wheel position: left, Equipment: full service history, power assisted steering, Features

I-See Predictive Cruise Control - Map based topography information

Cab: Globetrotter XL

Battery system type: Single energy battery system (2 batteries)

Engine & Turbo Package: D13K460TC Turbo-compound diesel engine, 460hp, 2600Nm SCR and EGR

Gearbox: I-shift Automated 12-speed - GCW 60 tonne

Automatic transmission manual shift options: Standard transmission shift - I-Shift or Powertronic

Engine Brake Type: Volvo Engine Brake - Retardation D13K-375kW/D16-500kW

Advanced Emergency Brake System AEBS

Driver attention support

Driver comfort

Kedpfxex Upmio Ag Uell

Cab Climate Unit: Electrically controlled air conditioning with sun sensor

Driver Seat: Comfort 4: suspended - belt in seat

Passenger seat: Comfort 4: suspended - belt in seat

Top bunk: Height adjustable foldable top bunk 700 x 1900mm

Lower bunk: Lower bunk 815mm wide in the centre

Aux. cab heater: 1.8kW Air to air

Refrigerator: 33 litre under bunk mounted fridge / freezer with dividers

Technical specifications

Continental VDO 4.1 smart tachograph version 2 - legal demand from 21/08/2023

Front Axle Tyre Size: 315/70R22.5

Drive Axle Tyre Size: 315/70R22.5

Fifth Wheel Type: Jost JSK 37 cast fixed or sliding fifth wheel

Wheelbase: 3800 mm

Drive Axle Ratio: 2.31:1

Fuel tank - RHS: 610 LITRE, RIGHT SIDE FUEL TANK

Fuel tank - LHS: 650 LITRE, LEFT SIDE FUEL TANK

Plastic AdBlue Tank: 65 litre under/behind cab

Cruise Control: Eco fleet software - with speed 85, I-See and push button I-shift

Technology

Secondary Information Display: Secondary colour information display

FMS gateway: FMS gateway for Fleet Management System

Exterior

Headlamps: LED headlamps

Daytime Running Lights: V-shaped

Front fog lamps: Front fog lights - white

Cornering lights: Static corner lights - works with indicator at low speed to light up direction

Air Deflector - Roof: Roof air deflector

Side air deflector: Cab side air deflector - long tractor

Listing

Heteren

Heteren

958 km

Standard tractor unit

VOLVOFH 460 Globetrotter XL i-Save

Call

Condition: used, functionality: fully functional, mileage: 416,591 km, power: 338 kW (459.55 HP), first registration: 06/2022, fuel type: diesel, overall weight: 8,461 kg, axle configuration: 4x2, wheelbase: 380 mm, color: white, gearing type: automatic, emission class: euro6, Year of construction: 2022, number of cylinders: 6, cubic capacity: 12,777 cm³, steering wheel position: left, Equipment: full service history, power assisted steering, Features

I-See Predictive Cruise Control - Map based topography information

Cab: Globetrotter XL

Battery system type: Single energy battery system (2 batteries)

Engine & Turbo Package: D13K460TC Turbo-compound diesel engine, 460hp, 2600Nm SCR and EGR

Gearbox: I-shift Automated 12-speed - GCW 60 tonne

Automatic transmission manual shift options: Standard transmission shift - I-Shift or Powertronic

Engine Brake Type: Volvo Engine Brake - Retardation D13K-375kW/D16-500kW

Advanced Emergency Brake System AEBS

Driver attention support

Driver comfort

Cab Climate Unit: Electrically controlled air conditioning with sun sensor

Driver Seat: Comfort 4: suspended - belt in seat

Passenger seat: Comfort 4: suspended - belt in seat

Top bunk: Height adjustable foldable top bunk 700 x 1900mm

Lower bunk: Lower bunk 815mm wide in the centre

Aux. cab heater: 1.8kW Air to air

Refrigerator: 33 litre under bunk mounted fridge / freezer with dividers

Technical specifications

Continental VDO 4.1 smart tachograph version 2 - legal demand from 21/08/2023

Front Axle Tyre Size: 315/70R22.5

Drive Axle Tyre Size: 315/70R22.5

Fifth Wheel Type: Jost JSK 37 cast fixed or sliding fifth wheel

Wheelbase: 3800 mm

Drive Axle Ratio: 2.31:1

Fuel tank - RHS: 610 LITRE, RIGHT SIDE FUEL TANK

Fuel tank - LHS: 650 LITRE, LEFT SIDE FUEL TANK

Plastic AdBlue Tank: 65 litre under/behind cab

Cruise Control: Eco fleet software - with speed 85, I-See and push button I-shift

Kljdpfxsx Upmcs Ag Ujl

Technology

Secondary Information Display: Secondary colour information display

FMS gateway: FMS gateway for Fleet Management System

Exterior

Headlamps: LED headlamps

Daytime Running Lights: V-shaped

Front fog lamps: Front fog lights - white

Cornering lights: Static corner lights - works with indicator at low speed to light up direction

Air Deflector - Roof: Roof air deflector

Side air deflector: Cab side air deflector - long tractor

Discover more used machines

Listing

Heteren

Heteren

958 km

Standard tractor unit

VOLVOFH 460 Globetrotter XL i-Save

Call

Condition: used, functionality: fully functional, mileage: 381,444 km, power: 338 kW (459.55 HP), first registration: 11/2022, fuel type: diesel, overall weight: 8,510 kg, axle configuration: 4x2, wheelbase: 380 mm, color: white, gearing type: automatic, emission class: euro6, Year of construction: 2022, number of cylinders: 6, cubic capacity: 12,777 cm³, steering wheel position: left, Equipment: full service history, power assisted steering, Features

Predictive Cruise Control: I-See. Map based topography information.

Cab: Globetrotter XL Cab, extra high sleeper.

2 x 210 Ah - AGM Absorbent Glass-fibre material type.

Battery conditioner.

D13K460TC Turbo-compound diesel engine, 460hp, 2600Nm SCR and EGR.

EURO 6.

I-Shift Automated 12-speed - GCW 60 tonne.

Standard transmission shift - I-Shift.

Volvo Engine Brake - Retardation D13K-375kW/D16-500kW.

Advanced Emergency Brake System AEBS

Driver attention support

Driver comfort

Electrically controlled air conditioning with sun sensor.

Comfortable, suspended driver seat with belt.

Comfortable suspended Passenger seat with seatbelt mounted in seat.

Height adjustable foldable top bunk 700 x 1900mm.

Lower bunk 815mm wide in the centre.

Cab parking heater - 1.8kW Air to air.

33 litre under bunk mounted fridge / freezer with dividers.

Technical specifications

Continental VDO 4.1 smart tachograph version 2 - legal demand from 21/08/2023

Forward collision warning with AEBS advanced emergency brake system.

Front tyres - 315/70 R22.5.

Ksdpjx Tzcgofx Ag Ujll

Rear tyres - 315/70 R22.5.

Jost JSK 37 cast fixed or sliding fifth wheel.

Wheelbase 3800 mm.

900 litre, left side fuel tank with steps.

65 litre AdBlue tank under/behind cab.

570 litre, right side fueltank.

Speed limiter setting 90 km/h - 56mph.

Technology

Secondary colour information display.

FMS gateway for Fleet Management System.

Exterior

LED Headlights. Automatic headlight switching between day running light and low beam.

Front fog lights - white.

Listing

Heteren

Heteren

958 km

Standard tractor unit

VOLVOFH 460 Globetrotter XL i-Save

Call

Condition: used, functionality: fully functional, mileage: 429,774 km, power: 338 kW (459.55 HP), first registration: 05/2022, fuel type: diesel, overall weight: 8,461 kg, axle configuration: 4x2, wheelbase: 380 mm, color: white, gearing type: automatic, emission class: euro6, Year of construction: 2022, number of cylinders: 6, cubic capacity: 12,777 cm³, steering wheel position: left, Equipment: full service history, power assisted steering, Features

I-See Predictive Cruise Control - Map based topography information

Cab: Globetrotter XL

Battery system type: Single energy battery system (2 batteries)

Engine & Turbo Package: D13K460TC Turbo-compound diesel engine, 460hp, 2600Nm SCR and EGR

Gearbox: I-shift Automated 12-speed - GCW 60 tonne

Automatic transmission manual shift options: Standard transmission shift - I-Shift or Powertronic

Engine Brake Type: Volvo Engine Brake - Retardation D13K-375kW/D16-500kW

Advanced Emergency Brake System AEBS

Driver attention support

Driver comfort

Cab Climate Unit: Electrically controlled air conditioning with sun sensor

Driver Seat: Comfort 4: suspended - belt in seat

Passenger seat: Comfort 4: suspended - belt in seat

Top bunk: Height adjustable foldable top bunk 700 x 1900mm

Lower bunk: Lower bunk 815mm wide in the centre

Aux. cab heater: 1.8kW Air to air

Refrigerator: 33 litre under bunk mounted fridge / freezer with dividers

Technical specifications

Continental VDO 4.1 smart tachograph version 2 - legal demand from 21/08/2023

Front Axle Tyre Size: 315/70R22.5

Drive Axle Tyre Size: 315/70R22.5

Fifth Wheel Type: Jost JSK 37 cast fixed or sliding fifth wheel

Wheelbase: 3800 mm

Drive Axle Ratio: 2.31:1

Fuel tank - RHS: 610 LITRE, RIGHT SIDE FUEL TANK

Fuel tank - LHS: 650 LITRE, LEFT SIDE FUEL TANK

Klsdpfx Agox Tzcao Uol

Plastic AdBlue Tank: 65 litre under/behind cab

Cruise Control: Eco fleet software - with speed 85, I-See and push button I-shift

Technology

Secondary Information Display: Secondary colour information display

FMS gateway: FMS gateway for Fleet Management System

Exterior

Headlamps: LED headlamps

Daytime Running Lights: V-shaped

Front fog lamps: Front fog lights - white

Cornering lights: Static corner lights - works with indicator at low speed to light up direction

Air Deflector - Roof: Roof air deflector

Side air deflector: Cab side air deflector - long tractor

Listing

Heteren

Heteren

958 km

Standard tractor unit

VOLVOFH 460 Globetrotter XL i-Save

Call

Condition: used, functionality: fully functional, mileage: 376,142 km, power: 338 kW (459.55 HP), first registration: 10/2022, fuel type: diesel, overall weight: 8,510 kg, axle configuration: 4x2, wheelbase: 380 mm, color: white, gearing type: automatic, emission class: euro6, Year of construction: 2022, number of cylinders: 6, cubic capacity: 12,777 cm³, steering wheel position: left, Equipment: full service history, power assisted steering, Features

Predictive Cruise Control: I-See. Map based topography information.

Cab: Globetrotter XL Cab, extra high sleeper.

2 x 210 Ah - AGM Absorbent Glass-fibre material type.

Battery conditioner.

D13K460TC Turbo-compound diesel engine, 460hp, 2600Nm SCR and EGR.

EURO 6.

Klsdpfxex Ty T Re Ag Ujl

I-Shift Automated 12-speed - GCW 60 tonne.

Standard transmission shift - I-Shift.

Volvo Engine Brake - Retardation D13K-375kW/D16-500kW.

Advanced Emergency Brake System AEBS

Driver attention support

Driver comfort

Electrically controlled air conditioning with sun sensor.

Comfortable, suspended driver seat with belt.

Comfortable suspended Passenger seat with seatbelt mounted in seat.

Height adjustable foldable top bunk 700 x 1900mm.

Lower bunk 815mm wide in the centre.

Cab parking heater - 1.8kW Air to air.

33 litre under bunk mounted fridge / freezer with dividers.

Technical specifications

Continental VDO 4.1 smart tachograph version 2 - legal demand from 21/08/2023

Forward collision warning with AEBS advanced emergency brake system.

Front tyres - 315/70 R22.5.

Rear tyres - 315/70 R22.5.

Jost JSK 37 cast fixed or sliding fifth wheel.

Wheelbase 3800 mm.

900 litre, left side fuel tank with steps.

65 litre AdBlue tank under/behind cab.

570 litre, right side fueltank.

Speed limiter setting 90 km/h - 56mph.

Technology

Secondary colour information display.

FMS gateway for Fleet Management System.

Exterior

LED Headlights. Automatic headlight switching between day running light and low beam.

Front fog lights - white.

Listing

Heteren

Heteren

958 km

Standard tractor unit

VOLVOFH 460 Globetrotter XL i-Save I-ParkCool

Call

Condition: used, functionality: fully functional, mileage: 391,641 km, power: 338 kW (459.55 HP), first registration: 07/2022, fuel type: diesel, overall weight: 8,461 kg, axle configuration: 4x2, wheelbase: 380 mm, color: white, gearing type: automatic, emission class: euro6, Year of construction: 2022, number of cylinders: 6, cubic capacity: 12,777 cm³, steering wheel position: left, Equipment: full service history, power assisted steering, Features

I-See Predictive Cruise Control - Map based topography information

Cab: Globetrotter XL

Battery system type: Single energy battery system (2 batteries)

Engine & Turbo Package: D13K460TC Turbo-compound diesel engine, 460hp, 2600Nm SCR and EGR

Gearbox: I-shift Automated 12-speed - GCW 60 tonne

Automatic transmission manual shift options: Standard transmission shift - I-Shift or Powertronic

Engine Brake Type: Volvo Engine Brake - Retardation D13K-375kW/D16-500kW

Advanced Emergency Brake System AEBS

Driver attention support

Driver comfort

Ksdpjx Ty T Djfx Ag Usll

Cab Climate Unit: Electrically controlled air conditioning with sun sensor

Driver Seat: Comfort 4: suspended - belt in seat

Passenger seat: Comfort 4: suspended - belt in seat

Top bunk: Height adjustable foldable top bunk 700 x 1900mm

Lower bunk: Lower bunk 815mm wide in the centre

Aux. cab heater: 1.8kW Air to air

Refrigerator: 33 litre under bunk mounted fridge / freezer with dividers

I-Park Cool

Technical specifications

Continental VDO 4.1 smart tachograph version 2 - legal demand from 21/08/2023

Front Axle Tyre Size: 315/70R22.5

Drive Axle Tyre Size: 315/70R22.5

Fifth Wheel Type: Jost JSK 37 cast fixed or sliding fifth wheel

Wheelbase: 3800 mm

Drive Axle Ratio: 2.31:1

Fuel tank - RHS: 610 LITRE, RIGHT SIDE FUEL TANK

Fuel tank - LHS: 650 LITRE, LEFT SIDE FUEL TANK

Plastic AdBlue Tank: 65 litre under/behind cab

Cruise Control: Eco fleet software - with speed 85, I-See and push button I-shift

Technology

Secondary Information Display: Secondary colour information display

FMS gateway: FMS gateway for Fleet Management System

Exterior

Headlamps: LED headlamps

Daytime Running Lights: V-shaped

Front fog lamps: Front fog lights - white

Cornering lights: Static corner lights - works with indicator at low speed to light up direction

Air Deflector - Roof: Roof air deflector

Side air deflector: Cab side air deflector - long tractor

Listing

Heteren

Heteren

958 km

Standard tractor unit

VOLVOFH 460 Globetrotter XL Varios i-Save

Call

Condition: used, functionality: fully functional, mileage: 307,486 km, power: 338 kW (459.55 HP), first registration: 05/2022, fuel type: diesel, overall weight: 8,441 kg, axle configuration: 4x2, wheelbase: 380 mm, color: white, gearing type: automatic, emission class: euro6, Year of construction: 2022, number of cylinders: 6, cubic capacity: 12,777 cm³, steering wheel position: left, Equipment: full service history, power assisted steering, Features

I-See Predictive Cruise: I-See Predictive Cruise Control - Map based topography information

Cab: Globetrotter XL

Battery system type: Single energy battery system (2 batteries)

Engine & Turbo Package: D13K460TC Turbo-compound diesel engine, 460hp, 2600Nm SCR and EGR

Gearbox: I-shift Automated 12-speed - GCW 60 tonne

Automatic transmission manual shift options: Standard transmission shift - I-Shift or Powertronic

Engine Brake Type: Volvo Engine Brake - Retardation D13K-375kW/D16-500kW

Advanced Emergency Brake System AEBS

Driver comfort

Cab Climate Unit: Electrically controlled air conditioning with sun sensor

Driver Seat: Comfort 4: suspended - belt in seat

Passenger seat: Comfort 4: suspended - belt in seat

Top bunk: Height adjustable foldable top bunk 700 x 1900mm

Kodpox Ty Tqefx Ag Uell

Lower bunk: Lower bunk 815mm wide in the centre

Aux. cab heater: 1.8kW Air to air

Refrigerator: 33 litre under bunk mounted fridge / freezer with dividers

Driver attention support

Technical specifications

Continental VDO 4.1 smart tachograph version 2 - legal demand from 21/08/2023

Front Axle Tyre Size: 315/60R22.5

Drive Axle Tyre Size: 315/60R22.5

Fifth Wheel Type: SAF-Holland/+GF+ SK-S 36.20 cast fixed fifth wheel

Wheelbase: 3800 mm

Drive Axle Ratio: 2.17:1

Fuel tank - RHS: 570litre aluminium diameter 710mm

Fuel tank - LHS: 900 LITRE, LEFT SIDE FUEL TANK WITH STEPS

Plastic AdBlue Tank: 65 litre under/behind cab

Cruise Control: Eco fleet software - with speed 85, I-See and push button I-shift

Technology

Secondary Information Display: Secondary colour information display

FMS gateway: FMS gateway for Fleet Management System

Exterior

Headlamps: LED headlamps

Daytime Running Lights: V-shaped

Front fog lamps: Front fog lights - white

Cornering lights: Static corner lights - works with indicator at low speed to light up direction

Air Deflector - Roof: Roof air deflector

Side air deflector: Cab side air deflector - long tractor

Listing

Heteren

Heteren

958 km

Standard tractor unit

VOLVOFH 460 XL Cab Varios, i-Save I-ParkCool

Call

Condition: used, functionality: fully functional, mileage: 325,522 km, power: 338 kW (459.55 HP), first registration: 10/2022, fuel type: diesel, overall weight: 8,510 kg, axle configuration: 4x2, wheelbase: 380 mm, color: white, gearing type: automatic, emission class: euro6, Year of construction: 2022, number of cylinders: 6, cubic capacity: 12,777 cm³, steering wheel position: left, Equipment: full service history, power assisted steering, Features

I-See Predictive Cruise: I-See Predictive Cruise Control - Map based topography information

Cab: Globetrotter XL

Battery system type: Single energy battery system (2 batteries)

Engine & Turbo Package: D13K460TC Turbo-compound diesel engine, 460hp, 2600Nm SCR and EGR

Gearbox: I-shift Automated 12-speed - GCW 60 tonne

Automatic transmission manual shift options: Standard transmission shift - I-Shift or Powertronic

Engine Brake Type: Volvo Engine Brake - Retardation D13K-375kW/D16-500kW

Advanced Emergency Brake System AEBS

Driver comfort

Cab Climate Unit: Electrically controlled air conditioning with sun sensor

Driver Seat: Comfort 4: suspended - belt in seat

Passenger seat: Comfort 4: suspended - belt in seat

Top bunk: Height adjustable foldable top bunk 700 x 1900mm

Lower bunk: Lower bunk 815mm wide in the centre

Aux. cab heater: 1.8kW Air to air

Refrigerator: 33 litre under bunk mounted fridge / freezer with dividers

I-park cooling

Technical specifications

Continental VDO 4.1 smart tachograph version 2 - legal demand from 21/08/2023

Front Axle Tyre Size: 315/60R22.5

Drive Axle Tyre Size: 315/60R22.5

Fifth Wheel Type: SAF-Holland/+GF+ SK-S 36.20 cast fixed fifth wheel

Wheelbase: 3800 mm

Drive Axle Ratio: 2.17:1

Fuel tank - RHS: 570litre aluminium diameter 710mm

Fuel tank - LHS: 900 LITRE, LEFT SIDE FUEL TANK WITH STEPS

Plastic AdBlue Tank: 65 litre under/behind cab

Cruise Control: Eco fleet software - with speed 85, I-See and push button I-shift

Technology

Secondary Information Display: Secondary colour information display

FMS gateway: FMS gateway for Fleet Management System

Driver attention support

Kodpfxjx Ty Tke Ag Uoll

Exterior

Headlamps: LED headlamps

Daytime Running Lights: V-shaped

Front fog lamps: Front fog lights - white

Cornering lights: Static corner lights - works with indicator at low speed to light up direction

Air Deflector - Roof: Roof air deflector

Side air deflector: Cab side air deflector - long tractor

Listing

Stuhr

Stuhr

1,132 km

Bale press

PrestoCC 40 M

Call

Condition: good (used), Year of construction: 2017, operating hours: 1,640 h, functionality: fully functional, Baler Presto CC 40 M

Technical specifications:

Manufacturer: Presto

Model: CC 40 M

Year of manufacture: 2017

Pressing force: 40 t

Cycle time: 34 s

Drive power: 15 kW

Feed opening: 1080 x 1100 mm

Feed volume: 0.85 m³

Tying: 4-fold, polyester strapping, manual

Throughput at bulk density of

35 kg/m³ – 1.8 t/h

60 kg/m³ – 2.5 t/h

100 kg/m³ – 3.1 t/h

Bale dimensions: 750 x 1100 mm

Bale weight: 400 kg

Dimensions: 3650 x 1590 x 2010 mm (LxWxH)

Machine weight: approx. 3800 kg

Materials: Paper, cardboard, film

The baler is in good condition. It has been inspected and tested by us. A video is available on our website or YouTube channel. The operating manual and CE declaration are available.

Note: Channel exit is fully automatic and self-regulating.

Inspections, including powered demonstrations, are possible at any time by prior arrangement. Upon request, we can also perform tests with your material for a nominal fee.

If you have any questions about the machine, we are happy to assist you by phone from Monday to Thursday between 08:00 and 14:00, and Friday from 08:00 to 13:00.

Please note:

Kljdox Uzxkspfx Ag Usl

All technical data are based on manufacturer information. We do not assume any liability for the supplied information or possible errors.

This offer is subject to change, prior sale excepted, and may be withdrawn at any time.

Inspections are available by appointment.

Sale is ex works, advance payment required, without warranty or guarantee.

Listing

Heteren

Heteren

958 km

Standard tractor unit

VOLVOFH 500 Globetrotter XL

Call

Condition: used, functionality: fully functional, mileage: 463,932 km, power: 368 kW (500.34 HP), first registration: 04/2022, fuel type: diesel, overall weight: 8,479 kg, axle configuration: 4x2, wheelbase: 380 mm, color: white, gearing type: automatic, emission class: euro6, Year of construction: 2022, number of cylinders: 6, cubic capacity: 12,777 cm³, steering wheel position: left, Equipment: full service history, power assisted steering, Features

I-See Predictive Cruise Control - Map based topography information

Cab: Globetrotter XL

Battery system type: Single energy battery system (2 batteries)

Engine & Turbo Package: D13K500 diesel engine, 500hp, 2500Nm SCR and EGR

Gearbox: I-shift Automated 12-speed - GCW 60 tonne

Automatic transmission manual shift options: Standard transmission shift - I-Shift or Powertronic

Engine Brake Type: Volvo Engine Brake - Retardation D13K-375kW/D16-500kW

Advanced Emergency Brake System AEBS

Klsdpfx Agsx Rv Rte Uel

Driver attention support

Driver comfort

Cab Climate Unit: Electrically controlled air conditioning with sun sensor

Driver Seat: Comfort 4: suspended - belt in seat

Passenger seat: Comfort 4: suspended - belt in seat

Top bunk: Height adjustable foldable top bunk 700 x 1900mm

Lower bunk: Lower bunk 815mm wide in the centre

Aux. cab heater: 1.8kW Air to air

Refrigerator: 33 litre under bunk mounted fridge / freezer with dividers

Technical specifications

Continental VDO 4.1 smart tachograph version 2 - legal demand from 21/08/2023

Front Axle Tyre Size: 315/70R22.5

Drive Axle Tyre Size: 315/70R22.5

Fifth Wheel Type: Jost JSK 37 cast fixed or sliding fifth wheel

Wheelbase: 3800 mm

Drive Axle Ratio: 2.31:1

Fuel tank - RHS: 570litre aluminium diameter 710mm

Fuel tank - LHS: 900 LITRE, LEFT SIDE FUEL TANK WITH STEPS

Plastic AdBlue Tank: 65 litre under/behind cab

Cruise Control: Eco fleet software - with speed 85, I-See and push button I-shift

Technology

Secondary Information Display: Secondary colour information display

FMS gateway: FMS gateway for Fleet Management System

Exterior

Headlamps: LED headlamps

Daytime Running Lights: V-shaped

Front fog lamps: Front fog lights - white

Cornering lights: Static corner lights - works with indicator at low speed to light up direction

Air Deflector - Roof: Roof air deflector

Side air deflector: Cab side air deflector - long tractor

Listing

Borken

Borken

1,034 km

Thermal shock testing system –70 to +240 °C

RS-SimulatorenST2K320/70D

Call

Condition: excellent (used), RS Simulators

Klodpfjwx Ip Djx Ag Ujl

RS Simulators ST2K 320/70D

Water-cooled Shock Test System

For sale is a high-performance thermal shock test system, model ST2K 320/70D.

This unit is ideally suited for standardized thermal shock testing

according to DIN EN 60068‑2‑14, including optional humidity testing in the upper test chamber.

With its two temperature chambers (–70 °C to +240 °C) and automatic test basket transfer, this system provides the perfect solution for component, material, and reliability testing in industry, research, and quality assurance.

Main technical data:

Temperature ranges:

Upper test chamber: +40 °C to +240 °C

Temporal deviation: ±0.8 K (per DIN 50011, empty chamber)

Lower test chamber: –70 °C to +240 °C

Temporal deviation: ±0.8 K (per DIN 50011, empty chamber)

Optional humidity test – Upper test chamber:

Temperature: +40 °C to +90 °C

Relative humidity: 20% to 98% r.h. (±2–5%)

Test basket transfer:

Vertical movement, < 10 seconds changeover time

Power supply:

Total power: 16 kVA

Current consumption: 32 A

Main fuse: 3 × 35 A slow-blow

Mains connection: 3 × 400 V / N / PE / 50 Hz

Main cable: 5 × 16 mm²

Water & compressed air connections:

Cooling water inlet: G ¾", approx. 3 bar, max. 10 bar / max. 15 °C

Cooling water requirement: max. 1.4 m³/h

Cooling water return: G ¾", max. 25.2 °C

Condensate drains: 2 × G ½", 1 × G ¼", unpressurized

Deionized water inlet: G ⅜", approx. 3 bar, max. 6 bar

Compressed air connection: Quick coupling NW 7.2 (G ¼"), min. 4 bar, max. 10 bar

Dimensions & weight:

Test basket internal dimensions (Type ST2K 320):

Internal dimensions: Width approx. 430 mm, Height approx. 470 mm, Depth approx. 700 mm

External dimensions: Width: approx. 1100 mm, Height: approx. 2300 mm, Depth: approx. 2300 mm

Weight: approx. 1150 kg

Other technical data:

Sound level: approx. 60 dB(A) at 1 m distance (free field)

Refrigerants:

R-404A: approx. 2.5 kg (GWP 3800, limit value 0.48 kg/m³)

R-23: approx. 0.8 kg (GWP 12100, limit value 0.68 kg/m³)

Permissible operating environment:

Temperature: +12 °C to +30 °C

Humidity: 25%–75% r.h.

For your safety as the buyer, please note the following information!

The following steps are carried out on our offered chambers in advance:

1. Functional check and replacement of necessary components

2. Refilling with legally compliant refrigerant, if required

3. Leak test with certificate

4. After successful inspection, the chambers undergo a documented test run.

Condition: used

Scope of delivery: (See picture)

(Specifications and details subject to change and errors reserved!)

We are happy to answer further questions by phone.

Listing

Vilnius

Vilnius

2,167 km

Standard tractor unit

VOLVOFH 460 Globetrotter XL i-Save SideSkirts

Call

Condition: used, functionality: fully functional, mileage: 333,503 km, power: 338 kW (459.55 HP), first registration: 05/2023, fuel type: diesel, overall weight: 8,400 kg, axle configuration: 4x2, wheelbase: 380 mm, color: white, gearing type: automatic, emission class: euro6, Year of construction: 2023, number of cylinders: 6, cubic capacity: 12,777 cm³, steering wheel position: left, Equipment: full service history, power assisted steering, Features

I-See Predictive Cruise Control - Map based topography information

Cab: Globetrotter XL

Battery system type: Single energy battery system (2 batteries)

Engine & Turbo Package: D13K460TC Turbo-compound diesel engine, 460hp, 2600Nm SCR and EGR

Gearbox: I-shift Automated 12-speed - GCW 60 tonne

Automatic transmission manual shift options: Standard transmission shift - I-Shift or Powertronic

Engine Brake Type: Volvo Engine Brake - Retardation D13K-375kW/D16-500kW

Advanced Emergency Brake System AEBS

Driver attention support

Driver comfort

Cab Climate Unit: Electrically controlled air conditioning with carbon filter, sun, mist, and air quality

Driver Seat: Comfort 5: suspended & heated - belt in seat

Passenger seat: Comfort 5: suspended & heated - belt in seat

Top bunk: Height adjustable foldable top bunk 700 x 1900mm

Lower bunk: Lower manual recline bunk 815mm wide in the centre

Aux. cab heater: 1.8kW Air to air

Refrigerator: 33 litre under bunk mounted fridge / freezer with dividers

Technical specifications

Continental VDO 4.1 smart tachograph version 2 - legal demand from 21/08/2023

Kedpfx Agsx Tzddj Usll

Front Axle Tyre Size: 315/70R22.5

Drive Axle Tyre Size: 315/70R22.5

Fifth Wheel Type: Jost JSK 37 cast fixed or sliding fifth wheel

Wheelbase: 3800 mm

Drive Axle Ratio: 2.31:1

Fuel tank - RHS: 610 LITRE, RIGHT SIDE FUEL TANK

Fuel tank - LHS: 650 LITRE, LEFT SIDE FUEL TANK

Plastic AdBlue Tank: 65 litre under/behind cab

Cruise Control: Eco torque software - Improved economy mode. Fuel economy optimized cruise control for I-Save

Standard transmission shift - I-Shift or Powertronic

Technology

Secondary Information Display: Secondary colour information display

FMS gateway: FMS gateway for Fleet Management System

Exterior

Headlamps: LED headlamps

Daytime Running Lights: V-shaped

Front fog lamps: Front fog lights - white

Cornering lights: Static corner lights - works with indicator at low speed to light up direction

Air Deflector - Roof: Roof air deflector

Side air deflector: Cab side air deflector - long tractor

Painted all cab (MB,VO)

Side skirts on fuel tanks

Listing

Heteren

Heteren

958 km

Standard tractor unit

VOLVOFH 460 Globetrotter XL Varios i-Save

Call

Condition: used, functionality: fully functional, mileage: 439,111 km, power: 338 kW (459.55 HP), first registration: 07/2022, fuel type: diesel, overall weight: 8,441 kg, axle configuration: 4x2, wheelbase: 380 mm, color: white, gearing type: automatic, emission class: euro6, Year of construction: 2022, number of cylinders: 6, cubic capacity: 12,777 cm³, steering wheel position: left, Equipment: full service history, power assisted steering, Features

I-See Predictive Cruise: I-See Predictive Cruise Control - Map based topography information

Cab: Globetrotter XL

Battery system type: Single energy battery system (2 batteries)

Engine & Turbo Package: D13K460TC Turbo-compound diesel engine, 460hp, 2600Nm SCR and EGR

Gearbox: I-shift Automated 12-speed - GCW 60 tonne

Automatic transmission manual shift options: Standard transmission shift - I-Shift or Powertronic

Engine Brake Type: Volvo Engine Brake - Retardation D13K-375kW/D16-500kW

Advanced Emergency Brake System AEBS

Driver comfort

Cab Climate Unit: Electrically controlled air conditioning with sun sensor

Driver Seat: Comfort 4: suspended - belt in seat

Passenger seat: Comfort 4: suspended - belt in seat

Top bunk: Height adjustable foldable top bunk 700 x 1900mm

Klsdoxtvlgepfx Ag Uel

Lower bunk: Lower bunk 815mm wide in the centre

Aux. cab heater: 1.8kW Air to air

Refrigerator: 33 litre under bunk mounted fridge / freezer with dividers

Driver attention support

Technical specifications

Continental VDO 4.1 smart tachograph version 2 - legal demand from 21/08/2023

Front Axle Tyre Size: 315/60R22.5

Drive Axle Tyre Size: 315/60R22.5

Fifth Wheel Type: SAF-Holland/+GF+ SK-S 36.20 cast fixed fifth wheel

Wheelbase: 3800 mm

Drive Axle Ratio: 2.17:1

Fuel tank - RHS: 570litre aluminium diameter 710mm

Fuel tank - LHS: 900 LITRE, LEFT SIDE FUEL TANK WITH STEPS

Plastic AdBlue Tank: 65 litre under/behind cab

Cruise Control: Eco fleet software - with speed 85, I-See and push button I-shift

Technology

Secondary Information Display: Secondary colour information display

FMS gateway: FMS gateway for Fleet Management System

Exterior

Headlamps: LED headlamps

Daytime Running Lights: V-shaped

Front fog lamps: Front fog lights - white

Cornering lights: Static corner lights - works with indicator at low speed to light up direction

Air Deflector - Roof: Roof air deflector

Side air deflector: Cab side air deflector - long tractor

Listing

Darwen

Darwen

384 km

HURCO HAWK 5D

HURCOHAWK 5D

Call

Condition: used, Hurco Hawk Model 5D, with Dynapath Delta CNC control, 70-3800 RPM, 1000mm x 330mm table. Bt 40 Spindle. Immaculate condition from University.

Kjdpeya Hrrsfx Ag Uoll

Listing

Wakefield

Wakefield

447 km

Saddle stitcher

HorizonStitchliner 5500

Call

Condition: excellent (used), Year of construction: 2008, Ref: 11054 . 2008 Horizon Stitchliner 5500

Fully automatic setting Sheet Collating and Saddle Stitched Booklet System.

Features:

• 10.4” icon-based 200 job memory colour touchscreen

• Simple, fast set-ups by non-specialist finishing operators

• Advanced all-system automation

• Make-ready in seconds, next-to-no-waste, on-demand working

• Works from flat-sheet 4-page sections

• No need to pre-fold

• Integrated automatic set-up 3-knife trimmer

• No need to pre-trim

• Score, plough fold, registration and genuine saddlestitch

• High quality books with sharp spine definition

• High efficiency from runs-of-one

Comprising:

30 station - 5 x VAC60 (a+m+c) 6 station tower suction collators

Kedox Sq S Iepfx Ag Usll

with touch-screen control, double- and miss-sheet control

Separate collating from 'C' tower

ST-40 Stacker /bypass to;

ACF-40 Accumulator/Folder with double gate-fold to;

SPF-30 Saddle stitcher with 2 x Hohner 43/6S stitching heads to;

HTS-30 Three knife trimmer unit with hand-feed station

LC-20 Long belt delivery

Specification:

Max sheet size: 350W x 500L mm

Min sheet size: 148 x 210 mm

Max stitch thickness: 6 mm.

Production speed up to 6,000 booklets per hour, dependent on stock.

Listing

Bury St Edmunds

Bury St Edmunds

617 km

Net clipping machine for fruit and vegetables.

GIROCA-10

Call

Condition: excellent (used), The Giro CA-10 is an advanced clipping system designed for efficient net packaging of fruits and vegetables. Key features include: • Versatile Bagging Capacity: Suitable for packaging products ranging from 500 grams to 4 kilograms. Immaculate condition having been in storage for at least five years.

Kjdpsv Hh Nhefx Ag Uoll

Listing

Baughurst

Baughurst

532 km

Digital print machine

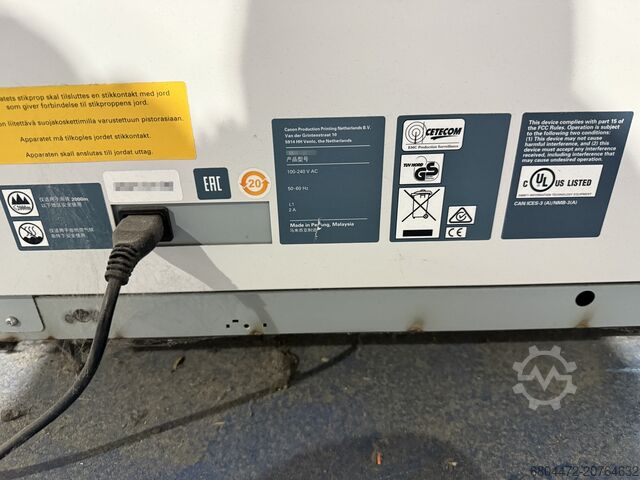

CanonOce VarioPrint 6330

Call

Condition: used, Year of construction: 2018, functionality: fully functional, FOR SALE:

Canon Océ VarioPrint 6330 TP Titan – High-Speed Monochrome Production Press

Boost Print Production & Efficiency

A fully functional, high-speed Canon Océ VarioPrint 6330 TP Titan digital production printer is for sale. This machine is known in the commercial print industry for its productivity, offset-like quality, and media versatility.

It is ideal for high-volume environments, commercial print shops, and in-house operations. These operations focus on books, manuals, transactional documents, and direct mail.

Key Features & Benefits:

Ultra-High Speed: It can achieve speeds of up to 328 A4 impressions per minute with Océ Gemini Instant Duplex Technology. This technology prints both sides at once in a single pass.

Kedpjx Hz T Eefx Ag Ujll

Superior Print Quality: It delivers quality with a 600 x 1200 dpi resolution. It uses advanced Océ Copy Press technology for a matte finish and precise registration.

Wide Media Versatility: It handles media weights from 50 gsm up to 300 gsm (and up to 350 gsm for validated stock). This includes specialty and textured papers, tabs, and carbonless forms.

Robust Paper Handling: It comes with a high-capacity system, expandable to multiple trays. It has a paper input capacity of up to 24,000 sheets.

Eco-Friendly Operation: It features low power consumption, minimal ozone emissions, and low heat output. This makes it efficient and operator-friendly for any print room.

Workflow Integration: It is managed by the PRISMAsync controller. It includes DFD interface support for connection to third-party finishing options (binding, saddle-stitching, punching).

Machine Specifications:

Model: Canon Océ VarioPrint 6330 TP Titan

Condition: Ready for operation (used), fully functional

Year of Manufacture: Year 2018

Resolution: 600 x 1200 dpi (up to 180 lpi)

Max Monthly Volume: Up to 10,000,000 A4 images

Max Paper Size: Up to 350 mm x 500 mm (13.8" x 19.7")

Configuration Includes: (Please check photos to be sure)

Paper Input Modules, 8x Duo Paper Trays]

2x High Capacity Stackers]

PCL, IPDS, PostScript language support]

PRISMAsync Controller]

Current Meter Readings:

See Photo.

Price:

(Negotiable)

The original price for this configuration was over €140,000!

Logistics:

The buyer is responsible for arranging shipping. . The machine is located in [UK].

Listing

Erith

Erith

609 km

Center lathe

Ex Display EUROPAEUROPA VS660

Call

Condition: as good as new (ex-display), Year of construction: 2013, functionality: fully functional, machine/vehicle number: 0153, Specification

Europa VS660

Centre height 330mm

Distance between centres 1500mm

Swing over bed 660mm

Swing over cross slide 430mm

Spindle bore (max. bar dia) 104mm

Spindle nose mounting D1-11 Camlock

Taper in spindle bore No. 7 Morse

Swing in gap 860mm

Width of bedways 480mm

Total travel of cross slide 390mm

Total travel of top slide 190mm

Total travel of tailstock barrel 300mm

Spindle speeds (infinitely variable) 18 – 1400rpm

Drive vee belt and clutches

Spindle motor 20HP

Imperial pitches (73) 2-84TPI

Diametral pitches (27) 8-72DP

Metric pitches (51) 0.2 – 14mm

Module pitches (20) 0.2 –3.5 MOD

Approx. weight 3800 kg

Machine in Imperial execution

Kodpfx Agsnxi H Uj Uell

Europa VS660 Gap Bed Centre Lathe in stock in the UK

Machine equipped with

Fagor 2 axis DRO system with CSS ( Metric and imperial read out options)

3 jaw chuck

Quick change toolpost and toolholders

Rapid power traverse to saddle

lighting

Coolant system

Chuck guard

Rear splash guard

Trust Seal

Dealers certified through Machineseeker

Listing

Derby

Derby

455 km

FISCHER Milk Pasteuriser 5000 Litres/Hour De Areator

FISCHER5000 Litres

Call

Condition: used, Year of construction: 2008, The Fischer milk pasteuriser 5000 is an industrial-grade machine designed for pasteurizing milk on a large scale. Here are some details about such a pasteuriser:

- Capacity: The "5000" typically indicates that this pasteuriser can handle up to 5000 litres of milk per batch, making it suitable for large dairy processing operations.

- Functionality: The pasteuriser is designed to heat milk to a specific temperature, holding it there for a required amount of time to eliminate harmful bacteria and pathogens while preserving the milk's quality and nutritional value.

- Construction: Fischer machines are commonly made from stainless steel, ensuring hygiene and durability. The materials used are designed to withstand high temperatures and pressures encountered during the pasteurization process.

- Design: It often features an insulated design for energy efficiency and may include a user-friendly control panel for monitoring and adjusting the pasteurisation parameters.

- Efficiency: The pasteurising process is usually continuous, allowing for high throughput, which is essential for commercial operations to meet demand.

- Temperature Control: It may include advanced temperature control systems to ensure precise pasteurization, which is crucial for product safety and quality.

- Safety Features: Modern pasteurisers often come with safety mechanisms to prevent overheating or pressure build-up, ensuring safe operations.

- Applications: Suitable for dairy farms, creameries, and food manufacturers looking to process large quantities of milk while adhering to health and safety regulations.

Capacity: 5000 Litres per hour

Temperatures: 4-55-65-78(90) - 55-65-4 c

Stages exchange plates : 5

Outlets: Separator / Homogeniser / De Aerator / Holding Tube

DeAerator: Included

Klsdjx Tdaujpfx Ag Usl

Heated: Steam with Heat Exchanger and Steam Valve Positioning

Balance Tabk: Included

Chart recorder: In control panel

Control Panel: Included

Divert Valve: Included

Product Pump: Included

Skid Mounted: On Stainless steel Skid

Hot water Pump: Included

Electrical Requirements: 3 phase 400 V / 50/60 hz

Cooling: Connection with old water connection

Condition: Still in use

Available: 3 weeks from order

Listing

Derby

Derby

455 km

ALFA LAVAL BBRPX 618 -HGV 14C -60 Bactofuge 25,000 L/H

Alfa LavalBBRPX 618 - HGV 14C -60

Call

Condition: used, The Alfa Laval Bactofuge 618 is a specific model of separator designed predominantly for the food and beverage industry, particularly for the dairy sector. Here’s an overview of its key features and applications:

Key Features

- Centrifugal Separation: Utilizes high centrifugal forces to separate bacteria and particles from liquids, which significantly improves the quality and shelf life of products.

- High Efficiency: Known for its efficient separation capabilities, effectively removing unwanted microorganisms and solids from liquids.

- Hygienic Design: Built with food safety in mind, featuring materials and designs that comply with industry hygiene standards to minimize contamination risks.

- Compact Size: Designed to fit into smaller spaces within processing plants, making it suitable for various production environments.

- Automated Control: Many models feature advanced automation options for monitoring and controlling the separation process, optimizing performance and ease of use.

Applications

- Dairy Industry: Mainly used in the processing of milk and whey, the Bactofuge helps in improving the microbial quality of products, ensuring longer shelf life and safety.

- Beverages: Can also be utilized in the clarification and purification of fruit juices and other beverages, helping to remove sediment and enhance clarity.

- Biotechnology and Pharmaceuticals: It may find applications in the removal of cell debris or particulates from culture broths in Biotech and Pharma industries.

Maintenance

- Service Support: Alfa Laval usually provides good after-sales support, including maintenance schedules, spare parts availability, and service contracts.

- User Training: Training for operators is generally recommended to ensure proper handling and maintenance of the equipment

Capacity: 25,000 L/H

Kljdpfoxnbrhex Ag Uol

Usage: Bacteria Removal Centrifuge

Tools: Included

Control panel: Included

Valves: Included

Available: Immediately

Condition: Good

Machine Top Part No.: 545525-04

Inlet and Outlet No.: 546664-01

Separator Bowl No.: 546823-01

Machine Bottom Part No.: 546215-04

Listing

Navan

Navan

105 km

High Speed Decanter Centrifuge

GEAWestfalia Decanter Centrifuge

Call

Condition: ready for operation (used), Year of construction: 2005, functionality: fully functional, machine/vehicle number: 0509, 🔧 Key Features

Continuous Operation: Designed for uninterrupted processing, ensuring efficient separation of solids and liquids.

High Separation Efficiency: Capable of achieving significant separation of solids, oil, and water, with capacities up to 30 m³/h, depending on the model.

Kodewnx Ngopfx Ag Uell

Robust Construction: Built with durable materials, such as 304 stainless steel for product contact parts, ensuring longevity and resistance to corrosion.

Advanced Control Systems: Equipped with PLC control panels featuring user-friendly interfaces for precise operation and monitoring.

Listing

Deinze

Deinze

846 km

Deep hole drilling machines

AtamecØ 20 x 800 mm CNC deepdrilling

Call

Condition: ready for operation (used), empty load weight: 6,000 kg, total width: 2,350 mm, total height: 2,450 mm, Type: FCN 540

gundrilling, high precision deep hole drilling

movement of drillinghead: 0 600 mm

movement of table (X-movement): 0 800 mm

max drillingdepth: 800 mm

Y-travel: 600 mm

Kjdpfxoyauhus Ag Uoll

Z-travel: 450 mm

table: 1100 x 600 mm

Heidenhain control

including Filtra high pressure cooling through spindle

including tools

total power: 16 kW

Max drilling dia: 4-20 mm

Speed: 0 > 12 000 rpm

Power on drillingspindle: 3,7 kW

Total length: 3800 mm

Numbre of drillingheads: 1x

We make it easier for you to find: "advance 3800"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Advance 3800 (3,366)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month