HORIZONTAL GLASS WASHING MACHINEGİRMAKSAN GLASS MACHINERY

GM-1000-1200-1400-1600-1800-2000-2500H

HORIZONTAL GLASS WASHING MACHINE

GİRMAKSAN GLASS MACHINERY

GM-1000-1200-1400-1600-1800-2000-2500H

Year of construction

2024

Condition

New

Location

Yiğitler

Show images

Show map

Machine data

- Machine type:

- HORIZONTAL GLASS WASHING MACHINE

- Manufacturer:

- GİRMAKSAN GLASS MACHINERY

- Machine number:

- GM-1400H

- Year of construction:

- 2024

- Condition:

- new

- Functionality:

- fully functional

Price & Location

- Location:

- B21 Sokak No:5/7, 16300 Bursa, Türkiye

Call

Technical details

- Total width:

- 3,000 mm

- Total length:

- 5,000 mm

- Total height:

- 3,250 mm

- Type of input current:

- three-phase

- Energy consumption:

- 60 kWh

- Input current:

- 80 A

- Workpiece weight (max.):

- 2,720 kg

- Power:

- 48 kW (65.26 HP)

- Workpiece height (max.):

- 950 mm

- Warranty duration:

- 1 months

- Working range:

- 319 mm

- Number of chambers:

- 3

- Equipment:

- adjustable chassis

Details about the offer

- Listing ID:

- A15409939

- Update:

- 18.04.2024

Description

Conveyors are produced in such a way that they will not scratch the glass and leave no stains.

The machine is made of steel and aluminum materials.

Thanks to specially designed water sprays and brushes, the glasses comes out completely free from oils, stains and dust and cleaned.

Angles of water nozzles will be adjustable.

Conveyor rollers are produced of Ø 55 mm vulcanized rubber .

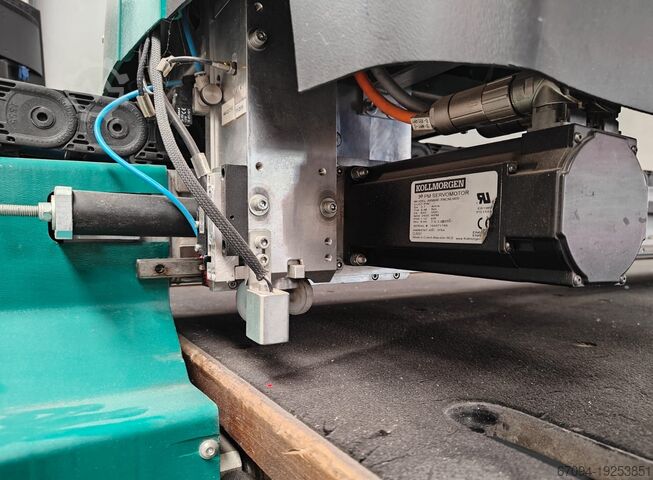

Induction hardened gears are used in transmission gears.

There will be 3 Washing Cabins, pre-washing, washing and rinsing washing system.

In the pre-washing section, the upper and lower surfaces of the glass are washed with high-pressure spray nozzles.

In the same cabin ,will be compressed air to the upper surface of the glass with air knife and the water will be completely cleansed.

Thanks to this process, the glasses will go into the wash without entering the brush washing compartment, free from their dirt.

There are 6 Brushes (Ø 120 mm.) in the Washing Machine and they will be able to wash laminated glasses.

2 of the brushes will be in the inlet (pre-wash) and 4 in the outlet (rinse-wash). there are brushes in total, 2 piece of them at the entrance and 4 pieces at the exit. 2 of the brushes will be suitable for laminated glass washing.

the other 4 brushes will be for normal standard use.

Features of brushes to wash laminated glass is ;

Bristle material will be 6.6 P.A.

The bristle diameter will be 0.15mm.

The bristle length will be between 30-35 mm.

Brush shaft will be produced of ASI 304L quality stainless material.

During washing, the brush suitable for the laminated coated glass, whose properties are given above, will come into contact with the surface of the glass.

To the other part of the glass will come into contact standard glass washing brush.

The washing and air drying section will have an elevator system with a 350 mm opening and closing structure for maintenance and cleaning.

Thanks to the elevator, the glass thickness (3-19 mm) can be adjusted easily.

The speed of the conveyors will be adjustable between 0 m/min and 5 m/min.

There will be a sound insulation cabinet in the drying fan.

1 piece of G4 filter and 1 piece of F7 filter will be at the air inlet of the drying fan .

Bwjdpfjr Ak Exsx Afnsh

The filters will be of standard size and can be changed and will be 592*592*20 mm square type. 23. Thanks to the powerful air knives, the glasses will come to the exit conveyor dry.

The height of the air knives will be adjustable.

All pipes and hoses in the machine will be in a matte color to prevent algae formation in daylight. 26. Digital displays and many electronic equipment will be Delta or Schneider brand.

There will be a stop sensor at the exit of the conveyor to prevent the glass coming from the machine from falling to the ground.

There will be lighting system in the washing exit area for quality control from the bottoms and top of the conveyor towards the glasses.

These lightnings will have the ability to be switched on and off separately.

There are 3 separate water tanks in the machine.

There will be an overflow water line that will prevent the water in the water tanks from overflowing.

The machine is made of steel and aluminum materials.

Thanks to specially designed water sprays and brushes, the glasses comes out completely free from oils, stains and dust and cleaned.

Angles of water nozzles will be adjustable.

Conveyor rollers are produced of Ø 55 mm vulcanized rubber .

Induction hardened gears are used in transmission gears.

There will be 3 Washing Cabins, pre-washing, washing and rinsing washing system.

In the pre-washing section, the upper and lower surfaces of the glass are washed with high-pressure spray nozzles.

In the same cabin ,will be compressed air to the upper surface of the glass with air knife and the water will be completely cleansed.

Thanks to this process, the glasses will go into the wash without entering the brush washing compartment, free from their dirt.

There are 6 Brushes (Ø 120 mm.) in the Washing Machine and they will be able to wash laminated glasses.

2 of the brushes will be in the inlet (pre-wash) and 4 in the outlet (rinse-wash). there are brushes in total, 2 piece of them at the entrance and 4 pieces at the exit. 2 of the brushes will be suitable for laminated glass washing.

the other 4 brushes will be for normal standard use.

Features of brushes to wash laminated glass is ;

Bristle material will be 6.6 P.A.

The bristle diameter will be 0.15mm.

The bristle length will be between 30-35 mm.

Brush shaft will be produced of ASI 304L quality stainless material.

During washing, the brush suitable for the laminated coated glass, whose properties are given above, will come into contact with the surface of the glass.

To the other part of the glass will come into contact standard glass washing brush.

The washing and air drying section will have an elevator system with a 350 mm opening and closing structure for maintenance and cleaning.

Thanks to the elevator, the glass thickness (3-19 mm) can be adjusted easily.

The speed of the conveyors will be adjustable between 0 m/min and 5 m/min.

There will be a sound insulation cabinet in the drying fan.

1 piece of G4 filter and 1 piece of F7 filter will be at the air inlet of the drying fan .

Bwjdpfjr Ak Exsx Afnsh

The filters will be of standard size and can be changed and will be 592*592*20 mm square type. 23. Thanks to the powerful air knives, the glasses will come to the exit conveyor dry.

The height of the air knives will be adjustable.

All pipes and hoses in the machine will be in a matte color to prevent algae formation in daylight. 26. Digital displays and many electronic equipment will be Delta or Schneider brand.

There will be a stop sensor at the exit of the conveyor to prevent the glass coming from the machine from falling to the ground.

There will be lighting system in the washing exit area for quality control from the bottoms and top of the conveyor towards the glasses.

These lightnings will have the ability to be switched on and off separately.

There are 3 separate water tanks in the machine.

There will be an overflow water line that will prevent the water in the water tanks from overflowing.

Documents

Seller

Note: Register for free or log in, to access all information.

Registered since: 2024

Send inquiry

Telephone & Fax

+90 224 3... show

These listings may also fit your interest.

Listing

Italy

Italy

2,009 km

Automatic Loading Panel Saws

SCHELLINGFH6 430

SCHELLINGFH6 430

Listing

Rheinbach

Rheinbach

1,084 km

Dry spray wall Spray wall Paint wall

D&MTSWc 3x2 10.800 m³/h

D&MTSWc 3x2 10.800 m³/h

Listing

Geseke

Geseke

1,151 km

Warehouse

Hallenbau in SystembauweiseHallenbau

Hallenbau in SystembauweiseHallenbau

Listing

Pfalzgrafenweiler

Pfalzgrafenweiler

1,293 km

Laboratory-Press

JoosLAP-M 30

JoosLAP-M 30

Listing

Maasmechelen

Maasmechelen

987 km

Glass cutting table

Bottero353BKM-J

Bottero353BKM-J

Listing

Thurmaston

Thurmaston

486 km

Vertical machining center

DMG MORIDMC1150V

DMG MORIDMC1150V

Listing

Matelica (MC)

Matelica (MC)

1,922 km

Laser Cutting Machines - Fiber laser cutting

PRIMA POWERPLATINO FIBER 1530

PRIMA POWERPLATINO FIBER 1530

Listing

Szczecin

Szczecin

1,506 km

Glass tempering furnace

TAMGLASS / GLASTONHTF ProE – 2448-ADS-R

TAMGLASS / GLASTONHTF ProE – 2448-ADS-R

Listing

Germany

Germany

1,100 km

Painting Line Venjakob Perfect, OIR, Air Jet, 3D-

VenjakobVEN SPRAY and Drying, UV Line

VenjakobVEN SPRAY and Drying, UV Line

Listing

Kozy

Kozy

1,920 km

Vacuum suction cup BEFARD XP602

BEFARDXP 602

BEFARDXP 602

Your listing has been deleted successfully

An error has occurred