Second-hand machinery for sale (2,399)

Sort results

- Lowest price Highest price

- Latest listings Oldest listings

- Shortest distance Farthest distance

- Latest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Latest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Latest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation A to Z

- Designation

- designation Z to A

- Designation

- Model A to Z

- Model

- Model Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest running time

- Runtime

- Relevance

- Relevance

Auctions

Auction

Auction ended

Dolnośląskie

Dolnośląskie

1,728 km

Injection molding machine

KraussMaffeiKM 300-1000 C1

Condition: ready for operation (used), Year of construction: 2005, Functionality: fully functional, machine/vehicle number: 61007465, clamping force: 3,000 kN, screw diameter: 55 mm, clearance between the columns: 630 mm, injection pressure: 1,904 bar, injection weight: 476 g, opening stroke: 820 mm, Including robot - Wittmann W 731

X-axis: 800 mm

Y-axis: 1,400 mm

Z-axis: 4,000 mm

TECHNICAL DETAILS

Clamping force: 3,000 kN

Mold opening force (max.): 160 kN

Moving platen pusher force (opening): 86 kN

Moving platen pusher force (closing): 68 kN

Mold platen size (H x V): 995 x 1,050 mm

Fe Ievzrp Ija Uny Uopg

Column spacing (H x V): 630 x 630 mm

Mold opening stroke: 820 mm

Minimum mold height: 330 mm

Maximum clear height: 1,150 mm

Injection unit

Screw diameter: 55 mm

L/D ratio: 20

Injection pressure: 1,904 bar

Injection volume: 523 cm³

Injection weight (PS): 476 g

Injection rate: 428 cm³/s

MACHINE DETAILS

Machine dimensions (L x W x H): 5.97 x 2.04 x 2.36 m

Total weight: 12.5 t

Auction

Auction ended

Bayern

Bayern

1,378 km

Combined machine

IMACOMBIMA K II R75 1075 V R3

Condition: ready for operation (used), Year of construction: 1995, Functionality: fully functional, working width: 1,000 mm, product height (max.): 35 mm, product height (min.): 10 mm, product length (max.): 2,500 mm, product length (min.): 290 mm, product width (max.): 1,000 mm, product width (min.): 230 mm, TECHNICAL DETAILS

Working width: 1,000 mm

Feed speed: 8 - 40 m/min

Control system: IMATRONIC 152

manufactured product

Product: Box furniture, sides + bottoms, 4-sided edging and sizing

Product length: 290 - 2500 mm

Product width: 230 - 1000 mm

Product thickness: 10 / 35 mm

Product speed: 60 m/min

Min. strip length (roll material): approx. 300 mm

Min. strip height (roll material): approx. 14 mm

Max. Strip thickness (roll material): approx. 3.0 mm

Min. workpiece length: approx. 150 mm

Min. workpiece thickness: approx. 10 mm

Max. Workpiece thickness: approx. 45 mm

Max. Workpiece size: approx. 35 mm (temporarily possible)

Workpiece distance and width

Min. workpiece projection from chain track, per side: approx. 35 mm (plus edge thickness)

Max. Workpiece projection from chain conveyor, per side: approx. 80 mm

Min. throughfeed width with workpiece projection 35 mm: approx. 230 mm

Fpj Ia Uju Ttp Usny Ueg

MACHINE DETAILS

Mains voltage: 2 × 400 V

Control voltage: 24 V

Design: Left-hand machine, stop side left

EQUIPMENT AND AGGREGATES

- Feeding device: With three inclined, rubberized rollers, can be folded up by hand.

- Pneumatic pressure rollers: For lateral pressure, controllable.

- Metal detector: 2 pieces, detection of small metal parts in the edge area. Detection width 80 mm, workpiece height: 30 mm, workpiece projection 10 - 90 mm

- Cutting units: Double cutting units with vertical adjustment and 4.4/6.6 kW motor power. 6000 rpm, tool diameter 200 - 250 mm

- Routing/profiling units: Swivel routing units with height sensing and mechanical digital readouts. 6000 rpm

- Hot melt adhesive feeder (654232): QuickMelt with 2.5 kW heating power and 50 kg granulate tank. Melting capacity 10 - 12 kg/h

- Milling units: For rough and fine milling with 6.6-8.0 kW motors and digital control.

- Cross-cut unit: cross-cut height 50 mm, cross-cut thickness 2.5 mm, edge 30 m/min, 2 HM cross-cut saw blades 160 x 22 mm

- Trimming unit for rough trimming: 2 x 1000 W, 12,000 rpm, with height sensing, side sensing

- Trimming unit for fine trimming: 2 x 150 W, 12,000 rpm, with height sensing, side sensing

- Trimming unit for profile trimming: 2 x 600 W, 18,000 rpm, with height sensing, side sensing

- Profile scraper units: For subsequent smoothing and polishing of profiles.

- Scraper unit: Removal of hot-melt adhesive residue from the edge area

- Buffing units: For polishing PVC edgeband profiles.

- Smoothing units: For smoothing and rounding off profiles.

- and more - see PDF \/

Auction

Auction ended

Bayern

Bayern

1,487 km

Automatic lathe

TraubTNL 12-7

Condition: excellent (used), Year of construction: 2000, operating hours: 49,274 h, Functionality: fully functional, machine/vehicle number: 247, turning length: 80 mm, spindle speed (max.): 12,000 rpm, feed length X-axis: 35 mm, feed length Y-axis: 37 mm, feed length Z-axis: 75 mm, bar diameter: 12 mm, No reserve price - guaranteed sale at the highest bid!

TECHNICAL DETAILS

Control: Mitsubishi TX-8i

Turning length: 80 mm

Fpo Ia Unovrz E Hsy Uog

Main spindle

Technology: belt spindle

Speed: 12,000 rpm

Power: 4 kW

Torque: 7 Nm

Bar capacity: 12.7 mm

Travel path in Z1: 75 mm

Workpiece clamping: collet chuck

Counter spindle

Technology: belt spindle

Speed: 12,000 rpm

Power: 4 kW

Torque: 7 Nm

Travel path in X3/Z4: 222 mm / 139 mm

Rapid traverse in X3/Z4: 30 m/min

Workpiece clamping: collet chuck

Tool carrier I (X/Y)

Technology: turret with 6 stations (total drive)

Tool holder: Ø 25 mm

Tool drive: 8,000 rpm, 1.5 kW, 2.4 Nm

Travel path in X1/Y1: 35 mm / 37.5 mm

Rapid traverse in X1/Y1: 15 m/min

Front attachment

Number of stations: 4

Tool holder: Ø 28 mm

Pitch spacing: 32 mm

Tool drive: 12,000 rpm, 4 kW, 7 Nm

Number of driven stations: 4

Travel path in X3/Z3: 222 mm / 139 mm

Rapid traverse in X3/Z3: 30 m/min

Rear attachment

Number of stations: 4

Tool holder: Ø 28 mm

Pitch spacing: 32 mm

MACHINE DETAILS

Dimensions: 1,450 x 950 x 1,480 mm

Weight: 1,600 kg

Connected load: 16 kW

Installation dimensions: 7,943 x 1,430 x 1,480 mm

Control switch-on time: 96,171 h

Switch-on time: 100,147 h

Production time: 45,983 h

Spindle 1: 49,274 h

Spindle 2: 47,771 h

Spindle 5: 15,297 h

EQUIPMENT

- Chip management: Chip conveyor

- Coolant management: KSS pump

- Raw material feed: Bar loader, FMB minimag 3200

- Finished part removal: Workpiece removal device (pipe)

- Emulsion mist extraction: Interface mechanically prepared

- Tool holder: Various rigid and driven holders

Find out now

+44 20 806 810 84

+44 20 806 810 84

Create listing

*per listing / month

Auction

Auction ended

Bayern

Bayern

1,381 km

Laser cutting machine

Mercury1620

Condition: ready for operation (used), Year of construction: 2005, operating hours: 25,253 h, Functionality: fully functional, laser power: 300 W, travel distance X-axis: 2,000 mm, travel distance Y-axis: 1,620 mm, travel distance Z-axis: 80 mm, No minimum price - guaranteed sale at the highest bid!

Reason for selling: Space for new machine - machine must be collected by the end of September

Under power until 12.10. Bidders are obliged to collect the machine by the deadline of 18.10.24.

Fj Ieuq I Inea Uny Uepg

TECHNICAL DETAILS

Laser cutting system: Mercury 1620

Laser: Rofin SCx, water-cooled, cutting head with lens

Laser power: 300 W

Table: Anodized aluminium cutting base

Work surface: 1620 x 2000 mm

Clearance height: 70 mm

Material width: 1650 mm

Z-travel: 80 mm

Speed (X-Y axis): 2000 mm/s

Acceleration: 18 m/s²

Resolution (X-Y axis): 0.001 mm

Resolution Z axis: 0.1 mm

Accuracy: ± 0.05 mm on the entire work surface

Repeat accuracy: ± 0.025 mm

Laser system protection class: 1

Laser source: ROFIN ScX Series 300, closed and maintenance-free

Cooling circuit: closed incl. water recooler for laser

Cutting head: with lens, cutting nozzle, cutting gas supply

MACHINE DETAILS

Dimensions: 2390 x 4150 x 1550 mm

Weight: 2000 kg

Machine: 380 V, 50 Hz, 32 A 3P+N+T / 15 kW

Cooler: 380 V, 50 Hz, 16 A, 4 kW

Suction fan: not included in scope of delivery

Compressed air: 200 l/min, 7 bar, oil-free

EQUIPMENT

- Service set for optics

- ICARO software and user manual

- Shuttle table system

- 2 cutting tables positioned one above the other with motorized height adjustment

- Aluminum cutting base

- Vacuum / suction tray for small parts and dust; suction from below is through the tray. Extraction from above is through a specially designed slot in the upper part of the machine cover

- The cover closes/opens automatically before/after the job is completed

CONTROL

- Speed, acceleration, material thickness, laser power and frequency fully adjustable in the ICARO software

- Import HPGL, DXF, BMP, CF2 ...

- Execution of curves with constant speed

- Execution of curves with spline interpolation

- Motor load control for all X, Y, Z axes

- Position and speed control using encoders

- Control system specially developed for laser technology

- Safety standards according to European standards (CE)

The extraction system with filter is not sold.

Auction

Auction ended

Switzerland

Switzerland

1,381 km

Thread rolling machine

GRTZ28-500

Condition: good (used), Year of construction: 2019, Functionality: fully functional, TECHNICAL DETAILS

Rolling diameter: 6-80 mm

Width of the rolling tool: max. 150 mm

Outer diameter of the rolling tool: max. 240 mm

Fo Ia Unjtwbkqsy Uspg

Center distance tool spindle - center: 190-240 mm

Pitch size range (normal): 1-12 mm

motor

Rollers: 15 kw-6

Hydraulic: 5.5 kw-4

Cooling: 0. 125 kw

Rolling force: max. 500 KN

Spindle diameter: 85 mm

Inclination angle of the spindle: +/- 10°

Volatility: 380 V, 50 HZ, 3 phase

MACHINE DETAILS

Size of the basic machine: 2600 x 2100 x 1600 mm

Size of the hydraulic station: 800 x 500 x 1250 mm

Weight of the machine: 4500 kg

Length of the workpiece: Unlimited

Auction

Auction ended

Bayern

Bayern

1,384 km

Laser cutting machine

TRUMPFTruLaser 5030

Condition: ready for operation (used), Year of construction: 2007, operating hours: 38,093 h, Functionality: fully functional, laser power: 6,000 W, sheet thickness aluminum (max.): 15 mm, sheet thickness steel (max.): 25 mm, travel distance X-axis: 3,000 mm, travel distance Y-axis: 1,500 mm, feed length X-axis: 3,000 mm, feed length Y-axis: 1,500 mm, feed length Z-axis: 115 mm, Laser cutting system incl. Liftmaster

TECHNICAL DETAILS

X-axis: 3,000 mm

Y-axis: 1,500 mm

Fe Iajvb El Ao Uny Uepg

Z-axis: 115 mm

max. sheet format: 3,000 x 1,500 mm

max. workpiece weight: 1,800 kg

CNC control: Siemens Sinumerik 840D SL

laser

Model: TruFlow 6000

Laser power: 6 kW

Laser type: CO₂

Wavelength: 10.6 µm

Sheet thickness steel: max. 25 mm

Sheet thickness stainless steel: max. 25 mm

Sheet thickness aluminum: max. 15 mm

Axis movement

Simultaneous traversing speed: 300 m/min

Position deviation (Pa): 0.05 mm

Average positioning accuracy (Ps): 0.03 mm

MACHINE DETAILS

Beam switch-on time: approx. 38,093 h

Laser switch-on time: approx. 72,733 h

Beam on / HP pump 2: approx. 37,700 h

Space requirement: 10.9 x 14.9 x 4.3 m

Machine dimensions: 4.6 x 11.25 x 2.4 m

Weight: 12 tons

EQUIPMENT

Auction

Auction ended

Dolnośląskie

Dolnośląskie

1,728 km

Injection molding machine

BATTENFELDTM 4500/2800

Condition: ready for operation (used), Year of construction: 2001, Functionality: fully functional, clamping force: 4,500 kN, screw diameter: 75 mm, clearance between the columns: 800 mm, injection weight: 1,506 g, mold height (min.): 425 mm, opening stroke: 760 mm, TECHNICAL DETAILS

Control: Unilog B4

Clamping force: 4,500 kN

Minimum mold height: 425 mm

Maximum mold height: 770 mm

Column spacing (H x V): 800 x 800 mm

Mounting plates (H x V): 1,155 x 1,195 mm

Mold opening stroke: 760 mm

Robot interface: Euromap 12

Injection unit

Fo Ia Uevzrn Dsny Uepg

Screw diameter: 75 mm

Injection weight (PS): 1,506 g

Injection volume: 1,657 cm³

Specific injection pressure: 1,739 bar

MACHINE DETAILS

Machine dimensions (L x W x H): 8.3 x 1.9 x 2.4 m

Total weight: 20,400 kg

Oil tank capacity: 800 l

Auction

Auction ended

Bayern

Bayern

1,378 km

Veneer press

BuerkleFFAII 1300

Condition: good (used), Year of construction: 2001, Functionality: fully functional, machine/vehicle number: 9555, working width: 1,300 mm, product height (max.): 40 mm, product height (min.): 8 mm, product length (max.): 3,000 mm, product length (min.): 400 mm, product width (max.): 1,300 mm, product width (min.): 200 mm, working height: 940 mm, TECHNICAL DETAILS

Machine model: BÜRKLE thermal laminating line FFAII 1300

Machine no.: 9555

Application: Single and double-sided continuous laminating of foils and decorative papers on MDF and chipboard using urea adhesive.

Working range

Working width max.: 1,300 mm

Panel dimensions

Width: 200 - 1,300 mm

Length: 400 - 3,000 mm

Thickness: 8 - 40 mm, ±0.2 mm

Film dimensions

Max. width: 1,320 mm, lateral protrusion up to 20 mm

Max. roll diameter: 500 mm

Sleeve diameter: 76 mm or 152 mm (3" or 6")

Overall height

Working height above floor: 940 mm

Output

System speed: 15 - 45 m/min

Rotary drum drive: with Vector-Control

Fpo Ia Unju R R S Dsy Ueg

EQUIPMENT

Brushing machine DBM (warp brushes)

Preheating and smoothing calender GKL, diameter 500 mm

Thermal oil heater 36 kW

Hardener application machine DAH, complete hardening mula system with monitoring

Transport section with IR zones and temperature sensors

DAK adhesive application machine with automatic level sensing

Cooling unit for DOW cooling

Glue feed

TKE cone transport section

Laminating calender EKM, diameter 500 mm with film unwinding stations and automatic splicing system FVE, vacuum bars, symmetrical clamping shafts, safety folding cheeks with pneumatic brakes, separating station STR with film clamping roller,

TRB belt transport section with operating bridge for FVE

expansion shafts

Smoothing calender GKL, diameter 500 mm arranged at the outlet of the conveyor belt

Thermal oil heater 96 kW

Central switchgear with separate control panel on the laminating calender

Auction

Auction ended

Bayern

Bayern

1,385 km

Jig

AGIE CHARMILLESHyperspark 3 HS (AT)

Condition: ready for operation (used), Year of construction: 2008, Functionality: fully functional, machine/vehicle number: 360, travel distance X-axis: 500 mm, travel distance Y-axis: 350 mm, travel distance Z-axis: 500 mm, workpiece weight (max.): 800 kg, TECHNICAL DETAILS

Travel X / Y / Z: 500 / 350 / 500 mm

Rotation: 0 - 60 rpm

Table dimensions: 800 x 600 mm

Automatically lowerable container: 200 - 700 mm

Workpiece weight: 800 kg

Internal dimensions of work bowl: 1,090 x 730 x 490 mm

MACHINE DETAILS

Weight: 5,000 kg

Installation dimensions: 3,200 x 2,400 x 2,700 mm

Operating voltage: 3 x 400 V

Frequency: 50 Hz

Fj Ia Ueuh Tmisny Uspg

Connection: 8.3 kVA

Rated current: 12 A

Auction

Auction ended

Bayern

Bayern

1,385 km

Injection molding machine

NetstalSynErgy 2000-230/110

Condition: good (used), Year of construction: 2014, operating hours: 20,209 h, Functionality: fully functional, clamping force: 2,000 kN, Machine with exemplary maintenance and servicing

Fe Iajuh Tkzs Uny Uopg

TECHNICAL DETAILS

Clamping force: 2000 kN

Cylinder size AG1: 20 mm

Cylinder size AG2: 16 mm

Machine drive power: 45 kW

Flow Box DETAILS

Type: LMP 105

Manufacturer: Max Petek

Serial number: S 140743

Year of manufacture: 2014

Robot DETAILS

Robot: Krauss - Maffei MH 50

Designation 6 -axis: Yaskawa

Type: DX 100

Operating hours: approx. 8900 h

Year of construction: 2014

MACHINE DETAILS

Weight: 13,300 kg

Length: 6,901 mm

Width: 2,075 mm

Height: 2,240 mm + 800 mm flow box

Auction

Auction ended

Bayern

Bayern

1,385 km

Automation system for injection molding

WITTMANNW833PRO

Year of construction: 2016, Condition: excellent (used), Functionality: fully functional, Automation system of the Wittmann brand was newly installed in 2016 and used on a Netstal Synergy 2000.

All documents, operating instructions, maintenance plans, measurement diagrams etc. included as well as control modules, power supply units and control panels.

The Wittmann Picker can be used as a stand alone.

Fs Ia Unjpm Htgsy Ujpg

TECHNICAL DETAILS

travel X / Y / Z: 900 / 1800 / 3000 mm

payload: 15 kg

Scope of delivery: robot, console, support V/2614-3104, adapter, conveyor system standard MB belt, SE protective enclosure incl. safety door with SIPA

MACHINE DETAILS

dimensions plant (LxWxH): 6560 x 4423 x 4154 mm

Robot weight: 560 kg

Mains connection: 3PH/N/PE

mains voltage: 400 V

tolerated voltage fluctuations: up to 10%

connected load: 11 kVA

frequency: 50-60 Hz

tolerated frequency fluctuations: up to 2%

supply line fuse: 16 A

air pressure: max 6 bar

maintenance of system functions: up to min 5 bar

Auction

Auction ended

Bayern

Bayern

1,385 km

Jig

CHARMILLESRoboform 35 P Roboter Automation

Year of construction: 2001, Condition: good (used), Functionality: fully functional, Machine extensively overhauled worth EUR 18,000

Optional configuration QCRI 54/8: available, see pictures

placement automation: available, see video

Pressure flushing: 1 x through workpiece 1 x through electrode, 2 x lateral

Suction flushing: 1 x through workpiece

Central lubrication system automatically via NC in all axes

TECHNICAL DETAILS

Travel (X, Y, Z): 350, 250 300 mm

Max man. Feeding speed: 900 mm/min

Weight of electrodes: max. 20 kg

Weight of workpieces: max. 40 kg

Magazine configuration: 54/8

electrodes: 54 pieces

Electrode dimensions: 70 x 70 x 200

Plates: 8 pieces

workpiece dimensions: (4x) 320 x320 x 270 mm, (4x) 320 x 320 x 170 mm

work table: 500 x 400 mm

T-slots: 3 x 12 mm

distance of grooves: 125 mm

Available clamping systems: Erowa IST 3R Macro Megatool GPS 70

Fs Ia Unen Arnxey Uepg

MACHINE DETAILS

Dimensions (H x L x W): 2400 x 1900 x 1690 mm

Auction

Auction ended

Dolnośląskie

Dolnośląskie

1,728 km

Injection molding machine

KraussMaffeiKM 150 - 520 C2

Condition: ready for operation (used), Year of construction: 2005, Functionality: fully functional, clamping force: 1,500 kN, screw diameter: 45 mm, clearance between the columns: 500 mm, injection weight: 250 g, opening stroke: 900 mm, Including robot - LR 100

TECHNICAL DETAILS

Control: MC 4 with color monitor, integrated control panel and plate station

Closing system: Fully hydraulic

Screw diameter: 45 mm

Suitable for: Thermoplastics

Closing unit

Closing force: 1,500 kN

Clamping plates (H x V): 780 x 790 mm

Free space between the columns (H x V): 500 x 500 mm

Maximum opening width: 900 mm

Injection unit

Screw diameter: 45 mm

Injection volume: 275 cm³

Injection weight: 250 g

Fpe Ia Ujvzrmgjny Uog

Injection pressure: 1,878 bar

Electro-hydraulic equipment

Pump motor power: 30 kW

Heating element power: 16 kW

ROBOT - Krauss-Maffei linear robot LR 100

Load capacity: < 10 kg (gripper + drives + parts)

Loading side: opposite the operator

X-axis (stroke from mold): 550 mm (servo motor)

Y-axis (vertical stroke with motor brake): 1,200 mm (servo motor)

Z-axis (lateral stroke): 1,500 mm (servo motor)

C-axis (folding axis for depositing): 0-90° (pneumatic)

Torque (Md): 30 Nm

Position measurement: encoder

MACHINE DETAILS

Net weight (with control cabinet): 7.1 t

Machine dimensions (L x W x H): 4.66 x 1.51 x 2.19 m

Auction

Auction ended

Bayern

Bayern

1,387 km

3D metal printer

ALPHALASERAL3D-METAL 200

Condition: like new (used), Year of construction: 2022, operating hours: 70 h, Functionality: fully functional, machine/vehicle number: AL-001-0007, laser power: 200 W, travel distance X-axis: 100 mm, travel distance Y-axis: 100 mm, travel distance Z-axis: 100 mm, HIGHLIGHTS

- Very fine laser spot for the finest geometries

- Powerful laser

- High powder yield

- Reliable printing process thanks to intelligent AL3D-OS software

- Small footprint 600 × 617 mm

- Closed gas circuit for reduced gas consumption

- Low energy consumption

- Unpacking station: Clean separation of the sintered component from unused residual powder + collection of the residual powder for possible reuse

TECHNICAL DETAILS

Installation space size: d = 100 mm, h = 100 mm

Resolution: 50 µm

Laser & optics

Laser type/wavelength: fiber laser 200 W CW, 1070 nm

Focus diameter: 50 µm

Scanning speed: max. 5 m/s

Process parameters: Open access to all machine and process parameters

software

Operation: 15.6" touchscreen, keyboard and mouse possible

Connectivity: Ethernet; 2 × USB

Software: AL3D-OS, offline version for project creation

Remote access: TeamViewer

External software: Autodesk Netfabb, Materialise Magics, CIM Systems Pyramis

Software interface: Open interface for external postprocessors

File format: CAD import STL

Print preparation: Simple support generation; slicer integrated in software

Materials

Material: Metal powder, grain size fraction 10-45 µm

Alloys: Iron, nickel-based, cobalt-chromium, precious metals, reactive metals (others on request)

Component density: > 99 %

Layer thickness: 10 - 50 µm

MACHINE DETAILS

Machine dimensions

Weight: approx. 180 kg

W × D × H: 600 × 617 × 1,770 mm

Unpacking station dimensions

Weight: approx. 100 kg

W × D × H: 600 × 617 × 1,770 mm

Operating hours: 70 h

Electrics & connection

Electrical connection: 230 V, 50 Hz / 60 Hz, max. 16 A

Permissible humidity: max. 70 %

Permissible ambient temperature: 15 - 30 °C

Shielding gas/argon connection: 4.5 - 6 bar inlet pressure, Ø 6 mm hose connection

Gas consumption in operation: < 5 l/min

Gas consumption purge function: 20 l/min

Fpj Ia Usu S H E Hjny Ujg

Unpacking station

Vacuum cleaner connection: NW32 connection

EQUIPMENT

- 3D printer

- Unpacking station

- 9 print cartridges.

Auction

Auction ended

Bayern

Bayern

1,506 km

Telescopic arm forklift

MerloP 38.13

Condition: ready for operation (used), Functionality: fully functional, machine/vehicle number: C7004367, Year of construction: 2019, operating hours: 1,706 h, load capacity: 3,800 kg, lifting height: 13,800 mm, arm reach: 8,600 mm, Equipment: sideshift, TECHNICAL DETAILS

Lifting height: max. 13.80 m

Reach: max. 8.60 m

Load capacity: max. 3,800 kg

Load capacity at full reach: max. 800 kg

Drive and engine

Engine: diesel (Kubota engine)

Drive: 4x4 all-wheel drive

Steering: all-wheel steering

Tires

Tires (VR/VL, HR/HL): approx. 75%

Type: off-road tires

MACHINE DETAILS

Transport dimensions (L x W): 5.24 x 2.22 m

Clearance height: 2.44 m

Own weight: 8,900 kg

Operating hours: 1,706 h (as of January 20, 2025)

Previous owner: first owner

Visual condition: good

Technical condition: good

Place of use: inside, outside, Terrain

Maintenance and inspections

Last service: 11/2024

Last UVV inspection: 11/2024

UVV valid until: 11/2025

Condition: Without UVV-relevant defects

Fpj Iovr Tdzsa Uny Uog

EQUIPMENT

- Tow bar

- Heating

- 4x4x4 drive

- Kubota engine

- Quick coupler

- Level control

- Supports

- Merlo sideshift

- All-wheel steering

- Cab with heating

Auction

Auction ended

Bayern

Bayern

1,393 km

Gear grinding machine

Gleason-PfauterG 320

Condition: excellent (used), Year of construction: 2002, Functionality: fully functional, Gleason Pfauter G320 CNC generating grinding machine + Promot Automation handling unit

Functionality and machine features

Generating grinding machine with 8 numerically controlled axes for machining gears with straight and helical teeth that can be produced by generating, including a dressable worm profile wheel.

Linear and rotary main axes are hydrostatic.

High-performance machine for finishing cylindrical gears with straight or helical involute teeth.

TECHNICAL DETAILS

Control: Siemens 840 incl. control panel

Module: 0.5-7.0

Workpiece diameter: 10 - 380 mm

Number of teeth: 10 - 600

Vertical slide stroke Z: 200 mm

Horizontal slide stroke X: 230 mm

Tangential slide stroke Y: 135 mm

Swivel angle of clamping head A: ± 45°

Stroke - tailstock center: 125 mm

Tangential slide stroke - dressing V: 180 mm

radial slide stroke - dressing U: 110 mm

C-axis (table rotation): 360°

rapid traverse speed - linear axes: 10,000 mm/min

Rotation speed: 3,000 rpm (infinitely variable)

Table rotation speed: 240 rpm

Table resolution: 0.001°

Fe Ia Unyjtu T S Uo Uopg

Processing feeds: stepless

Working feeds: infinitely variable

Grinding wheel diameter: 270 - 350 mm

Grinding wheel width: 104 mm

Grinding wheel bore: 160 mm

MACHINE DETAILS

Machine weight: 11,500 kg

Machine space requirement: approx. 3.7 x 2.4 x 2.75 m

Promot Automation space requirement: approx. 4.5 x 1.6 x 4.0 m

EQUIPMENT

- Promot automation

- Conveyor belt

- Cooling belt system

- Hydraulic unit

- Complete documentation

Auction

Auction ended

Germany

Germany

1,393 km

CNC lathe

EMCOHYPERTURN 45

Condition: used, Year of construction: 2016, Functionality: fully functional, machine/vehicle number: BF15103648, TECHNICAL DETAILS

WORKING RANGE

Travel in X/Y/Z: 160 /+40/-30 / 510 mm

Bar passage: max. 45 (51) mm

Turning diameter: max. 300 mm

Rotation diameter over bed 430 mm

Fe Istt D Adja Uny Uepg

Rapid traverse speed X/Y/Z 30 / 15 / 45 m/min

MAIN SPINDLE

Speed: max. 7000 rpm

Drive power: max. 15 kW

Torque: max. 100 Nm

COUNTERSPINDLE

Speed: max. 7000 rpm

Drive power: max. 15 kW

Torque: max. 100 Nm

TOOL TURRET 1

VDI size: VDI 25

Number of tool positions: 12

Driven tools: 12

Speed: max. 6000 rpm

Drive power: max. 4 kW

Torque: max. 16 Nm

TOOL TURRET 2

VDI size: VDI 25

Number of tools: 12

Of which driven: 12

Speed: max. 6000 rpm

Drive power: max. 4 kW

Torque: max. 16 Nm

EQUIPMENT

- Chip conveyor

- Parts catcher

- Accessories shown

Auction

Auction ended

Banskobystrický kraj

Banskobystrický kraj

1,974 km

CNC lathe

DMGMSL 60/7

Condition: not inspected (used), Year of construction: 2012, operating hours: 44,079 h, Functionality: unexamined, machine/vehicle number: 8089000198B, spindle bore: 65 mm, spindle speed (max.): 5,000 rpm, bar passage: 60 mm, controller model: Fanuc 31i, Extensive accessories included (see pictures)

TECHNICAL DETAILS

Control: Fanuc 31i MSL

Bar passage: 60 mm

Spindle bore: 65 mm

Maximum spindle speed: 5,000 rpm

C-axis: available

Fpj Ia Unysv Hrw Nj Uog

Counter spindle: 5,0000 rpm

MACHINE DETAILS

Total weight: 3,500 kg

EQUIPMENT

- Hinged belt chip conveyor

- Bar loader preparation

- Driven tools for drilling and milling

- Double tool holder

- Tool holder 20x20 mm for slide and reverse machining

- Drill holder for turret (diameter 32 mm)

- Collet holder for main and counter spindle

- Collet chuck ROEHM KFD HS 112-3

- Software for tool wear monitoring for Fanuc

- Bar loader is not included delivery included

Auction

Auction ended

Dolnośląskie

Dolnośląskie

1,728 km

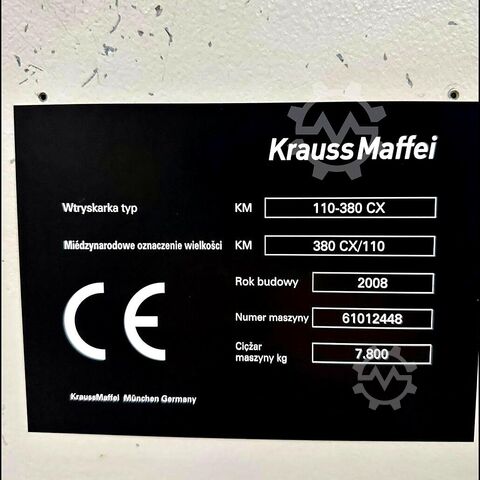

Injection molding machine

KraussMaffeiKM 110 - 380 CX

Condition: ready for operation (used), Year of construction: 2008, operating hours: 42,000 h, Functionality: fully functional, machine/vehicle number: 61012448, clamping force: 1,100 kN, screw diameter: 35 mm, clearance between the columns: 470 mm, injection weight: 140 g, ejector stroke: 150 mm, opening stroke: 600 mm, TECHNICAL DETAILS

Control: MC5 with color monitor, integrated control panel and 3 USB ports

Screw diameter: 35 mm

Design: Scuff protection for thermoplastics

Non-return valve: Yes

Nozzle: Open nozzle

Clamping unit

Mold clamping force: 1,100 kN

Mold opening force: 70 kN

Mounting plates (H x V): 745 x 770 mm

Column spacing (H x V): 470 x 470 mm

Mold opening stroke: 600 mm

Mold height: 300 mm

Plate opening stroke: 900 mm

Ejector stroke: 150 mm

Ejector force: 22.6 / 9.9 kN

Injection unit

Screw diameter: 35 mm

Injection pressure: 2,429 bar

Injection volume: 154 cm³

Injection weight (HP): 140 g

Screw revolutions (standard/option): 390 / 490 rpm

MACHINE DETAILS

Working hours: approx. 42,000 h

Machine weight (with control cabinet): 5.8 t

Machine dimensions (L x W x H): 4.5 x 1.6 x 2.1 m

Fo Ia Uovzrkfeny Uopg

Pump motor power: 18 kW

Heating power: 10.97 kW

Cylinder heating zones: 5

Drying cycles according to Euromap: 1,850 / h

Oil tank capacity: 489 l

Auction

Auction ended

Baden-Württemberg

Baden-Württemberg

1,397 km

Vertical machining center

CHIRONFZ 08 K W Magnum

Condition: refurbished (used), Year of construction: 2004, operating hours: 5,000 h, Functionality: fully functional, travel distance X-axis: 450 mm, travel distance Y-axis: 270 mm, travel distance Z-axis: 310 mm, controller manufacturer: Siemens, controller model: 840D, rotational speed (max.): 15,000 rpm, TECHNICAL DETAILS

Travel X / Y / Z: 450 / 270 / 310 mm

Fpj Ia Unyjt R R A Ie Uog

Drilling capacity in St 60: 16 mm (indexable insert drill)

Thread cutting Milling capacity in St 60: M12, 60 cm³/min

Speed range: 20 - 15,000 rpm

Control: SIEMENS 840D

Spindle power at 100%/25% ED: 2.2 / 7.2 kW

Torque: 23 Nm

Rapid traverse X,Y / Z: 40 / 60 m/min

Workpiece changing device: 0 / 180°

Clamping surface: 2 x 550 x 300 mm

Thread and fitting hole grid: M16 x Ø 15H7 x 50 mm

Load weight: max. 200 kg per side

Weight difference: max. 50 kg between both sides

Workpiece changeover time: approx. 2.0 s

Tool places: 24 pieces

Tool taper: HSK A 40 DIN 69893

Tool diameter: max. 50 mm

Tool diameter with free adjacent positions: max. 100 mm

Tool length: max. 160 mm

Tool weight: max. 1.2 kg

Tool change time: 0.8 s (depending on control system)

Chip-to-chip time: approx. 2.2 s (depending on control)

MACHINE DETAILS

Operating voltage: 400 / 230 V, 50 Hz/N/PE

Compressed air: 6 bar ±1 bar

Ambient temperature: max. 40°

EQUIPMENT

- Moving column machine with workpiece changing device Guides with long-term grease lubrication

- Digital main drive with spindle with sealing air supply

- Tool clamping monitoring

- Automatic tool changer with robust, fully encapsulated pick-up chain magazine, with mechanical collision protection as well as,

Cone cleaning via blast air

- Look Ahead with dynamic pilot control, Bellshape acceleration ramp, software limit switch, access authorization

via key switch for tool corrections, NC program changes and machine parameters

- CHIRON Powersafe software package for the targeted switch-off of installed consumers

- Definable time for variable "warm-up" program

- Thermocontrol

- Thermodrive

- Operating hours and piece counter on screen

- 230 V socket

- Socket for portable mini handwheel

- Splash guard cover

- Switch cabinet cooler

- Oil-free maintenance unit

- Installation elements

- Flushing gun

- Extraction connection Extraction Ø 150

- Machine preparation for IKZ

- CHIRON tool life monitoring

- Chip conveyor (scraper belt)

- Fixture flushing

- 4th + 5th NC axis, ready to plug in

- Documentation

Floor vehicle on site / electrician for dismantling can be provided by the seller for an additional charge.

Auction

Auction ended

Germany

Germany

1,401 km

Vertical machining center

Deckel MahoDMC 635 V

Year of construction: 2008, Condition: good (used), Functionality: fully functional, machine/vehicle number: 1540503266A, TECHNICAL DETAILS

X axis: 635 mm

Y-axis: 510 mm

Z-axis: 460 mm

Control: Heidenaihn İTNC 530

Number of tools: 30

Tool holder: SK 40

Fpe Ia Unyjng Amvs Usg

MACHINE DETAILS

on request

EQUIPMENT

Direct path measuring system X,Y,Z

Measuring probe Heidenhain TS640

Spindle conveyor

Operating mode 4

Trust Seal

Dealers certified through Machineseeker

Auction

Auction ended

Bayern

Bayern

1,393 km

High-precision rack grinding machine

MägerleMFP 260

Condition: excellent (used), Year of construction: 2008, Functionality: fully functional, Commissioning took place in 2009

TECHNICAL DETAILS

Model: MFP L 260 - 75

Control: Siemens 840D Sinumerik

Table clamping surface X / Z: 2202 / 352 mm

Longitudinal stroke: 2600 mm

Transverse stroke sanding support: 650 mm

Distance spindle to table: 806 mm

Head design: fixed, not adjustable

Grinding wheel dimension: Ø400 x 160 mm

Grinding wheel bore: 127 mm

Peripheral speed of grinding wheel: 35 / 50 m/s

Stroke speed longitudinal / transverse / vertical: 30 / 5 / 5 m/min

Resolution: 0.001 mm

MACHINE DETAILS

Machine weight: 21 t

Space requirement: 7.06 x 2.7 x 3.26 m

Fe Ia Uettazfsny Ujpg

Drive power of grinding wheel: 75 kW

Total connected load: 113 kVA

Knoll coolant cleaning system Dimensions: 5.6 x 2.4 x 3 m

Knoll coolant cleaning system Weight: 2,000 kg

EQUIPMENT

- Handwheel included

- Complete documentation

Purchase price of the machine was € 1,450,000

Auction

Auction ended

Bayern

Bayern

1,396 km

CNC lathe

GildemeisterCTX 510 V

Condition: good (used), Year of construction: 2007, operating hours: 25,000 h, Functionality: fully functional, TECHNICAL DETAILS

Turning diameter: max. 465 mm

turning length: 1050 mm

Rotation diameter: 680 mm

Chuck diameter: 325 mm

x-path: 300 mm

z-path: 1,050 mm

C-axis: 360°

Control: Heidenhain Plus IT

Speed range: max. 3,500 rpm

Drive power: 33 kW

Torque: max. 630 Nm

Fpe Iastt Du Ne Uny Uog

Spindle bearing diameter: 120 mm

Spindle bore: 100 mm

Max. Bar diameter: 90 mm

Tailstock travel: 850 mm

Quill stroke: 150 mm

Tailstock holder: MK 5

Rapid traverse X / Z: 30 m/min

Number of tool positions: 12 positions

Tool holder: VDI 40

Driven tool stations: 12

Speed of driven tools: max. 4,000 rpm

Drive power of driven stations: 8.4 kW

Torque: max. 20 Nm

MACHINE DETAILS

Total power requirement: 50 kVA

Machine weight: 9,000 kg

Space requirement: 6.5 x 3.0 x 2.2 m

Spindle hours: 25,000 h

Auction

Auction ended

Dolnośląskie

Dolnośląskie

1,728 km

Injection molding machine

ENGELVictory 330/60 Tech

Condition: excellent (used), Year of construction: 2007, Functionality: fully functional, machine/vehicle number: 164225, clamping force: 600 kN, screw diameter: 35 mm, clearance between the columns: 450 mm, mold height (min.): 600 mm, plate width: 720 mm, TECHNICAL DETAILS

Closure system: Hydraulic

Closure force: 600 kN

Plate size (table size): 720 mm

Fpe Iovzrhdoa Uny Uog

Distance between the columns: 450 mm

Mold height: 600 mm

Opening stroke: 900 mm

Ejector stroke: 115 mm

Ejector force: 125 kN

Injection system

Screw diameter: 35 mm

Injection volume: 154 cm³

Injection pressure: 2,400 bar

MACHINE DETAILS

Total weight: 5,300 kg

Auction

Auction ended

Dolnośląskie

Dolnośląskie

1,728 km

Injection molding machine

DEMAGMulti 80/420-80h/120v (800 - 80 h/120v)

Condition: ready for operation (used), Year of construction: 2005, Functionality: fully functional, machine/vehicle number: 7154 - 0118, clamping force: 800 kN, clearance between the columns: 750 mm, opening stroke: 500 mm, plate length: 590 mm, plate width: 600 mm, TECHNICAL DETAILS

Fps Ia Uovzrf Nony Ueg

Control: NC 4 control, DIAS

Closing system: Hydraulic

Closing force: 800 kN

Distance between columns: 420 mm x 420 mm

Plate dimensions: 590 mm x 600 mm

Mold size (min.): 250 mm

Bar width: 420 mm

Maximum opening distance: 500 mm

Maximum distance between plates: 750 mm

Two-component system

Horizontal system: Nitrided screw, diameter 18 mm

Vertical system: Bimetallic screw, diameter 25 mm

MACHINE DETAILS

Motor power: 18.5 kW

Heating power: 8.8 kW

Machine dimensions (L x W x H): 3.9 m x 1.4 m x 1.9 m

Weight: 4,100 kg

EQUIPMENT

- Two-component injection molding machine with hydraulic closing system

- Complete machine history available

We make the search easier for you

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

This may be of interest to you

Find out now

+44 20 806 810 84

+44 20 806 810 84

Create listing

*per listing / month